IEC TS 60519-5:2008

(Main)Safety in electroheat installations - Part 5: Specifications for safety in plasma installations

Safety in electroheat installations - Part 5: Specifications for safety in plasma installations

IEC/TS 60519-5 specifies safety requirements applicable to both plasma torch systems and installations using plasma torch systems. Determines safety requirements for all components, including the electrical equipment, the cooling circuits, the gas supply circuits, the furnace or reactor and more generally, all other equipment associated with the use of the furnace or reactor.

Sécurité dans les installations électrothermiques - Partie 5: Spécifications pour la sécurité dans les installations plasma

La CEI/TS 60519-5 spécifie les exigences de sécurité applicables à la fois aux systèmes de torche plasma et aux installations utilisant ces systèmes. Détermine les exigences de sécurité pour tous les composants, y compris les matériels électriques, les circuits de refroidissement, les circuits d'alimentation en gaz, le four ou le réacteur et plus généralement tout autre équipement associé à l'utilisation du four ou du réacteur.

General Information

- Status

- Withdrawn

- Publication Date

- 10-Mar-2008

- Withdrawal Date

- 11-Mar-2018

- Technical Committee

- TC 27 - Industrial electroheating and electromagnetic processing

- Drafting Committee

- MT 25 - TC 27/MT 25

- Current Stage

- WPUB - Publication withdrawn

- Start Date

- 13-Mar-2018

- Completion Date

- 12-Mar-2018

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

IEC TS 60519-5:2008 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Safety in electroheat installations - Part 5: Specifications for safety in plasma installations". This standard covers: IEC/TS 60519-5 specifies safety requirements applicable to both plasma torch systems and installations using plasma torch systems. Determines safety requirements for all components, including the electrical equipment, the cooling circuits, the gas supply circuits, the furnace or reactor and more generally, all other equipment associated with the use of the furnace or reactor.

IEC/TS 60519-5 specifies safety requirements applicable to both plasma torch systems and installations using plasma torch systems. Determines safety requirements for all components, including the electrical equipment, the cooling circuits, the gas supply circuits, the furnace or reactor and more generally, all other equipment associated with the use of the furnace or reactor.

IEC TS 60519-5:2008 is classified under the following ICS (International Classification for Standards) categories: 25.180.10 - Electric furnaces. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 60519-5:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TS 60519-5

