IEC 60068-2-65:2013

(Main)Environmental testing - Part 2-65: Tests - Test Fg: Vibration - Acoustically induced method

Environmental testing - Part 2-65: Tests - Test Fg: Vibration - Acoustically induced method

IEC 60068-2-65:2013 provides standard procedures and guidance for conducting acoustic tests in order to determine the ability of a specimen to withstand vibration caused by a specified sound-pressure level environment to which it is, or is liable to be, subjected. This second edition cancels and replaces the second edition, published in 1993, and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- minor technical and editorial changes were made throughout the document as originally requested by the DE National Committee;

- following comments at the CD stage, particularly from the UK National Committee, significant technical and editorial additions were made to the standard for acoustic testing employing the progressive wave tube technique.

Essais d'environnement - Partie 2-65: Essais - Essai Fg: Vibrations - Méthode induite acoustiquement

La CEI 60068-2-65:2013 fournit des méthodes normalisées et un guide pour la conduite d'essais acoustiques afin de déterminer l'aptitude d'un spécimen à résister à des vibrations provoquées par un environnement de niveau de pression acoustique spécifié auquel il est, ou est susceptible d'être, exposé. Cette deuxième édition annule et remplace la deuxième édition, publiée en 1993, dont elle constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- des modifications techniques et rédactionnelles mineures ont été faites dans toute la norme, tel qu'il a été demandé à l'origine par le Comité national allemand;

- conformément aux commentaires émis au stade CD, en particulier ceux du Comité national britannique, des ajouts techniques et éditoriaux significatifs ont été réalisés dans la norme pour l'essai acoustique employant le technique du tube à ondes progressives.

General Information

- Status

- Published

- Publication Date

- 05-Feb-2013

- Technical Committee

- TC 104 - Environmental conditions, classification and methods of test

- Drafting Committee

- MT 17 - TC 104/MT 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 06-Feb-2013

- Completion Date

- 15-Mar-2013

Overview

IEC 60068-2-65:2013 is an international standard published by the International Electrotechnical Commission (IEC) that specifies test methods for assessing a specimen’s resistance to vibration induced by acoustic noise. This standard outlines procedures for conducting vibration tests using acoustically induced methods, primarily through reverberant chambers or progressive wave tubes, to simulate high sound pressure environments. The testing focuses on evaluating how electronic components, equipment, and assemblies withstand vibration caused by sound-pressure fluctuations.

Updated in 2013, this second edition of IEC 60068-2-65 replaces the 1993 version and includes technical revisions like enhanced guidance for testing with progressive wave tube techniques. It is part of the broader IEC 60068 series on environmental testing, serving as a critical reference for manufacturers and test laboratories working in industries exposed to intense acoustic environments.

Key Topics

Scope and Application

IEC 60068-2-65 applies to components and equipment (referred to as specimens) likely subjected to acoustic vibration, such as aerospace parts, electronic assemblies, optical devices, solar panels, and printed circuit boards. The standard covers testing in gaseous media to replicate vibration caused by external sound effects, like jet engine noise or turbulent gas flows.Acoustic Test Methods

Two primary testing techniques are covered:- Reverberant Chamber Testing

Creates a diffuse high sound pressure environment where sound waves reflect to produce a reverberant field around the test specimen. - Progressive Wave Tube Testing

Produces a controlled progressive wave, allowing precise sound pressure level exposures, particularly useful for elongated or cylindrical specimens.

- Reverberant Chamber Testing

Test Setup and Instrumentation

Guidelines include specifications for the acoustic environment, sound source characteristics, specimen mounting, instrumentation requirements for acoustic and vibration measurement, and data analysis methods.Test Severity and Conditioning

The document provides recommended exposure levels, durations, and preconditioning procedures to ensure test consistency and repeatability. It also stresses the importance of intermediate and final measurements to assess specimen performance before, during, and after testing.Safety and Compliance

Given the high-intensity noise levels used in testing, the standard emphasizes protective measures to prevent hearing damage to test operators. It aligns with international safety norms while encouraging conformance with relevant national regulations.

Applications

Aerospace and Aviation

Testing aircraft components like engines, avionics, antennas, and other systems exposed to extreme acoustic environments during flight operations.Electronics Manufacturing

Ensuring the structural integrity of printed circuit boards, connectors, and delicate electronic assemblies against acoustically induced vibrations encountered in industrial or transport settings.Automotive and Transportation

Assessing vibration durability of vehicle components situated near high sound pressure sources such as engines and exhaust systems.Defense and Space Systems

Verifying the resilience of satellites, launch vehicles, and related equipment subjected to intense acoustic loads during launch and operation phases.Industrial Equipment

Testing machinery exposed to turbulent flow noise, gas circulators, and other high sound-pressure generating environments.

