IEC TR 62271-312:2021

(Main)High-voltage switchgear and controlgear - Part 312: Guidance for the transferability of type tests of high-voltage/low-voltage prefabricated substations

High-voltage switchgear and controlgear - Part 312: Guidance for the transferability of type tests of high-voltage/low-voltage prefabricated substations

IEC TR 62271-312:2021(E) refers to high-voltage / low-voltage prefabricated substations (hereinafter prefabricated substations) as specified in IEC 62271-202:2014.

This document, among other options as agreed between manufacturer and user, can be used for the transferability of type tests performed on one or more prefabricated substations with a defined set of ratings and arrangement of components to another prefabricated substation with a different set of ratings or different arrangement of components. It supports the selection of appropriate representative test objects for that purpose in order to optimize the type testing procedure for a consistent conformity assessment.

This document utilises a combination of sound technical and physical principles, manufacturer and user experience and mutually agreed upon methods of calculation to establish pragmatic guidance for the transferability of type test results, covering various design and rating aspects.

General Information

- Status

- Published

- Publication Date

- 04-Jan-2021

- Technical Committee

- SC 17C - Assemblies

- Current Stage

- PPUB - Publication issued

- Start Date

- 05-Jan-2021

- Completion Date

- 21-Jan-2021

Overview

IEC TR 62271-312:2021 provides guidance on the transferability of type tests for high-voltage/low-voltage prefabricated substations (as defined in IEC 62271-202:2014). The Technical Report helps manufacturers, users and test laboratories determine when type-test results performed on one prefabricated substation can be applied to another substation with different ratings or component arrangements. It combines engineering principles, manufacturer/user experience and agreed calculation methods to optimize type testing and ensure a consistent conformity assessment.

Keywords: IEC TR 62271-312, transferability of type tests, prefabricated substations, type testing, high-voltage/low-voltage.

Key Topics

The document defines transferability criteria and the technical information needed to assess whether test results can be reused. Main technical topics include:

- Temperature rise: layout, ventilation, transformer losses, conductor currents and calculation methods for thermal behavior.

- Dielectric performance: clearances, insulating supports, materials and live part arrangements.

- Electromagnetic field: field generation, enclosure shielding, phase interconnections, rated voltages/frequencies and materials.

- Mechanical stress: enclosure materials, fasteners, reinforcement and load paths for mechanical integrity.

- Short-time and peak withstand current: rated short-circuit current, duration, conductor geometry and supports.

- Internal arc: arc-fault currents, compartment layouts, expansion volumes, ventilation paths and gas-flow cooling devices.

- Calculations and modelling: temperature rise, electric and electromagnetic fields, mechanical stresses, short-circuit and internal arc analyses.

- Documentation: information and test-report elements required to support transferability decisions.

The TR includes informative annexes with rationale for criteria and a collection of design parameters needed for assessments.

Applications

IEC TR 62271-312 is practical for:

- Manufacturers optimizing type-test programs to reduce redundant testing and cost.

- Test laboratories evaluating whether existing test reports can be applied to new substation variants.

- Utilities and specifiers accepting type-test evidence during procurement and conformity assessment.

- Design engineers validating design modifications or alternative component arrangements.

- Certification bodies assessing the adequacy of representative test objects.

Typical uses: transferring type-test reports between similar designs, validating a substation design from a portfolio of tests, and supporting documented conformity assessments.

Related Standards

- IEC 62271-202:2014 (prefabricated substations definitions and requirements) - primary reference.

- The broader IEC 62271 series (high-voltage switchgear and controlgear) for complementary type-test and performance requirements.

Applying IEC TR 62271-312 can streamline testing, reduce time-to-market and provide a transparent, engineering‑based basis for reusing type-test evidence across prefabricated substation variants.