Edition 1.0 2008-03

TECHNICAL

SPECIFICATION

SPÉCIFICATION

TECHNIQUE

Safety in electroheat installations –

Part 5: Specifications for safety in plasma installations

Sécurité dans les installations électrothermiques –

Partie 5: Spécifications pour la sécurité dans les installations plasma

IEC/TS 60519-5:2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/TS 60519-5

Edition 1.0 2008-03

TECHNICAL

SPECIFICATION

SPÉCIFICATION

TECHNIQUE

Safety in electroheat installations –

Part 5: Specifications for safety in plasma installations

Sécurité dans les installations électrothermiques –

Partie 5: Spécifications pour la sécurité dans les installations plasma

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

Q

CODE PRIX

ICS 25.180.10 ISBN 2-8318-9635-5

– 2 – TS 60519-5 © IEC:2008

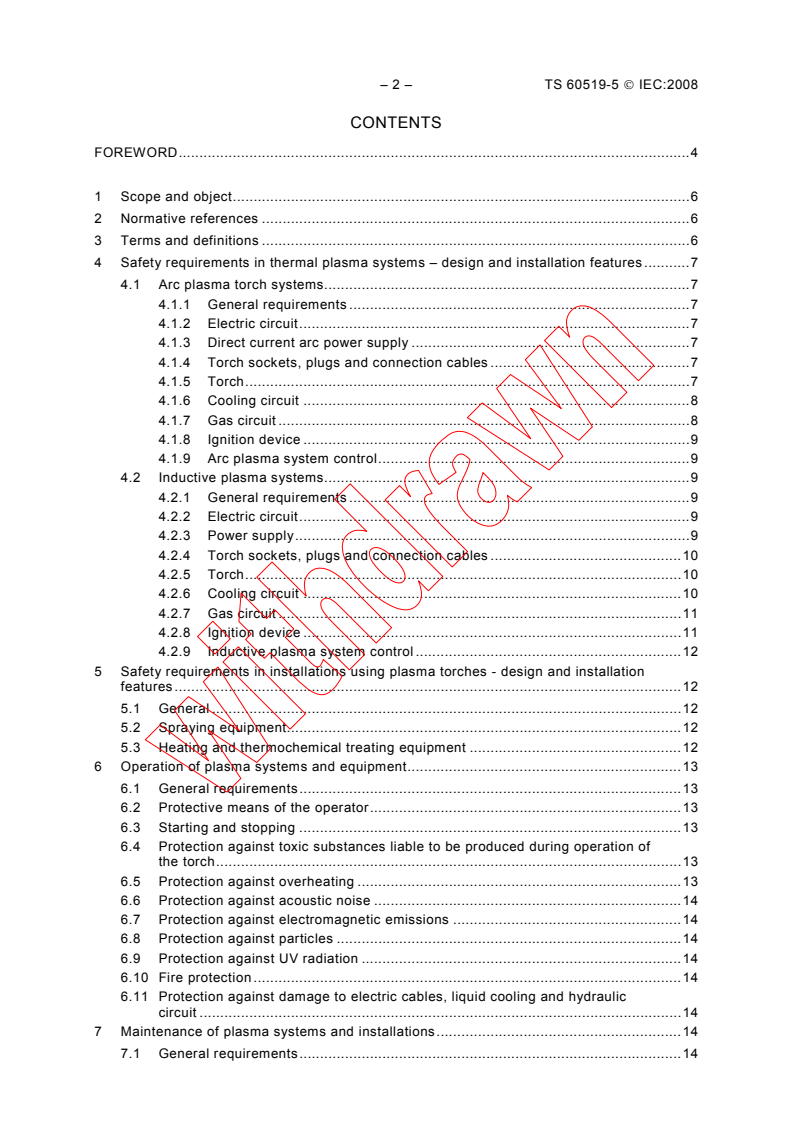

CONTENTS

FOREWORD.4

1 Scope and object.6

2 Normative references .6

3 Terms and definitions .6

4 Safety requirements in thermal plasma systems – design and installation features .7

4.1 Arc plasma torch systems.7

4.1.1 General requirements .7

4.1.2 Electric circuit.7

4.1.3 Direct current arc power supply .7

4.1.4 Torch sockets, plugs and connection cables .7

4.1.5 Torch.7

4.1.6 Cooling circuit .8

4.1.7 Gas circuit .8

4.1.8 Ignition device .9

4.1.9 Arc plasma system control.9

4.2 Inductive plasma systems.9

4.2.1 General requirements .9

4.2.2 Electric circuit.9

4.2.3 Power supply.9

4.2.4 Torch sockets, plugs and connection cables .10

4.2.5 Torch.10

4.2.6 Cooling circuit .10

4.2.7 Gas circuit .11

4.2.8 Ignition device .11

4.2.9 Inductive plasma system control .12

5 Safety requirements in installations using plasma torches - design and installation

features.12

5.1 General .12

5.2 Spraying equipment.12

5.3 Heating and thermochemical treating equipment .12

6 Operation of plasma systems and equipment.13

6.1 General requirements.13

6.2 Protective means of the operator.13

6.3 Starting and stopping .13

6.4 Protection against toxic substances liable to be produced during operation of

the torch.13

6.5 Protection against overheating .13

6.6 Protection against acoustic noise .14

6.7 Protection against electromagnetic emissions .14

6.8 Protection against particles .14

6.9 Protection against UV radiation .14

6.10 Fire protection .14

6.11 Protection against damage to electric cables, liquid cooling and hydraulic

circuit .14

7 Maintenance of plasma systems and installations.14

7.1 General requirements.14

TS 60519-5 © IEC:2008 – 3 –

7.2 Specific requirements.14

8 Marking, labelling and technical documentation .14

Annex A (informative) Electromagnetic emission threshold values around the torch

system in operation.15

Bibliography.16

– 4 – TS 60519-5 © IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY IN ELECTROHEAT INSTALLATIONS –

Part 5: Specifications for safety

in plasma installations

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC 60519-5 which is a technical specification, has been prepared by IEC technical

committee 27: Industrial electroheating equipment.

This first edition of TS cancels and replaces the first edition of International Standard

IEC 60519-5 published in 1980. It constitutes a technical revision.

