IEC 62319-1:2005

(Main)Polymeric thermistors - Directly heated positive step function temperature coefficient - Part 1: Generic specification

Polymeric thermistors - Directly heated positive step function temperature coefficient - Part 1: Generic specification

IEC 62319-1:2005(E) prescribes terms and methods of test for polymeric positive temperature coefficient thermistors, insulated and non-insulated types, typically intended for use in current limiting and overcurrent protection applications. It establishes standard terms, inspection procedures and methods of test for use in detail specifications for Qualification Approval and for Quality Assessment Systems for electronic components. The contents of the corrigendum of March 2009 have been included in this copy.

General Information

- Status

- Published

- Publication Date

- 14-Feb-2005

- Technical Committee

- TC 40 - Capacitors and resistors for electronic equipment

- Current Stage

- PPUB - Publication issued

- Start Date

- 15-Feb-2005

- Completion Date

- 15-Apr-2005

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62319-1:2005 is the international generic specification for polymeric directly heated positive step‑function temperature coefficient (PTC) thermistors. The standard prescribes standard terms, units and symbols, inspection procedures and methods of test for insulated and non‑insulated polymeric PTC thermistors, typically intended for current limiting and overcurrent protection applications. This edition includes the March 2009 corrigendum.

Key topics and technical requirements

The standard defines terminology and the measurement basis used for PTC thermistors and sets out quality assessment and test procedures including:

- Units, symbols and definitions (zero power resistance, nominal resistance, trip event, upper/lower category temperature, etc.)

- Marking and preferred values required in detail specifications

- Quality assessment procedures covering:

- Primary manufacture and subcontracting controls

- Qualification approval and fixed sample‑size test schedules

- Lot release, periodic testing, rework/repair and certified test records

- Test and measurement procedures such as:

- Standard test conditions and drying/recovery

- Visual and dimensional inspection

- Zero power resistance and resistance/temperature characteristics

- Insulation resistance and dielectric (voltage proof) tests for insulated types

- Robustness of terminations, soldering and mounting tests

- Environmental tests: temperature change, climatic sequence, vibration, shock, bump

- Electrical endurance tests: cycle life, trip endurance, trip/hold current, residual current, time‑to‑trip and thermal runaway

- Annexes with normative schedules and mechanical/environmental test definitions (vibration, bump, shock, shear, substrate bending)

Applications and practical value

IEC 62319-1 is focused on the reliable specification and assessment of polymeric PTC thermistors used where devices must limit or interrupt current during fault or surge conditions. Practical uses include:

- Design and qualification of components for circuit protection and inrush/current‑limiting functions

- Creating supplier detail specifications and procurement requirements

- Defining factory test routines, lot release criteria and qualification testing for components in power supplies, consumer electronics and industrial equipment

Who should use this standard

- Component manufacturers and R&D teams specifying polymeric PTC thermistors

- Test laboratories and quality engineers implementing inspection and qualification programs

- OEM design and procurement engineers writing detail specifications for overcurrent protection components

- Certification bodies and IECQ participants assessing compliance and quality systems

Related standards (normative references)

IEC 62319-1 references and aligns terminology and test practices with other IEC/ISO documents, notably:

- IEC 60068 series (environmental testing)

- IEC 60027, IEC 60050 (symbols and vocabulary)

- IEC 60294, IEC 60410, IEC 60617, ISO 1000

- IECQ quality assessment guidance and approval procedures

Keywords: IEC 62319-1, polymeric thermistors, PTC thermistors, current limiting, overcurrent protection, qualification approval, quality assessment, test methods.

Frequently Asked Questions

IEC 62319-1:2005 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Polymeric thermistors - Directly heated positive step function temperature coefficient - Part 1: Generic specification". This standard covers: IEC 62319-1:2005(E) prescribes terms and methods of test for polymeric positive temperature coefficient thermistors, insulated and non-insulated types, typically intended for use in current limiting and overcurrent protection applications. It establishes standard terms, inspection procedures and methods of test for use in detail specifications for Qualification Approval and for Quality Assessment Systems for electronic components. The contents of the corrigendum of March 2009 have been included in this copy.

IEC 62319-1:2005(E) prescribes terms and methods of test for polymeric positive temperature coefficient thermistors, insulated and non-insulated types, typically intended for use in current limiting and overcurrent protection applications. It establishes standard terms, inspection procedures and methods of test for use in detail specifications for Qualification Approval and for Quality Assessment Systems for electronic components. The contents of the corrigendum of March 2009 have been included in this copy.