Buy Documents

IEC TR 62271-312:2021 - High-voltage switchgear and controlgear - Part 312: Guidance for the transferability of type tests of high-voltage/low-voltage prefabricated substations Released:1/5/2021 Isbn:9782832292280

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TR 62271-312:2021 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "High-voltage switchgear and controlgear - Part 312: Guidance for the transferability of type tests of high-voltage/low-voltage prefabricated substations". This standard covers: IEC TR 62271-312:2021(E) refers to high-voltage / low-voltage prefabricated substations (hereinafter prefabricated substations) as specified in IEC 62271-202:2014. This document, among other options as agreed between manufacturer and user, can be used for the transferability of type tests performed on one or more prefabricated substations with a defined set of ratings and arrangement of components to another prefabricated substation with a different set of ratings or different arrangement of components. It supports the selection of appropriate representative test objects for that purpose in order to optimize the type testing procedure for a consistent conformity assessment. This document utilises a combination of sound technical and physical principles, manufacturer and user experience and mutually agreed upon methods of calculation to establish pragmatic guidance for the transferability of type test results, covering various design and rating aspects.

IEC TR 62271-312:2021(E) refers to high-voltage / low-voltage prefabricated substations (hereinafter prefabricated substations) as specified in IEC 62271-202:2014. This document, among other options as agreed between manufacturer and user, can be used for the transferability of type tests performed on one or more prefabricated substations with a defined set of ratings and arrangement of components to another prefabricated substation with a different set of ratings or different arrangement of components. It supports the selection of appropriate representative test objects for that purpose in order to optimize the type testing procedure for a consistent conformity assessment. This document utilises a combination of sound technical and physical principles, manufacturer and user experience and mutually agreed upon methods of calculation to establish pragmatic guidance for the transferability of type test results, covering various design and rating aspects.

IEC TR 62271-312:2021 is classified under the following ICS (International Classification for Standards) categories: 29.130.10 - High voltage switchgear and controlgear. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62271-312:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 62271-312 ®

Edition 1.0 2021-01

TECHNICAL

REPORT

colour

inside

High-voltage switchgear and controlgear –

Part 312: Guidance for the transferability of type tests of high-voltage/

low-voltage prefabricated substations

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 62271-312 ®

Edition 1.0 2021-01

TECHNICAL

REPORT

colour

inside

High-voltage switchgear and controlgear –

Part 312: Guidance for the transferability of type tests of high-voltage/

low-voltage prefabricated substations

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.130.10 ISBN 978-2-8322-9228-0

– 2 – IEC TR 62271-312:2021 © IEC 2021

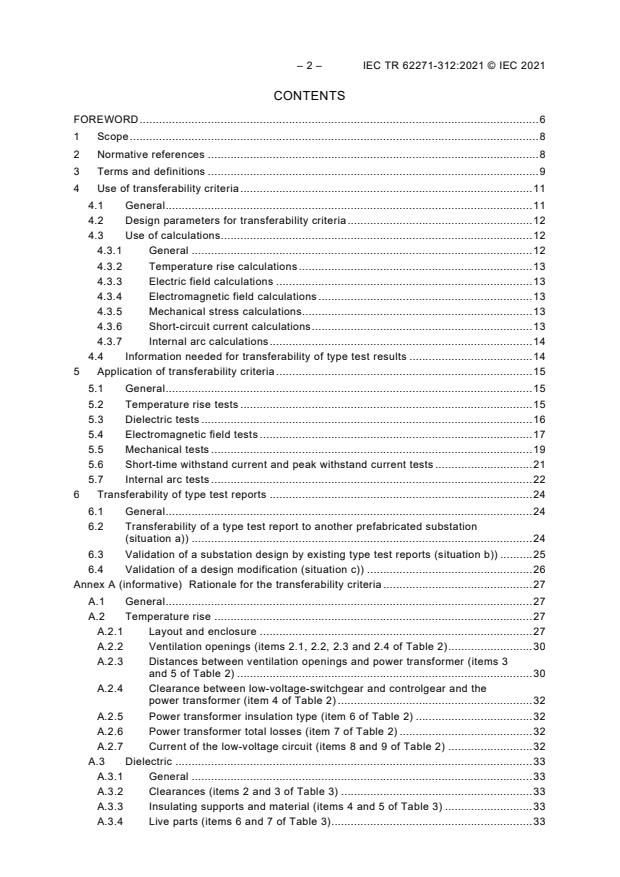

CONTENTS

FOREWORD . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Use of transferability criteria . 11

