IEC 60099-6:2019

(Main)Surge arresters - Part 6: Surge arresters containing both series and parallel gapped structures - System voltage of 52 kV and less

Surge arresters - Part 6: Surge arresters containing both series and parallel gapped structures - System voltage of 52 kV and less

IEC 60099-6: 2019 applies to non-linear metal-oxide resistor type surge arresters with spark gaps designed to limit voltage surges on AC power circuits with system voltages Us above 1 kV up to and including 52 kV. This document basically applies to all metal-oxide distribution class surge arresters with internal series and/or parallel gaps and housed in either porcelain or polymeric housings. This second edition cancels and replaces the first edition published in 2002. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) A new concept of arrester classification and energy withstand testing was introduced: the line discharge classification was replaced by a classification based on repetitive charge transfer rating (Qrs) and thermal charge transfer rating (Qth). The new concept clearly differentiates between impulse and thermal energy handling capability, which is reflected in the requirements as well as in the related test procedures.

b) Power-frequency voltage versus time tests – with and without prior duty – were introduced as type tests.

c) Requirements and tests on disconnectors were added.

d) Definitions for new terms have been added.

e) Clause 10 contains particular requirements for polymer-housed surge arresters. These are indicated in the form of replacements, additions or amendments to the original clauses or subclauses concerned.

Keywords: testing of metal-oxide surge arresters

Parafoudres - Partie 6: Parafoudres contenant des structures à éclateurs en série et en parallèle - Tension de réseau inférieure ou égale à 52 kV

IEC 60099-6: 2019 s'applique aux parafoudres à résistance variable à oxyde métallique avec éclateur conçus pour limiter les surtensions sur les circuits d'alimentation à courant alternatif avec des tensions de réseau Us supérieures à 1 kV, et inférieures ou égales à 52 kV. Le présent document s’applique fondamentalement à tous les parafoudres de classe de distribution à oxyde métallique avec éclateurs en série et/ou en parallèle internes, et à enveloppes en porcelaine ou synthétiques. Cette deuxième édition annule et remplace la première édition parue en 2002. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente.

a) Un nouveau concept de classification des parafoudres et d'essai de tenue énergétique a été introduit: la classification de décharge de ligne a été remplacée par une classification fondée sur les caractéristiques assignées de transfert de charges répétitives (Qrs) et les caractéristiques assignées de transfert de charges thermiques (Qth). Le nouveau concept différencie clairement le choc de la capacité de traitement de l'énergie thermique, cette différence étant reflétée dans les exigences, ainsi que dans les procédures d’essai associées.

b) Des essais de tension de tenue à fréquence industrielle en fonction du temps – avec et sans service préalable – ont été introduits comme essais de type.

c) Des exigences et des essais portant sur les dispositifs de déconnexion ont été ajoutés.

d) Les définitions de nouveaux termes ont été ajoutées.

e) L’Article 10 contient des exigences particulières pour les parafoudres à enveloppe synthétique. Celles-ci sont indiquées sous la forme de remplacements, d'ajouts ou d'amendements aux articles ou paragraphes concernés.

Mots clés : essais des parafoudres à oxyde métallique

General Information

- Status

- Published

- Publication Date

- 21-May-2019

- Technical Committee

- TC 37 - Surge arresters

- Drafting Committee

- MT 4 - TC 37/MT 4

- Current Stage

- PPUB - Publication issued

- Start Date

- 22-May-2019

- Completion Date

- 14-Jun-2019

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60099-6:2019 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies requirements and testing procedures for metal-oxide surge arresters containing both series and parallel gapped structures designed for AC power systems with system voltages above 1 kV and up to 52 kV. This edition, published in 2019, replaces the 2002 version with significant technical revisions to improve surge arrester performance, classification, and testing methodologies.

Surge arresters are essential protective devices in electrical power systems, limiting transient overvoltages caused by lightning strikes, switching operations, or fault conditions. IEC 60099-6:2019 ensures the reliable operation of non-linear metal-oxide resistors with spark gaps enclosed in either porcelain or polymeric housings. This standard is critical for manufacturers, testing laboratories, utilities, and system designers seeking compliance with international quality and safety benchmarks.