Related Standards

IEC 60068 Series

A comprehensive collection of standards on environmental testing for electrotechnical products, including mechanical vibration, shock, and climatic tests.ISO 4042 – Specifies cleaning procedures and test methods related to fasteners and small parts that may be subjected to vibration.

ISO 10816 – Guides vibration monitoring procedures for rotating machinery, complementing IEC 60068-2-65 when assessing machinery noise impact.

IEC 60512 – Focused on connector testing, including vibration and mechanical stress resistance, useful in combination with acoustic vibration standards.

Practical Value

Implementing IEC 60068-2-65 enables manufacturers and testing laboratories to:

- Accurately simulate real-world acoustic vibration exposure for critical components.

- Identify potential vulnerabilities to acoustic vibration early in the design process.

- Ensure product reliability and safety in environments with high sound pressure levels.

- Standardize testing procedures globally, facilitating international market access.

- Protect personnel by adhering to noise exposure limits during testing.

By following the standardized test procedures and guidance in IEC 60068-2-65, industries can enhance product robustness, minimize failures caused by acoustically induced vibration, and maintain compliance with international environmental testing protocols.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60068-2-65:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 2-65: Tests - Test Fg: Vibration - Acoustically induced method". This standard covers: IEC 60068-2-65:2013 provides standard procedures and guidance for conducting acoustic tests in order to determine the ability of a specimen to withstand vibration caused by a specified sound-pressure level environment to which it is, or is liable to be, subjected. This second edition cancels and replaces the second edition, published in 1993, and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - minor technical and editorial changes were made throughout the document as originally requested by the DE National Committee; - following comments at the CD stage, particularly from the UK National Committee, significant technical and editorial additions were made to the standard for acoustic testing employing the progressive wave tube technique.

IEC 60068-2-65:2013 provides standard procedures and guidance for conducting acoustic tests in order to determine the ability of a specimen to withstand vibration caused by a specified sound-pressure level environment to which it is, or is liable to be, subjected. This second edition cancels and replaces the second edition, published in 1993, and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - minor technical and editorial changes were made throughout the document as originally requested by the DE National Committee; - following comments at the CD stage, particularly from the UK National Committee, significant technical and editorial additions were made to the standard for acoustic testing employing the progressive wave tube technique.

IEC 60068-2-65:2013 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60068-2-65:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60068-2-65 ®

Edition 2.0 2013-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Environmental testing –

Part 2-65: Tests – Test Fg: Vibration – Acoustically induced method

Essais d’environnement –

Partie 2-65: Essais – Essai Fg: Vibrations – Méthode induite acoustiquement

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60068-2-65 ®

Edition 2.0 2013-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Environmental testing –

Part 2-65: Tests – Test Fg: Vibration – Acoustically induced method

Essais d’environnement –

Partie 2-65: Essais – Essai Fg: Vibrations – Méthode induite acoustiquement

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX V

ICS 19.040; 29.020 ISBN 978-2-83220-641-6

– 2 – 60068-2-65 © IEC:2013

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, symbols and abbreviations. 7

3.1 Terms and definitions . 7

3.2 Symbols and abbreviations . 11

4 Acoustic environments and requirements for testing . 11

4.1 Acoustic environment for testing . 11

4.1.1 General . 11

4.1.2 Reverberant field . 13

4.1.3 Progressive wave field . 14

4.1.4 Cavity resonance . 14

4.1.5 Standing wave . 14

4.2 Sound sources . 14

4.3 Measuring apparatus . 14

4.3.1 General . 14

4.3.2 Acoustic measurements . 14

4.3.3 Vibration response measurements . 15

4.3.4 Analysis of results . 15

4.4 Requirements for testing . 15

4.4.1 Type of facility . 15

4.4.2 Mounting . 15

4.4.3 Specimen instrumentation . 16

4.4.4 Preparation of test control . 17

5 Recommended severities . 18

6 Preconditioning . 18

7 Initial measurements . 19

8 Testing . 19

8.1 Normal testing . 19

8.2 Accelerated testing . 19

9 Intermediate measurements . 19

10 Recovery . 19

11 Final measurements . 19

12 Information to be given in the relevant specification . 20

13 Information to be given in the test report . 20

Annex A (informative) Guidance for the test requirements. 22

Bibliography . 30

Figure 1 – Third-octave band spectrum for aeronautical applications . 12

Figure 2 – Octave band spectra for fans derived from [4] . 13

Figure 3 – Octave band spectrum for noisy industrial machinery derived from [4] . 13