IEC 62319-1:2005 is classified under the following ICS (International Classification for Standards) categories: 31.040.30 - Thermistors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62319-1:2005 has the following relationships with other standards: It is inter standard links to IEC 62319-1:2005/COR1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62319-1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 62319-1

First edition

2005-02

Polymeric thermistors –

Directly heated positive step function

temperature coefficient –

Part 1:

Generic specification

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 62319-1

First edition

2005-02

Polymeric thermistors –

Directly heated positive step function

temperature coefficient –

Part 1:

Generic specification

IEC 2005 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

V

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

– 2 – 62319-1 IEC:2005(E)

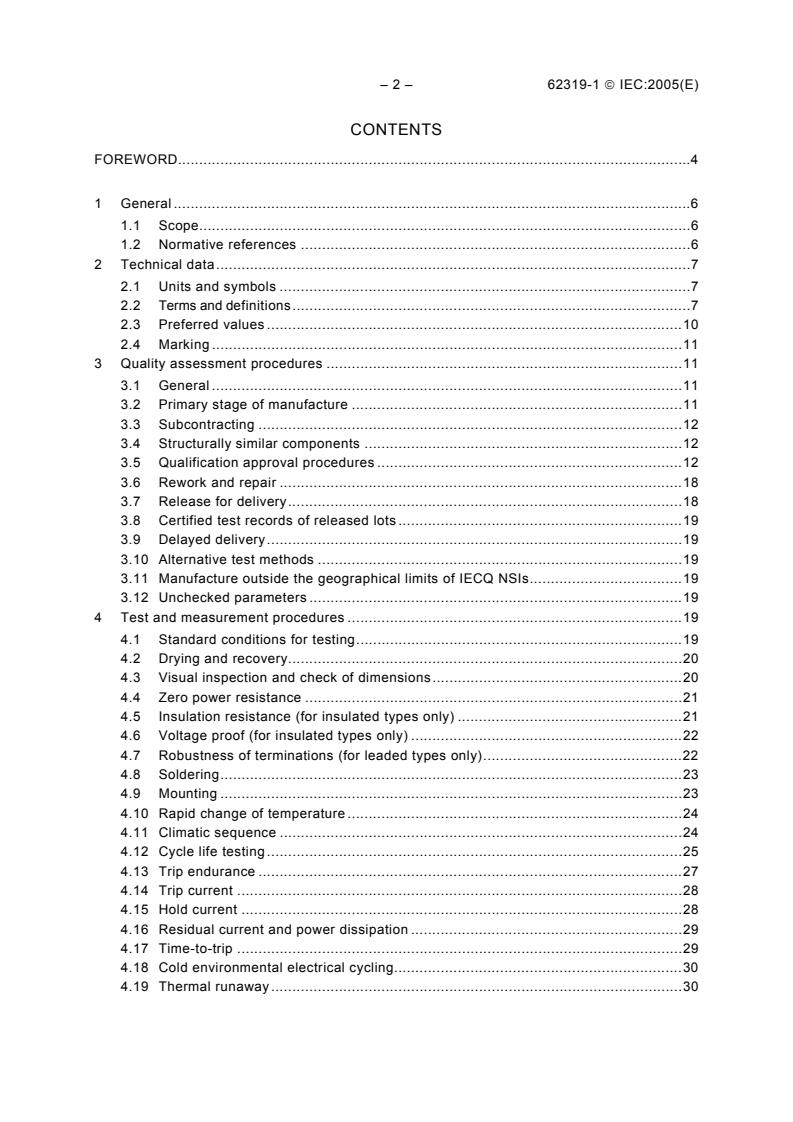

CONTENTS

FOREWORD.4

1 General .6

1.1 Scope.6

1.2 Normative references .6

2 Technical data.7

2.1 Units and symbols .7

2.2 Terms and definitions.7

2.3 Preferred values .10

2.4 Marking .11

3 Quality assessment procedures .11

3.1 General .11

3.2 Primary stage of manufacture .11

3.3 Subcontracting .12

3.4 Structurally similar components .12

3.5 Qualification approval procedures .12

3.6 Rework and repair .18

3.7 Release for delivery.18

3.8 Certified test records of released lots .19

3.9 Delayed delivery.19

3.10 Alternative test methods .19

3.11 Manufacture outside the geographical limits of IECQ NSIs.19

3.12 Unchecked parameters .19

4 Test and measurement procedures .19

4.1 Standard conditions for testing.19

4.2 Drying and recovery.20

4.3 Visual inspection and check of dimensions.20

4.4 Zero power resistance .21

4.5 Insulation resistance (for insulated types only) .21

4.6 Voltage proof (for insulated types only) .22

4.7 Robustness of terminations (for leaded types only).22

4.8 Soldering.23

4.9 Mounting .23

4.10 Rapid change of temperature .24

4.11 Climatic sequence .24

4.12 Cycle life testing .25

4.13 Trip endurance .27

4.14 Trip current .28

4.15 Hold current .28

4.16 Residual current and power dissipation .29

4.17 Time-to-trip .29

4.18 Cold environmental electrical cycling.30

4.19 Thermal runaway.30

62319-1 IEC:2005(E) – 3 –

Annex A (normative) Fixed sample size test schedules for qualification approval.31

Annex B (normative) Vibration-, bump-, shock-, shear-, substrate bending test.32

B.1 Vibration .32

B.2 Bump .32

B.3 Shock.33

B.4 Shear (adhesion) test .33

B.5 Substrate bending test.33

Figure 1 – Test schedule flow chart.15

Figure 2 – Circuit for Trip endurance .28

Table 1 – Fixed sample size test schedule for qualification approval of Polymeric PTC

thermistors for current limitation, assessment level EZ.16

Table 2 – Quality conformance inspection for lot-by-lot inspection.17

Table 3 – Quality conformance inspection for periodic testing .18

Table 4 – Loading weight for wire terminations .22

Table 5 – Number of cycles.25