TS 60519-5 © IEC:2008 – 5 –

The significant changes with respect to the previous edition are as follows:

– the previous edition focused on arc heating means and on spraying applications – this TS

applies to all means of production of thermal plasma, i.e. arc and induction heating, and to

the equipment directly coupled to these means. Applications include both the spraying

plasma process, as well as the heating and/or thermochemical plasma treatment;

– new technical issues, such as those referring to the protection against electromagnetic

emissions have been introduced;

– IEC 60519-1:2003 has been taken into account;

– definitions have been brought into line with the second edition of IEC 60050-841.

This technical specification is to be used in conjunction with IEC 60519-1:2003.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

27/579/DTS 27/604A/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The list of all parts of the IEC 60519 series, under the general title Safety in electroheat

installations, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – TS 60519-5 © IEC:2008

SAFETY IN ELECTROHEAT INSTALLATIONS –

Part 5: Specifications for safety

in plasma installations

1 Scope and object

This Technical Specification specifies safety requirements applicable to

a) thermal plasma torch systems:

– arc plasma systems,

– inductive plasma systems;

b) installations using plasma torch systems:

– spraying equipment,

– solid, liquid and gaseous charge heating and thermochemical treatment equipment.

For both plasma torch systems and installations using plasma torch systems, this

specification determines safety requirements for all components, including the electrical

equipment, the cooling circuits, the gas supply circuits, the furnace or reactor and more

generally, all other equipment associated with the use of the furnace or reactor.

Safety and construction requirements for plasma torches for welding, cutting and allied

processes are specified in IEC 60974-7.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-841:2004, International Electrotechnical Vocabulary – Part 841: Industrial

electroheat

IEC 60519-1:2003, Safety in electroheat installations – Part 1: General requirements

IEC/TS 60680, Test methods of plasma equipment for electroheat and electrochemical

applications

CISPR 11, Industrial, scientific and medical (ISM) radio-frequency equipment –

Electromagnetic disturbance characteristics – Limits and methods of measurement

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-841,

IEC 60519-1 and IEC/TS 60680 apply.

TS 60519-5 © IEC:2008 – 7 –

4 Safety requirements in thermal plasma systems – design and installation

features

4.1 Arc plasma torch systems

4.1.1 General requirements

See IEC 60519-1.

4.1.2 Electric circuit

See IEC 60519-1, Clause 6. In addition, 6.4.1 of IEC 60519-1 applies to the complete

installation.

4.1.3 Direct current arc power supply

The following specific requirements apply to systems with d.c. arc power supply.

4.1.3.1 Power supply grounding

One pole (positive or negative, depending on the torch polarity), on the d.c. side of the arc

power supply, shall be grounded using a separated earth from the main one of the system, so

as to avoid possible leakage currents towards electrical circuits such as those used for the

torch control.

4.1.3.2 Connection of the power supply to the torch

When the torch is off, the cables on the d.c. side shall be grounded through an earth

grounding switch, so as to safely handle the torch.

A specific procedure shall be performed before the arc ignition, through a manual

locking/unlocking device (generally operated with safety keys), authorizing in particular the

main breaker to be online and the earth grounding switch to be in the off position. Moreover, a

final clearance key may be used by the operator to start the ignition sequence. This procedure

shall meet the regulations in force in the country where the equipment is to be installed.

4.1.4 Torch sockets, plugs and connection cables

See IEC 60519-1, Clause 8.

4.1.5 Torch

An arc plasma torch of any design has the following characteristic features: a high

temperature gas, high voltage (in general) and liquid cooling (generally water). Consequently,

the design and construction shall satisfy the following criteria for safe operation:

a) electrical features:

– permanent electrical contact, during operation, between parts designed to be at the

same voltage, including the clamping of electrodes and pieces to be earth grounded, to

avoid overheating;

– for a high voltage torch, automatic shut down of the torch in case the leakage current

through the torch body excesses 10 mA;

– permanent electrical insulation between pieces to be brought to different voltages (and

specifically between the electrodes), so that no unintended breakdown can occur

under normal operating conditions;

b) cooling liquid features:

– 8 – TS 60519-5 © IEC:2008

– cooling liquid resistivity and torch circuit designed to maintain, during operation, the

required insulation between pieces to be brought to different voltages, and specifically

the electrodes;

– in case of electrode break through (accidental or normal wear), the phenomenon shall

remain under control firstly through the electrode material and/or design, secondly by

its detection to shut down the torch.

