IEC 60519-7:2008

(Main)Safety in electroheat installations - Part 7: Particular requirements for installations with electron guns

Safety in electroheat installations - Part 7: Particular requirements for installations with electron guns

Deals with safety of electroheat installations with electron guns and applies to all electroheat applications with electron guns. May also be used for non-thermal applications with electron guns and equipment employing glow discharge systems. Applies also to high-voltage sources feeding electron guns. The main changes with respect to the previous edition cover:

- new editions of IEC publications taken into account;

- addition of new clauses;

- requirements for the earthing system updated;

- arrangement of return conductor changed.

Sécurité dans les installations électrothermiques - Partie 7: Exigences particulières pour les installations comportant des canons à électrons

Traite de la sécurité des installations électrothermiques comportant des canons à électrons et s'applique à toutes les applications de l'électrothermie comportant des canons à électrons. Peut être utilisé pour des applications non thermiques comportant des canons à électrons et des équipements employant des systèmes à décharge luminescente. S'applique aussi aux sources à haute tension alimentant les canons à électrons. Les modifications principales par rapport à l'édition précédente comprennent: prise en compte des dernières éditions des publications CEI; addition de nouveaux articles; mise à jour des exigences du système de mise à la terre; modification de la disposition du conducteur de retour.

General Information

- Status

- Published

- Publication Date

- 26-Feb-2008

- Technical Committee

- TC 27 - Industrial electroheating and electromagnetic processing

- Drafting Committee

- MT 26 - TC 27/MT 26

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Feb-2008

- Completion Date

- 15-May-2008

Overview

IEC 60519-7:2008 is an international standard developed by the International Electrotechnical Commission (IEC) that addresses safety requirements specifically for electroheat installations using electron guns. This standard plays a critical role in ensuring safe operation and maintenance of equipment that utilizes electron beams for heating or related applications.

The document extends the general safety rules outlined in IEC 60519-1 by providing particular requirements tailored for electron gun installations, covering electroheat and certain non-thermal applications such as glow discharge systems. It also includes guidance for the safe handling of high-voltage sources that feed electron guns, crucial for minimum risk in industrial environments.

Updates in this second edition include revised earthing systems, new clauses on operational safety, and re-arranged conductor layouts to enhance protection. This standard is essential for designers, operators, and safety engineers working with electron beam technologies.

Key Topics

Scope and Application

Applies to all electron gun electroheat installations and related high-voltage feeding systems; also useful for non-thermal electron beam uses such as glow discharge apparatus.Definitions and Terminology

Includes precise definitions for terms such as electron beam, electron gun components (anode, cathode), beam accelerating voltage, return conductor, interlock systems, and vacuum chambers.Components of Electron Beam Installations

Key elements include the electron gun, high-voltage power supply, beam deflection and focusing systems, bending systems, process chambers, vacuum plants, control mechanisms, and auxiliary facilities like cooling and pneumatics.Main Risks and Safety Measures

Identifies electric shock, overcurrent, overvoltage, fire, explosion, environmental pollution, health hazards, and X-ray emissions as primary risks. Mitigation methods include earthing protocols, insulation, control interlocks, and protective bonding.Earthing and High-Voltage Handling

Specifies requirements for manual, mechanical, or automatic earthing during maintenance and detailed management of high-voltage feeder cables and return conductors to prevent unintended current paths.Control Circuits and Interlocks

Emphasizes the importance of reliable control circuits and safety interlocks to prevent hazardous operation when unsafe conditions exist.Marking and Documentation

Requires clear labeling, comprehensive technical documentation, and user instructions to ensure safe installation, inspection, commissioning, operation, and maintenance.

Applications

IEC 60519-7 addresses the practical safety needs of industries and technologies utilizing electron guns in:

Industrial Electroheat Processes

Such as electron beam welding, surface treatment, and material processing where high-energy electron beams are used for precise thermal applications.Non-Thermal Electron Beam Uses

Including scientific instrumentation (electron microscopy), vacuum systems involving glow discharge, and electron beam curing processes.High-Voltage Electron Beam Systems

In manufacturing setups with dedicated high-voltage power supplies feeding electron guns, requiring stringent electrical safety and earthing arrangements.Research and Development

Facilities employing electron beam technologies benefit from standardized safety requirements that help minimize operational risks.