Key Topics

Scope and Application

Applicable to surge arresters with system voltages from above 1 kV up to 52 kV, covering distribution class non-linear metal-oxide resistor types with series and/or parallel spark gaps.Arrester Classification and Ratings

Introduction of a new classification approach based on:- Repetitive charge transfer rating (Qrs) - indicating impulse energy handling capability

- Thermal charge transfer rating (Qth) - reflecting thermal energy endurance

This differentiation allows better evaluation of surge arrester performance under transient and thermal stresses.

Testing Procedures

Detailed test methods include:- Insulation withstand (impulse and power-frequency voltage) tests

- Residual voltage and protective level verification

- Thermal stability and repetitive charge transfer tests

- Power-frequency voltage versus time tests with and without prior electrical duty

- Short-circuit and mechanical load tests

- Tests on disconnectors integrated in surge arresters

- Seal leak rate and partial discharge measurement

Design Requirements

Requirements cover internal elements such as grading components, spark gaps, and disconnectors, as well as mechanical robustness against bending moments and environmental stressors.Polymer-Housed Arresters

Dedicated clauses address polymeric housing requirements and testing adaptations, ensuring the safe deployment of modern lightweight surge arresters.

Applications

IEC 60099-6:2019 surge arresters are designed for widespread use in medium-voltage power distribution networks and industrial installations where voltages do not exceed 52 kV. Their role includes:

- Protecting transformers, switchgear, capacitors, and motors from transient overvoltages

- Enhancing system reliability by limiting insulation stress and preventing equipment damage

- Supporting grid stability through fast surge energy dissipation

- Ensuring compliance with international standards for quality assurance in surge protection components

- Providing data for utility asset management and maintenance planning

Usage of these surge arresters aligns with national grid codes and improves safety margins in electrical distribution systems exposed to lightning and switching surges.

Related Standards

IEC 60099-4: Surge arresters - Metal-oxide surge arresters with non-linear resistors

Provides general requirements and tests for metal-oxide surge arresters used at various system voltages beyond 52 kV.IEC 60099-5: Surge arresters - Selection and application recommendations

Offers guidelines for selecting appropriate surge arresters based on system characteristics and environmental conditions.IEC 60099-1: Surge arresters - Requirements and tests for arresters without gaps

Covers another category of metal-oxide surge arresters without spark gaps, complementing the scope of IEC 60099-6.IEC 61000 Series: Electromagnetic Compatibility (EMC)

Relevant for ensuring surge arresters meet electromagnetic interference requirements during operation.

Users and manufacturers referring to IEC 60099-6:2019 benefit from adherence to a comprehensive and technically updated framework essential for the design, testing, and application of surge arresters in low and medium voltage power systems. This ensures improved durability, safety, and functionality in protecting electrical infrastructure against transient voltage phenomena.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60099-6:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Surge arresters - Part 6: Surge arresters containing both series and parallel gapped structures - System voltage of 52 kV and less". This standard covers: IEC 60099-6: 2019 applies to non-linear metal-oxide resistor type surge arresters with spark gaps designed to limit voltage surges on AC power circuits with system voltages Us above 1 kV up to and including 52 kV. This document basically applies to all metal-oxide distribution class surge arresters with internal series and/or parallel gaps and housed in either porcelain or polymeric housings. This second edition cancels and replaces the first edition published in 2002. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) A new concept of arrester classification and energy withstand testing was introduced: the line discharge classification was replaced by a classification based on repetitive charge transfer rating (Qrs) and thermal charge transfer rating (Qth). The new concept clearly differentiates between impulse and thermal energy handling capability, which is reflected in the requirements as well as in the related test procedures. b) Power-frequency voltage versus time tests – with and without prior duty – were introduced as type tests. c) Requirements and tests on disconnectors were added. d) Definitions for new terms have been added. e) Clause 10 contains particular requirements for polymer-housed surge arresters. These are indicated in the form of replacements, additions or amendments to the original clauses or subclauses concerned. Keywords: testing of metal-oxide surge arresters

IEC 60099-6: 2019 applies to non-linear metal-oxide resistor type surge arresters with spark gaps designed to limit voltage surges on AC power circuits with system voltages Us above 1 kV up to and including 52 kV. This document basically applies to all metal-oxide distribution class surge arresters with internal series and/or parallel gaps and housed in either porcelain or polymeric housings. This second edition cancels and replaces the first edition published in 2002. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) A new concept of arrester classification and energy withstand testing was introduced: the line discharge classification was replaced by a classification based on repetitive charge transfer rating (Qrs) and thermal charge transfer rating (Qth). The new concept clearly differentiates between impulse and thermal energy handling capability, which is reflected in the requirements as well as in the related test procedures. b) Power-frequency voltage versus time tests – with and without prior duty – were introduced as type tests. c) Requirements and tests on disconnectors were added. d) Definitions for new terms have been added. e) Clause 10 contains particular requirements for polymer-housed surge arresters. These are indicated in the form of replacements, additions or amendments to the original clauses or subclauses concerned. Keywords: testing of metal-oxide surge arresters