4.1.6 Cooling circuit

The following specific requirements apply to the cooling utilities:

a) mechanical features:

– the cooling liquid hoses of the torch, fixed or hand operated, shall have a sufficient

length, flexibility and appropriate radius of curvature (if any), so as to be facing the

stresses generated by the cooling liquid high pressure and to allow handling of the

particular hand operated torch;

– taking into account the high pressure necessary to obtain the specified mass flow rate

in the hoses, their mechanical strength shall not be appreciably affected by accidental

or steady state exposure to hot particles (hot material from a furnace) or thermal

heating from the torch itself or from hot material coming out from the process;

– if the direction of the cooling liquid flow is important, it shall be indicated by arrows

and/or colour codes on the connecting fittings of the torch and hoses. Non-

interchangeable couplers shall be used;

– the torch cooling liquid hoses, pipes and fittings shall remain liquid tight in the event of

liquid hammer or blocking during operation at the specified mass flow rate, taking into

account also the effects of heat on the hoses, also possibly due to radiation and ultra

violet radiation;

– flexing at the coupling of the cooling liquid inlets and outlets to the torch shall be

minimized as far as possible at the torch body and the couplings be provided at least

with a basic insulation to reduce the possibility of electrical breakdown within the torch

body;

b) electrical features:

– for the high-voltage torch, the hoses shall be made of insulated material, with length

defined to limit the leakage current to a value below 10 mA;

– the torch shall be electrically shut down when the cooling circuit is disconnected or

when the flow rate is below that specified;

– the operator shall have access to the cooling circuit control and monitoring devices, to

be able to read their indications and take necessary steps when required.

4.1.7 Gas circuit

The following specific requirements apply to the gas utilities:

a) general features:

– safety rules for the use of industrial gas in high pressure tanks, taking account of the

work regulations in force in the country where the equipment is to be installed;

b) mechanical features:

– the gas hoses of installations, fixed or hand operated, shall have a sufficient length,

flexibility and appropriate radius of curvature (if any), so as to sustain the constraints

generated by the gas high pressure and to allow handling in the case of hand-operated

torch;

– the gas admission hose(s) shall be so designed as to withstand the pressure required

to obtain the specified mass flow rate, which shall not be appreciably diminished by

accidental or steady-state exposure to hot particles or hot material. Their resistance to

heat and ultra violet radiation under normal operating conditions shall meet the

requirements;

TS 60519-5 © IEC:2008 – 9 –

– the fastening of gas hose(s) and pipes to the connecting fittings shall withstand the

gas pressure occurring in the event of circuit blockage;

c) electrical features:

– for the high-voltage torch, the hose(s) shall be made of insulated material, with length

defined to limit the leakage current to a value below 10 mA;

– a safety device shall prevent the ignition of the torch when the gas circuit is shut off or

when the minimum mass flow rate specified by the torch manufacturer is not reached;

– the operator shall have access to the gas circuit control and monitoring devices, to

read their indications when desired;

d) other features:

– the compressed gas containers installed close to the place of use of the plasma torch

shall be protected against possible overheating, electric discharges and ejections of

incandescent material. Similar precautions shall be taken for portable compressed gas

containers.

4.1.8 Ignition device

The following specific requirements apply to ignition devices:

a) high-frequency ignition device:

– protection against high voltage, in agreement with the regulations in force in the

country where the equipment is to be installed;

b) short-circuit ignition device:

– in general, a high-pressure hydraulic cylinder is used to move the device. The

requirements, as defined for the cooling liquid circuit, apply to this device;

– non-flammable and biodegradable hydraulic liquid shall be used.

NOTE The ignition device can be the main source of electromagnetic emissions.

4.1.9 Arc plasma system control

For safety purpose, several emergency push buttons shall be available to shut off the plasma

system, through a wired circuit.

4.2 Inductive plasma systems

4.2.1 General requirements

See IEC 60519-1.

4.2.2 Electric circuit

See IEC 60519-1, Clause 6. In addition, 6.4.1 of IEC 60519-1 applies to the complete

installation.

4.2.3 Power supply

4.2.3.1 Power supply grounding

The power supply shall be grounded using a separate earth from the main one of the system,

so as to avoid possible paths for leakage currents such as those created by the torch control

circuits.

