IEC 60099-6:2002

(Main)Surge arresters - Part 6: Surge arresters containing both series and parallel gapped structures - Rated 52 kV and less

Surge arresters - Part 6: Surge arresters containing both series and parallel gapped structures - Rated 52 kV and less

This standard basically applies to all metal-oxide surge arresters with gaps and housed in either porcelain or polymeric housings. This standard also specifies requirements and tests for metal-oxide surge arresters with internal series gaps,with rated voltages of 52KV and below.

General Information

- Status

- Published

- Publication Date

- 13-Aug-2002

- Technical Committee

- TC 37 - Surge arresters

- Drafting Committee

- MT 4 - TC 37/MT 4

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-May-2019

- Completion Date

- 30-Mar-2018

Relations

- Effective Date

- 05-Sep-2023

Overview - IEC 60099-6:2002 (Surge arresters, rated 52 kV and less)

IEC 60099-6:2002 is the International Electrotechnical Commission standard that specifies requirements and test procedures for metal‑oxide surge arresters containing both series and parallel gapped structures, with rated voltages of 52 kV and below. It applies to arresters housed in porcelain or polymeric enclosures and defines minimum design, type-test, routine-test and accelerated ageing criteria for internal series‑gapped metal‑oxide arresters used on AC power systems.

Key points:

- Covers metal‑oxide resistor type surge arresters with integrated gapped structures.

- Focused on arresters with internal series gaps and rated ≤ 52 kV.

- Incorporates an accelerated ageing procedure to simulate long‑term voltage and temperature effects.

- Excludes certain types (e.g., externally gapped, shunt‑gapped, series gapped above ~54 kV and some line‑discharge classes).

Key topics and technical requirements

The standard organizes requirements and tests to ensure arrester safety, performance and durability. Major technical topics include:

- Insulation withstand of housing (porcelain or polymeric)

- Reference voltage measurement and tolerances

- Impulse protective level (residual voltage) - tests with switching and lightning impulses

- Partial discharge measurement techniques and limits

- Seal leakage and moisture ingress tests

- Thermal stability and verification of power losses at elevated temperatures

- Long‑duration current impulse and operating duty tests (to verify behavior under fault/current stress)

- Power‑frequency sparkover and voltage‑vs‑time characteristics

- Short‑circuit withstand and pressure relief provisions

- Disconnectors, internal/external grading components and grading current requirements

- Weather ageing and artificial pollution testing

- Defined type tests, routine tests and acceptance tests for manufacturers and test laboratories

Applications and who uses this standard

IEC 60099-6 is intended for:

- Surge arrester manufacturers - to design and certify series‑gapped metal‑oxide arresters

- Test laboratories - to perform type and routine testing per IEC procedures

- Utility and transmission engineers - for specifying arresters for overhead lines and substations

- Procurement and quality teams - to evaluate supplier conformity and acceptance testing

- Standards and safety assessors - to ensure long‑term performance under pollution, thermal and electrical stress

Typical applications include protection of overhead distribution and transmission equipment where gapped metal‑oxide arresters are chosen to control overvoltages and provide energy‑dispersing performance on AC systems.

Related standards

Commonly referenced IEC standards that complement IEC 60099-6:

- IEC 60099‑1 (non‑linear resistor type gapped arresters)

- IEC 60099‑3 (artificial pollution testing)

- IEC 60099‑4 (metal‑oxide arresters without gaps)

- IEC 60060‑1 / IEC 60060‑2 (high‑voltage test techniques)

- IEC 60270 (partial discharge measurements)

Keywords: IEC 60099-6, surge arresters, metal-oxide, series gapped, parallel gapped, 52 kV, impulse protective level, operating duty, thermal stability, weather ageing, insulation withstand.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60099-6:2002 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Surge arresters - Part 6: Surge arresters containing both series and parallel gapped structures - Rated 52 kV and less". This standard covers: This standard basically applies to all metal-oxide surge arresters with gaps and housed in either porcelain or polymeric housings. This standard also specifies requirements and tests for metal-oxide surge arresters with internal series gaps,with rated voltages of 52KV and below.

This standard basically applies to all metal-oxide surge arresters with gaps and housed in either porcelain or polymeric housings. This standard also specifies requirements and tests for metal-oxide surge arresters with internal series gaps,with rated voltages of 52KV and below.

