IEC TS 60071-5:2002

(Main)Insulation co-ordination - Part 5: Procedures for high-voltage direct current (HVDC) converter stations

Insulation co-ordination - Part 5: Procedures for high-voltage direct current (HVDC) converter stations

Provides guidance on the procedures for insulation co-ordination of high-voltage direct current (HVDC) converter stations, without prescribing standardized insulation levels. Applies only for HVDC applications in high-voltage a.c. power systems and not for industrial conversion equipment. Principles and guidance given are for insulation co-ordination purposes only. The requirements for human safety are not covered.

General Information

- Status

- Replaced

- Publication Date

- 17-Jun-2002

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 24-Oct-2014

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 10-Feb-2026

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TS 60071-5:2002 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Insulation co-ordination - Part 5: Procedures for high-voltage direct current (HVDC) converter stations". This standard covers: Provides guidance on the procedures for insulation co-ordination of high-voltage direct current (HVDC) converter stations, without prescribing standardized insulation levels. Applies only for HVDC applications in high-voltage a.c. power systems and not for industrial conversion equipment. Principles and guidance given are for insulation co-ordination purposes only. The requirements for human safety are not covered.

Provides guidance on the procedures for insulation co-ordination of high-voltage direct current (HVDC) converter stations, without prescribing standardized insulation levels. Applies only for HVDC applications in high-voltage a.c. power systems and not for industrial conversion equipment. Principles and guidance given are for insulation co-ordination purposes only. The requirements for human safety are not covered.

IEC TS 60071-5:2002 is classified under the following ICS (International Classification for Standards) categories: 29.080.30 - Insulation systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 60071-5:2002 has the following relationships with other standards: It is inter standard links to IEC 60071-5:2014, EN 60099-9:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 60071-5:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL IEC

SPECIFICATION TS 60071-5

First edition

2002-06

Insulation co-ordination –

Part 5:

Procedures for high-voltage direct

current (HVDC) converter stations

Coordination de l’isolement -

Partie 5:

Procédures pour les stations de conversion CCHT

Reference number

IEC/TS 60071-5:2002(E)

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/catlg-e.htm) enables

you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/JP.htm) is also

available by email. Please contact the Customer Service Centre (see below) for

further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

TECHNICAL IEC

SPECIFICATION TS 60071-5

First edition

2002-06

Insulation co-ordination –

Part 5:

Procedures for high-voltage direct

current (HVDC) converter stations

Coordination de l’isolement -

Partie 5:

