IEC TR 62721:2012

(Main)Reliability of devices used in fibre optic systems - General and guidance

Reliability of devices used in fibre optic systems - General and guidance

IEC/TR 62721:2012(E) provides information on the IEC documents concerning reliability for optical fibres, optical connectors, optical passive components, optical active components, optical amplifiers, and optical dynamic modules used for optical fibre communications.

General Information

- Status

- Published

- Publication Date

- 09-Jan-2012

- Technical Committee

- TC 86 - Fibre optics

- Drafting Committee

- TC 86 - Fibre optics

- Current Stage

- PPUB - Publication issued

- Start Date

- 10-Jan-2012

- Completion Date

- 15-Apr-2012

Overview

IEC TR 62721:2012 - “Reliability of devices used in fibre optic systems – General and guidance” - is an IEC Technical Report from TC86 (Fibre optics) that collects and summarizes IEC documents and guidance on the reliability of components used in optical fibre communications. It covers reliability theory, failure modes, test methodologies and qualification approaches for optical fibres, optical connectors, passive and active optical components, optical amplifiers, and optical dynamic modules.

Key topics

- Scope and objective: Provides a consolidated reference to IEC reliability documents applicable to fibre optic products and modules.

- Reliability theory: Explains fundamentals such as the bathtub curve, design reliability vs field reliability, failure-rate metrics and common lifetime distributions (Weibull, lognormal).

- Failure mode analysis: Guidance on identifying degradation mechanisms (e.g., fibre crack growth, laser diode wear-out) and using failure-mode data to set tests and pass/fail criteria.

- Accelerated testing and lifetime estimation: Use of accelerated environmental and stress tests to derive acceleration factors and lifetime models.

- Qualification tests: Summaries of test items, conditions and qualification approaches used to establish merchantability and field readiness for modules composed of multiple parts.

- Test & measurement methods: References measurement standards and environmental test suites (e.g., mechanical, thermal, humidity) required for robust reliability assessment.

- Document mapping: Lists IEC standards and Technical Reports from TC86 subcommittees (SC86A, SC86B, SC86C) that apply to specific device classes.

Practical applications

IEC TR 62721 is useful for:

- Design and reliability engineers creating reliability plans, failure analyses and lifetime estimates for fibre-optic products.

- Test laboratories and qualification teams defining accelerated tests, pass/fail criteria and measurement methods.

- Manufacturers and suppliers of optical fibres, connectors, amplifiers, laser modules and dynamic modules seeking standardized reliability approaches.

- System integrators and network operators who need to understand component reliability expectations for deployment and maintenance planning.

- Standards developers and auditors mapping applicable IEC reliability documents across product categories.

Related standards

The report references and complements several IEC publications including (but not limited to):

- IEC 60068 (Environmental testing)

- IEC 60793-1 / 60794 (Optical fibres & cables tests)

- IEC 61300, IEC 62005 (Interconnecting devices, passive components, reliability)

- IEC 62150, IEC 62572 (Active components, laser modules)

- IEC 61290, IEC 62343 (Optical amplifiers, dynamic modules)

- IEC TRs on power law theory, failure mode analysis and laser degradation

For teams building or qualifying fibre‑optic systems, IEC TR 62721 is a centralized guide to the relevant IEC reliability documents and standard test methods, helping ensure consistent, defensible reliability assessments across the product lifecycle.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC TR 62721:2012 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Reliability of devices used in fibre optic systems - General and guidance". This standard covers: IEC/TR 62721:2012(E) provides information on the IEC documents concerning reliability for optical fibres, optical connectors, optical passive components, optical active components, optical amplifiers, and optical dynamic modules used for optical fibre communications.

IEC/TR 62721:2012(E) provides information on the IEC documents concerning reliability for optical fibres, optical connectors, optical passive components, optical active components, optical amplifiers, and optical dynamic modules used for optical fibre communications.