IEC 60099-6:2002 is classified under the following ICS (International Classification for Standards) categories: 29.240.10 - Substations. Surge arresters. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60099-6:2002 has the following relationships with other standards: It is inter standard links to IEC 60099-6:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60099-6:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

60099-6

First edition

2002-08

Surge arresters –

Part 6:

Surge arresters containing both series

and parallel gapped structures –

Rated 52 kV and less

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/catlg-e.htm) enables

you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/JP.htm) is also

available by email. Please contact the Customer Service Centre (see below) for

further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

60099-6

First edition

2002-08

Surge arresters –

Part 6:

Surge arresters containing both series

and parallel gapped structures –

Rated 52 kV and less

IEC 2002 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

X

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

– 2 – 60099-6 IEC:2002(E)

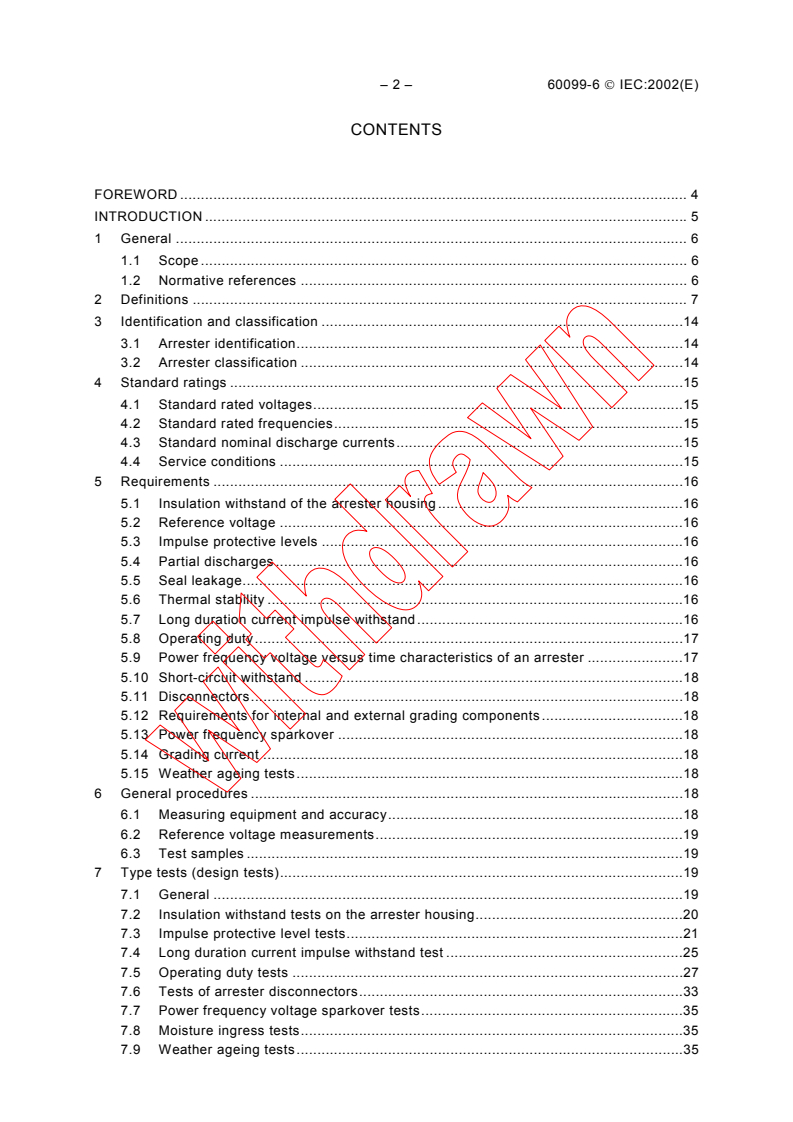

CONTENTS

FOREWORD . 4

INTRODUCTION .5

1 General . 6

1.1 Scope . 6

1.2 Normative references . 6

2 Definitions . 7

3 Identification and classification .14

3.1 Arrester identification.14

3.2 Arrester classification .14

4 Standard ratings .15

4.1 Standard rated voltages.15

4.2 Standard rated frequencies.15

4.3 Standard nominal discharge currents.15

4.4 Service conditions .15

5 Requirements .16

5.1 Insulation withstand of the arrester housing.16

5.2 Reference voltage .16

5.3 Impulse protective levels .16

5.4 Partial discharges .16

5.5 Seal leakage.16

5.6 Thermal stability .16

5.7 Long duration current impulse withstand.16

5.8 Operating duty.17

5.9 Power frequency voltage versus time characteristics of an arrester .17

5.10 Short-circuit withstand .18

5.11 Disconnectors.18

5.12 Requirements for internal and external grading components .18

5.13 Power frequency sparkover .18

5.14 Grading current .18

5.15 Weather ageing tests.18

6 General procedures .18

6.1 Measuring equipment and accuracy.18

6.2 Reference voltage measurements.19

6.3 Test samples .19

7 Type tests (design tests).19

7.1 General .19

7.2 Insulation withstand tests on the arrester housing.20

7.3 Impulse protective level tests.21

7.4 Long duration current impulse withstand test .25

7.5 Operating duty tests .27

7.6 Tests of arrester disconnectors.33

7.7 Power frequency voltage sparkover tests.35

7.8 Moisture ingress tests.35

7.9 Weather ageing tests.35

60099-6 IEC:2002(E) – 3 –

8 Routine tests and acceptance tests.36

8.1 Routine tests .36

8.2 Acceptance tests .36

Annex A (normative) Abnormal service conditions .39

Annex B (normative) Test to verify thermal equivalency between complete arrester

and arrester section .40

Annex C (normative) Procedure to verify the power frequency voltage versus time

characteristics of an arrester.41

Annex D (normative) Artificial pollution testing of metal-oxide surge arresters

containing gapped structures .42

Annex E (informative) Typical information given with inquiries and tenders .43

Annex F (informative) Typical maximum protective levels.45

Bibliography.46

Figure 1 – Power losses of arrester at elevated temperatures vs. time .30

Table 1 – Arrester classification and tests .14

Table 2 – Steps of rated voltages.15

Table 3 – Peak currents for switching impulse residual voltage tests.22

Table 4 – Parameters for the line discharge test (10 000 A arresters) .26

Table 5 – Requirements for the long-duration current impulse test

on 5 000 A and 2 500 A arresters.27