Procédures pour les stations de conversion CCHT

© IEC 2002 ⎯ Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale W

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

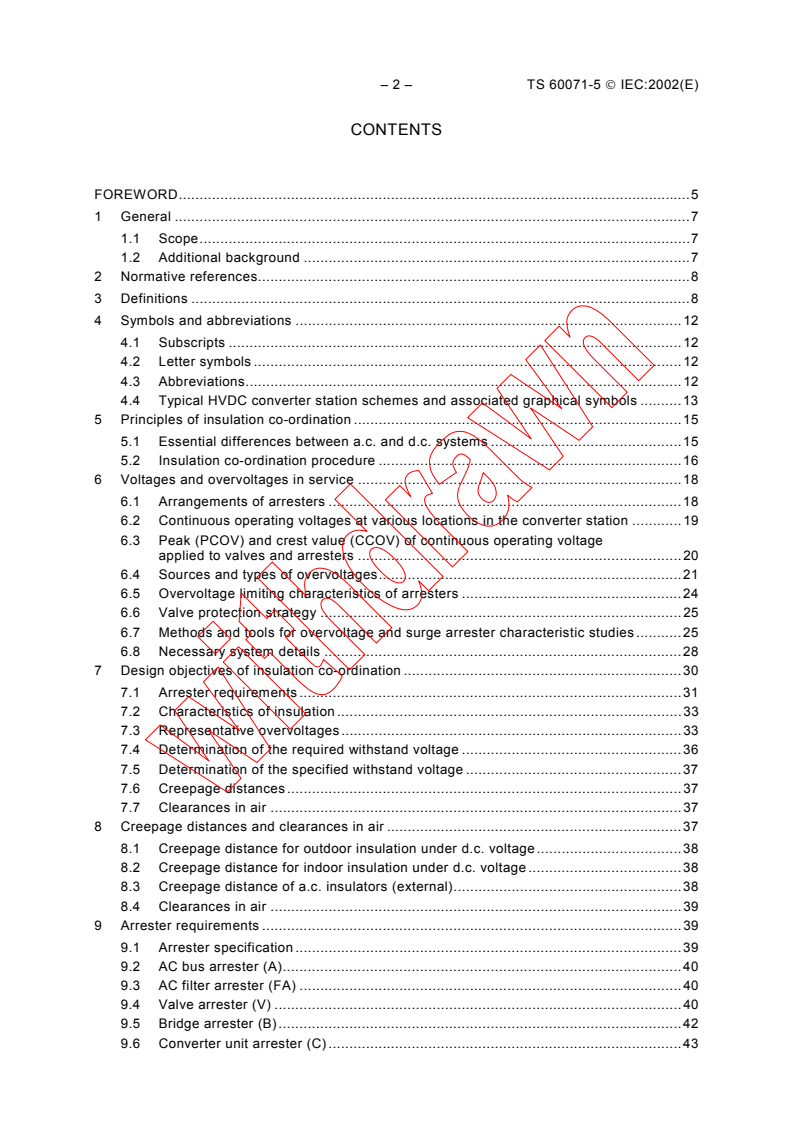

– 2 – TS 60071-5 IEC:2002(E)

CONTENTS

FOREWORD.5

1 General .7

1.1 Scope.7

1.2 Additional background .7

2 Normative references.8

3 Definitions .8

4 Symbols and abbreviations .12

4.1 Subscripts .12

4.2 Letter symbols .12

4.3 Abbreviations.12

4.4 Typical HVDC converter station schemes and associated graphical symbols .13

5 Principles of insulation co-ordination .15

5.1 Essential differences between a.c. and d.c. systems .15

5.2 Insulation co-ordination procedure .16

6 Voltages and overvoltages in service .18

6.1 Arrangements of arresters .18

6.2 Continuous operating voltages at various locations in the converter station .19

6.3 Peak (PCOV) and crest value (CCOV) of continuous operating voltage

applied to valves and arresters .20

6.4 Sources and types of overvoltages.21

6.5 Overvoltage limiting characteristics of arresters .24

6.6 Valve protection strategy .25

6.7 Methods and tools for overvoltage and surge arrester characteristic studies .25

6.8 Necessary system details .28

7 Design objectives of insulation co-ordination .30

7.1 Arrester requirements .31

7.2 Characteristics of insulation .33

7.3 Representative overvoltages.33

7.4 Determination of the required withstand voltage .36

7.5 Determination of the specified withstand voltage .37

7.6 Creepage distances.37

7.7 Clearances in air .37

8 Creepage distances and clearances in air .37

8.1 Creepage distance for outdoor insulation under d.c. voltage.38

8.2 Creepage distance for indoor insulation under d.c. voltage .38

8.3 Creepage distance of a.c. insulators (external).38

8.4 Clearances in air .39

9 Arrester requirements .39

9.1 Arrester specification .39

9.2 AC bus arrester (A).40

9.3 AC filter arrester (FA) .40

9.4 Valve arrester (V) .40

9.5 Bridge arrester (B).42

9.6 Converter unit arrester (C) .43

TS 60071-5 IEC:2002(E) – 3 –

9.7 Mid-point d.c. bus arrester (M) .43

9.8 Converter unit d.c. bus arrester (CB).43

9.9 DC bus and d.c. line/cable arrester (DB and DL) .44

9.10 Neutral bus arrester (E) .44

9.11 DC reactor arrester (DR).45

9.12 DC filter arrester (FD) .45

9.13 Earth electrode station arrester.45

Annex A (informative) Example of insulation co-ordination for conventional HVDC

converters .46

Annex B (informative) Example of insulation co-ordination for Controlled Series

Capacitor Converters (CSCC) and Capacitor Commutated Converters (CCC).55

Annex C (informative) Considerations for insulation co-ordination of some special

converter configurations.69

Bibliography .75

Figure 1 – Single line diagram of typical converter pole with two 12-pulse

converters in series.13

Figure 2 – Single line diagram of typical capacitor commutated converter (CCC) pole

with two 12-pulse converters in series .14

Figure 3 – Single line diagram of typical controlled series compensated converter