Figure 4 – Typical locations of microphone checkpoints (1 – 6) on a fictitious surface

around a specimen . 17

60068-2-65 © IEC:2013 – 3 –

Figure A.1 – Typical microphone arrangement around a specimen in a reverberation

chamber. 22

Figure A.2 – Typical microphone checkpoint arrangement around a long cylindrical

specimen . 25

Table 1 – Tolerances for acoustic measurement . 14

Table 2 – Overall sound pressure level and duration of exposure . 18

Table A.1 – Octave band/room volume relationship . 23

Table A.2 – Reverberation room, ratios of dimensions . 23

Table A.3 – Examples of sound sources with waveforms and typical power outputs. 28

Table A.4 – Typical OASPL and exposure durations . 28

– 4 – 60068-2-65 © IEC:2013

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-65: Tests –

Test Fg: Vibration –

Acoustically induced method

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-65 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test.

This second edition cancels and replaces the second edition, published in 1993, and

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– minor technical and editorial changes were made throughout the document as originally

requested by the DE National Committee;

– following comments at the CD stage, particularly from the UK National Committee,

significant technical and editorial additions were made to the standard for acoustic testing

employing the progressive wave tube technique.

60068-2-65 © IEC:2013 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

104/591/FDIS 104/597/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60068 series, published under the general title Environmental

testing, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data related to

the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60068-2-65 © IEC:2013

INTRODUCTION

Acoustic noise may produce significant vibration in components and equipment. In the acoustic

noise field, sound pressure fluctuations impinge directly on the specimen and the response

may be different to that produced by mechanical excitation.

Items particularly sensitive to acoustic noise include relatively lightweight items whose

dimensions are comparable to an acoustic wavelength in the frequency range of interest and

whose mass per unit area is low, such as dish antennas and solar panels, electronic devices,

printed circuit boards, optical elements, etc.

Acoustic testing is applicable to components, equipment, functional units and other products,

hereinafter referred to as “specimens”, which are liable to be exposed to and/or are required to

function in conditions of high sound pressure levels. It should be noted that, under service

conditions, the specimen may be subjected to simultaneous mechanical and acoustical

excitation.

High sound pressure levels may be generated by jet engines and other aircraft propulsion

systems, rocket motors, high-powered gas circulators, turbulent gas flow around aircraft or

launchers, etc. This part of IEC 60068 deals with acoustic testing in compressible gases and

can also be used to simulate the excitation response caused by turbulence resulting from high-

velocity separated gas flows.

The intent of the test procedure contained in this standard is to produce a high intensity

acoustic noise field by either reverberant methods (known as reverberant chamber testing) or

by progressive wave methods (known as progressive wave tube testing).

Testing for the effects of vibration caused by acoustic noise demands a certain degree of

engineering judgement and this should be recognized both by the manufacturer/supplier and

the purchaser of the specimen. Based on the guidance provided in this standard, the writer of

the relevant specification is expected to select the most appropriate method of test and values

of severity, taking account of the nature of the specimen and its intended use.

Since the acoustic levels occurring during testing are high enough to be damaging to human

hearing, appropriate protective measures need to be taken to reduce the noise exposure of

operators performing the test to a level regarded as permissible from the standpoint of hearing

conservation.

60068-2-65 © IEC:2013 – 7 –

ENVIRONMENTAL TESTING –

Part 2-65: Tests –

Test Fg: Vibration –

Acoustically induced method

1 Scope

This part of IEC 60068 provides standard procedures and guidance for conducting acoustic

tests in order to determine the ability of a specimen to withstand vibration caused by a

specified sound-pressure level environment to which it is, or is liable to be, subjected.

For sound pressure level environments of less than 120 dB acoustic tests are not normally

required.

This standard determines the mechanical weakness and/or degradation in the performance of

specimens and to use this information, in conjunction with the relevant specification, to decide

on their acceptability for use. The methods of test may also be used as a means of establishing

the mechanical robustness or fatigue resistance of specimens.

Two procedures are described for conducting tests and for measurement of the sound

pressure levels within the acoustic noise field and considers the need for measurement of the

vibration responses at specified points on the specimen. It also gives guidance for the

selection of the acoustic noise environment, spectrum, sound pressure level and duration of

exposure.