Table 6 – Arrester design and ageing test requirements.28

Table 7 – Determination of elevated rated and continuous operating voltages.30

Table 8 – Requirements for high current impulses.32

Table 9 – Weather ageing test selection.35

Table 10 – Summary of high current operating duty test (see 7.5.3) .38

Table 11 – Thermal stability test .38

Table F.1 – Typical maximum protective levels for 10 kA, 5 kA, 2,5 kA and 1,5 kA

arresters per unit of rated voltage .45

– 4 – 60099-6 IEC:2002(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

SURGE ARRESTERS –

Part 6: Surge arresters containing both series

and parallel gapped structures –

Rated 52 kV and less

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard lEC 60099-6 has been prepared by lEC technical committee 37: Surge

arresters.

The text of this standard is based on the following documents:

FDIS Report on voting

37/282/FDIS 37/283/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

Annexes A, B, C and D form an integral part of this standard.

Annexes E and F are for information only.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

The committee has decided that the contents of this publication will remain unchanged until 2004.

At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

60099-6 IEC:2002(E) – 5 –

INTRODUCTION

This part of IEC 60099 presents the minimum criteria for the requirements and testing of

metal-oxide surge arresters containing gapped structures that are applied to a.c. power

systems.

Arresters covered by this standard can be applied to overhead installations in place of the

non-linear type arresters covered in lEC 60099-1 and IEC 60099-4.

An accelerated ageing procedure is incorporated in the standard to simulate the long-term

effects of voltage and temperature on the arrester. This is necessary since during the

arrester's service life the gaps and resistor elements will have portions of the system power

frequency voltage continuously applied across them.

– 6 – 60099-6 IEC:2002(E)

SURGE ARRESTERS –

Part 6: Surge arresters containing both series

and parallel gapped structures –

Rated 52 kV and less

1 General

1.1 Scope

This part of IEC 60099 applies to non-linear metal-oxide resistor type surge arresters with

spark gaps designed to limit voltage surges on a.c. power circuits.

This standard basically applies to all metal-oxide surge arresters with gaps and housed in

either porcelain or polymeric housings.

This standard specifies requirements and tests for metal-oxide surge arresters with internal

series gaps, with rated voltages 52 kV and below.

The following arrester types and ratings are presently under consideration, but are not

addressed in this standard. They will not be addressed until more information can be

ascertained on the individual subjects:

• series gapped arresters above 54 kV;

• externally gapped arresters, all ratings;

• shunt gapped arresters, all ratings;

• line discharge class 2, 3, 4 and 5.

1.2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

lEC 60060-1:1989, High-voltage test techniques – Part 1: General definitions and test

requirements

IEC 60060-2:1994, High-voltage test techniques – Part 2: Measuring systems

lEC 60099-1:1991, Surge arresters – Part 1: Non-linear resistor type gapped surge arresters

for a.c. systems

lEC 60099-3:1990, Surge arresters – Part 3: Artificial pollution testing of surge arresters

IEC 60099-4:1991, Surge arresters – Part 4: Metal-oxide surge arresters without gaps for a.c.

systems

Amendment 1 (1998)

Amendment 2 (2001)

IEC 60270: 2000, High-voltage test techniques – Partial discharge measurements

___________

A consolidated edition 1.2 exists (2001) that includes edition 1.0 (1991), its amendment 1 (1998) and

amendment 2 (2001).