IEC 60099-6:2019 is classified under the following ICS (International Classification for Standards) categories: 29.240.10 - Substations. Surge arresters. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60099-6:2019 has the following relationships with other standards: It is inter standard links to IEC 60099-6:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60099-6:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60099-6 ®

Edition 2.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Surge arresters –

Part 6: Surge arresters containing both series and parallel gapped structures –

System voltage of 52 kV and less

Parafoudres –

Partie 6: Parafoudres contenant des structures à éclateurs en série et en

parallèle – Tension de réseau inférieure ou égale à 52 kV

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and once 67 000 electrotechnical terminology entries in English and

a month by email. French extracted from the Terms and Definitions clause of IEC

publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or need CISPR.

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Le premier dictionnaire d'électrotechnologie en ligne au monde,

webstore.iec.ch/advsearchform avec plus de 22 000 articles terminologiques en anglais et en

La recherche avancée permet de trouver des publications IEC français, ainsi que les termes équivalents dans 16 langues

en utilisant différents critères (numéro de référence, texte, additionnelles. Egalement appelé Vocabulaire

comité d’études,…). Elle donne aussi des informations sur les Electrotechnique International (IEV) en ligne.

projets et les publications remplacées ou retirées.

Glossaire IEC - std.iec.ch/glossary

IEC Just Published - webstore.iec.ch/justpublished 67 000 entrées terminologiques électrotechniques, en anglais

Restez informé sur les nouvelles publications IEC. Just et en français, extraites des articles Termes et Définitions des

Published détaille les nouvelles publications parues. publications IEC parues depuis 2002. Plus certaines entrées

Disponible en ligne et une fois par mois par email. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

Electropedia - www.electropedia.org

IEC 60099-6 ®

Edition 2.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Surge arresters –

Part 6: Surge arresters containing both series and parallel gapped structures –

System voltage of 52 kV and less

Parafoudres –

Partie 6: Parafoudres contenant des structures à éclateurs en série et en

parallèle – Tension de réseau inférieure ou égale à 52 kV

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.240.10 ISBN 978-2-8322-6919-0