The progressive wave tube method is relevant to material where aerodynamic turbulence will

excite part, or all, of the total external surface. Such applications include aircraft panel

assemblies where the excitation exists on one side only. The reverberant chamber method is

relevant where it is preferable to induce vibration onto the entire external surface of equipment

by distributed excitation rather than fixed points by means of electro-dynamic shakers.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies.

IEC 61672-1, Electroacoustics – Sound level meters – Part 1: Specifications

ISO/IEC 17025:2005, General requirements for the competence of testing and calibration

laboratories

3 Terms, definitions, symbols and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

– 8 – 60068-2-65 © IEC:2013

3.1.1

acoustic horn

tube with increasing cross-section of generally exponential envelope, used to couple an

acoustic source to the test volume, for example the inside of a reverberation room, thus

achieving the maximum transfer of sound energy

Note 1 to entry: Each acoustic horn has individual transfer characteristics which affect the sound spectrum.

3.1.2

analysis integration time

time duration over which a signal is averaged

Note 1 to entry: See Clause A.8.

3.1.3

bandwidth

difference between the nominal upper and lower cut-off frequencies

Note 1 to entry: It may be expressed

a) in hertz,

b) as a percentage of the pass-band centre frequency, or

c) as the interval between the upper and lower nominal cut-off frequencies in octaves.

3.1.4

overall sound pressure level

OASPL

value computed from the third-octave or octave band sound pressure levels L

i

m

L /10

i

L = 10 log 10

∑

G 10

i=1

where

L is the overall sound pressure level in dB;

G

L is the sound pressure level in the ith third-octave or octave band;

i

m is the number of third-octave or octave bands.

3.1.5

centre frequency

geometric mean of the nominal cut-off frequencies of a pass-band

Note 1 to entry: The nominal upper and lower cut-off frequencies of a filter pass-band are defined as those

frequencies above and below the frequency of maximum response of a filter at which the response to a sinusoidal

signal is 3 dB below the maximum response.

½

Note 2 to entry: The geometric mean is equal to (f × f ) , where f and f are the cut-off frequencies.

1 2 1 2

3.1.6

constant-bandwidth filter

filter which has a bandwidth of constant value when expressed in hertz; it is independent of the

centre frequency of the filter

3.1.7

cut-off frequency (of acoustic horn)

frequency below which an acoustic horn becomes increasingly ineffective

Note 1 to entry: This cut-off frequency is a main characteristic of an acoustic horn.

60068-2-65 © IEC:2013 – 9 –

3.1.8

diffuse sound field

sound field which, in a given region, has statistically uniform energy density, for which the

directions of propagation at any point are randomly distributed

Note 1 to entry: In a diffuse sound field, the sound pressure level measured with a directional microphone would

give the same results whatever its orientation.

[SOURCE: IEC 60050-801:1994 [1] , definition 801-23-31, modified – Addition of the Note 1 to

entry]

3.1.9

electro-pneumatic transducer

hydraulic-pneumatic transducer

most generally employed laboratory source of acoustic noise to simulate sound pressure levels

encountered in a high operational ambient acoustic noise environment

Note 1 to entry: This transducer consists of a pneumatic transducer supplied with pressurized gas modulated by

an electromagnetic or hydraulic valve.

Note 2 to entry: This type of transducer provides a continuous spectrum of energy over a wide frequency band

with random amplitude distribution and is capable of providing a shaped sound spectrum to meet the specifications

in acoustic testing (see Clause A.5).

3.1.10

grazing incidence

angle between the direction of the acoustic wave and either the surface of the specimen and/or

the sensing surface of the acoustic transducer, 0 ° being parallel and 90 ° normal to the

surface

3.1.11

frequency interval

ratio of two frequencies

[SOURCE: IEC 60050-801:1994, definition 801-30-07]

3.1.11.1

octave

interval between two frequencies which have a ratio of 2

3.1.11.2

one-third octave

1/3

1/3

interval between two frequencies which have a ratio equal to 2

Note 1 to entry: Octave and third-octave frequency bands are defined by their geometric centre frequencies in

ISO 266 [2].

3.1.11.3

one-twelfth octave

1/12

1/12

interval between two frequencies which have a ratio equal to 2

3.1.12

measuring points

specific points in the sound field at which sound pressure is measured for the conduct of the

test

______________

Figures in square brackets refer to the bibliography.

– 10 – 60068-2-65 © IEC:2013

Note 1 to entry: Measurements may be made at points within the specimen in order to assess its behaviour but

these are not considered as measuring points in the sense of this standard.