60099-6 IEC:2002(E) – 7 –

2 Definitions

For the purposes of this part of IEC 60099, the following definitions apply.

2.1

metal-oxide surge arrester without gaps

arrester having non-linear metal-oxide resistors connected in series and/or in parallel without

any integrated series or parallel spark gaps

NOTE See 2.55 for metal-oxide surge arrester with series gapped structures.

2.2

non-linear metal-oxide resistor

part of the surge arrester which by its non-linear voltage versus current characteristics acts as

a low resistance to overvoltages, thus limiting the voltage across the arrester terminals, and

as a high resistance at normal power frequency voltage

2.3

internal grading system of an arrester

grading impedance, in particular linear/non-linear resistors and/or grading capacitors

connected in parallel to one or to a group of non-linear metal-oxide resistors and/or series

gap, to control the voltage distribution along the arrester and/or between the metal oxide

resistors and gaps

2.4

grading ring of an arrester

metal part usually circular in shape, mounted to modify electrostatically the voltage

distribution along the arrester

2.5

section of an arrester

complete, suitably assembled part of an arrester necessary to represent the behaviour of a

complete arrester with respect to a particular test

NOTE A section of an arrester is not necessarily a unit of an arrester.

2.6

unit of an arrester

completely housed part of an arrester which may be connected in series and/or in parallel with

other units to construct an arrester of higher voltage and/or current rating

NOTE A unit of an arrester is not necessarily a section of an arrester.

2.7

pressure relief device of an arrester

means for relieving internal pressure in an arrester and preventing violent shattering of the

housing following prolonged passage of fault current or internal flashover of the arrester

2.8

rated voltage of an arrester, U

r

maximum permissible r.m.s. value of power frequency voltage between its terminals at which

it is designed to operate correctly under temporary overvoltage conditions as established in

the operating duty tests, see 7.5

NOTE 1 The rated voltage is used as a reference parameter for the specification of operating characteristics.

NOTE 2 The rated voltage as defined in this standard is the 10 s power frequency voltage used in the operating

duty test after high current. Tests used to establish the voltage rating in the lEC 60099 series, as well as some

national standards, involve the application of repetitive impulses at nominal impulse current with power frequency

voltage applied. Attention is drawn to the fact that these two methods used to establish rating do not necessarily

produce equivalent values. (A resolution to this discrepancy is under consideration.)

– 8 – 60099-6 IEC:2002(E)

2.9

continuous operating voltage of an arrester, U

c

continuous operating voltage is the designated permissible r.m.s. value of power frequency

voltage that may be applied continuously between the arrester terminals in accordance

with 7.5

2.10

rated frequency of an arrester

frequency of the power system on which the arrester is designed to be used

2.11

disruptive discharge

phenomena associated with the failure of insulation under electric stress, which include a

collapse of voltage and the passage of current

NOTE 1 The term applies to electrical breakdowns in solid, liquid and gaseous dielectric, and combinations of

these.

NOTE 2 A disruptive discharge in a solid dielectric produces permanent loss of electric strength. In a liquid or

gaseous dielectric the loss may be only temporary.

2.12

puncture (breakdown)

disruptive discharge through a solid

2.13

flashover

disruptive discharge over a solid surface

2.14

impulse

unidirectional wave of voltage or current which without appreciable oscillations rises rapidly to

a maximum value and falls – usually less rapidly – to zero with small, if any, excursions of

opposite polarity

NOTE The parameters which define a voltage or current impulse are polarity, peak value, front time and time to

half value on the tail.

2.15

designation of an impulse shape

combination of two numbers, the first representing the virtual front time (T ) and the second

the virtual time to half value on the tail (T ), written as T /T , both in µs, the sign “/” having no

2 1 2

mathematical meaning

2.16

steep current impulse

current impulse with a virtual front time of 1 µs with limits in the adjustment of equipment such

that the measured values are from 0,9 µs to 1,1 µs and the virtual time to half value on the tail

not longer than 20 µs

NOTE The time to half value on the tail is not critical and may have any tolerance during the residual voltage type

tests, see 7.3.1.

2.17

lightning current impulse

an 8/20 current impulse with limits on the adjustment of equipment such that the measured

values are from 7 µs to 9 µs for the virtual front time and from 18 µs to 22 µs for the time to

half value on the tail

NOTE The time to half value on the tail is not critical and may have any tolerance during the residual voltage type

tests, see 7.3.1.

60099-6 IEC:2002(E) – 9 –

2.18

long duration current impulse

rectangular impulse which rises rapidly to maximum value, remains substantially constant for

a specified period and then falls rapidly to zero. The parameters which define a rectangular

impulse are polarity, peak value, virtual duration of the peak and virtual total duration.