4.2.3.2 Connection of the power supply to the torch

The following shall be taken into account:

– 10 – TS 60519-5 © IEC:2008

a) the torch shall be enclosed inside a Faraday cage to reduce electromagnetic emission and

to prevent the operator to get into contact with the high voltage terminals. An interlock

signal shall turn off the high voltage if the torch enclosure is opened;

b) the high voltage terminals shall be connected to earth to relieve the residual charge

potentially stored in the capacitors when the torch enclosure or Faraday cage is opened or

if the RF generator is shut down (see 6.2.4 of IEC 60519-1).

4.2.4 Torch sockets, plugs and connection cables

The following shall be taken in to account:

– the electrical terminal leads shall be positioned at a sufficient distance from each other

and earth to avoid arcing;

– 6.6 of IEC 60519-1 applies if usage of a water cooled electrical conductor is required;

– the tensile stresses and tight bending radius of the conductors shall be avoided.

4.2.5 Torch

An induction plasma torch, of any design has the following characteristic features: a high

temperature gas, high voltage (in general) and liquid cooling (generally water). Consequently,

the design and construction shall satisfy the following criteria for safe operation:

a) electrical features:

– permanent electrical contact, during operation, between parts designed to be at the

same voltage;

– no ferro-magnetic metal shall be used in the construction of the torch or inside the

Faraday cage;

– the induction coil shall be adequately insulated from the body of the torch or the

Faraday cage;

b) cooling liquid features:

– the cooling circuit design and the cooling liquid resistivity shall guarantee the required

insulation during operation;

– cooling liquid of the torch circuit shall be prevented from entering inside the torch

cavity. In case of a leak inside the torch cavity while in operation (accidental or normal

wear), the accident shall remain under control;

– 6.6 of IEC 60519-1 applies.

4.2.6 Cooling circuit

The following specific requirements apply to the cooling utilities:

a) mechanical features:

– the cooling hoses connected to the torch shall be manufactured of a non-conductive

and non-ferro-magnetic material;

– if the direction of the cooling liquid flow is important, it shall be indicated by arrows

and/or colour codes on the connecting fittings of the torch and hoses. Non-

interchangeable couplers shall be used;

– the torch cooling liquid hoses, piping and fitting shall remain tight in the event of liquid

hammer or blocking during operation at the specified mass flow rate, taking into

account also the effects of heat on the hoses, also possibly due to radiation and ultra

violet radiation;

b) electrical features:

– 6.6 of IEC 60519-1 applies;

– the hoses shall be of appropriate length to limit the leakage current;

TS 60519-5 © IEC:2008 – 11 –

– the electrical power supply for the torch shall be automatically interrupted when the

torch cooling mass flow rate is below a specified safe level and/or the temperature

exceeds a specified safe level;

– the operator shall have access to the cooling circuit control and monitoring devices, to

read their indications and take necessary steps when required.

4.2.7 Gas circuit

The following specific requirements apply to the gas utilities:

a) general features:

– safety rules for the use of industrial gas in high pressure tanks, taking account of the

work regulations in force in the country where the equipment is to be installed;

b) mechanical features:

– the gas hoses of the installations shall have a sufficient length, flexibility and

appropriate radius of curvature (if any), so as to sustain the constraints generated by

the gas high pressure;

– the gas admission hose(s) shall be designed as to withstand the pressure required to

obtain the specified mass flow rate, which shall not be appreciably diminished by

accidental or steady-state exposure to hot particles or hot material. Their resistance to

heat and ultra violet radiation shall meet the requirements under normal operating

conditions;

– the fastening of gas hose(s) and pipes to the connecting fittings shall withstand the

gas pressure occurring in the event of circuit blockage;

c) electrical features:

– the hose(s) shall be made of insulated material, with appropriate length to limit the

leakage current;

– the hose(s) shall be made of a non-ferro-magnetic material to prevent electromagnetic

coupling;

– a safety device shall prevent the ignition of the torch when the gas circuit is shut off or

when the minimum gas flow rate specified by the torch manufacturer is not reached;

– the operator shall have access to the gas circuit control and monitoring devices, to

read their indications when desired;

d) other features:

– the compressed gas containers installed close to the place of use of the plasma torch

shall be protected against possible overheating, electric discharges and ejections of

incandescent material. Similar precautions shall be taken for portable compressed gas

containers.