3.1.12.1

checkpoints

points located on a fictitious surface surrounding the specimen and at a fixed distance from it

3.1.12.2

reference points

points chosen from the checkpoints, whose signals are used to control the test so that the

requirements of this standard are satisfied

3.1.13

multipoint control

control achieved by using the average of the signals at the reference points

Note 1 to entry: When using multipoint control, each microphone signal relates to the sound pressure level at one

position. The average sound pressure level L can be computed as given in IEC 60050-801:1994, definition 801-

AV

31-36, when

n

L /10

i

L = 10 log 10

∑

AV 10

n

where

n is the number of reference points;

L is the sound pressure level in the ith third-octave or octave band.

i

3.1.14

narrowband frequency filter

band-pass filter for which the pass-band is generally smaller than third-octave

3.1.15

broadband frequency

wide band filter

band-pass filter for which the pass-band is relatively wide or broad, in general larger than an

octave

3.1.16

progressive wave tube

tube along which sound waves propagate from the acoustic source, which is coupled to a

suitable test section by an acoustic horn

Note 1 to entry: The tube is terminated by an acoustically absorptive termination placed at the end of the test

section to minimize reflection of the progressive acoustic waves in the frequency range of interest (see Clause A.2).

3.1.17

proportional-bandwidth filter

filter which has a bandwidth that is proportional to the frequency

Note 1 to entry: Octave bandwidth, third-octave bandwidth, etc. are typical bandwidths for proportional-bandwidth

filters.

3.1.18

reverberation chamber (or room)

chamber or room which has hard, highly reflective surfaces such that the sound field therein

becomes diffuse

Note 1 to entry: The geometry of the chamber or room may influence the test. Information on reverberant

chambers is given in Clause A.1.

60068-2-65 © IEC:2013 – 11 –

3.1.19

sound absorption coefficient

fraction of incident sound power not reflected from the surface of a material at a given

frequency and under specified conditions

Note 1 to entry: Sound absorption is the property possessed by materials and objects for converting sound energy

to heat.

[SOURCE: IEC 60050-801:1994, definition 801-31-02, modified – word order of definition

reversed, Note 1 to entry replaces previous NOTE and bears no relation]

3.1.20

sound pressure

p

root mean-square of instantaneous sound pressures over a given time interval, unless

specified otherwise

Note 1 to entry: Sound pressure characterizes the variation of pressure about the static pressure, produced by

acoustic waves, which are variations of pressure caused by disturbances in a gaseous medium.

[SOURCE: IEC 60050-801:1994, definition 801-21-20, modified – addition of Note 1 to entry]

3.1.21

sound pressure level L

p

p

L = 20 log dB

p 10

p

o

3.2 Symbols and abbreviations

NOTE Where appropriate, a cross-reference to the definition is given.

OASPL overall sound pressure level in dB (derived from 801-22-07), see 3.1.4;

L overall sound pressure level in dB (see 3.1.4);

G

L sound pressure level in third-octave or octave band in dB (see 3.1.4);

i

L sound pressure level in dB (see 3.1.21);

p

L average sound pressure level in dB (see 3.1.13);

AV

p r.m.s. sound pressure in N/m or Pa (see 3.1.20);

–5

p international reference sound pressure, standardized as 2 x 10 Pa or 20 µPa in

o

air (IEC 61672-1), 1 µPa in other media;

DOF statistical degrees of freedom, given by:

N = 2B × T

d e a

where

B is the frequency resolution;

e

T is the effective averaging time.

a

4 Acoustic environments and requirements for testing

4.1 Acoustic environment for testing

4.1.1 General

An acoustic test is conducted in order to determine the ability of a specimen to operate or

survive in a specified high-intensity acoustic noise field. In practice, the fluctuating pressure

environment exerted on a specimen under consideration may be a complex combination of

progressive waves and reverberant acoustic fields. Standing waves, formed within structures

and cavities exposed to noise may resonate and produce very high local sound pressure levels.

It is, therefore, necessary to select the most appropriate type of acoustic test for the specimen.

– 12 – 60068-2-65 © IEC:2013

The selection may be based upon real measured data from field tests or flight trials or be

obtained from general levels specified for particular equipment applications, for example as in

Figures 1, 2 and 3. The applied test spectrum may contain energy above and below the

frequencies given in the figures.

NOTE For further information on sound pressure levels associated with aircraft environments, see ISO 2671 [3].