2.19

peak (crest) value of an impulse

maximum value of a voltage or current impulse

NOTE Superimposed oscillations may be disregarded, see 7.4.2 c) and 7.5.3.2 e).

2.20

front of an impulse

part of an impulse which occurs prior to the peak

2.21

tail of an impulse

part of an impulse which occurs after the peak

2.22

virtual origin of an impulse

point on a graph of voltage versus time or current versus time determined by the intersection

between the time axis at zero voltage or zero current and the straight line drawn through two

reference points on the front of the impulse

NOTE 1 For current impulses the reference points are 10 % and 90 % of the peak value.

NOTE 2 This definition applies only when scales of both ordinate and abscissa are linear.

NOTE 3 If oscillations are present on the front, the reference points at 10 % and 90 % should be taken on the

mean curve drawn through the oscillations.

2.23

virtual front time of a current impulse, T

time in μs equal to 1,25 multiplied by the time in µs for the current to increase from 10 % to

90 % of its peak value

NOTE If oscillations are present on the front, the reference points at 10 % and 90 % should be taken on the mean

curve drawn through the oscillations.

2.24

virtual steepness of the front of an impulse

quotient of the peak value and the virtual front time of an impulse

2.25

virtual time to half value on the tail of an impulse, T

time interval between the virtual origin and the instant when the voltage or current has

decreased to half its peak value, expressed in µs

2.26

virtual duration of the peak of a rectangular impulse

time during which the amplitude of the impulse is greater than 90 % of its peak value

2.27

virtual total duration of a rectangular impulse

time during which the amplitude of the impulse is greater than 10 % of its peak value

NOTE If small oscillations are present on the front, a mean curve should be drawn in order to determine the time

at which the 10 % value is reached.

– 10 – 60099-6 IEC:2002(E)

2.28

peak (crest) value of opposite polarity of an impulse

maximum amplitude of opposite polarity reached by a voltage or current impulse when it

oscillates about zero before attaining a permanent zero value

2.29

discharge current of an arrester

impulse current which flows through the arrester

2.30

nominal discharge current of an arrester, I

n

peak value of lightning current impulse (see 2.17 and table 1) which is used to classify an

arrester

2.31

high current impulse of an arrester

peak value of discharge current having a 4/10 impulse shape which is used to test the stability

of the arrester on direct lightning strokes

2.32

switching current impulse of an arrester

peak value of discharge current having a virtual front time greater than 30 µs but less than

100 µs and a virtual time to half value on the tail of roughly twice the virtual front time

2.33

continuous current of an arrester

continuous current is the current flowing through the arrester when energized at the

continuous operating voltage, expressed either by its r.m.s. or peak value

NOTE The continuous current, which consists of a resistive and a capacitive component, may vary with

temperature, stray capacitance and external pollution effects. The continuous current of a test sample may,

therefore, not be the same as the continuous current of a complete arrester.

2.34

reference current of an arrester

peak value (the higher peak value of the two polarities if the current is asymmetrical) of the

resistive component of a power frequency current used to determine the reference voltage of

the arrester

NOTE 1 The reference current should be high enough to make the effects of stray capacitance at the measured

reference voltage of the arrester units (with designed grading system) negligible and should be specified by the

manufacturer.

NOTE 2 Depending on the nominal discharge current and/or line discharge class of the arrester, the reference

current will be typically in the range of 0,05 mA to 1,0 mA per square centimetre of disc area for single column

arresters.

2.35

reference voltage of the main series metal-oxide resistors

peak value of power frequency voltage divided by 2 applied to the main series metal-oxide

resistors of arrester to obtain the reference current

NOTE The reference voltage of a multi-unit arrester is the sum of the reference voltages of the main series metal-

oxide resistors of the individual units.

2.36

residual voltage of an arrester, U

res

peak value of voltage that appears between the terminals of an arrester during the passage of

discharge current

NOTE The term “discharge voltage” is used in some countries.

60099-6 IEC:2002(E) – 11 –

2.37

power frequency withstand voltage versus time characteristic of an arrester

(temporary overvoltage, TOV)

power frequency withstand voltage versus time characteristic showing maximum time dura-

tions for which corresponding power frequency voltages may be applied to arresters without

causing damage or thermal instability under specified conditions in accordance with 5.9.