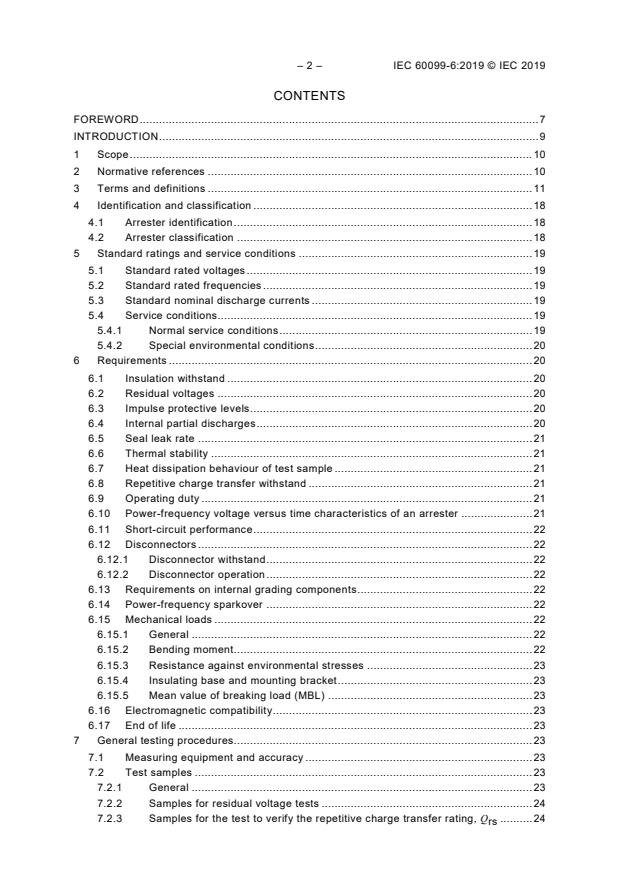

– 2 – IEC 60099-6:2019 © IEC 2019

CONTENTS

FOREWORD . 7

INTRODUCTION . 9

1 Scope . 10

2 Normative references . 10

3 Terms and definitions . 11

4 Identification and classification . 18

4.1 Arrester identification . 18

4.2 Arrester classification . 18

5 Standard ratings and service conditions . 19

5.1 Standard rated voltages . 19

5.2 Standard rated frequencies . 19

5.3 Standard nominal discharge currents . 19

5.4 Service conditions . 19

5.4.1 Normal service conditions . 19

5.4.2 Special environmental conditions . 20

6 Requirements . 20

6.1 Insulation withstand . 20

6.2 Residual voltages . 20

6.3 Impulse protective levels . 20

6.4 Internal partial discharges . 20

6.5 Seal leak rate . 21

6.6 Thermal stability . 21

6.7 Heat dissipation behaviour of test sample . 21

6.8 Repetitive charge transfer withstand . 21

6.9 Operating duty . 21

6.10 Power-frequency voltage versus time characteristics of an arrester . 21

6.11 Short-circuit performance . 22

6.12 Disconnectors . 22

6.12.1 Disconnector withstand . 22

6.12.2 Disconnector operation . 22

6.13 Requirements on internal grading components . 22

6.14 Power-frequency sparkover . 22

6.15 Mechanical loads . 22

6.15.1 General . 22

6.15.2 Bending moment . 22

6.15.3 Resistance against environmental stresses . 23

6.15.4 Insulating base and mounting bracket . 23

6.15.5 Mean value of breaking load (MBL) . 23

6.16 Electromagnetic compatibility . 23

6.17 End of life . 23

7 General testing procedures. 23

7.1 Measuring equipment and accuracy . 23

7.2 Test samples . 23

7.2.1 General . 23

7.2.2 Samples for residual voltage tests . 24

7.2.3 Samples for the test to verify the repetitive charge transfer rating, Q . 24

rs

8 Type tests (design tests) . 24

8.1 General . 24

8.2 Insulation withstand tests . 25

8.2.1 General . 25

8.2.2 Tests on individual unit housing . 26

8.2.3 Ambient air conditions during tests . 26

8.2.4 Wet test procedure . 26

8.2.5 Lightning impulse voltage test. 26

8.2.6 Power- frequency voltage test . 26

8.3 Impulse protective level tests . 27

8.3.1 General . 27

8.3.2 Residual voltage tests . 27

8.3.3 Sparkover tests . 28

8.4 Test to verify the repetitive charge transfer rating, Q . 30

rs

8.4.1 General . 30

8.4.2 MO resistors . 30

8.4.3 Series gaps . 31

8.5 Operating duty tests . 32

8.5.1 General . 32

8.5.2 Test procedure . 33

8.5.3 Rated thermal charge values, Q . 35

th

8.6 Power-frequency voltage-versus-time test . 35

8.6.1 General . 35

8.6.2 Test samples . 36

8.6.3 Initial measurements . 36

8.6.4 Test procedure . 36

8.6.5 Test evaluation . 37

8.7 Tests of arrester disconnectors . 38

8.7.1 General . 38

8.7.2 Operating withstand test . 38

8.7.3 Disconnector operation . 39

8.7.4 Mechanical tests . 40

8.7.5 Temperature cycling and seal pumping test . 40

8.8 Power-frequency voltage sparkover tests . 40

8.9 Short-circuit tests . 41

8.9.1 General . 41

8.9.2 Preparation of the test samples . 41

8.9.3 Mounting of the test sample . 45

8.9.4 High-current short-circuit tests . 46

8.9.5 Low-current short-circuit test . 48

8.9.6 Evaluation of test results . 48

8.10 Test of the bending moment . 49

8.10.1 General . 49

8.10.2 Overview . 49

8.10.3 Sample preparation . 49

8.10.4 Test procedure . 49

8.10.5 Test evaluation . 50

8.10.6 Test on insulating base and mounting bracket . 50

– 4 – IEC 60099-6:2019 © IEC 2019

8.11 Environmental tests . 50

8.11.1 General . 50

8.11.2 Sample preparation . 51

8.11.3 Test procedure . 51

8.11.4 Test evaluation . 51

8.12 Seal leak rate test . 51

8.12.1 General . 51

8.12.2 Sample preparation . 51

8.12.3 Test procedure . 51

8.12.4 Test evaluation . 52

8.13 Test to verify the dielectric withstand of internal components . 52

8.13.1 General . 52

8.13.2 Test procedure . 52

8.13.3 Test evaluation . 52

8.14 Test of internal grading components . 52

8.14.1 Test to verify long term stability under continuous operating voltage . 52

8.14.2 Thermal cyclic test . 53