–9

3 dB/Octave –3 dB/Octave

Upper limit

–16

Lower limit

10 dB/Octave –10 dB/Octave

50 250 1 250 8 000

Third octave band centre frequency (Hz)

IEC 382/13

Figure 1 – Third-octave band spectrum for aeronautical applications

Third octave band sound pressure levels (dB)

relative to test overall sound pressure level

60068-2-65 © IEC:2013 – 13 –

Upper limit

Lower limit

–10

Axial flow

fans

–20

Upper limit

Lower limit

–30 Centrifugal

fans

–40

–50

63 125 250 500 1 000 2 000 4 000 8 000

Octave band centre frequency (Hz)

IEC 383/13

Figure 2 – Octave band spectra for fans derived from [4]

Upper limit

–10

Lower limit

–20

–30

–40

63 125 250 500 1 000 2 000 4 000 8 000

Octave band centre frequency (Hz)

IEC 384/13

Figure 3 – Octave band spectrum for noisy industrial machinery

derived from [4]

4.1.2 Reverberant field

A reverberant field is generally used for specimens intended to be located in enclosed spaces,

when the pressure fluctuations seen by the specimens are evenly distributed. However, it may

Octave band sound pressure levels (dB)

Octave band sound pressure levels (dB)

relative to test overall sound pressure level

relative to test overall sound pressure level

– 14 – 60068-2-65 © IEC:2013

also be used for testing the enclosures themselves, for example nose cone fairings of large

launch vehicles, etc., where no other more suitable simulation is possible. Reverberant fields

may arise in enclosures, from excitation of the boundary structures by turbulent gas flow or

flow separation over a surface, radiated propulsion noise, and within for example, gas-cooled

reactor pressure vessels (see Clause A.1).

4.1.3 Progressive wave field

A progressive wave field is used where the acoustic sound pressure sweeps over the surface

of the specimen. Examples of the occurrence of this environment include externally carried

items on aircraft, rocket engine heat shields, aircraft panels or tail surfaces (see Clause A.2).

4.1.4 Cavity resonance

A cavity resonance can occur as a result of turbulent flow over the cavities or when they are

exposed to acoustic excitation. Examples include aircraft landing gear wheel cavities when

wheels are lowered for landing or combustion chambers (see Clause A.3).

4.1.5 Standing wave

A standing wave may produce very high tonal sound pressure levels (see Clause A.4).

4.2 Sound sources

Guidance on the selection of an appropriate sound source for testing is given in Clause A.5.

4.3 Measuring apparatus

4.3.1 General

Measuring apparatus is required to monitor the sound pressure field around the specimen and,

if necessary, to measure the acoustically induced vibrations in the specimen. These

measurements require being analysed with respect to their frequency content (see 4.3.3).

4.3.2 Acoustic measurements

The monitoring instrumentation system shall be capable of measuring sound pressure levels in

the frequency range between 22,4 Hz and 11 200 Hz in either octave or third-octave bands,

with centre frequencies between 31,5 Hz/25 Hz (octave/third-octave) and 8 kHz/10 kHz.

This instrumentation system shall have a nominally flat frequency response within ± 5 % over

the frequency range of interest within the tolerances given in Table 1.

Table 1 – Tolerances for acoustic measurement

Frequency range Tolerance of frequency response

Hz dB (relative to the required test severity)

22,4 – 125 ± 1

126 – 2 500

± 2

2 501 – 11 200

± 3

The microphones used shall be capable of random incidence measurements for reverberant

chamber testing and grazing incidence measurements for progressive wave testing. In either

case, they should be capable of measuring peak values of at least three times the maximum

rated r.m.s. value.

60068-2-65 © IEC:2013 – 15 –

The instrumentation shall be capable of measuring sound pressure levels at least 10 dB higher

than the specified test level. This capability refers both to the overall level and to individual

frequency band levels.

4.3.3 Vibration response measurements

The monitoring of the vibration of the specimen, where specified by the relevant specification,

may be performed on the basis of acceleration and/or strain measurements. Also interface

forces, displacement or velocity response may also be monitored, if appropriate.

The monitoring equipment shall be capable of measuring overall vibration response at least in

the frequency range between 16 Hz and 2 000 Hz. This instrumentation shall have a nominally

flat frequency response over the frequency range of interest and be suitable for the application

and the type of measurement.

4.3.4 Analysis of results

The measured data obtained from 4.3.2 and, if appropriate, 4.3.3, shall be analysed for

frequency composition:

a) acoustic measurements shall be analysed with a resolution of at least one octave or,

preferably, third-octave, bands;

b) vibration response measurements usually require finer resolution analysis.

The frequency resolution bandwidths shall be prescribed by the relevant specification for the

particular application.