(CSCC) pole with two 12-pulse converters in series .14

Figure 4 – HVDC converter station diagram with 12-pulse converter bridges .18

Figure 5 – Continuous operating voltages at various locations (location identification

according to figure 4) .20

Figure 6 – Operating voltage of a valve arrester (V), rectifier operation .21

Figure 7 – One pole of an HVDC converter station.29

Figure A.1 – AC and DC arresters (400 kV a.c. side for conventional HVDC converters) .52

Figure A.2 – Simplified circuit configuration for stresses of valve arrester at slow-front

overvoltages from a.c. side (conventional HVDC converters) – Illustration of

slow-front overvoltage wave (applied voltage).53

Figure A.3 – Stresses on valve arrester V2 at slow-front overvoltage from a.c. side

(conventional HVDC converter ) .53

Figure A.4 – Circuit configuration for stresses on valve arrester at earth fault on

transformer HV bushing (conventional HVDC converters) .54

Figure A.5 – Stresses on valve arrester V1 during earth fault on HV bushing of

converter transformer (conventional HVDC converter) .54

Figure B.1a – AC and DC arresters (400 kV a.c. side for CCC converters) .62

Figure B.1b – AC and DC arresters (400 kV a.c. side for CSCC converter) .63

Figure B.2a – Simplified circuit configuration for stresses on valve arrester at slow-front

overvoltages from a.c. side (CCC converter) .64

Figure B.2b – Simplified circuit configuration for stresses on valve arrester at slow-front

overvoltages from a.c. side (CSCC converter) .64

Figure B.3a – Stresses on valve arrester V2 at slow-front overvoltage from a.c. side

(CCC converter).65

Figure B.3b – Stresses on valve arrester V2 at slow-front overvoltage from a.c. side

(CSCC converter).65

– 4 – TS 60071-5 IEC:2002(E)

Figure B.4a – Circuit configuration for stresses on valve arrester at earth fault on HV

bushing of converter transformer (CCC converter).66

Figure B.4b – Circuit configuration for stresses on valve arrester at earth fault

on HV bushing of converter transformer (CSCC converter) .66

Figure B.5a – Stresses on valve arrester V1 during earth fault on HV bushing of

converter transformer (CCC converter).67

Figure B.5b – Stresses on valve arrester V1 during earth fault on HV bushing of

converter transformer (CSCC converter) .67

Figure B.6a – Stresses on CCC capacitor arrester Ccc during earth fault on HV bushing

of converter transformer (CCC converter).68

Figure B.6b – Stresses on CSCC capacitor arrester Csc during earth fault on HV

bushing of converter transformer (CSCC converter).68

Figure C.1 – Expanded HVDC converter with parallel valve groups .70

Figure C.2 – Upgraded HVDC converter with series valve group .72

Table 1 – Symbol description .14

Table 2 – Comparison of the selection of withstand voltages for three-phase a.c.

equipment with that for HVDC converter station equipment.17

Table 3 – Events stressing the different arresters .27

Table 4 – Types of stresses on arresters for different events .27

Table 5 – Origin of overvoltages and associated frequency ranges .28

Table 6 – Table for arrester requirements.32

Table 7 – Arrester protection of d.c. side of a HVDC converter station .34

Table 8 – Table gathering representative overvoltage levels and required withstand

voltage levels. .35

Table 9 – Indicative values of ratios of required impulse withstand voltage to impulse

protective level.37

TS 60071-5 IEC:2002(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INSULATION CO-ORDINATION –

Part 5: Procedures for high-voltage direct current (HVDC)

converter stations

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this technical specification may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC 60071-5, which is a technical specification, has been prepared by IEC technical committee

28: Insulation co-ordination.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

28/139/CDV 28/144A/RVC

Full information on the voting for the approval of this technical specification can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

– 6 – TS 60071-5 IEC:2002(E)

This technical specification is published in English only.

Annexes A, B and C are for information only.

The committee has decided that the contents of this publication will remain unchanged until

2008. At this date, the publication will be

• transformed into an International standard

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

TS 60071-5 IEC:2002(E) – 7 –

INSULATION CO-ORDINATION –

Part 5: Procedures for high-voltage direct current (HVDC)

converter stations

1 General

1.1 Scope

This part of IEC 60071 provides guidance on the procedures for insulation co-ordination of

high-voltage direct current (HVDC) converter stations, without prescribing standardized

insulation levels.