4.1 General . 11

4.2 Design parameters for transferability criteria . 12

4.3 Use of calculations . 12

4.3.1 General . 12

4.3.2 Temperature rise calculations . 13

4.3.3 Electric field calculations . 13

4.3.4 Electromagnetic field calculations . 13

4.3.5 Mechanical stress calculations. 13

4.3.6 Short-circuit current calculations . 13

4.3.7 Internal arc calculations . 14

4.4 Information needed for transferability of type test results . 14

5 Application of transferability criteria . 15

5.1 General . 15

5.2 Temperature rise tests . 15

5.3 Dielectric tests . 16

5.4 Electromagnetic field tests . 17

5.5 Mechanical tests . 19

5.6 Short-time withstand current and peak withstand current tests . 21

5.7 Internal arc tests . 22

6 Transferability of type test reports . 24

6.1 General . 24

6.2 Transferability of a type test report to another prefabricated substation

(situation a)) . 24

6.3 Validation of a substation design by existing type test reports (situation b)) . 25

6.4 Validation of a design modification (situation c)) . 26

Annex A (informative) Rationale for the transferability criteria . 27

A.1 General . 27

A.2 Temperature rise . 27

A.2.1 Layout and enclosure . 27

A.2.2 Ventilation openings (items 2.1, 2.2, 2.3 and 2.4 of Table 2) . 30

A.2.3 Distances between ventilation openings and power transformer (items 3

and 5 of Table 2) . 30

A.2.4 Clearance between low-voltage-switchgear and controlgear and the

power transformer (item 4 of Table 2) . 32

A.2.5 Power transformer insulation type (item 6 of Table 2) . 32

A.2.6 Power transformer total losses (item 7 of Table 2) . 32

A.2.7 Current of the low-voltage circuit (items 8 and 9 of Table 2) . 32

A.3 Dielectric . 33

A.3.1 General . 33

A.3.2 Clearances (items 2 and 3 of Table 3) . 33

A.3.3 Insulating supports and material (items 4 and 5 of Table 3) . 33

A.3.4 Live parts (items 6 and 7 of Table 3) . 33

A.4 Electromagnetic field . 34

A.4.1 General . 34

A.4.2 Substation layout and distance from components to external surfaces of

the enclosure (items 1 and 2 of Table 4) . 34

A.4.3 Rated voltages (item 3 of Table 4) . 36

A.4.4 Rated normal currents (item 4 of Table 4) . 36

A.4.5 Rated frequency (item 5 of Table 4) . 37

A.4.6 Permeability and conductivity of the enclosure material(s) (items 6 and

12 of Table 4) . 37

A.4.7 Interconnections (items 7, 8 and 9 of Table 4) . 38

A.4.8 Power transformer type of insulation (item 10 of Table 4) . 39

A.4.9 Distance between main circuit phases of the low-voltage switchgear and

controlgear (item 11 of Table 4) . 40

A.5 Mechanical stress . 40

A.5.1 General . 40

A.5.2 Common design parameters to be assessed for the key components . 40

A.5.3 Considerations for different enclosure materials, fasteners and

reinforcements (items 1, 2, 3 and 4 of Table 5) . 42

A.6 Short-time withstand current and peak withstand current . 43

A.6.1 General . 43

A.6.2 Rated short-time and peak currents (items 1 and 2 of Table 6) . 43

A.6.3 Rated duration of short-circuit (item 3 of Table 6) . 43

A.6.4 Centre distance between phase conductors (item 4 of Table 6) . 43

A.6.5 Conductors (items 5, 9 and 11 of Table 6) . 43

A.6.6 Insulating conductor supports (items 6, 7 and 8 of Table 6) . 44

A.6.7 Type of high-voltage and low-voltage terminations (item 10 of Table 6) . 44