4.4 Requirements for testing

4.4.1 Type of facility

The service or operational space-time behaviour of the sound field to be simulated influences

the choice of testing. The facilities encompassed by this procedure are the reverberation room

or chamber and the progressive wave tube. Other types of specialist facilities are described in

Annex A and the principles of this standard may be used as the basis for test procedures for

those alternative facilities.

The type of facility to be used shall be specified in the relevant specification.

If a combined test is required in which the specimen is exposed simultaneously to a high

intensity acoustic environment and some other environmental parameter, the acoustical portion

of the testing shall be in accordance with this standard. Combined testing may include acoustic

and extreme or varying temperatures as well as mechanical vibrations to augment the acoustic

excitation at low frequencies.

4.4.2 Mounting

4.4.2.1 Reverberation chambers

The specimen shall be located in the centre of the reverberation room in such a way as to

avoid, as far as possible, parallelism between walls (including floor and ceiling) and the main

surfaces of the specimen. The specimens (and its mechanical support, if appropriate) shall be

supported or suspended elastically inside the reverberation room. The relevant specification

shall prescribe, as necessary, the preferred points of mounting or attachment.

The resonance frequency of the specimen on its suspension shall be less than 25 Hz or a

quarter of the lowest frequency of interest, whichever gives the lower value.

The distance between the checkpoints and the surface of the specimen shall be greater than

half the wavelength of the lowest frequency of interest or half the distance of the specimen

– 16 – 60068-2-65 © IEC:2013

from the wall, whichever is the lesser. If this is not possible and it becomes necessary to

position a microphone closer than half the wavelength, then the measured noise levels may be

subject to large variations due to reflections from the specimen and this shall be considered

when assessing the results of tests.

If a structural member is required, either between the specimen and the elastic suspension, or

for attaching the elastic suspension itself, care shall be taken to avoid distortion of the noise

field or the introduction of extraneous vibration.

Any connections to the specimen such as cables, pipes, etc. shall be so arranged that they

impose similar restraint and mass to that when the specimen is installed in its operational

position. In order to achieve this, it may be necessary to fasten the cables, pipes, etc. to the

mounting fixture.

4.4.2.2 Progressive wave tubes

Test specimens shall be mounted within the working section, either on a soft suspension or by

the service attachment, such that the excitation is applied over the whole of the external

surface. Alternatively, the item may be mounted as part of the wall of the working section when

only one side shall be excited. Where the test specimen is provided with specific means of

mounting, the support system shall be attached to these points. Where no specific means of

attachment are provided, the support system shall be connected to the specimen in such a way

that it does not interfere with the free movement of independent parts or provide additional

restraint or damping to panels or other structural parts. The rigid body modes of the system

shall be lower than 25 Hz or one-quarter of the lowest test frequency, whichever is the lesser.

Care shall be exercised to ensure that no spurious acoustic or vibratory inputs are introduced

by the test support system or ancillary structure. Any connections to the specimen, such as

cables or pipes shall be arranged so they impose dynamic restraint and mass similar to that

when installed in-service.

Test specimens such as panels shall be mounted in the wall of the duct such that the required

test surface is exposed to the acoustic excitation. This surface shall be flush with the inner

surface of the duct so as to prevent the introduction of cavity resonance or local turbulence

effects.

The distance between the checkpoints shall be half the distance of the specimen from the wall

or shall be greater than half the wavelength of the lowest frequency of interest, whichever is

the lesser. If this is not possible and it becomes necessary to position a microphone closer

than half the wavelength, then the measured noise levels may be subject to large variations

due to reflections from the specimen and this shall be considered when assessing the results

of the test.

When testing panel assemblies, the control microphones should be preferably mounted flush in

the duct wall opposite to the test specimen. Other positions within the working section may be

selected, provided that the microphone is positioned so that it responds only to grazing

incidence waves and that the necessary corrections are applied to the measured levels.

4.4.3 Specimen instrumentation

Where appropriate, the relevant specification shall state the number, type and location of

transducers (accelerometers, microphones, strain gauges, etc.) applied to the specimen.

The proof of calibration for each transducer shall be available.

Microphones for use in reverberation chambers shall be calibrated for random incident noise

and for grazing incident noise when used in progressive wave tubes.