IEC TR 62721:2012 is classified under the following ICS (International Classification for Standards) categories: 33.180.01 - Fibre optic systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62721:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TR 62721 ®

Edition 1.0 2012-01

TECHNICAL

REPORT

Reliability of devices used in fibre optic systems – General and guidance

IEC/TR 62721:2012(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

IEC/TR 62721 ®

Edition 1.0 2012-01

TECHNICAL

REPORT

Reliability of devices used in fibre optic systems – General and guidance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

P

ICS 33.180.01 ISBN 978-2-88912-867-9

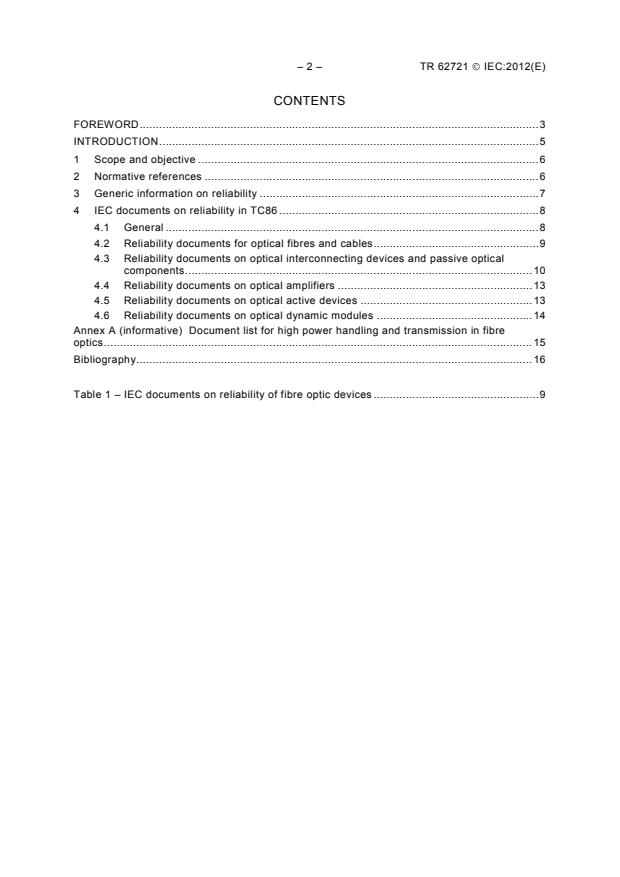

– 2 – TR 62721 IEC:2012(E)

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope and objective . 6

2 Normative references . 6

3 Generic information on reliability . 7

4 IEC documents on reliability in TC86 . 8

4.1 General . 8

4.2 Reliability documents for optical fibres and cables . 9

4.3 Reliability documents on optical interconnecting devices and passive optical

components . 10

4.4 Reliability documents on optical amplifiers . 13

4.5 Reliability documents on optical active devices . 13

4.6 Reliability documents on optical dynamic modules . 14

Annex A (informative) Document list for high power handling and transmission in fibre

optics . 15

Bibliography . 16

Table 1 – IEC documents on reliability of fibre optic devices . 9

TR 62721 IEC:2012(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RELIABILITY OF DEVICES USED IN FIBRE OPTIC SYSTEMS –

GENERAL AND GUIDANCE

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC 62721, which is a technical report, has been prepared by IEC technical committee 86:

Fibre optics.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

86/406/DTR 86/412/RVC

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – TR 62721 IEC:2012(E)

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

TR 62721 IEC:2012(E) – 5 –

INTRODUCTION

TC86 (Fibre optics) is a group that reviews and implements the standardization of optical

fibres and optical cables, optical interconnecting devices, passive and active optical

components and modules, and optical sub-systems. As these optical components and

modules are used for telecommunications as well as data communications systems, the

reliability required for these are extremely high. Since the 1980s, when fibre optic

communication systems were first deployed for commercial use, the reliability of optical fibres,

optical components and modules has been examined and checked. As a result, reliability

theories are nearly completely established for optical fibre, optical connectors, optical passive

components and optical active components.

How to check reliability differs depending on the type of optical device. For example, for

optical fibres, it is measured by the probability of fibre breaks under the condition of constant

stress. Optical passive components are generally tested using accelerated deterioration tests

under high temperature and high humidity conditions. For the reliability of laser diodes (LD) (a

typical optical active device), the primary failure mode is a decrease of optical output power

and an increase of threshold electric current caused by the increase of the leakage of

electrical current in the active layers of the LD chip. The lifetime has an inverse correlation

with the drive current.