A.6.8 Temperature class of insulating material in contact with conductors

(item 12 of Table 6) . 44

A.7 Internal arc . 44

A.7.1 General . 44

A.7.2 Rated arc fault current, arc fault peak current and arc fault duration

(items 1 and 2 of Table 7) . 45

A.7.3 High-voltage switchgear family (item 3 of Table 7) . 45

A.7.4 Layout of the prefabricated substation (item 4 of Table 7) . 46

A.7.5 Expansion volumes (items 5, 6 and 7 of Table 7) . 46

A.7.6 Cross-section of ventilation openings (item 8 of Table 7) . 51

A.7.7 Design, position, cross-section of the cooling device(s) and gas flow

(item 9 of Table 7) . 51

A.7.8 Distances between high-voltage switchgear and controlgear assembly

and the prefabricated substation enclosure (walls and roof) (item 10 of

Table 7) . 53

A.7.9 Mechanical strength of the enclosure (item 11 of Table 7) . 54

A.7.10 The shortest path length of hot gases in the last compartment to the

closest ventilation opening before leaving the substation (item 12 of

Table 7) . 54

A.7.11 Type of high-voltage interconnection and electrical protection of the

circuit (items 13 and 14 of Table 7) . 54

Annex B (informative) Collection of design parameters for the assessment of

transferability of type test results . 56

B.1 General . 56

B.2 Information needed for the assessment of the temperature-rise test . 56

B.3 Information needed for the assessment of the dielectric test . 57

– 4 – IEC TR 62271-312:2021 © IEC 2021

B.4 Information needed for the assessment of the electromagnetic field test . 58

B.5 Information needed for the assessment of the mechanical stress test . 59

B.6 Information needed for the assessment of the short-circuit current test . 59

B.7 Information needed for the assessment of the internal arc test . 60

Bibliography . 61

Figure 1 – Transferability of one type test report . 25

Figure 2 – Validation of a prefabricated substation by existing test reports . 26

Figure A.1 – Different examples of non-walk-in type-tested prefabricated substation

and related prefabricated substation under consideration . 28

Figure A.2 – Different examples of walk-in type-tested prefabricated substation and

related prefabricated substation under consideration . 29

Figure A.3 – Types of ventilation opening designs . 30

Figure A.4 – Distance from air inlet and air outlet ventilation openings . 31

Figure A.5 – Difference in height between power transformer and air outlet ventilation

openings . 31

Figure A.6 – Clearance between low-voltage-switchgear and controlgear and the

power transformer . 32

Figure A.7 – Prefabricated substation not acceptable alternative layouts . 35

Figure A.8 – Distances from main components to external surfaces of the enclosure . 36

Figure A.9 – Frequency influence on magnetic field . 37

Figure A.10 – Magnetic field behaviour under shielded technologies . 37

Figure A.11 – Example of magnetic field for different distributions of phase currents in

a three-phase interconnection having the same geometry and number of cables per

phase . 39

Figure A.12 – Examples of different door designs . 41

Figure A.13 – Examples of different roof designs . 41

Figure A.14 – Different size of prefabricated substations with same layout . 46

Figure A.15 – Gas flow in a non-walk-in type and walk-in type prefabricated

substations with separate high-voltage switchgear compartment . 48

Figure A.16 – Gas flow in a non-walk-in type and walk-in type prefabricated

substations without separate high-voltage switchgear compartment . 48

Figure A.17 – Gas flow in a walk-in type prefabricated substation with high-voltage

switchgear compartment without gas flow cooling device . 49

Figure A.18 – Gas flow in a walk-in type prefabricated substation with high-voltage

switchgear compartment and high-voltage switchgear and controlgear with integrated

gas flow cooling device . 49

Figure A.19 – Gas flow in a walk-in type prefabricated substation and high-voltage

switchgear and controlgear with integrated gas flow cooling device without separate

high-voltage switchgear compartment . 50

Figure A.20 – Transferability according to volume-criteria items 5, 6 and 7 of Table 7 . 51