4.2.8 Ignition device

The following specific requirements apply to ignition devices:

a) high-frequency ignition device:

– protection against high voltage, in agreement with the regulations in force in the

country where the equipment is to be installed;

– direct contact with live parts shall be strictly prevented. The device shall be operated

only by telemanipulators providing adequate electrical insulation;

b) discharge rod igniter:

– direct contact with live parts shall strictly be prevented. The device shall be operated

only by telemanipulators providing adequate electrical insulation;

c) vacuum ignition:

– 12 – TS 60519-5 © IEC:2008

– torch and vessel shall be designed to resist pressure of 1 bar below atmospheric

pressure. In the case of external overpressure, the design shall take into account the

increased pressure load.

NOTE The ignition device can be the main source of electromagnetic emissions.

4.2.9 Inductive plasma system control

The emergency push buttons shall shut off the plasma system, through the wired circuit.

5 Safety requirements in installations using plasma torches – design and

installation features

5.1 General

Installations using plasma torches comprise two categories according to their applications (as

in IEC 60680):

– spraying equipment;

– solid, liquid and gaseous charge heating and thermochemical treatment equipment.

The first group of applications refers to the use of the plasma without any furnace or reactor,

and consequently the safety requirements applicable are mainly those of the plasma torch

system. However, several additional requirements are specified in 5.2.

The second group of applications refers to the use of plasma with a furnace or reactor fed

with the material to be treated and supplied with the plasma. In this case, several additional

requirements apply as specified in 5.3.

5.2 Spraying equipment

See 4.1 and/or 4.2.

In addition, the wire or powder distributor shall comply with regulations and requirements in

force as regards:

– electrical connection,

– connection to a gas-circuit pressure (carrier gas),

– connection to the torch.

When using transferred plasma, the surface to be sprayed shall be grounded to avoid any

accessible voltage carrying part.

5.3 Heating and thermochemical treating equipment

See 4.1 and/or 4.2.

In addition:

– 4.1.1 and partially 4.1.6 apply to the furnace and/or reactor,

– the furnace metallic envelope shall be grounded to avoid any accessible voltage carrying

part,

– the toxic substances to be taken into account are not only those which can be produced by

the torch but also those resulting from the decomposition or transformation of the fed

materials due to plasma interaction,

– the explosion risks shall also be taken into account, following the regulations in force in

the country where the equipment is to be installed.

TS 60519-5 © IEC:2008 – 13 –

6 Operation of plasma systems and equipment

6.1 General requirements

See IEC 60519-1.

In addition, during operation of plasma systems and equipment, the working conditions of

operators shall be in accordance with work safety regulations in force in the country where the

equipment is to be installed (related to high-voltage protection, acoustic noise, toxic

discharges, temperature rise, etc.).

6.2 Protective means of the operator

Operators of plasma systems and equipment shall wear protective means adapted to the type

of work performed: apron, gloves, insulating face shield to protect especially the eyes against

heat, glare, ultra-violet and infrared radiation, appropriate insulating footwear.

In addition, they shall use suitable means such as ear protectors to protect themselves

against acoustic noise.

Workers in the vicinity shall also be protected by effective screening of the work place.

6.3 Starting and stopping

The necessary sequence to start and stop plasma systems and equipment shall be performed

in an order ensuring safe working. In particular, the cooling liquid flow and the gas supply

shall be adjusted before ignition of the torch.

Cooling and gas supply shall not be interrupted during operation and shall be maintained for a

necessary period after the power is shut off.

A control unit shall ensure the starting, steady state and stopping, the whole sequence in the

correct order.

The wired circuit is activated in case of error or in emergency situations (one of them being to

use an emergency push button), to shut off the high voltage.

6.4 Protection against toxic substances liable to be produced during operation of the

torch

If the use of a plasma torch gives rise to the creation of toxic compounds, these shall be

evacuated in a suitable way (for instance filtration, dilution or chemical treatment), to give a

concentration of compounds below the specified threshold limit in the operator’s breathing

zone, according to the regulations in force in the country where the equipment is to be

installed.

In particular, specific gas detectors shall be installed to check the atmosphere in the zone

where the operators are at work. Moreover, evacuation paths shall be defined and marked.

In addition, when the plasma is discharged to the atmosphere, the torch shall be inside a

specific cabinet or inside a danger delimited area. People working on the site shall be outside

this cabinet or area when the torch is in operation.