– 4 – 62319-1 IEC:2005(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POLYMERIC THERMISTORS –

DIRECTLY HEATED POSITIVE STEP FUNCTION

TEMPERATURE COEFFICIENT –

Part 1: Generic specification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62319-1 has been prepared by IEC technical committee 40:

Capacitors and resistors for electronic equipment.

The text of this standard is based on the following documents:

FDIS Report on voting

40/1505/FDIS 40/1534/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

62319-1 © IEC:2005(E) – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

The contents of the corrigendum of March 2009 have been included in this copy.

– 6 – 62319-1 IEC:2005(E)

POLYMERIC THERMISTORS –

DIRECTLY HEATED POSITIVE STEP FUNCTION

TEMPERATURE COEFFICIENT –

Part 1: Generic specification

1 General

1.1 Scope

This part of IEC 62319 prescribes terms and methods of test for polymeric positive

temperature coefficient thermistors, insulated and non-insulated types, typically intended for

use in current limiting and overcurrent protection applications.

It establishes standard terms, inspection procedures and methods of test for use in detail

specifications for Qualification Approval and for Quality Assessment Systems for electronic

components.

1.2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60027-1: Letter symbols to be used in electrical technology – Part 1: General

IEC 60050: International Electrotechnical Vocabulary

IEC 60068-1: Environmental testing – Part 1: General and guidance

IEC 60068-2-6: Environmental testing – Part 2: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-14: Environmental testing – Part 2: Tests – Test N: Change of temperature

IEC 60068-2-20: Environmental testing – Part 2: Tests – Test T: Soldering

IEC 60068-2-21: Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-27: Environmental testing – Part 2: Tests – Test Ea and guidance: Shock

IEC 60068-2-29: Environmental testing – Part 2: Tests – Test Eb and guidance: Bump

IEC 60068-2-45: Environmental testing – Part 2: Tests – Test XA and guidance: Immersion in

cleaning solvents

IEC 60294: Measurement of the dimensions of a cylindrical component having two axial

terminations

IEC 60410: Sampling plans and procedures for inspection by attributes.

62319-1 IEC:2005(E) – 7 –

IEC 60617-DB: 2001 Graphical symbols for diagrams

IECQ 001003: IEC Quality Assessment System for Electronic Components – Guidance

documents

IECQ 001002-3: IEC Quality Assessment System for Electronic Components – Rules of

Procedure – Part 3: Approval procedures

ISO 1000: SI units and recommendations for the use of their multiples and of certain other

units

2 Technical data

2.1 Units and symbols

Units, graphical symbols, letter symbols and terminology shall, whenever possible, be taken

from the following documents:

IEC 60027

IEC 60050

IEC 60617

ISO 1000

The following subclauses contain additional terminology applicable to thermistors.

Where further items are required they shall be derived in accordance with the principles of the

documents listed above.