2.38

prospective current of a circuit

current which would flow at a given location in a circuit if it were short-circuited at that

location by a link of negligible impedance

2.39

protective characteristics of an arrester

Regarded as a combination of the following:

a) residual voltage for steep current impulse and front-of-wave sparkover according to 7.3.2

and 7.3.6.2

b) residual voltage versus discharge current characteristic for lightning impulses and the

1,2/50 impulse sparkover according to 7.3.3 and 7.3.7.2

c) residual voltage for switching impulse and the switching impulse sparkover according

to 7.3.4 and 7.3.8.2

2.40

thermal runaway of an arrester

situation when the sustained power loss of an arrester exceeds the thermal dissipation

capability of the housing and connections, leading to a cumulative increase in the temperature

of the resistor elements culminating in failure

2.41

thermal stability of an arrester

arrester is thermally stable if, after an operating duty causing temperature rise, the

temperature of the resistor elements decreases with time when the arrester is energized

at specified continuous operating voltage and at specified ambient conditions

2.42

arrester disconnector

device for disconnecting an arrester from the system in the event of arrester failure, to

prevent a persistent fault on the system and to give visible indication of the failed arrester

NOTE The device is not required to clear arrester fault current.

2.43

type tests

(design tests)

tests, which are made upon the completion of the development of a new arrester design,

to establish representative performance and to demonstrate compliance with the relevant

standard

NOTE Once made, these tests need not be repeated unless the design is changed so as to modify its

performance. In such a case only the relevant tests need be repeated.

2.44

routine tests

tests made on each arrester, or on parts and materials, as required, to ensure that the

product meets the design specifications

– 12 – 60099-6 IEC:2002(E)

2.45

acceptance tests

tests which are made when it has been agreed between the manufacturer and the purchaser

that the arresters or representative samples of an order are to be tested

2.46

sparkover of an arrester

disruptive discharge between the electrodes of the gaps of an arrester

2.47

follow current of an arrester

current from the connected power source which flows through an arrester following the

passage of discharge current

2.48

average sparkover voltage

This can be sub-divided into two types:

2.48.1

power frequency sparkover voltage

average of at least five successive power frequency sparkovers

2.48.2

lightning impulse sparkover voltage

average of at least five successive lightning impulse sparkovers

2.49

impulse sparkover voltage of an arrester

highest value of voltage attained before sparkover during an impulse of given waveshape and

polarity applied between the terminals of an arrester

2.50

front-of-wave sparkover voltage of an arrester

impulse sparkover voltage obtained on the wavefront of the voltage which increases linearly

with time

2.51

standard lightning impulse sparkover voltage of an arrester

lowest prospective peak value of a standard lightning voltage impulse which, when applied to

an arrester, causes sparkover on every application

2.52

time to sparkover of an arrester

time interval between virtual origin and the instant of sparkover of the arrester, expressed

in µs

2.53

impulse sparkover voltage-time curve

curve which relates the impulse sparkover of the voltage to the time to sparkover

2.54

grading current

peak value of current flowing through the arrester while power frequency voltage is applied

2.55

metal-oxide surge arrester with gapped structures

arrester having non-linear metal-oxide resistors connected in series and/or in parallel with any

internal or external series or shunt spark gaps

60099-6 IEC:2002(E) – 13 –

2.56

power frequency sparkover voltage

value of the power frequency voltage, measured as the peak value divided by 2 applied

between the terminals of an arrester, which causes sparkover

2.57

line arrester

type of arrester that is commonly applied to power systems to reduce the risk of insulator

flashover during a lightning transient

NOTE It is not generally used to protect the insulator from other types of transients such as switching surges.

Neither is it generally used to protect any equipment other than line insulators.

2.58

impulse protective levels

These can be sub-divided into three types:

2.58.1

fast front protective level

highest of either the steep current residual voltage at (I ) or the front-of-wave impulse

n

sparkover voltage

2.58.2

standard lightning impulse protective level

highest of either the residual voltage at nominal current (I ) or 1,2/50 lighting impulse

n

sparkover voltage

2.58.3

switching impulse protective level

highest of either the maximum residual voltage for the specified switching current or the

specified switching impulse sparkover voltage

2.59

main series metal oxide resistors

resistors that carry energy during an impulse, not to be confused with resistors that separate

gaps for voltage grading

NOTE Measurement of reference voltage is necessary for the selection of a correct test sample in the operating

duty test, see 6.2

2.60

series gap

intentional gap(s), between spaced electrodes in series with one or more metal-oxide

resistors, across which all or part of the imparted terminal voltage appears

2.61

shunt gap

intentional gap(s) between spaced electrodes electrically in parallel with one or more main

metal-oxide resistors

2.62

switching voltage impulse

impulse voltage having a virtual front time greater than 30 µs

– 14 – 60099-6 IEC:2002(E)

3 Identification and classification

3.1 Arrester identification

Metal-oxide surge arresters containing gapped structures shall be identified by the following

minimum information which shall appear on a nameplate permanently attached to the arrester:

– continuous operating voltage;

– rated voltage;

– rated frequency, only if other than one of the standard frequencies, see 4.2;

– nominal discharge current;

– short-circuit withstand current rating in kA r.m.s. (for arresters with short-circuit withstand

ratings);

– manufacturer's name or trade mark, type and identification of the complete arrester;

– identification of the assembling position of the unit (for multi-unit arresters only);

– year of manufacture.