The guide applies only for HVDC applications in high-voltage a.c. power systems and not for

industrial conversion equipment. Principles and guidance given are for insulation co-ordination

purposes only. The requirements for human safety are not covered by this application guide.

1.2 Additional background

The use of power electronic thyristor valves in a series and/or parallel arrangement, along with

the unique control and protection strategies employed in the conversion process, has

ramifications requiring particular consideration of overvoltage protection of equipment in

converter stations compared with substations in a.c. systems. This guide outlines the

procedures for evaluating the overvoltage stresses on the converter station equipment

subjected to combined d.c., a.c. power frequency, harmonic and impulse voltages. The criteria

for determining the protective levels of series- and/or parallel combinations of surge arresters

used to ensure optimal protection is also presented.

The basic principles and design objectives of insulation co-ordination of converter stations, in

so far as they differ from normal a.c. system practice, are described.

Concerning surge arrester protection, this guide deals only with metal-oxide surge arresters,

without gaps, which are used in modern HVDC converter stations. The basic arrester

characteristics, requirements for these arresters and the process of evaluating the maximum

overvoltages to which they may be exposed in service, are presented. Typical arrester

protection schemes and stresses of arresters are presented, along with methods to be applied

for determining these stresses.

This guide includes insulation co-ordination of equipment connected between the converter a.c.

bus (including the a.c. harmonic filters, the converter transformer, the circuit breakers) and the

d.c. line side of the smoothing reactor. The line and cable terminations in so far as they

influence the insulation co-ordination of converter station equipment are also covered.

Although the main focus of the guide is on conventional HVDC systems where the commutation

voltage bus is at the a.c. filter bus, outlines of insulation co-ordination for the capacitor

commutated converter (CCC) as well as the controlled series compensated converter (CSCC)

and some other special converter configurations are covered in the annexes.

– 8 – TS 60071-5 IEC:2002(E)

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60060-1:1989, High-voltage test techniques – Part 1: General definitions and test

requirements

IEC 60071-1:1993, Insulation co-ordination – Part 1: Definitions, principles and rules

IEC 60071-2:1996, Insulation co-ordination – Part 2: Application guide

IEC 60099-4:1991, Surge arresters – Part 4: Metal-oxide surge arresters without gaps for a.c.

systems

IEC 60633:1998, Terminology for high-voltage direct current (HVDC) transmission

IEC 60700-1:1998,Thyristor valves for high-voltage direct current (HVDC) power transmission –

Part 1: Electrical testing

IEC 60815:1986, Guide for the selection of insulators in respect of polluted conditions

3 Definitions

For the purposes of this part of IEC 60071, the following terms and definitions apply.

Many of the following definitions refer to actual insulation co-ordination concepts, or to actual

arrester parameters. For more information on these, please refer to IEC 60071-1 or to

IEC 60099-4, respectively.

3.1

d.c. system voltage

highest mean or average operating voltage to earth, excluding harmonics and commutation

overshoots (IEC 123 pollution test of HVDC insulator)

3.2

peak value of continuous operating voltage (PCOV)

highest continuously occurring crest value of the voltage at the equipment on the d.c. side

of the converter station including commutation overshoots and commutation notches (see

figure 6)

3.3

crest value of continuous operating voltage (CCOV)

highest continuously occurring crest value of the voltage at the equipment on the d.c. side of

the converter station excluding commutation overshoots (see figure 6)

3.4

overvoltage

voltage between one phase conductor and earth or between phase conductors having a peak

value exceeding the corresponding peak of the highest voltage of the system on the a.c. side

and the PCOV on the d.c. side of the HVDC converter station

TS 60071-5 IEC:2002(E) – 9 –

3.4.1

temporary overvoltage (TOV)

power frequency overvoltage of relatively long duration (IEC 60071-1)

NOTE The overvoltage may be undamped or weakly damped. In some cases its frequency may be several times

smaller or higher than power frequency.

3.4.2

slow-front overvoltage

transient overvoltage, usually unidirectional, with time to peak 20 μs < Tp < 5 000 μs, and tail

duration T2 < 50 ms (IEC 60071-1)

NOTE For the purpose of insulation co-ordination, slow-front overvoltages are classified according to their shape,

regardless of their origin. Although considerable deviations from the standard shapes occur on actual systems, in

this standard it is considered sufficient in most cases to describe such overvoltages by their classification and

peak value.