2.2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.2.1

thermistor

thermally sensitive semiconducting resistor whose primary function is to exhibit an important

change in electrical resistance with a change in body temperature

2.2.2

positive temperature coefficient thermistor

thermistor in which the resistance increases with increasing temperature throughout the

useful part of its characteristic. The PTC thermistors covered in this specification typically

exhibit a very sharp increase in resistance over a narrow temperature range

2.2.3

directly heated positive temperature coefficient thermistor

thermistor in which the change in temperature is obtained either by the flow of current through

the thermo-sensitive element, or by a change in ambient temperature, or by a combination of

both of these means

___________

“DB” refers to the IEC on-line database.

– 8 – 62319-1 IEC:2005(E)

2.2.4

zero power resistance

R

T

value of the resistance of a PTC thermistor, at a given temperature, under such conditions

that the change in resistance due to the internal generation of heat is negligible with respect

to the total error of measurement

NOTE Any resistance value of a PTC thermistor is dependent on the value and the mode of the applied voltage

(AC or DC).

2.2.5

nominal zero power resistance

R

n

zero power resistance used as a reference value for which the following conditions should be

given in the detail specification:

a) reference temperature, preferably 25 °C

b) applied voltage (DC or AC)

2.2.6

resistance/temperature characteristics

relationship between the zero power resistance of a thermistor and the temperature of the

thermosensitive element when measured under specified reference conditions

2.2.7

upper category temperature

UCT

maximum ambient operating temperature of the thermistor

2.2.8

lower category temperature

LCT

minimum ambient operating temperature of the thermistor

2.2.9

trip event

event of rapid increasing resistance of the thermistor in response to an overcurrent surge

2.2.10

minimum initial resistance

R

min

minimum resistance of the thermistor

2.2.11

maximum initial resistance

R

max

maximum resistance of the thermistor before it’s initial trip event

2.2.12

maximum resistance 1 h after tripping

R

1max

for leaded thermistors the maximum resistance of the thermistor 1 h after it’s first trip event;

for surface mount thermistors, the maximum resistance of the thermistor 1 h after reflow

2.2.13

maximum voltage

U

max

maximum AC or DC voltage which may be applied to the thermistor

62319-1 IEC:2005(E) – 9 –

2.2.14

operating temperature range at maximum voltage

range of ambient temperatures at which the thermistor can operate at the maximum voltage

2.2.15

isolation voltage (applicable only to insulated thermistors)

maximum peak voltage which may be applied under continuous operating conditions between

any of the thermistor terminations and any conducting surface

2.2.16

maximum current

I

max

value of current for the operating temperature range, which should not be exceeded

2.2.17

residual current

I

res

value of current in the tripped thermistor at a specified ambient temperature (preferably

25 °C) under steady state conditions; the applied voltage is the maximum voltage unless

otherwise specified

2.2.18

trip current

I

t

lowest current which will cause the thermistor to trip to its high resistance state at a specified

temperature (preferably 25 °C) and within a time specified in the detail specification

2.2.19

hold current

I

h

the maximum current at specified ambient temperature, preferably 25 °C, which will not cause

the trip event

2.2.20

fault current

I

fault

current used when measuring time to trip

2.2.21

power dissipation

P

d

product of the current flowing through a device and the voltage across it, under steady state

conditions; the applied voltage is the maximum voltage unless otherwise specified

2.2.22

time-to-trip

t

trip

under specified ambient conditions, starting from the time the fault current (I ) is applied,

fault

the time-to-trip is the time required for a device to switch into the tripped state

2.2.23

insulated thermistors

thermistors capable of meeting the requirements of the insulation resistance and voltage proof

tests when specified in the test schedule

– 10 – 62319-1 © IEC:2005(E)

2.3 Preferred values

2.3.1 Climatic categories

The thermistors covered by this specification are classified into climatic categories according

to the general rules given in the annex to IEC 60068-1. The detail specification prescribes the

appropriate category.

2.3.2

Void

2.3.3 Shock test severities

Test severities given in detail specifications shall preferably be the following:

Test Ea (IEC 60068-2-27)

Pulse shape: Half sine

Acceleration: 500 m/s

Pulse duration: 11 ms.

Severity: 3 successive shocks in each axis direction per specimen. Separate specimens to be

used for each axis (6 shocks total per specimen).

NOTE The shock and bump tests are normally specified as alternatives.

2.3.4 Vibration severities

Test severities given in the detail specifications shall preferably be selected from the

following:

Test Fc (IEC 60068-2-6)

Frequency range: 10 Hz to 55 Hz or 10 Hz to 500 Hz

Amplitude: 0,75 mm or 100 m/s (whichever is the less severe)

Sweep endurance: Total duration 6 h.

Thermistors shall be mounted by their normal means, in such a manner that there shall be no

parasitic vibration. During vibration testing there shall be no interruption in electrical continuity

greater than 0,5 ms.