3.2 Arrester classification

Surge arresters are classified by their standard nominal discharge currents and they shall

meet at least the test requirements and performance characteristics specified in table 1.

Table 1 – Arrester classification and tests

Standard nominal discharge current

10 000 A 5 000 A 2 500 A 1 500 A

1 Rated voltage U (kV ) 3 ≤ U ≤ 52 3 ≤ U ≤ 52 3 ≤ U ≤ 52 3 ≤ U ≤ 52

r

RMS r r r r

2 Insulation withstand tests on arrester housings 7.2 7.2 7.2 7.2

3 Residual voltage tests: Table F.1 Table F.1 Table F.1 Table F.1

a) steep current impulse residual voltage test 7.3.2 7.3.2 7.3.2 7.3.2

b) lighting impulse residual voltage test 7.3.3 7.3.3 7.3.3 7.3.3

c) switching impulse residual voltage test 7.3.4 Not required Not required Not required

4 Sparkover voltage tests:

a) front-of-wave impulse sparkover voltage test 7.3.6 7.3.6 7.3.6 7.3.6

b) lightning impulse sparkover voltage test 7.3.7 7.3.7 7.3.7 7.3.7

c) switching impulse sparkover voltage test 7.3.8 Not required Not required Not required

5 Long duration current impulse withstand test 7.4.3 7.4.3 7.4.3 Not required

6 High current impulse operating duty test 7.5.3 and 7.5.3 and 7.5.3 and 7.5.3 and

table 8 table 8 table 8 table 8

7 Power frequency voltage versus time curve 5.9 5.9 5.9 5.9

8 Short-circuit withstand (when it applies) 5.10 5.10 Not required Not required

9 Arrester disconnector (when fitted) 7.6 7.6 7.6 7.6

10 Power frequency sparkover voltage test 7.7 7.7 7.7 7.7

11 Moisture ingress tests 7.8 7.8 7.8 7.8

12 Weather ageing tests (polymeric housing only) 7.9 and 7.9 and 7.9 and table 7.9 and

table 9 table 9 9 table 9

13 Artificial pollution test Annex D Annex D Annex D Annex D

60099-6 IEC:2002(E) – 15 –

4 Standard ratings

4.1 Standard rated voltages

Standard values of rated voltages for arresters (in kV r.m.s.) are specified in table 2 in equal

voltage steps within specified voltage ranges:

Table 2 – Steps of rated voltages

Range of rated voltage Steps of rated voltage

kV kV r.m.s.

3-30 1 kV

30-52 3 kV

NOTE All other ratings are considered non-standard but are still subject to conformance to this standard.

4.2 Standard rated frequencies

The standard rated frequencies are 50 Hz and 60 Hz.

4.3 Standard nominal discharge currents

The standard nominal 8/20 discharge currents are: 10 000 A, 5 000 A, 2 500 A and 1 500 A,

see 2.30.

4.4 Service conditions

4.4.1 Normal service conditions

Surge arresters that conform to this standard shall be suitable for normal operation under the

following normal service conditions:

a) ambient air temperature within the range of –40 °C to +40°C;

b) solar radiation;

NOTE The effects of maximum solar radiation (1,1 kW/m ) have been taken into account by preheating the

test specimen in the type tests. If there are other heat sources near the arrester, the application of the arrester

shall be subject to an agreement between the manufacturer and the purchaser.

c) altitude not exceeding 1 000 m;

d) frequency of the a.c. power supply shall not be less than 48 Hz and not exceeding 62 Hz;

e) power frequency voltage applied continuously between the terminals of the arrester not

exceeding its continuous operating voltage;

f) mechanical conditions (under consideration);

g) pollution conditions (no requirement at this time).

4.4.2 Abnormal service conditions

Surge arresters subject to other than normal application or service conditions may require

special consideration in design, manufacture or application. The use of this standard in case

of abnormal service conditions is subject to agreement between the manufacturer and the

purchaser. A list of possible abnormal service conditions is given in annex A.

– 16 – 60099-6 IEC:2002(E)

5 Requirements

5.1 Insulation withstand of the arrester housing

The arrester housing shall withstand the following voltages when tested according to 7.2:

– the standard lightning impulse protection level of the arresters (see 2.58.2) multiplied

by 1,3;

NOTE The 1,3 factor covers variations in atmospheric conditions and discharge currents higher than nominal.