3.4.3

fast-front overvoltage

overvoltage at a given location on a system, due to a lightning discharge or other cause, the

shape of which can be regarded, for insulation co-ordination purposes, as similar to that of the

standard impulse (IEC 60060-1) used for lightning impulse tests.

Transient overvoltage, usually unidirectional, with time to peak 0,1 μs < T1 < 20 μs, and tail

duration T2 < 300 μs (IEC 60071-1).

NOTE For the purpose of insulation co-ordination, slow-front and fast-front overvoltages are classified according

to their shape, regardless of their origin. Although considerable deviations from the standard shapes occur on

actual systems, in this standard it is considered sufficient in most cases to describe such overvoltages by their

classification and peak value.

3.4.4

very fast-front overvoltage

transient overvoltage, usually unidirectional, with time to peak T < 0,1 μs, total duration

f

< 3 ms, and with superimposed oscillations at frequency 30 kHz < f < 100 MHz (IEC 60071-1)

3.4.5

steep-front overvoltage

transient overvoltage classified as a kind of fast-front overvoltage with time to peak 3 ns < T1

< 1,2 μs). A steep-front impulse voltage for test purposes is defined in figure 1 of IEC 60700-1

NOTE The front time is decided by means of system studies.

3.4.6

combined overvoltage (temporary, slow-front, fast-front, very fast-front)

overvoltage consisting of two voltage components simultaneously applied between each of the

two phase terminals of a phase-to-phase (or longitudinal) insulation and earth. It is classified

by the component of higher peak value

3.5

representative overvoltages

overvoltages assumed to produce the same dielectric effect on the insulation as overvoltages

of a given class occurring in service due to various origins (IEC 60071-1)

NOTE In this specification it is generally assumed that the representative overvoltages are characterized by their

assumed or obtained maximum values.

3.5.1

representative slow-front overvoltage (RSLO)

voltage value between terminals of an equipment having the shape of a standard switching

impulse

– 10 – TS 60071-5 IEC:2002(E)

3.5.2

representative fast-front overvoltage (RFAO)

voltage value between terminals of an equipment having the shape of a standard lightning

impulse

3.5.3

representative steep-front overvoltage (RSTO)

voltage value with a standard shape having a time to crest less than that of a standard lightning

impulse, but not less than that of a very-fast-front overvoltage as defined by IEC 60071-1

NOTE A steep-front impulse voltage for test purposes is defined in figure 1 of IEC 60700-1. The front time is

decided by means of system studies.

3.6

continuous operating voltage of an arrester (U )

c

permissible r.m.s. value of power frequency voltage that may be applied continuously between

the terminals of the arrester in accordance with IEC 60099-4.

3.7

continuous operating voltage of an arrester including harmonics (U )

ch

r.m.s. value of the combination of power frequency voltage and harmonics that may be applied

continuously between the terminals of the arrester

3.8

equivalent continuous operating voltage of an arrester (ECOV)

r.m.s. value of the sinusoidal power frequency voltage at a metal-oxide surge arrester stressed

by operating voltage of any wave-shape that generates the same power losses in the metal-

oxide materials as the actual operating voltage

3.9

residual voltage of an arrester

peak value of voltage that appears between the terminals of an arrester during the passage of

a discharge current (IEC 60099-4)

3.10

co-ordination currents of an arrester

for a given system under study and for each class of overvoltage, the current through

the arrester for which the representative overvoltage is determined. Standard shapes of

co-ordination currents for steep-front, lightning and switching current impulses are given in

IEC 60099-4

NOTE The co-ordination currents are determined by system studies.

3.11

directly protected equipment

equipment connected in parallel to a surge arrester for which the separation distance can be

neglected and any representative overvoltage be considered equal to the corresponding

protective level

3.12

protective levels of an arrester

for each voltage class, residual voltage that appears between the terminals of an arrester

during the passage of a discharge current corresponding to the co-ordination current

For HVDC converter equipment the following specific definitions 3.12.1 to 3.12.3 apply.