NOTE The protection applies when the plasma gas itself is a toxic substance, for instance carbon monoxide.

6.5 Protection against overheating

For hand-operated torches, no part of the torch intended to be handled during operation shall

reach a temperature likely to expose the operator to danger.

– 14 – TS 60519-5 © IEC:2008

For fixed torches, parts defined as being at high temperature shall be inaccessible to the

operators.

6.6 Protection against acoustic noise

In addition to the ear protectors of the operators, acoustic noise shall comply with the

regulations in force for other people working on the same site. Consequently, specifically

when the plasma flow is discharged to the atmosphere, the torch shall be surrounded by a

protection, leaving the plasma flow to be developed and reducing the acoustic noise so that it

complies with the regulations in force in the country where the equipment is to be installed.

6.7 Protection against electromagnetic emissions

Electromagnetic emissions shall comply with the provisions of CISPR 11. In addition, the

electromagnetic field at the operator's normal workplace shall comply with the regulations in

the country where the equipment is to be installed (see also Annex A).

6.8 Protection against particles

Where applications can release particles to the open atmosphere, such as spraying and the

treatment or production of particles, a specific protection is required according to the

regulations in force in the country where the equipment is to be installed.

6.9 Protection against UV radiation

UV radiation, coming from the plasma flows or even directly from the arc requires eye and

skin protectors for the operators. More generally, protection against UV radiation shall comply

with the regulations in force in the country where the equipment is to be installed.

6.10 Fire protection

Requirements, according to the regulations in force in the country where the equipment is to

be installed, apply.

6.11 Protection against damage to electric cables, liquid cooling and hydraulic circuits

All connections, in particular those near the torch, shall be either protected against

overheating and fire, or located in a way they cannot suffer such damages. For hand-operated

torches, these cables, hoses and pipes shall be in particular protected against damage

caused by ejection of hot particles or by being trodden on.

7 Maintenance of plasma systems and installations

7.1 General requirements

See IEC 60519-1.

7.2 Specific requirements

In order to ensure safe working conditions, corrective and preventive maintenance work shall

be carried out, in agreement with the manufacturer. It may include daily checks as well as

major maintenance, for example once a year, of the whole system.

8 Marking, labelling and technical documentation

See IEC 60519-1, Clause 15.

TS 60519-5 © IEC:2008 – 15 –

Annex A

(informative)

Electromagnetic emission threshold values

around the torch system in operation

The minimum health and safety requirements regarding the exposure of workers to the risks

arising from electromagnetic fields are contained in Directive 2004/40/CE. The threshold

values, triggering corrective actions, are specified in Table 2 of the Directive.

The frequency range covered is from 0 Hz to 300 GHz. For the f frequency range from 1 MHz

to 10 MHz, the limit values are as follows (f expressed in MHz):

• electric field strength E (V/m): 610/f;

• magnetic field strength H (A/m): 1,6/f;

• magnetic flux density B (μT): 2/f;

(mA): 40.

• contact current I

c

– 16 – TS 60519-5 © IEC:2008

Bibliography

IEC 60974-7: Arc welding equipment – Part 7: Torches

Directive 2004/40/EC of the European Parliament and of the Council of 29 April 2004 on the

minimum health and safety requirements regarding the exposure of workers to the risks

arising from physical agents (electromagnetic fields)

___________

___________

The Directive is available at http://eur-lex.europa.eu/en/index.htm

– 18 – TS 60519-5 © CEI:2008

SOMMAIRE

AVANT-PROPOS.20

1 Domaine d'application et objet.22

2 Références normatives.22

3 Termes et définitions .22

4 Exigences de sécurité dans les systèmes plasma thermique – caractéristiques de

conception et d'installation .23

4.1 Systèmes de torche plasma d’arc .23

4.1.1 Exigences générales .23

4.1.2 Circuit électrique .23

4.1.3 Alimentation à courant continu.23

4.1.4 Supports de connexion, fiches de prises de courant et câbles de

raccordement d'une torche .23

4.1.5 Torche.23

4.1.6 Circuit de refroidissement.24

4.1.7 Circuit d’alimentation en gaz.24

4.1.8 Dispositif d'amorçage .25

4.1.9 Commande du système plasma d’arc .25

4.2 Sy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...