Figure A.21 – Layers with different transmittance for a multi-layer gas flow cooling

device . 52

Figure A.22 – Top view of a prefabricated substation design with different gas flow

cooling device arrangements . 53

Figure A.23 – Top view of one basic substation design with different positions of high-

voltage switchgear and controlgear within the high-voltage switchgear compartment . 53

Figure A.24 – Prefabricated substations with different length of hot gases flow path

with regard to ventilation openings . 54

Table 1 – Examples of design parameters. 12

Table 2 – Transferability criteria for temperature rise performance . 15

Table 3 – Transferability criteria for dielectric withstand performance . 17

Table 4 – Transferability criteria for electromagnetic field performance . 18

Table 5 – Transferability criteria for the mechanical strength of the enclosure . 19

Table 6 – Transferability criteria for short-time and peak withstand current performance . 21

Table 7 – Transferability criteria for internal arc fault withstand performance . 23

Table A.1 – Material thermal conductivity . 29

Table B.1 – Information needed for the assessment of temperature-rise test . 56

Table B.2 – Information needed for the assessment of dielectric test . 58

Table B.3 – Information needed for the assessment of electromagnetic field test . 58

Table B.4 – Information needed for the assessment of mechanical test. 59

Table B.5 – Information needed for the assessment of short-circuit current test . 60

Table B.6 – Information needed for the assessment of internal arc test . 60

– 6 – IEC TR 62271-312:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

Part 312: Guidance for the transferability of type tests

of high-voltage/low-voltage prefabricated substations

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a Technical Report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 62271-312, which is a Technical Report, has been prepared by subcommittee 17C:

Assemblies, of IEC technical committee 17: High-voltage switchgear and controlgear.

The text of this Technical Report is based on the following documents:

Draft TR Report on voting

17C/737/DTR 17C/753B/RVDTR

Full information on the voting for the approval of this Technical Report can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62271 series, published under the general title High-voltage

switchgear and controlgear, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 8 – IEC TR 62271-312:2021 © IEC 2021

HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

Part 312: Guidance for the transferability of type tests

of high-voltage/low-voltage prefabricated substations

1 Scope

This document refers to high-voltage / low-voltage prefabricated substations (hereinafter

prefabricated substations) as specified in IEC 62271-202:2014.

This document, among other options as agreed between manufacturer and user, can be used

for the transferability of type tests performed on one or more prefabricated substations with a

defined set of ratings and arrangement of components to another prefabricated substation with

a different set of ratings or different arrangement of components. It supports the selection of

appropriate representative test objects for that purpose in order to optimize the type testing

procedure for a consistent conformity assessment.

This document utilises a combination of sound technical and physical principles, manufacturer

and user experience and mutually agreed upon methods of calculation to establish pragmatic

guidance for the transferability of type test results, covering various design and rating aspects.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-441:1984, International Electrotechnical Vocabulary (IEV) – Part 441: Switchgear,

controlgear and fuses

IEC 60050-441:1984/AMD1:2000

IEC 60076-1:2011, Power transformers – Part 1: General

IEC 60076-2, Power transformers – Part 2: Temperature rise for liquid-immersed transformers

IEC 60076-7, Power transformers – Part 7: Loading guide for mineral-oil-immersed power

transformers

IEC 60076-11, Power transformers – Part 11: Dry-type transformers

IEC 60076-12, Power transformers – Part 12: Loading guide for dry-type power transformers

IEC 60282-1:2020, High-voltage fuses – Part 1: Current-limiting fuses

IEC 61439-1:2020, Low-voltage switchgear and controlgear assemblies – Part 1: General rules

IEC 62271-1:2017, High-voltage switchgear and controlgear – Part 1: Common specifications

for alternating current switchgear and controlgear

IEC 62271-200:2011, High-voltage switchgear and controlgear – Part 200: AC metal-enclosed

switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV

IEC 62271-202:2014, High-voltage switchgear and controlgear – Part 202: High-voltage/low-

voltage prefabricated substation

IEC TR 62271-208:2009, High-voltage switchgear and controlgear – Part 208: Methods to

quantify the steady state, power-frequency electromagnetic fields generated by HV switchgear

assemblies and HV/LV prefabricated substations

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-441,

IEC 62271-202 and the following apply.