TS 60071-5 IEC:2002(E) – 11 –

3.12.1

switching impulse protective level (SIPL)

residual voltage of a surge arrester subjected to a discharge current corresponding to the

co-ordination switching impulse current

3.12.2

lightning impulse protective level (LIPL)

residual voltage of a surge arrester subjected to a discharge current corresponding to the co-

ordination lightning impulse current

3.12.3

steep-front impulse protective level (STIPL)

residual voltage of a surge arrester subjected to a discharge current corresponding to the

co-ordination steep-front impulse current

3.13

co-ordination withstand voltage

for each class of voltage, value of the withstand voltage of the insulation configuration,

in actual service conditions, that meets the performance criterion (IEC 60071-1)

3.14

required withstand voltage

test voltage that the insulation withstands in a standard withstand test to ensure that the

insulation will meet the co-ordination withstand voltage in actual service

(IEC 60071-1 modified)

3.15

specified withstand voltage

test voltage suitably selected equal or above the required withstand voltage (see 3.14)

NOTE 1 For a.c. equipment, values of specified withstand voltages are standardized as per IEC 60071-1. For

HVDC equipment, there is no standardized values for the specified withstand voltages which are rounded up to

convenient practical values.

NOTE 2 The standard impulse shapes used for withstand tests on equipment as well as the test procedures are

defined in IEC 60060-1 and IEC 60071-1. For some d.c. equipment (e.g. the thyristor valves), the standard impulse

shapes may be modified in order to more realistically reflect expected conditions.

3.15.1

specified switching impulse withstand voltage (SSIWV)

withstand voltage of insulation with the shape of the standard switching impulse

3.15.2

specified lightning impulse withstand voltage (SLIWV)

withstand voltage of insulation with the shape of the standard lightning impulse

3.15.3

specified steep-front impulse withstand voltage (SSFIWV)

withstand voltage of insulation with the shape specified in IEC 60700-1

3.16

thyristor valve protective firing (PF)

method of protecting the thyristors from excessive voltage in the forward direction by firing

them at a pre-determined voltage

– 12 – TS 60071-5 IEC:2002(E)

4 Symbols and abbreviations

The list covers only the most frequently used symbols and abbreviations some of which are

illustrated graphically in the single-line diagram of figure 1 and table 1. For a more complete list

of symbols which has been adopted for HVDC converter stations, and also for insulation co-

ordination, refer to the standards listed in the normative references and to the bibliography.

4.1 Subscripts

0 (zero) at no load (IEC 60633)

d direct current or voltage (IEC 60633)

i ideal (IEC 60633)

max maximum (IEC 60633)

n pertaining to harmonic component of order n (IEC 60633)

4.2 Letter symbols

K atmospheric correction factor (IEC 60071-1)

a

K co-ordination factor (IEC 60071-1)

c

K safety factor (IEC 60071-1)

s

U continuous operating voltage of an arrester including harmonics

ch

U ideal no-load direct voltage (IEC 60633)

dio

U maximum value of U taking into account a.c. voltage measuring

dio

dim

tolerances, and transformer tap-changer offset by one step

U highest voltage of an a.c. system (IEC 60071-1 and 60071-2)

s

U no-load phase-to-phase voltage on the valve side of converter

v0

transformer, r.m.s. value excluding harmonics

α delay angle (IEC 60633); “firing angle” also used in this standard

advance angle (IEC 60633)

β

extinction angle (IEC 60633)

γ

overlap angle (IEC 60633)

μ

4.3 Abbreviations

CCC capacitor commutated converter

CSCC controlled series compensated converter

CCOV crest value of continuous operating voltage

ECOV equivalent continuous operating voltage

LIPL lightning impulse protective level

PCOV peak continuous operating voltage

PF protective firing

RFAO representative fast-front overvoltage (the maximum voltage stress value)

RSLO representative slow-front overvoltage (the maximum voltage stress value)

RSTO representative steep-front overvoltage (the maximum voltage stress value)

RLIWV required lightning impulse withstand voltage

RSIWV required switching impulse withstand voltage

RSFIWV required steep-front impulse withstand voltage

SIPL switching impulse protective level

TS 60071-5 IEC:2002(E) – 13 –

STIPL steep-front impulse protective level

SLIWV specified lightning impulse withstand voltage

SSIWV specified switching impulse withstand voltage

SSFIWV specified steep-front impulse withstand voltage

TOV temporary overvoltage

4.4 Typical HVDC converter station schemes and associated graphical symbols

Figures 1, 2 and 3 show the single line diagrams of typical HVDC converter stations equipped

with two 12-pulse converter bridges in series. The main differences between the schemes

consist in the presence, or not, of commutated capacitors (figure 2) or controlled series

capacitors (figure 3) on the a.c. side of the HVDC converter station.