Adoption of this standard helps organizations minimize injury, equipment damage, and ensure compliance with international safety protocols.

Related Standards

IEC 60519-7 is designed to be used alongside these key IEC references to cover the full spectrum of electrical and safety requirements in electroheat installations:

- IEC 60519-1:2003 – General requirements for safety in electroheat installations; forms the base document for Part 7.

- IEC 60050-841:2004 – International Electrotechnical Vocabulary, providing terminology for industrial electroheat.

- IEC 60204-1:2005 – Safety of machinery – Electrical equipment of machines – General requirements.

- IEC 60364-4-43 – Electrical installations of buildings – Protection against overcurrent.

These standards combined offer comprehensive guidance for designing, installing, and maintaining safe electron gun electroheat systems.

By following IEC 60519-7:2008, industries can achieve enhanced safety in electron beam installations, reducing risks associated with high-voltage equipment, electron radiation, and complex control systems - making it an indispensable resource for modern electroheat technology safety management.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

IEC 60519-7:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety in electroheat installations - Part 7: Particular requirements for installations with electron guns". This standard covers: Deals with safety of electroheat installations with electron guns and applies to all electroheat applications with electron guns. May also be used for non-thermal applications with electron guns and equipment employing glow discharge systems. Applies also to high-voltage sources feeding electron guns. The main changes with respect to the previous edition cover: - new editions of IEC publications taken into account; - addition of new clauses; - requirements for the earthing system updated; - arrangement of return conductor changed.

Deals with safety of electroheat installations with electron guns and applies to all electroheat applications with electron guns. May also be used for non-thermal applications with electron guns and equipment employing glow discharge systems. Applies also to high-voltage sources feeding electron guns. The main changes with respect to the previous edition cover: - new editions of IEC publications taken into account; - addition of new clauses; - requirements for the earthing system updated; - arrangement of return conductor changed.

IEC 60519-7:2008 is classified under the following ICS (International Classification for Standards) categories: 25.180.10 - Electric furnaces. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60519-7:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60519-7

Edition 2.0 2008-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety in electroheat installations –

Part 7: Particular requirements for installations with electron guns

Sécurité dans les installations électrothermiques –

Partie 7: Exigences particulières pour les installations comportant des canons à

électrons

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60519-7

Edition 2.0 2008-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety in electroheat installations –