NOTE Some standard terms and definitions are recalled here for ease of reference.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

prefabricated substation

prefabricated and type-tested assembly comprising an enclosure containing in general power

transformers, high-voltage and low-voltage switchgear and controlgear, high-voltage and low-

voltage interconnections, auxiliary equipment and circuits

Note 1 to entry: The term type-tested assembly includes prefabricated substations verified based on the

transferability of type test results in accordance with this document.

[SOURCE: IEC 62271-202:2014, 3.101, modified – New Note 1 to entry.]

3.2

prefabricated substation under consideration

prefabricated substation being verified based on the transferability of type test results in

accordance with this document

3.3

component

essential part of the prefabricated substation, which serves one or several specific functions

Note 1 to entry: Examples of components include power transformer, high-voltage switchgear and controlgear, low-

voltage switchgear and controlgear, etc.

[SOURCE: IEC 62271-202:2014, 3.105, modified – Addition of "power" in Note 1 to entry.]

3.4

enclosure

part of a prefabricated substation providing protection against external influences to the

components and a specified degree of protection for operators and the general public with

respect to approach to, or contact with, live parts and against contact with moving parts

[SOURCE: IEC 62271-202:2014, 3.103, modified – Replacing “substation” by “components" in

the definition.]

3.5

class of enclosure

difference of temperature rise between the power transformer in the enclosure and the same

power transformer outside the enclosure at normal operating conditions

– 10 – IEC TR 62271-312:2021 © IEC 2021

[SOURCE: IEC 62271-202:2014, 3.112, modified – In the definition, "power" was added,

"normal service conditions as defined in 2.1" was replaced by "normal operating condition", and

the note was deleted.]

3.6

compartment

part of a prefabricated substation enclosed except for openings necessary for interconnection,

control or ventilation

Note 1 to entry: A compartment can be designated by the component contained therein, for example, power

transformer, high-voltage switchgear and controlgear, low-voltage switchgear and controlgear respectively.

[SOURCE: IEC 62271-202:2014, 3.104, modified – In Note 1 to entry, addition of "power".]

3.7

prefabricated substation layout

three-dimensional spatial arrangement of main components, covers, doors, ventilation openings

and compartments, if any

Note 1 to entry: Relative clearances and distances from main components to one another and to the enclosure can

vary.

3.8

high-voltage switchgear compartment

compartment inside the prefabricated substation where the high-voltage switchgear and

controlgear or high-voltage electrical protection of the circuit is installed

3.9

switchgear and controlgear

general term covering switching devices and their combination with associated control,

measuring, protective and regulating equipment, also assemblies of such devices and

equipment with associated interconnections, accessories, enclosures and supporting structures

[SOURCE: IEC 60050-441:1984, 441-11-01]

3.10

family of high-voltage switchgear and controlgear

functional units designed to be physically combined in assemblies and providing a range of

ratings and characteristics (e.g. current, voltage, degree of protection)

[SOURCE: IEC TR 62271-307:2015, 2.102, modified – Addition of "high-voltage" in the term.]

3.11

main circuit

all conductive parts of a prefabricated substation included in a circuit which is intended to

transmit electrical energy

[SOURCE: IEC 62271-202:2014, 3.107]

3.12

high-voltage interconnection

electrical connection between the terminals of the high-voltage switchgear and controlgear and

the high-voltage terminals of the power transformer

[SOURCE: IEC 62271-202:2014, 3.105.1, modified – Replacing "high-voltage/low-voltage

power transformer" by “power transformer” in the definition.]

3.13

low-voltage interconnection

electrical connection between the low-voltage terminals of the power transformer and the

incoming terminals of the low-voltage switchgear and controlgear

[SOURCE: IEC 62271-202:2014, 3.105.2, modified – Replacing "high-voltage/low-voltage

power transformer" by “power transformer” in the definition.]