NOTE Figures 1, 2 and 3 show all the possible arresters covered in this standard. However, some of them may be

eliminated because of specific designs.

Table 1 presents the specific graphical symbols associated with figures 1, 2 and 3 and which

are defined for the purpose of this report. Arrester designations and details on their design and

specific roles are presented in clause 9.

DC line / cable

Valve

arrester

[DR]

[V]

DC reactor

Bridge

DC bus DC line/cable

arrester

arrester

arrester arrester

[V]

[B] [CB]

[A]

Converter

[V] [DB] [DL]

d.c. bus

arrester

[V]

AC bus

DC filter

[V]

arrester

arrester

[FD]

[V]

Mid-point

[M] d.c. bus

arrester

[V]

AC filter AC reactor

[A]

arrester

arrester

[V]

[SR]

Neutral bus Electrode line

[FA]

Neutral bus

arrester

[E]

IEC 1610/02

Figure 1 – Single line diagram of typical converter pole

with two 12-pulse converters in series

– 14 – TS 60071-5 IEC:2002(E)

DC line/cable

Valve

arrester

[CC]

[DR]

[V]

DC reactor

Bridge DC bus DC line

arrester

arrester arrester

arrester

[V]

Capacitor

[B] [CB]

arrester

[A] Converter

[V] [DB] [DL]

d.c. bus

arrester

[V]

[CC]

DC filter

AC bus

[V]

arrester arrester

[FD]

[V]

Mid-point

[CC]

d.c. bus

[M]

arrester

[V]

[A]

AC reactor

AC filter

arrester arrester

[V]

[SR]

[CC]

Neutral bus Electrode line

[FA]

Neutral bus

arrester

[E]

IEC 1611/02

Figure 2 – Single line diagram of typical capacitor commutated converter (CCC) pole

with two 12-pulse converters in series

Valve

arrester

DC line/cable

[DR]

[V]

DC reactor

DC bus

Bridge DC line

arrester

arrester

arrester arrester

[V]

[B]

[CB]

Converter

[A]

[V] [DB] [DL]

d.c. bus

arrester

[SC] [CSC]

[V]

AC bus DC filter

[V]

arrester

arrester

[FD]

[V]

Mid-point

[M] d.c. bus

arrester

[V]

AC filter AC reactor

[A]

arrester

arrester

[V]

[SR]

Neutral bus Electrode line

[FA]

Neutral bus

arrester

[E]

IEC 1612/02

Figure 3 – Single line diagram of typical controlled series

compensated converter (CSCC) pole with two 12-pulse converters in series

Table 1 – Symbol description

Symbol Description

Valve (commutation group)

Valve (one arm)

Arrester

Resistor

Reactor

Capacitor

Transformer with two windings

Earth (ground)

TS 60071-5 IEC:2002(E) – 15 –

5 Principles of insulation co-ordination

The primary objectives of insulation co-ordination are

– to establish the maximum steady state, temporary and transient overvoltage levels to which

the various components of a system may be subjected in practice,

– to select the insulation strength and characteristics of equipment, including those for

protective devices, used in order to ensure a safe, economic and reliable installation in the

event of the above overvoltages.

5.1 Essential differences between a.c. and d.c. systems

In terms of the above objectives, insulation co-ordination applied to an HVDC converter station

is basically the same in principle as that of an a.c. substation. However, essential differences

exist which warrant particular consideration when dealing with HVDC converter station

insulation co-ordination. For example, there is a need to consider the following:

• the requirements of series-connected valve groups involving surge arresters connected

across individual valves and between terminals away from earth potential which involves

the use of different insulation levels for different parts of the HVDC converter station;

• the topology of the converter circuits with no direct exposure to the external overvoltage

since these circuits are bounded by inductances of converter transformers and smoothing

reactors (see also 9.4.3);

• the presence of reactive power sources and harmonic filters on both the a.c. and d.c. sides;

• the presence of converter transformers with two major windings including the valve side

winding floating from earth potential when the valves are not conducting, and a d.c.

component of current flowing when the valves are conducting;