62319-1 IEC:2005(E) – 11 –

2.4 Marking

2.4.1 General

The following shall be clearly marked on the thermistor in the following order of precedence

as space permits:

a) values of the primary characteristics appropriate to the application of the thermistor to be

specified in the detail specification. When these values are coded (including colour

coding), details shall be given in the detail specification or type designation;

b) manufacturer's name and/or trade mark;

c) date of manufacture or date code;

d) the number of the detail specification and style.

The package containing the thermistors shall be clearly marked with all the information listed

above.

Any additional marking shall be so applied that no confusion can arise.

3 Quality assessment procedures

3.1 General

When these documents are being used for the purposes of a full quality assessment system

such as the IEC Quality Assessment System for Electronic Components (IECQ), compliance

with 3.5 is required.

When these documents are used outside such quality assessment systems for purposes such

as design proving or type testing, the procedures and requirements of 3.5.1 and 3.5.3 b) may

be used, but if used, the test and parts of tests shall be applied in the order given in the test

schedule.

Before thermistors can be qualified according to the procedures of this clause, the

manufacturer shall obtain the approval of his organisation in accordance with the provisions of

IECQ 001002-3.

The method for the approval of thermistors of assessed quality given in 3.5 is qualification

approval according to the provisions of Clause 3 of IECQ 001002-3.

3.1.1 Applicability of qualification approval

Qualification approval is appropriate for a standard range of thermistors manufactured to

similar design and production processes and conforming to a published detail specification.

The programme of tests defined in the detail specification for the appropriate assessment and

performance levels applies directly to the subfamily of thermistors to be qualified, as

prescribed in 3.5 and the relevant blank detail specification.

3.2 Primary stage of manufacture

The primary stage of manufacture is defined as the initial compounding process of the

ingredients.

– 12 – 62319-1 IEC:2005(E)

3.3 Subcontracting

If subcontracting of the primary stage of manufacture and/or subsequent stages is employed it

shall be in accordance with 4.2.2 of IECQ 001002-3.

The blank detail specification may restrict subcontracting in accordance with 4.2.2.2 of

IECQ 001002-3.

3.4 Structurally similar components

Thermistors may be grouped as structurally similar for the purpose of forming inspection lots

provided the following requirements are met:

a) they shall be produced by one manufacturer on one site using essentially the same

design, materials, processes and methods;

b) the sample taken shall be determined from the total lot size of the grouped devices;

c) structurally similar devices should preferably be included in one detail specification but the

details of all claims to structural similarity shall be declared in the qualification approval

test reports.

3.4.1 For electrical tests, devices having the same electrical characteristics may be

grouped provided the element determining the characteristic is similar for all the devices

concerned.

3.4.2 For environmental tests, devices having the same type of insulation, basic internal

structure and finishing processes may be grouped.

3.4.3 For visual inspection (except marking), devices may be grouped if they have been

made on the same production line, have the same dimensions, type of insulation and external

finish.

This grouping may also be used for robustness of terminations and soldering tests where it is

convenient to group devices with different internal structures.

3.4.4 For endurance tests, thermistors may be grouped if they have been made on the

same production line using the same design and differing only in electrical characteristics. If it

can be shown that one type from the group is more heavily stressed than the others then tests

on this type may be accepted for the remaining members of the group.

3.5 Qualification approval procedures

3.5.1 Eligibility for qualification approval

The manufacturer shall comply with 3.1.1 of IECQ 001002-3.

3.5.2 Application of qualification approval

The manufacturer shall comply with 3.1.3 of IECQ 001002-3.

3.5.3 Test procedures for qualification approval

One of the two following procedures shall be followed:

a) the manufacturer shall produce test evidence of conformance to the specification

requirements on three inspection lots for lot-by-lot inspection taken in as short a time as

possible and one lot for periodic inspection. No major changes in the manufacturing

process shall be made in the period during which the inspection lots are taken.

62319-1 IEC:2005(E) – 13 –

Samples shall be taken from the lots in accordance with IEC 60410. Normal inspection

shall be used, but when the sample size would give acceptance on zero non-

conformances, additional specimens shall be taken to meet the sample size requirements

to give acceptance on one non-conforming item.

b) the manufacturer shall produce test evidence to show conformance to the specification

requirements on the fixed sample size test schedule given in 3.5.4.

The specimens taken to form the sample shall be selected at random from current

production or as agreed with the National Supervising Inspectorate (NSI).