Part 7: Particular requirements for installations with electron guns

Sécurité dans les installations électrothermiques –

Partie 7: Exigences particulières pour les installations comportant des canons à

électrons

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

M

CODE PRIX

ICS 25.180.10 ISBN 2-8318-9634-7

– 2 – 60519-7 © IEC:2008

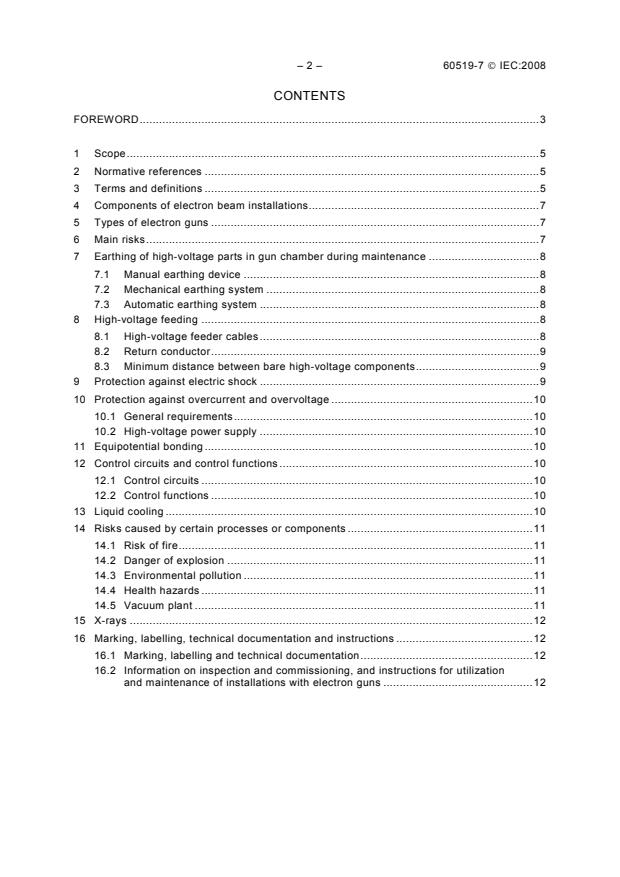

CONTENTS

FOREWORD.3

1 Scope.5

2 Normative references .5

3 Terms and definitions .5

4 Components of electron beam installations.7

5 Types of electron guns .7

6 Main risks.7

7 Earthing of high-voltage parts in gun chamber during maintenance .8

7.1 Manual earthing device .8

7.2 Mechanical earthing system .8

7.3 Automatic earthing system .8

8 High-voltage feeding .8

8.1 High-voltage feeder cables .8

8.2 Return conductor.9

8.3 Minimum distance between bare high-voltage components.9

9 Protection against electric shock .9

10 Protection against overcurrent and overvoltage .10

10.1 General requirements.10

10.2 High-voltage power supply .10

11 Equipotential bonding .10

12 Control circuits and control functions .10

12.1 Control circuits .10

12.2 Control functions .10

13 Liquid cooling .10

14 Risks caused by certain processes or components .11

14.1 Risk of fire.11

14.2 Danger of explosion .11

14.3 Environmental pollution .11

14.4 Health hazards .11

14.5 Vacuum plant .11

15 X-rays .12

16 Marking, labelling, technical documentation and instructions .12

16.1 Marking, labelling and technical documentation.12

16.2 Information on inspection and commissioning, and instructions for utilization

and maintenance of installations with electron guns .12

60519-7 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY IN ELECTROHEAT INSTALLATIONS –

Part 7: Particular requirements for installations

with electron guns

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60519-7 has been prepared by IEC technical committee 27:

Industrial electroheating equipment.

This second edition cancels and replaces the first edition published in 1983 and constitutes a

technical revision.

The significant changes with respect to the previous edition are as follows:

• the latest edition of IEC 60519-1 has been taken into account (the structure of clauses

was adapted to it as far as practicable);

• some definitions have been modified or brought into line with IEC 60050-841:2004;

• Clauses 4 and 5 were added;

• requirements for the earthing system were updated according to technical progress;

• the arrangement of the return conductor was changed to avoid earthing connections from

the process current as far as possible;

– 4 – 60519-7 © IEC:2008

• possible risks caused by certain processes or components were described in Clause 14.

This part of IEC 60519 is to be used in conjunction with IEC 60519-1:2003. It is intended to

specify particular requirements for electroheating installations with electron guns.

The text of this standard is based on the following documents:

FDIS Report on voting

27/578/CDV 27/622/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The list of all parts of the IEC 60519 series, under the general title Safety in electroheat

installations, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60519-7 © IEC:2008 – 5 –

SAFETY IN ELECTROHEAT INSTALLATIONS –

Part 7: Particular requirements for installations

with electron guns

1 Scope

This part of IEC 60519 deals with safety of electroheat installations with electron guns. It

applies to all the electroheat applications with electron guns.

This standard, whilst prepared for electroheat installations with electron guns may, however,

also be used for non-thermal applications with electron guns and equipment employing glow

discharge systems, where applicable.

This standard applies also to high-voltage sources feeding electron guns.

All requirements of IEC 60519-1 apply. Additional requirements for installations covered by

this part of the standard are given in Clauses 6 to 16.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-841:2004, International Electrotechnical Vocabulary – Part 841: Industrial

electroheat

IEC 60204-1:2005, Safety of machinery – Electrical equipment of machines – Part 1: General

requirements

IEC 60364-4-43, Electrical installations of buildings – Part 4-43: Protection for safety –

Protection against overcurrent

IEC 60519-1:2003, Safety in electroheat installations – Part 1: General requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-841,

IEC 60519-1 and the following apply.