60068-2-65 © IEC:2013 – 17 –

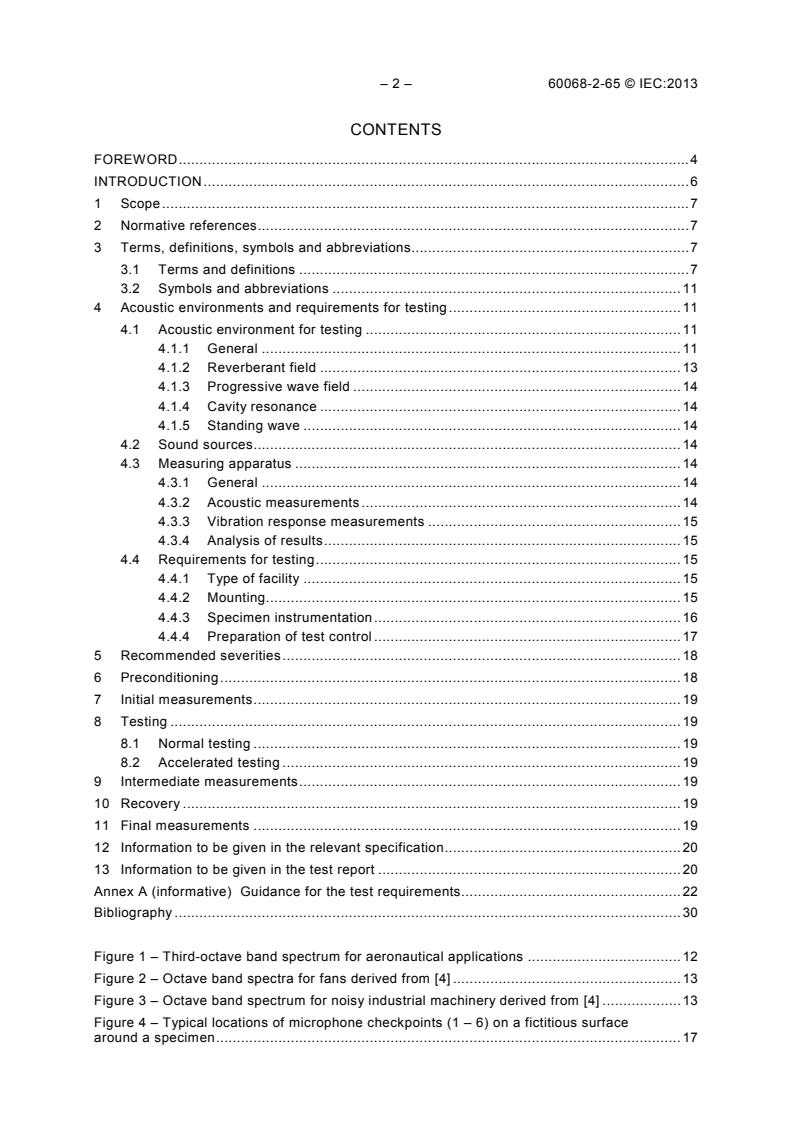

4.4.4 Preparation of test control

4.4.4.1 Number and location of checkpoints

For specimens located entirely within either a reverberant chamber or progressive wave tube,

there shall be at least three control microphones to measure the sound pressure levels around

the specimen. To determine the number of checkpoints, the size of the specimen shall be

considered with respect to the size of the sound field known to be homogeneous. The number

and position of the microphones, which shall be located on the major orthogonal axes of the

specimen and of the fictitious surface, shall be prescribed by the relevant specification (see

Figure 4).

For specimens located in the wall of a progressive wave tube, control may be achieved with

either a single microphone or, for example with large specimens, with microphones distributed

over the surface area occupied by the specimen.

Z

Test specimen

M1

M4

M6

M3

M2

M5

Fictitious surface

–Z

M Microphone

IEC 385/13

Figure 4 – Typical locations of microphone checkpoints (1 – 6)

on a fictitious surface around a specimen

4.4.4.2 Control of spectrum

The responses from each control microphone shall be subjected to octave or third-octave

analysis as prescribed in the relevant specification. The average level in each band shall be

– 18 – 60068-2-65 © IEC:2013

obtained as in 3.1.13. The overall average value shall then be calculated from the band levels.

The band levels and overall level of the averaged spectrum shall be within the specified level

limits given in Figures 1, 2 or 3, or the spectrum prescribed by the relevant specification. The

averaged values shall remain within the specified limits for the duration of the testing.

The analysis integration time, as prescribed by the relevant specification, shall be sufficiently

long to ensure statistical confidence in the results (see Clause A.8).

Where test durations are of sufficient length, real time analysis of the responses of the control

microphones shall be carried out at intervals during the test in order to ensure that the sound

pressure levels are within the specified limits.

NOTE 1 The maximum allowable variation in band level and overall sound pressure level measured by each

microphone may be prescribed by the relevant specification.

NOTE 2 If the relevant specification prescribes one-third octave analysis, then it will also need to provide the one-

third octave spectr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...