For the two procedures, the same sample sizes shall be of comparable order. The test

conditions and requirements shall be the same.

3.5.4 Qualification approval on the basis of the fixed sample size procedure

The fixed sample size test schedule for qualification approval given hereinafter is appropriate

to the intended application of the thermistor that is to be approved. The schedule provides

information on the test grouping and sampling and acceptance criteria. The conditions of test

and the end of test requirements shall be identical to those specified in the related blank

detail specification for the lot-by-lot and periodic tests.

Tests

The complete series of tests specified in Table 1 are required for the approval of thermistors

covered by the detail specification. The tests of each group shall be carried out in the order

given.

The whole sample shall be subjected to the tests of Group 0 and then divided for the other

groups.

Non-conforming specimens during the tests of Group 0 shall not be used for the other groups.

“One non-conforming item” is counted when a thermistor has not satisfied the whole or a part

of the tests of a group.

The approval is granted when the number of non-conformances does not exceed the specified

number of permissible non-conforming items for each group or subgroup and the total number

of permissible non conformances.

The following list applies to the test schedule detailed in Table 1:

a) clause number references are to clauses in this specification;

b) 1) where the test schedule of a blank detail specification omits a test, that test may be

omitted from the fixed sample size schedule in this specification;

2) where additional tests are specified in the detail specification, that test shall be included

in the fixed sample schedule, either by its addition to an existing group or, by the addition

of another group. In the former case there shall be no change in the number of specimens

to be tested or in the acceptance criteria. In the latter case the number of specimens to be

tested and the acceptance criteria shall be comparable to those already specified;

c) in this table:

n is the sample size;

c is the group acceptance criteria (permitted number of defectives per group);

D indicates a destructive test;

ND indicates a non-destructive test;

– 14 – 62319-1 IEC:2005(E)

d) the temperature at which the zero power resistance shall be measured is specified in the

detail specification. The temperature shall be stated, where required, in the test schedule;

e) data for conditions of test are defined in the detail specification;

f) the additional specimens are to permit substitution for incidents not attributable to the

manufacturer. The specimens may be used to replace non-conforming specimens which

occur as a result of a test in a group which is identified as being “destructive”. Where a

specimen is used for this purpose, it shall be subjected to those tests in the group to

which the non-conforming item had already been subjected, before proceeding with the

remaining tests in the group;

g) the specimens used for this group may, at the discretion of the manufacturer, be used for

any subsequent group which is identified as being “destructive”;

h) ten samples from Group 0 test samples have to be chosen, 5 having the lowest zero

power resistance of the samples shall be used for Group 1A, 5 having the highest zero

power resistance of the samples for Group 1B;

i) the soldering – solderability and soldering – resistance to soldering heat tests shall only

be applied where the thermistor has terminations which are appropriate for soldering;

j) where the terminations are stated to be suitable for printed wiring applications, the

appropriate test conditions in IEC 60068 shall apply;

k) the thermistors shall be mounted by their normal means;

l) the vibration, bump and shock tests are only conducted if required in the detail

specification.

62319-1 IEC:2005(E) – 15 –

Trip Residual Voltage

Group 0 current current and proof

5 pcs

Power

dissipation

80 pcs

Group 1

(+5 spare)

Destructive

Hold

5 pcs

current

(Power

dissipation

at I

hold

5 pcs Solder Robustness

heat

Group 2

Destructive

Tests

5 pcs Vibration Bump (or)

shock

Visual

Marking

Group 3 10 pcs Rapid temp.

Destructive

change

Zero

Group 4 10 pcs Detail

power

Non

Dimens.

resistance

Destructive

Group 5 10 pcs Cycle life

Destructive

Group 6 10 pcs Trip

Destructive

endurance

Group 7 10 pcs Climatic

Destructive

sequence

Cold envir.

Group 8 10 pcs

electr.

Destructive

Non

cycling

Destructive

Group 9 10 pcs Thermal

Destructive

runaway

Group 10 10 pcs Solderability

Destructive

IEC 218/05

Vibration, bump and shock tests are not required but may be performed to obtain

supplementary information.