3.1

electron beam

electron flux emitted from one source (cathode or plasma) and moving along the exactly

determined tracks at very great velocities

[IEV 841-30-01, modified]

3.2

electron (beam) gun

system of generating, forming and accelerating one or more electron beams

– 6 – 60519-7 © IEC:2008

[IEV 841-30-08, modified]

3.3

anode (of an electron gun)

electrode capable of educing and accelerating electrons from the medium of lower

conductivity

[IEV 841-22-31, modified]

3.4

cathode (of an electron gun)

electrode capable of emitting electrons from the medium of low conductivity and also of

receiving positive carriers, if necessary

[IEV 841-22-32, modified]

3.5

beam accelerating voltage

potential difference between the cathode and the anode, to generate an electric field for

acceleration of electrons

[IEV 841-30-29]

3.6

high-voltage power supply

source of the acceleration voltage and of the emission current for electron guns

3.7

return conductor

electrical interconnection between the high-voltage power supply (positive pole) and anodic

part of the electron gun system including the vacuum chamber around the workpiece

3.8

interlock

device that prevents activation of a piece of equipment when any form of hazard or danger

exists

3.9

vacuum chamber

enclosed space of a vacuum plant constructed in such a way that it can withstand a rarefied

atmosphere inside, in which the workpiece to be treated is placed

3.10

electron gun chamber

vacuum chamber in which the electron gun is located

NOTE This chamber may be separated from the workpiece by an aperture, so that between the electron gun and

the workpiece, a pressure difference can be established.

3.11

electron beam deflection system

electromagnetic coil or deflecting electrodes system, applied to place the beam to different

working positions or move the beam over the charge heat surface

[IEV 841-30-25, modified]

3.12

electron beam bending system

electromagnetic coil or permanent magnet for changing the direction of the electron beam

outside the electron gun

60519-7 © IEC:2008 – 7 –

3.13

electron beam focussing system

electromagnetic coil, system of coils or capacitor plates for focusing the electron beam over

the charge heating surface

[IEV 841-30-27, modified]

4 Components of electron beam installations

An electron beam installation primarily consists of:

a) an electron gun;

b) a high-voltage power supply;

c) an electron beam deflection and focussing system including the necessary current supply

and control systems;

d) an electron beam bending system;

e) a process chamber and workpiece handling;

f) a vacuum plant;

g) a control system;

h) facilities (electrical supply, cooling liquid, pneumatics, hydraulics, etc.).

NOTE Some components are only in specific installations, for example there is no bending system in many

installations.

5 Types of electron guns

The principle of electron beam exploited in electron guns is mainly used in

• optical applications (for example CRT, video projection, image scanning, electron

microscopy),

• other non-thermal applications (for example polymer modification, curing, sterilization,

disinfection) and

• electroheat applications.

Typical electroheat applications are for example melting, heating, evaporation and surface

treatment.

Depending on the application, electron beam guns can be classified according to

• the level of the acceleration voltage,

• the rated power,

• the electron beam geometry and

• the system for beam deflection and bending.

6 Main risks

Electron guns used for electroheat applications, due to their properties, may basically

generate the following risks:

7, 8, 9 and 11);

• high-voltage electric shock (see Clauses

• X-rays (see Clause 15);

• thermal destruction of components inside a vacuum chamber caused by high energy

density (see Clause 14).

– 8 – 60519-7 © IEC:2008

In addition, there may exist hazards caused by components of the electron beam installation

like a vacuum plant (see Clause 12) and by the process realized by electron beam guns (see

Clause 14).

7 Earthing of high-voltage parts in gun chamber during maintenance

7.1 Manual earthing device

After switching off the high-voltage supply and gaining access by opening the door of the

electron gun chamber or the housing of the electron gun, a portable earthing device of an

approved design shall be used to remove any remaining charge before touching parts, which

are normally live during operation.

The highly flexible earth conductor of the portable earthing device shall be permanently fixed

to its earthing point. This earth connection point shall be visible for easy checking by the

operator and be clearly and durably marked.

7.2 Mechanical earthing system

Alternatively, a mechanically self-acting earthing mechanism that is activated by the

mechanical action of opening the gun chamber may be installed, provided that the proper

function of this self-acting mechanism can be easily checked by eyesight from a safe distance.

7.3 Automatic earthing system

Alternatively, an automatically operating earthing mechanism may be installed under the

following conditions:

a) the mechanism is automatically activated when the gun operation is stopped;

b) the proper functioning of the automatic mechanism is detected by a fail-proof automatic

detection system;

c) a signal visible to personnel opening the gun chamber indicates proper functioning of the

automatic earthing system;

d) an electro-mechanic lock of approved design disables opening of the gun chamber before

the proper functioning of the earthing device has been positively detected.

Also, in the immediate vicinity of the high-voltage supply(ies), portable earthing devices shall

be installed so as to be clearly visible.