9 Routine tests and acceptance tests . 54

9.1 Routine tests . 54

9.2 Acceptance tests . 55

9.2.1 Standard acceptance tests . 55

9.2.2 Special thermal stability test . 55

10 Test requirements on polymer-housed surge arresters . 55

10.1 Scope . 55

10.2 Normative references . 56

10.3 Terms and definitions. 56

10.4 Identification and classification . 56

10.5 Standard ratings and service conditions . 56

10.6 Requirements . 56

10.7 General testing procedure . 56

10.8 Type tests (design tests) . 57

10.8.1 General . 57

10.8.2 Insulation withstand tests . 57

10.8.3 Impulse protective level tests . 57

10.8.4 Test to verify the repetitive charge transfer rating, Q . 57

rs

10.8.5 Operating Duty tests . 57

10.8.6 Power frequency voltage-versus-time test . 57

10.8.7 Tests of arrester disconnectors . 58

10.8.8 Power frequency voltage sparkover tests . 58

10.8.9 Short-circuit tests . 58

10.8.10 Test of the bending moment . 63

10.8.11 Environmental tests . 69

10.8.12 Seal leak rate test. 69

10.8.13 Test to verify the dielectric withstand of internal components . 69

10.8.14 Test of internal grading components . 69

10.8.15 Weather ageing test . 69

10.9 Routine tests . 71

Annex A (normative) Special Environmental Conditions . 72

Annex B (normative) Typical information given with enquiries and tenders . 73

B.1 Information given with enquiry . 73

B.1.1 System data . 73

B.1.2 Service conditions . 73

B.1.3 Arrester duty . 73

B.1.4 Characteristics of arrester . 74

B.1.5 Additional equipment and fittings . 74

B.1.6 Any special abnormal conditions . 74

B.2 Information given with tender . 74

Annex C (normative) Mechanical considerations . 76

C.1 Test of bending moment . 76

C.2 Definition of mechanical loads . 77

C.3 Definition of seal leak rate . 77

C.4 Calculation of wind-bending-moment. 78

C.5 Procedures of tests of bending moment for porcelain/cast resin and polymer-

housed arresters . 79

Figure 1 – procedure to verify the repetitive charge transfer rating, Q , for MO

rs

resistors. 30

Figure 2 – Procedure to verify the repetitive charge transfer rating, Q , for series gaps . 32

rs

Figure 3 – Test procedure to verify the thermal charge transfer rating, Q . 33

th

Figure 4 – Test procedure to verify the power frequency versus time characteristic

(TOV test) . 36

Figure 5 – Examples of arrester units. 44

Figure 6 – Examples of fuse wire locations for “Design A“ arresters . 45

Figure 7 – Examples of fuse wire locations for “Design B“ arresters . 45

Figure 8 – Short-circuit test setup for porcelain-housed arresters . 46

Figure 9 – Short-circuit test setup for polymer-housed arresters . 61

Figure 10 – Example of a test circuit for re-applying pre-failing circuit immediately

before applying the short-circuit test current . 63

Figure 11 – Thermomechanical test . 66

Figure 12 – Example of the test arrangement for the thermomechanical test and

direction of the cantilever load . 67

Figure 13 – Water immersion . 68

Figure C.1 – Bending moment – multi-unit surge arrester . 76

Figure C.2 – Definition of mechanical loads . 77

Figure C.3 – Surge arrester unit . 78

Figure C.4 – Surge-arrester dimensions . 79

Figure C.5 – Flow chart of bending moment test procedures . 80

– 6 – IEC 60099-6:2019 © IEC 2019

Table 1 – Arrester classification . 19

Table 2 – Steps of rated voltages. 19

Table 3 – Arrester type tests . 25

Table 4 – Requirements for high current impulses . 34

Table 5 – Rated values of thermal charge transfer rating, Q . 35

th

Table 6 – Test requirements for porcelain housed arresters . 43

Table 7 – Required currents for short-circuit tests . 47

Table 8 – Test requirements for polymer-housed arresters . 60

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SURGE ARRESTERS –

Part 6: Surge arresters containing both series and parallel gapped

structures – System voltage of 52 kV and less

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard lEC 60099-6 has been prepared by lEC technical committee 37: Surge

arresters.