• the characteristics of the converter valves, including their controls;

• the impact of control and protection in reducing overvoltages;

• voltage polarity effects of d.c. stress which, by attracting greater contaminants to the d.c.

insulation because of constant polarity, lead to greater creepage and clearance

requirements and to worse pollution and flashover performance compared with a.c.

insulation under the same environment;

• long overhead transmission lines and cables without intervening switching stations;

• interaction between the a.c. and d.c. systems, particularly where the a.c. system is

relatively weak;

• composite continuous operating voltages which include in some cases direct voltage,

fundamental frequency voltage, harmonic voltages and high frequency components;

• the various operating modes of the converter such as monopolar, bipolar, parallel or multi-

terminal.

– 16 – TS 60071-5 IEC:2002(E)

5.2 Insulation co-ordination procedure

Table 2 is a flow chart showing the comparison between the insulation co-ordination procedure

for a.c. systems (refer to figure 1 of IEC 60071-1) and for HVDC converter stations.

The general method of investigation is basically the same for an a.c. scheme as it is for an

HVDC converter station. This requires:

• an evaluation of characteristics of the system and the HVDC converter station;

• an assessment of the nature of the insulation in each equipment;

• the determination of different representative overvoltages;

• consideration of the type of overvoltage protection adopted and of current/energy stresses

imposed to surge arresters and determinant on their design.

However, characteristics of insulation and voltage distribution are different for a.c. and d.c.

systems.

TS 60071-5 IEC:2002(E) – 17 –

Table 2 – Comparison of the selection of withstand voltages for three-phase a.c.

equipment with that for HVDC converter station equipment

Flow chart for the

determination of rated or

Deviations from IEC 60071-1

standard insulation levels

in the selection of withstand

for three-phase a.c.

voltages for HVDC converter

equipment according to

station equipment

IEC 60071-1

System analysis.

System analysis

Same approach as for a.c.

Representative voltages and overvoltages.

Representative voltages

Same approach as for a.c.

and overvoltages

Selection of the insulation

Selection of the insulation meeting the

performance criterion.

meeting the performance

Same approach as for a.c.

criterion

In general, co-ordination withstand voltages

are determined in the same way as for a.c.

Co-ordination

For HVDC converter equipment requiring a

withstand very close protection with surge arresters

(directly protected equipment), co-ordination

voltages

withstand voltages are deduced from a

process involving the determination of the

co-ordination currents

Application of factors to account

Application of factors to account for the

for the differences between type

differences between test conditions and

test conditions and actual

actual service conditions.

service conditions

Same approach as for a.c.

Required withstand voltages.

Required withstand voltages

Same approach as for a.c.

Selection of standard withstand voltages for

a.c. side equipment only.

The present step is skipped for equipment

Selection of standard

on d.c. side because there are no

withstand voltages

standardized withstand voltage levels for

such equipment

Set of standard withstand voltages is

Rated or standard insulation

applicable only for equipment on the a.c. side.

level: set of standard

For equipment on the d.c. side, specified

withstand voltages insulation levels are rounded up to

convenient practical values

– 18 – TS 60071-5 IEC:2002(E)

6 Voltages and overvoltages in service

6.1 Arrangements of arresters

Since the late 1970s, overvoltage protection of HVDC converter stations has been based

exclusively on metal-oxide surge arresters. This is largely due to their superior protection

characteristics compared with the gapped SiC arresters (earlier technology) and their reliable

performance when connected in series or parallel with other arresters. The actual arrangement

of the arresters depends on the configuration of the HVDC converter station and the type of

transmission circuit. The basic criteria used however is that each voltage level and the

equipment connected to it is adequately protected at a cost commensurate with the desired

reliability and equipment withstand capability.

A typical arrester arrangement between the a.c. side of the converter bridges and the d.c.

transmission circuit is shown in figure 4 for a two terminal bipolar HVDC scheme with one 12-

pulse converter per pole. It should be noted however, that some of the arresters may be

deleted, depending upon the overvoltage withstand capability of the equipment connected at

that point, and upon the overvoltage protection afforded by a combination of other arresters

at the same point. For example, the d.c. bus can be protected by a series combination of

the bridge (B) and mid-point d.c. bus (M) arresters, instead of the converter unit d.c.

bus arrester (CB).

AC bus

FA1

9 DC line

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...