8 High-voltage feeding

8.1 High-voltage feeder cables

The high-voltage feeder cables shall be adequately insulated and efficiently protected against

mechanical damage.

Shielded cables shall be used for the high-voltage feeders or the feeder cables shall be

installed inside conductive conduits or flexible hoses. Cable shields, conduits or flexible hoses

shall be connected to the equipotential bonding.

When high-voltage feeder cables are laid inside conduits or flexible hoses, other cables shall

not be included, except a return conductor. Each electron gun shall have its own conduit or

flexible hose.

If the high-voltage feeder cable runs inside a conduit or flexible hose, the conduit or flexible

hose shall extend into the high-voltage terminal connection compartment.

60519-7 © IEC:2008 – 9 –

High-voltage feeder cables and low-voltage cables may run together inside cable trenches or

cable troughs providing the high-voltage feeder cables are protected mechanically and

electrically. The cable trenches or troughs are not considered as protection.

8.2 Return conductor

Each electron gun shall have its own return conductor to carry the beam current back to the

high-voltage power supply in a specified way. The cross-sectional area of this conductor shall

be of a size corresponding to the current of the gun but not less than 6 mm copper. The

return conductor shall be installed with flexible and insulated cable.

The return conductor shall be connected to earth potential at the termination point near the

workpiece or the electron gun.

To enable a defined return current path, the return conductor shall not be earthed at the high-

voltage power supply, but the voltage between the termination point and earth shall be limited

by reliable means. If the return conductor is also directly connected to earth at the high-

voltage supply, EMC requirements and grounding shall be taken under special care.

If, for special guns, a conductor of less than 6 mm copper is employed, it shall be installed

with special care, be mechanically protected and be at least of the size of the feeder

conductors.

The voltage drop along the return conductor shall not exceed 1,5 V at rated current. Return

conductors between electron guns and the high-voltage power supply shall be installed

together with the feeders.

NOTE 1 Each installation should have at least two return conductors so that safety is maintained even if one fails.

The exact arrangement of return conductors depends on the quality of the electrical interconnections of the

electron gun chamber and the vacuum chamber as well as on the number of electron guns.

NOTE 2 In an installation with electron guns, the return current flows through the chamber and the framework of

the installation in the direct surroundings of the electron gun.

8.3 Minimum distance between bare high-voltage components

Safety spacing applicable for high-voltage equipment need not be observed for electron guns

and their supply as they are designed for use in dry and clean rooms. Such conditions of

usage shall be specified in the manufacturer's installation instructions.

9 Protection against electric shock

The voltage supplies of the electron guns shall be switched off by safety interlocks, if:

• the electron gun chamber is opened and live parts become accessible;

• high-voltage cables are disconnected or assembled in a wrong way, and

• high-voltage enclosures of the power supply are opened.

In these cases, the interlock system shall switch off the voltage supply, discharge high-

voltage capacitors and prevent resetting by reliable means.

In addition, frequently used openings shall be interlocked as long as voltage on covered parts

may occur.

NOTE In the case of more than one gun in the installation, there might be the risk, that different sets of cables be

connected to the high-voltage power supply and the related electron gun. Unconnected ends of these cables could

become live this way. The same risk exists, if spare cables are present in the installation.

– 10 – 60519-7 © IEC:2008

10 Protection against overcurrent and overvoltage

10.1 General requirements

According to IEC 60519-1, protective measures against overcurrent shall be provided in

compliance with relevant standards, for example IEC 60364-4-43 and IEC 60204-1.

10.2 High-voltage power supply

The high-voltage power supply shall be provided with overcurrent and overvoltage protection

adjustable by system settings.

The high-voltage power supply shall not be affected by excessive mains voltage.

11 Equipotential bonding

The provisions of Clause 11 of IEC 60519-1:2003 apply.

To protect operators against voltages between accessible metallic parts, equipotential

bonding shall connect all conductive bodies, frames and enclosures with each other. The

connection between vacuum chamber, electron gun and the high-voltage supply enclosure is

especially important, but working platforms, liquid, hydraulic and gas pipes as well as metallic

constructions of the building shall also be included into equipotential bonding. That way, all

these parts are fixed to earth potential.

The cross-sectional area of these conductors shall be of a size corresponding to the current

of the gun but not less than 6 mm copper.

The equipotential bonding shall be able to carry the current of the electron beam from the

surrounding of the heated work piece and of the electron gun to the termination point of the

return connector without voltage drops exceeding 1,5 V.