3.14

test object

item submitted to a test, including any accessories, unless otherwise specified

[SOURCE: IEC 60050-151:2001, 151-16-28]

3.15

transferability criteria

principle for evaluating based on the design parameters, which can be applied to validate the

performance of an untested prefabricated substation based on the positive results of a test

performed on another prefabricated substation for a specific characteristic

4 Use of transferability criteria

4.1 General

Because of the variety of types of prefabricated substations, size of enclosures, layout and

different types of components, it is neither practical nor affordable to perform type tests with all

the possible variations and combinations. Therefore, the performance of a particular

prefabricated substation can be evaluated with reference to type test reports of other

prefabricated substation(s). This document gives support for the transferability of type test

results concerning the following characteristics according to 6.1 of IEC 62271-202:2014:

– temperature rise;

– dielectric;

– electromagnetic field;

– mechanical;

– short-circuit; and

– internal arc.

Subclauses 5.2 to 5.7 provide, for each kind of characteristic, a non-exhaustive list of design

parameters, which should be analysed for the transferability of type test results.

The analysis should be based on sound technical and physical principles and may be supported

by calculations, if applicable.

For each characteristic, the design parameters of the prefabricated substation under

consideration, listed in the respective column of Table 2 to Table 7, should be compared with

the design parameters of the already type-tested prefabricated substation(s) by applying the

transferability criteria provided in the same tables. The affirmation of every transferability

criteria for a determined characteristic supports the type test results transferability from the

original prefabricated substation(s) to the prefabricated substation under consideration. The

transferability of the type test results of a particular characteristic does not imply immediate

acceptance of other characteristic(s), as each characteristic should be independently assessed.

For example, the affirmation of item 7 in Table 2 for transferability assessment of temperature

rise type test results reads: power transformer total losses of the prefabricated substation under

consideration should be equal or smaller than those of the type-tested prefabricated substation.

– 12 – IEC TR 62271-312:2021 © IEC 2021

If any of the transferability criteria cannot be affirmed, further evidence e.g. by technical

arguments, calculation or simulation, or specific tests may be used and it can be subjected to

agreement between the manufacturer and the user. Calculations can only be applied in a

comparative sense as indicated in 4.3.

4.2 Design parameters for transferability criteria

Some ratings of a prefabricated substation are not linked to the parameters of specific main

components. For example, a layout change can significantly affect the performance of a

prefabricated substation characteristic.

The criteria for the transferability of type test results available for a prefabricated substation

depend on a number of design parameters such as the examples listed in Table 1. Every

prefabricated substation is characterized by its own set of design parameters.

The transferability of type test results of a component with regard to its particular product

standard is outside the scope of this document.

Table 1 – Examples of design parameters

Design parameter

Thermal conductivity of enclosure material (steel, reinforced concrete, polyester)

Insulation type of the power transformer (oil- or dry-type)

Effective cross-section of ventilation openings (inlet and outlet)

Degree of protection (IP code) of the enclosure

Distance from components incorporating the main circuits of a prefabricated substation to the enclosure

Mechanical strength of the enclosure roof material

Material of high voltage interconnections conductors

Design, position and cross-section area of gas flow cooling device(s)

NOTE This table includes examples only; it is not intended to be complete.

4.3 Use of calculations

4.3.1 General

For the purpose of this document, calculations and simulations may only be applied in a

comparative sense. Calculation results available for a type-tested prefabricated substation can

be used for validation and be compared with calculation results obtained for the prefabricated

substation under consideration. The comparison is always based on the design parameters and

the acceptance criteria provided in Table 2 to Table 7.

In many cases the performance of a given prefabricated substation, with respect to a particular

type test, cannot be evaluated by a single value of a design parameter due to the complexity of

the design. For example, the low-voltage interconnection layout can vary considerably along

the current path. Calculations have the potential to compare the respective design parameter

with spatial resolution supporting a comparison using technical arguments and expertise.