Figure 1 – Test schedule flow chart

– 16 – 62319-1 IEC:2005(E)

Table 1 – Fixed sample size test schedule for qualification approval of polymeric PTC

thermistors for current limitation, assessment level EZ

Group Test Clause/subclause D or Number of Permissible

No of this standard ND specimens number of non-

conforming

items

n c

0 Visual examination 4.3.1 ND 80 + 5 0

Marking 4.3.2

Zero power resistance 4.4

1 D

1A Trip current 4.14 5 0

Residual current and power 4.16

dissipation

Voltage proof 4.6

1B Hold current 4.15 5 0

Power dissipation at I hold

Voltage proof 4.6

2A Resistance to soldering heat 4.8.2 D 5 0

Robustness of terminations 4.7

2B Vibration B.1 D 5 0

Bump (or) shock B.2 (or) B.3

3 Rapid change of temperature 4.10 D 10 0

4 Detail dimensions 4.3.3 ND 10 0

5 Cycle life 4.12 D 10 0

6 Trip endurance 4.13 D 10 0

7 Climatic sequence 4.11 D 10 0

8 Cold environmental electrical 4.18 D 10 0

cycling

9 Thermal runaway 4.19 D 10 0

10 Solderability 4.8.1 D 10 0

62319-1 © IEC:2005(E) – 17 –

3.5.5 Granting of qualification approval

Qualification approval shall be granted when the procedures in accordance with 3.1.4 of

IECQ 001002-3 have been completed satisfactorily.

3.5.6 Maintenance of qualification approval

Qualification approval shall be maintained by regular demonstration of compliance with the

requirements for quality conformance (see 3.5.7).

3.5.7 Quality conformance inspection

3.5.7.1 The blank detail specifications associated with this specification shall prescribe the

test schedule for quality conformance inspection. This schedule shall also specify the

grouping, sampling and periodicity for the lot-by-lot and periodic inspection (see Table 2 and

Table 3).

Sampling plans and inspection levels shall be selected from those given in IEC 60410.

If required, more than one schedule may be specified.

An inspection lot shall consist of thermistors of the same style. It should be representative of

those extremes of resistance and switching temperature range produced during the inspection

period.

The sample for Groups C and D shall be collected over the last 13 weeks of the inspection

procedure.

3.5.7.2 Assessment level

The assessment level given in the blank detail specification shall be in accordance with

Table 2 and Table 3.

Table 2 – Quality conformance inspection for lot-by-lot inspection

Inspection Assessment level

d

subgroup EZ

a a a

IL n c

b

A0 100 %

c

A1 S-4 0

c

A2 S-3 0

c

B1 S-2 0

c

B2 S-2 0

a

IL is the inspection level.

n is the sample size

c is the permissible number of non-conforming items

b

100 % testing shall be followed by re-inspection by sampling in order to monitor outgoing quality level by non-

-6

conforming items per million (10 ). The sampling level shall be established by the manufacturer. For the

-6

calculation of 10 values parametric failures shall be counted as a non-conforming item. In case one or more non-

conforming items occur in a sample, this lot shall be rejected.

c

Number to be tested: sample size as directly allocated to the code letter for IL in Table IIA of IEC 60410 (single

sampling plan for normal inspection)

d

The content of the inspection subgroups is described in Clause 2 of the relevant blank detail specification.

– 18 – 62319-1 IEC:2005(E)

Table 3 – Quality conformance inspection for periodic testing

Inspection Assessment level

b

subgroup EZ

a a a

p n c

C1A 24 5 0

C1B 24 5 0

C1 24 10 0

C2A 24 5 0

C2B 24 5 0

C3 24 10 0

C4 24 10 0

D1 24 10 0

D2 24 10 0

D3 24 10 0

a

p is the periodicity in months;

n is the sample size;

c is the permissible number of non-conforming items.

b

The content of the inspection subgroups is described in Clause 2 of the relevant blank detail

specification.

3.6 Rework and Repair

3.6.1 Rework

Rework, as defined in 4.1.4 of IECQ 001002-3, shall not be carried out if prohibited by the

relevant specification. The relevant specification shall state if there is a restriction on the

number of occasions that rework may take place on a specific component.

All rework shall be carried out prior to the formation of the inspection lot offered for inspection

to the requirements of the detail specification.

Such rework procedures shall be fully described in the relevant documentation produced by

the manufacturer and shall be carried out under the direct control of the designated

management representative (DMR). Rework shall not be subcontracted.

3.6.2 Repair

Thermistors which have been repaired as defined in IECQ 001002-3, shall not be released

under the IECQ system.

3.7 Release for delivery

Thermistors shall be released for delivery according to 3.2.6 and 4.3.2 of IECQ 001002-3,

after the Quality Conformance Inspection prescribed in the detail specification has been

carried out.

3.7.1 Release for delivery under qualification approval before the completion of

Group B tests

When the conditions of IEC 60410 for changing to reduced inspection have been satisfied for

all Group B tests, the manufacturer is permitted to release components before the completion

of such tests.