12 Control circuits and control functions

12.1 Control circuits

Control circuits shall comply with Clause 9 of IEC 60204-1:2005 and Clause 12 of IEC 60519-

1:2003.

12.2 Control functions

To avoid destruction by the electron beam, its energizing shall be possible only if the following

conditions are fulfilled:

• the operating pressure is reached inside the vacuum chamber;

• the electron beam deflection system is running without any fault;

• the electron beam bending system is energized (if necessary);

• the cooling liquid is running in the specified amount;

• the gun valve is opened (if it exists).

13 Liquid cooling

Where liquid cooling is applied (e.g. in crucibles), appropriate monitoring devices shall be

provided in accordance with 6.6 of IEC 60519-1:2003.

60519-7 © IEC:2008 – 11 –

The clearness of cooling liquid is required to avoid blocking the tube of cooling liquid inside

the electron gun and deflection system.

The requirements for cooling liquid quality shall be given by the manufacturer.

The flow direction of cooling liquid shall be shown.

14 Risks caused by certain processes or components

14.1 Risk of fire

Some process materials can build up at the chamber wall or protection shields in porous

structures. High process temperatures may inflame these layers while venting the process

chamber. Equipment that processes material such as titanium, should give the operator the

possibility for a quick re-evacuation as long as the chamber is being vented with air.

Installations with high power electron guns often use oil insulated transformers placed near

the process chamber. The installation of transformers shall comply with regulations of the

country in which the equipment is to be installed. The manufacturer of the electron gun shall

inform the user about the amount and properties of the transformer oil. The fire load of the oil

shall be considered in planning of fire prevention for the shop floor.

14.2 Danger of explosion

Different materials handled in the process chamber may cause explosion, especially in the

case of cooling water leak. As long as any possibility of explosion cannot be eliminated,

bursting of the chamber shall be avoided by the design of the chamber door locking

mechanism or comparable means.

14.3 Environmental pollution

Process materials and the high-voltage transformer oil may constitute essential risks of

environmental pollution.

If the high-voltage transformer is filled with oil, the transformer shall be installed inside a

container or pit, which is able to collect the entire oil in the case of leak.

Taking into account the kind of the processed materials, the user shall check and take care of

any hazardous substances if exhausted by the vacuum system and/or deposited inside the

process chamber.

14.4 Health hazards

15), other hazards may be caused by processed materials.

In addition to radiation (see Clause

In the case of processing ceramic materials, it is to be considered, that the material may build

up at the chamber wall and protection shields in threadlike structures. Inhalation protection

shall be used in process chamber cleaning to avoid the risk of lung related diseases.

Some applications, especially the operation of electron beams in thin gases, may cause UV-

emission. Protection measures shall be taken according to national regulations.

14.5 Vacuum plant

The exhaust system shall be of adequate size and all precautions shall be taken to protect the

personnel from harmful emissions.

– 12 – 60519-7 © IEC:2008

Moving parts of pumps such as belts, belt pulleys, etc., shall be safeguarded against

accidental touch.

If the vacuum chamber is large enough for a person to enter, means shall be provided to

prevent evacuation of the chamber whilst a person is inside.

15 X-rays

Equipment with electron guns shall be designed and installed to avoid during its operation any

dangerous exposure of the operators to X-ray emission. The levels of radiations shall not

exceed those laid down by national regulations.

The amount of X-ray exposure depends especially on the high-voltage level and also on the

beam current. Design of shielding and the measurement inspection procedure of exposure

shall consider the maximum values of acceleration voltage and beam current.

Parts relevant for X-ray shielding that can be removed during maintenance shall be designed

such that the operation of the gun is not possible without re-mounting these parts. Preferably,

all shielding relevant parts should also be parts of the vacuum chamber.

16 Marking, labelling, technical documentation and instructions

16.1 Marking, labelling and technical documentation

Marking, labelling and technical documentation shall comply with Clause 15 of

IEC 60519-1:2003.

Electrical equipment, generating or distributing high voltage, shall be specially marked in

compliance with local regulations.

The manufacturer of equipment with electron guns shall point out risks of the equipment and

designated processes by danger signs and in the technical documentation. It is the

responsibility of the user to advise against additional risks caused by the real working

conditions, to add corresponding signs and to provide operating instructions.