Depending on the type test and the particular design parameter, sometimes a simple model of

the relevant prefabricated substation can be sufficient using an analytical or empirical formula,

and sometimes a complete three-dimensional simulation model should be required using a

complex numerical tool provided that the results of the simulation tool are consistent and

repeatable.

The validation of software tools and calculation methods themselves is outside the scope of

this document. Some of these calculation methods are briefly mentioned below as examples.

4.3.2 Temperature rise calculations

The assessment procedure is applied to the prefabricated substation under consideration taking

into account the total losses generated inside the prefabricated substation, the layout, and the

area and mounting conditions of the enclosure walls and the effective area of the ventilation

openings. The air temperature inside the enclosure in various locations is the parameter to

compare.

For complex geometries, a comparison may be performed by thermal networks, where the whole

assembly with all components is divided into discrete elements built from heat generating

resistors and heat conducting and convection elements. Furthermore, more complex CFD tools

(computational fluid dynamics) or other techniques such as nodal tools may be applied requiring

a complete three-dimensional model of the prefabricated substation and main components.

IEC 61439-1 gives conditions for the verification of temperature rise by calculation and

IEC TR 60890 [1] provides calculation procedures for low voltage assemblies, which can also

be applied to a prefabricated substation while having due regard for the particular limitations of

this calculation method.

4.3.3 Electric field calculations

Since IEC 62271-202:2014 only requires dielectric type tests on interconnections between the

main components (i.e. interconnection between the high-voltage switchgear and controlgear

and the power transformer and interconnection between the power transformer and the low-

voltage switchgear and controlgear), the dielectric withstand performance of two prefabricated

substations may be assessed by an electric field simulation of both designs comparing the

resulting electric field strengths.

When the installation conditions can affect their dielectric withstand, finite element (FE) or finite

volume (FV) software tools exist, which allows the simulation of complex three-dimensional

geometries. It should be noted that this document does not provide information for the

extrapolation but only for the interpolation of design parameters, e.g. extending validity to higher

values of electric field strengths is not covered.

4.3.4 Electromagnetic field calculations

In case the reference prefabricated substation has been evaluated following the calculation

methodology described in IEC TR 62271-208, the same procedure should be applied to the

prefabricated substation under consideration in a comparative sense.

4.3.5 Mechanical stress calculations

The mathematical methods of calculation make provision for the full assessment in relation to

the mechanical withstand capability of the enclosure. Furthermore, national structural codes

and other local regulations may also make provision for the assessment in relation to the

mechanical withstand capability of the enclosure.

4.3.6 Short-circuit current calculations

This subclause may only be applied to the interconnection between the components, (i.e.

interconnection between the high-voltage switchgear and controlgear and the power

transformer and interconnection between the power transformer and the low-voltage switchgear

and controlgear) and the earthing circuit of the prefabricated substation.

___________

Numbers in square brackets refer to the Bibliography.

– 14 – IEC TR 62271-312:2021 © IEC 2021

With respect to the short-time and peak current withstand performance, guidance and

calculation formulas for bus-bar designs can be found in IEC 60865-1 [4] and IEC TR 60865-2

[5]. This includes the determination of mutual electromagnetic forces between phase conductors

and the resulting mechanical stresses, which may overstress conductors and damage

insulators. The mechanical stresses on conductors and forces on the supports may be assessed

through stress analysis programs, when applying the calculated electro-magnetic forces.

Additionally, a calculation of the thermal stress using I t can be done when the assessment

k k

is made for a lower I and higher t than those tested, considering that short-time withstand

k k

current (I ) and duration of short-circuit (t ) are in accordance with 4.5 and 4.7 of

k k

IEC 62271-202:2014.

4.3.7 Internal arc calculations

The assessment of the effects of an internal arc inside of a prefabricated substation may be

substantiated by pressure-rise calculations and hot gas flow simulations for the compartments,

exhausting ducts and pressure relief volumes [7, 8].

The calculations are able to provide the pressure-rise in the compartments under consideration.

They also provide parameters for the mechanical strength design of pressure relief device

elements, if any. An assessment of the strength of the enclosure walls under the pressure str

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...