This second edition cancels and replaces the first edition published in 2002. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) A new concept of arrester classification and energy withstand testing was introduced: the

line discharge classification was replaced by a classification based on repetitive charge

transfer rating (Q and thermal charge transfer rating (Q ). The new concept clearly

rs) th

differentiates between impulse and thermal energy handling capability, which is reflected

in the requirements as well as in the related test procedures.

– 8 – IEC 60099-6:2019 © IEC 2019

b) Power-frequency voltage versus time tests – with and without prior duty – were introduced

as type tests.

c) Requirements and tests on disconnectors were added.

d) Definitions for new terms have been added.

e) Clause 10 contains particular requirements for polymer-housed surge arresters. These are

indicated in the form of replacements, additions or amendments to the original clauses or

subclauses concerned.

The text of this International Standard is based on the following documents:

FDIS Report on voting

37/450/FDIS 37/451/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60099 series, published under the general title Surge arresters,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

This part of IEC 60099 presents the minimum criteria for the requirements and testing of

metal-oxide surge arresters containing gapped structures that are applied to AC power

systems with U above 1 kV up to and including 52kV.

s

Arresters covered by this document can be applied to overhead installations in place of the

non-linear type arresters covered in IEC 60099-4.

An accelerated ageing procedure is incorporated in this document to simulate the long-term

effects of voltage and temperature on the arrester. This is necessary since during the

arrester's service life the gaps and resistor elements will have portions of the system power

frequency voltage continuously applied across them.

– 10 – IEC 60099-6:2019 © IEC 2019

SURGE ARRESTERS –

Part 6: Surge arresters containing both series and parallel gapped

structures – System voltage of 52 kV and less

1 Scope

This part of IEC 60099 applies to non-linear metal-oxide resistor type surge arresters with

spark gaps designed to limit voltage surges on AC power circuits with system voltages U

s

above 1 kV up to and including 52 kV. This document basically applies to all metal-oxide

distribution class surge arresters with internal series and/or parallel gaps and housed in either

porcelain or polymeric housings.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60060-2, High-voltage test techniques – Part 2: Measuring systems

IEC 60068-2-11:1981, Basic environmental testing procedures – Part 2-11: Tests – Test Ka:

Salt mist

IEC 60068-2-14, Environmental testing – Part 2-14: Tests – Test N: Change of temperature

IEC 60071-2:2018, Insulation co-ordination – Part 2: Application guidelines

IEC 60270, High-voltage test techniques – Partial discharge measurements

IEC TS 60815-2, Selection and dimensioning of high-voltage insulators intended for use in

polluted conditions – Part 2: Ceramic and glass insulators for a.c. systems

IEC 62217, Polymeric HV insulators for indoor and outdoor use – General definitions, test

methods and acceptance criteria

ISO 4287, Geometrical Product Specifications (GPS) – Surface texture: Profile method –

Terms, definitions and surface texture parameters

ISO 4892-1, Plastics – Methods of exposure to laboratory light sources – Part 1: General

guidance

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 4892-3, Plastics – Methods of exposure to laboratory light sources – Part 3: Fluorescent

UV lamps

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

acceptance test

test made on arresters or representative samples after agreement between manufacturer and

user

3.2

arrester disconnector

device for disconnecting an arrester from the system in the event of arrester failure, to

prevent a persistent fault on the system and to give visible indication of the failed arrester

Note 1 to entry: Clearing of the fault current through the arrester during disconnection generally is not a function

of the device.

3.3

bending moment

force perpendicular to the longitudinal axis of an arrester multiplied by the vertical distance

between the mounting base (lower level of the flange) of the arrester and the point of

application of the force

3.4

breaking load

force perpendicular to the longitudinal axis of a porcelain-housed or cast resin arrester

leading to mechanical failure of the arrester housing

3.5

cast resin housed arrester

arrester using a housing made from only one organic based material (e.g. cycloaliphatic

epoxy) that fractures similarly to a porcelain housing under mechanical overstress

3.6

continuous current of an arrester

current flowing through the arrester when energized at the continuous operating voltage

3.7

continuous operating voltage of an arrester

U

c

designated permissible RMS value of power-frequency voltage that may be applied

continuously between the arrester terminals in accordance with 8.5

3.8

damage limit

lowest value of a force perpendicular to the longitudinal axis of a polymer-housed arrester

leading to mechanical failure of the arrester housing

– 12 – IEC 60099-6:2019 © IEC 2019

3.9

designation of an impulse shape

combination of two numbers, the first representing the virtual front time (T ) and the second

the virtual time to half-value on the tail (T )

Note 1 to entry: This is written as T /T , both in microseconds, the sign "/ " having no mathematical meaning.