16.2 Information on inspection and commissioning, and instructions for utilization and

maintenance of installations with electron guns

Information on inspection and commissioning, and instructions for utilization and maintenance

of installations with electron guns shall comply with Clause 16 of IEC 60519-1:2003.

Maintenance at the high-voltage power supply, high-voltage cables and connectors as well as

safety equipment shall only be carried out by:

• manufacturer's staff,

• service personnel, trained and authorized by the manufacturer,

• other skilled and experienced persons, if authorized personnel are not available.

The maintenance instructions shall point out the measures necessary for all risk prevention, in

particular:

• all return conductors shall be checked frequently, for example for loose connections,

broken conductors or frayed ends;

• X-ray inspection shall be done according to national requirements and shall consider the

maximum values for acceleration voltage and beam current. After exchanging X-ray

shielding relevant parts, the emission of X-rays of the system shall be re-checked;

60519-7 © IEC:2008 – 13 –

• in order to avoid damage of devices of the electron beam gun as a result of arcing, each

part of the electron beam gun shall be clean. The cleanness is especially important for all

high-voltage parts;

• according to the process, the user of the equipment shall pay attention to the exhausting

gases of the vacuum system and to the cleaning procedure for the process chamber (see

14.3 and 14.4).

___________

– 14 – 60519-7 © CEI:2008

SOMMAIRE

AVANT-PROPOS.15

1 Domaine d’application .17

2 Références normatives.17

3 Termes et définitions .17

4 Composants des installations à canon à électrons.19

5 Types de canons à électrons .19

6 Dangers principaux.20

7 Mise à la terre des parties haute tension dans l'enceinte du canon au cours de la

maintenance.20

7.1 Dispositif manuel de mise à la terre.20

7.2 Dispositif mécanique de mise à la terre .20

7.3 Dispositif automatique de mise à la terre .20

8 Alimentation à haute tension .21

8.1 Câbles d'alimentation à haute tension .21

8.2 Conducteur de retour .21

8.3 Distance minimale entre les composants à haute tension nus .22

9 Protection contre les chocs électriques.22

10 Protection contre les surintensités et les surtensions.22

10.1 Exigences générales .22

10.2 Alimentation à haute tension .22

11 Liaison équipotentielle.22

12 Circuits de commande et fonctions de commande .23

12.1 Circuits de commande.23

12.2 Fonctions de commande.23

13 Refroidissement par un liquide .23

14 Dangers causés par certains traitements ou composants .23

14.1 Danger dû au feu.23

14.2 Danger d'explosion.24

14.3 Pollution environnementale .24

14.4 Dangers pour la santé .24

14.5 Installation à vide .24

15 Rayons X.24

16 Marques et indications, étiquetage, documentation technique et instructions.25

16.1 Marquage, étiquetage et documentation technique.25

16.2 Informations relatives à l’inspection et la mise en marche, et instructions

concernant l’exploitation et l’entretien des installations à canons à électrons .25

60519-7 © CEI:2008 – 15 –

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

_____________

SÉCURITÉ DANS LES INSTALLATIONS ÉLECTROTHERMIQUES –

Partie 7: Exigences particulières pour les installations

comportant des canons à électrons

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60519-7 a été établie par le comité d’études 27 de la CEI:

Chauffage électrique industriel.

Cette seconde édition annule et remplace la première édition publiée en 1983 et constitue

une révision technique.

Les modifications significatives par rapport à l'édition antérieure sont les suivantes:

• la prise en compte de la dernière édition de la CEI 60519-1 (la structure des articles a été

adaptée à celle-ci autant que possible);

• la modification ou l’alignement avec la CEI 60050-841:2004 de quelques définitions;

• l’addition des Articles 4 et 5;

• la mise à jour des exigences du système de mise à la terre en fonction du progrès

technique;

– 16 – 60519-7 © CEI:2008

• la modification de la disposition du conducteur de retour afin d'éviter autant que possible

des connexions de mise à la terre dues au courant de traitement;

• la description dans l'Article 14 des éventuels dangers causés par certains traitements ou

composants.

La présente partie de la CEI 60519 doit être utilisée conjointement avec la

CEI 60519-1:2003. Elle a pour objet de spécifier les exigences particulières pour les

installations électrothermiques comportant des canons à électrons.

Le texte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...