– power frequency voltage in wet conditions for arrester housings for outdoor use and in dry

conditions for arrester housings for indoor use.

Housings of 1 500 A, 2 500 A and 5 000 A arresters shall withstand a power frequency

voltage with a peak value equal to the standard lightning impulse protection level (see 2.58.2)

multiplied by 0,88 for a duration of 1 min.

Housings of 10 000 A arresters shall withstand a power frequency voltage with a peak value

equal to the switching impulse protection level multiplied by 1,06 for a duration of 1 min

(see 2.58.3)

5.2 Reference voltage

The reference voltage of each of the main series metal-oxide resistors shall be measured by

the manufacturer at the reference current selected by the manufacturer, see 6.2. The

minimum reference voltage of the main series of metal-oxide prorated section shall be stated

in the type test report.

5.3 Impulse protective levels

The arrester shall be tested to determine whether the protective level for a specified wave-

shape (7.3.6, 7.3.7, 7.3.8) is a function of the maximum impulse sparkover value or residual

voltage (7.3.2, 7.3.3, 7.3.4), whichever is greatest.

5.4 Partial discharges

When required, the partial discharge level in the arrester energized at 1,05 times its

continuous operating voltage shall not exceed 10 pC, see 8.1 b) and 8.2.1 c).

5.5 Seal leakage

Arrester units with sealed housings containing gaseous material shall meet the gas leakage

requirements of 8.1 c). Arresters with polymeric housings shall be tested per the moisture

ingress test see 7.8.

5.6 Thermal stability

When agreed between manufacturer and purchaser, a special thermal stability test may be

performed according to 8.2.2.

5.7 Long duration current impulse withstand

Arresters shall withstand long duration currents as verified during type tests, see 7.4.

For 10 000 A arresters, the long duration withstand is demonstrated by a line discharge test

(see 7.4.2) with the line discharge class specified by the user.

60099-6 IEC:2002(E) – 17 –

For 5 000 A and 2 500 A arresters, the long duration withstand is demonstrated by a long

duration impulse test, see 7.4.3.

The samples shall be considered to have passed if all the following requirements are met:

a) The residual voltage at nominal discharge current has not changed by more than 5 %.

b) The average power frequency sparkover voltage or average standard lightning impulse

sparkover voltage has not changed by more than 5 %.

c) If the manufacturer declares that the resistors may be removed, then visual examination

of the test samples after the test shall reveal no evidence of puncture, flashover, cracking

or other significant damage of the metal-oxide resistors, or the gap structure. In other

cases, visual inspection only applies to external parts. To check the integrity of the

internal parts, an additional long duration impulse shall be performed after the sample

has cooled down to ambient temperature to verify that no damage occurred. If the sample

withstood the nineteenth long duration current impulse with no damage (checked by

oscillographic records) then the sample has passed the test.

5.8 Operating duty

Arresters shall be able to withstand the combination of stresses arising in service as

demonstrated by the operating duty tests, see 7.5. These stresses shall not cause damage or

thermal runaway.

For 1 500 A, 2 500 A, 5 000 A and 10 000 A line discharge class 1 arresters, this is

demonstrated by the high current impulse operating duty test, see 7.5.3 and table 8.

The arrester has passed the test if:

a) residual voltage has not changed by more than 5 %;

b) the average power frequency sparkover voltage or average standard lightning impulse

sparkover voltage has not changed by more than 5 %;

c) if the manufacturer declares that the internal components may be removed, then visual

examination of the test samples after the test shall reveal no evidence of puncture,

flashover, cracking or other significant damage of the metal-oxide resistors or gap

structures. In other cases. visual inspection only applies to external parts;

d) there is a decrease in watts loss, leakage current, or temperature during the application

of U for 30 min after the application of U ;

c r

e) final interruption of the follow current occurs not later than at the end of the half cycle

following that in which the impulse is applied. There shall be no further sparkover of

the test sample in any subsequent half-cycle.

5.9 Power frequency voltage versus time characteristics of an arrester

The manufacturer shall supply data on the allowable time duration of power frequency voltage

and the corresponding voltage value which may be applied to the arrester after the arrester

has been preheated to 60 °C and subjected to the high current or line discharge class energy

duty respectively, without damage or thermal runaway.

This information shall be presented, together with initial temperature, as power frequency voltage

versus time curves with the impulse energy absorption prior to this power frequency voltage

application stated on the curve.

NOTE 1 Such curves are necessary for the selection of the arrester rated voltage depending on local system

conditions, such as lightning, switching and temporary overvoltages.

NOTE 2 The curves may be established by calculation.

NOTE 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...