62319-1 IEC:2005(E) – 19 –

3.8 Certified test records of released lots

When certified test records are requested by a purchaser, they shall be specified in the detail

specification.

3.9 Delayed delivery

Thermistors held for a period exceeding three years (unless otherwise specified in the

relevant specification) following the release of the lot shall, before delivery, be re-examined

as specified in the relevant specification.

The re-examination procedure adopted by the manufacturer’s DMR shall by approved by the

NSI.

Once a lot has been satisfactorily re-inspected, its quality is re-assured for the specified

period.

3.10 Alternative test methods

See 3.2.3.7 of IECQ 001002-3 with the following details:

• in case of dispute, for referee and reference purposes, only the specified methods shall be

used.

3.11 Manufacture outside the geographical limits of IECQ NSIs

A manufacturer may have his approval extended to cover part or complete manufacture of

thermistors in a factory of his company located in a country which does not have a NSI for the

technical area concerned, whether this country is a IECQ member country or not, provided

that the requirements of 2.5.1.3 of IECQ 001002-3 are met.

3.12 Unchecked parameters

Only those parameters of a component which have been specified in a detail specification and

which were subject to testing shall be assumed to be within the specified limits.

It cannot be assumed that any unspecified parameter will remain unchanged from one

component to another. Should for any reason it be necessary for further parameters to be

controlled, then a new, more extensive specification shall be used.

The additional test method(s) shall be fully described and appropriate limits, sampling plans

and inspection levels specified.

4 Test and measurement procedures

This clause contains test and measurement procedures applicable to polymeric PTC

thermistors.

4.1 Standard conditions for testing

Unless otherwise specified, all tests shall be carried out under standard atmospheric

conditions for testing as specified in IEC 60068-1.

The thermistors shall attain thermal equilibrium before results are recorded.

The ambient temperature during the measurements shall be stated in the test report.

– 20 – 62319-1 IEC:2005(E)

During measurements, the thermistor shall not be exposed to draughts, direct sun rays or

other influences likely to cause error.

The total error of measurement from power dissipation, temperature tolerance and the

tolerance of the measuring equipment shall not exceed 10 % of the tolerance in the detail

specification.

The test shall be carried out in the prescribed order.

4.2 Drying and recovery

4.2.1 Drying

Where drying is called for in the specification, the thermistor shall be conditioned before

measurement is made, using Procedure 1 or Procedure 2 as called for in the detail

specification.

Procedure 1

For (24 ± 4) h in an oven at a temperature of (55 ± 2) °C and relative humidity not exceeding

20 %.

Procedure 2

For (36 ± 4) h in an oven at (100 ± 5) °C

The thermistor shall then be allowed to cool in a desiccator using a suitable desiccant such as

activated alumina or silica gel, and shall be kept therein from the time of the removal from the

oven to the beginning of the specified tests.

4.2.2 Recovery

Where recovery is required, the thermistor shall be stored at standard atmospheric conditions

for testing for 1 h to 2 h.

4.3 Visual inspection and check of dimensions

4.3.1 Visual examination

The condition, workmanship and finish shall be satisfactory as determined by visual

examination.

4.3.2 Marking

Marking shall be legible as determined by visual examination.

4.3.3 Dimensions (detail)

All dimensions prescribed in the detail specification shall be checked and they shall comply

with the values prescribed. Where applicable, measurements shall be made in accordance

with IEC 60294.

62319-1 IEC:2005(E) – 21 –

4.4 Zero-power resistance

4.4.1 The zero power resistance shall be measured at the temperature given in the detail

specification.

4.4.2 The thermistors shall be mounted by their normal means.

All measurements shall be made without self-heating of the devices (zero power condition).

The measuring method shall be such that:

a) for absolute resistance measurement, the error does not exceed 10 % of the resistance

tolerance;

b) for measurements of variation of resistance, the error does not exceed 10 % of the

specified maximum change of resistance.

The zero power resistance shall be within the limits given in the detail specification.

4.5 Insulation resistance (for insulated types only)

4.5.1 The insulation resistance of the protective coating shall be measured.

4.5.2 According to the instructions given in the detail specification one of the following test

methods is used.

Method 1

The thermistor is placed in a vessel containing metallic balls of (1,6 ± 0,2) mm diameter, so

that only the insulated parts of the thermistor are immersed (the metal of the balls shall be

such that it does not develop a resistive surface).

An electrode is placed in the metallic balls.

Method 2

A metal foil shall be wrapped closely around the body of the thermistor.

For those types not having axial terminations, a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...