1 2

3.10

discharge current of an arrester

impulse current which flows through the arrester

3.11

disruptive discharge

phenomenon associated with the failure of insulation under electric stress, which includes a

collapse of voltage and the passage of current

Note 1 to entry: The term applies to electrical breakdowns in solid, liquid and gaseous dielectric, and

combinations of these.

Note 2 to entry: A disruptive discharge in a solid dielectric produces permanent loss of electric strength. In a

liquid or gaseous dielectric the loss may be only temporary.

3.12

distribution class arrester

arrester intended for use on distribution systems, typically of U ≤ 52 kV, to protect

s

components primarily from the effects of lightning

Note 1 to entry: Distribution class arresters may have nominal discharge currents, I , of 2,5 kA; 5 kA or 10 kA.

n

Note 2 to entry: Distribution arresters are classified as “Distribution DH”, “Distribution DM” and “Distribution DL”

(see Table 1).

3.13

electrical unit

portion of an arrester in which each end of the unit is terminated with an electrode which is

exposed to the external environment

3.14

fault indicator

device intended to provide an indication that the arrester is faulty and which does not

disconnect the arrester from the system

3.15

flashover

disruptive discharge over a solid surface

3.16

follow current

current from the connected power source that flows through an arrester during and following

the passage of discharge current

3.17

front of an impulse

part of an impulse which occurs prior to the peak

3.18

high current impulse

peak value of discharge current having a 4/10 impulse shape which is used

to test the stability of the arrester on direct lightning strokes

3.19

housing

external insulating part of an arrester, which provides the necessary creepage distance and

protects the internal parts from the environment

Note 1 to entry: A housing may consist of several parts providing mechanical strength and protection against the

environment.

3.20

impulse

unidirectional wave of voltage or current which, without appreciable oscillations, rises rapidly

to a maximum value and falls, usually less rapidly, to zero with small, if any, excursions of

opposite polarity, with defining parameters being polarity, peak value, front time and time to

half-value

3.21

insulating base

a short insulator (or set of insulators) on which the arrester is mounted to provide a means of

connecting a current monitoring device between the base of the arrester and earth

3.22

internal grading components of an internally gapped arrester

grading impedances, connected in parallel with the internal gap(s), to control the voltage

across the gap section

3.23

internal parts

MO resistor with supporting structure and internal grading system, if equipped

3.24

lightning current impulse

8/20 current impulse with limits on the adjustment of equipment such that the measured

values are from 7 µs to 9 µs for the virtual front time and from 18 µs to 22 µs for the time to

half-value

Note 1 to entry: The time to half-value is not critical and may have any tolerance during the residual voltage type

tests (see 8.3.2.3).

3.25

lightning impulse discharge

an approximately sine half-wave current impulse having a time duration within 200 µs to 230

µs during which the instantaneous value of the impulse current is greater than 5 % of its peak

value

3.26

lightning impulse protection level

LIPL or U

pl

the maximum residual voltage of the arrester for the nominal discharge current

3.27

long-duration current impulse

rectangular current impulse which rises rapidly to maximum value, remains substantially

constant for a specified period and then falls rapidly to zero, with defining parameters being

polarity, peak value, virtual duration of the peak and virtual total duration.

3.28

mean breaking load

MBL

the average breaking load for porcelain or cast resin-housed arresters determined from tests

– 14 – IEC 60099-6:2019 © IEC 2019

3.29

mechanical unit

portion of an arrester in which the MO resistors within the unit are mechanically restrained

from moving in an axial direction

Note 1 to entry: An arrester may contain more than one mechanical units within an electrical unit (see Figure 5).

Note 2 to entry: A mechanical unit may have more than one electrical unit (see Figure 5).

3.30

mounting bracket

means by which a distribution class arrester is physically attached to a pole or other structure

Note 1 to entry: For polymer housed distribution class arresters, the mounting bracket is typically of an insulating

material and is typically attached to the bottom (ground) end of the arrester; for porcelain-housed d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...