In addition, the industry has established and uses standard reliability evaluation tests

developed for the purpose of commercialisation in addition to the approach of estimating the

lifetime by failure mode analysis mentioned above.

Information on failure mode and lifetime estimates are discussed and summarised in many

documents prepared by the Subcommittees (SC) and Working Groups (WG) of TC86. Test

items and conditions for reliability qualification tests are described in documents prepared and

set forth by each SC.

– 6 – TR 62721 IEC:2012(E)

RELIABILITY OF DEVICES USED IN FIBRE OPTIC SYSTEMS –

GENERAL AND GUIDANCE

1 Scope and objective

This technical report provides information on the IEC documents concerning reliability for

optical fibres, optical connectors, optical passive components, optical active components,

optical amplifiers, and optical dynamic modules used for optical fibre communications.

Documents on reliability include summaries of reliability theory and quality management

methods, technical information on failure mode analysis and failure mechanisms, lifetime and

fit-rate estimates using acceleration tests, test items, conditions, and pass/fail criteria in

reliability qualification tests, and tests and measurement methods for optical fibres, optical

components, and optical modules.

Each SC in TC86 has already created documents on reliability. This technical report provides

this information in a user-friendly manner.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068 (all parts), Environmental testing

IEC 60749 (all parts), Semiconductor devices – Mechanical and climatic test methods

IEC 60793-1 (all parts), Optical fibres – Part 1: Measurement methods and test procedures

IEC 60793-1-30, Optical fibres – Part 1-30: Measurement methods and test procedures –

Fibre proof test

IEC 60794-1-2, Optical fibre cables – Part 1-2: Generic specification – Basic optical cable test

procedures

IEC 61290 (all parts), Optical amplifiers – Test methods

IEC 61291-5-2, Optical amplifiers – Part 5-2: Qualification specifications – Reliability

qualification for optical fibre amplifiers

IEC 61300 (all parts), Fibre optic interconnecting devices and passive components – Basic

test and measurement procedures

IEC 62005 (all parts), Reliability of fibre optic interconnecting devices and passive

components

IEC 62007-2, Semiconductor optoelectronic devices for fibre optic system applications –

Part 2: Measuring methods

TR 62721 IEC:2012(E) – 7 –

IEC 62150 (all parts), Fibre optic active components and devices – Test and measurement

procedures

IEC 62343-2, Dynamic modules – Part 2: Reliability qualification

IEC 62343-5-1, Dynamic modules – Test methods – Part 5-1: Dynamic gain tilt equalizer –

Response time measurement

IEC 62572-3, Fibre optic active components and devices – Reliability standards – Part 3:

Laser modules used for telecommunication

IEC/TR 62048, Optical fibres – Reliability – Power law theory

IEC/TR 62343-6-6, Dynamic modules – Part 6-6: Failure mode effect analysis for optical units

of dynamic modules

IEC/TR 62572-2, Fibre optic active components and devices – Reliability standards – Part 2:

Laser module degradation

IEC/TR 62627-03-01, Fibre optic interconnecting devices and passive components –

Part 03-01: Reliability – Design of an acceptance test for fibre pistoning failure of connectors

during temperature and humidity cycling: demarcation analysis

3 Generic information on reliability

Reliability generally means the characteristics of keeping the required performance over a

long period of time and/or on repeated operation (driving). Components and modules degrade

and finally fail after long term operation. Reliability is usually expressed in this case as failure

rate per unit time (e.g. hours) or a time. The curve of the failure rate is called a bathtub curve,

and is generally divided into three regions: initial failure region, random failure region, and

wear-out failure region. Screening tests are sometimes applied to reduce the initial failure rate.

In the random failure region, the failure rate is independent of the operating time. In the wear-

out failure region, the failure rate increases as operating time extends. Generally, reliability is

expressed by the failure-in-test (fit) rate in the random failure region, and in the wear-out

failure region by the accumulated failure rate depending on the operating time of the product.

There are two types of reliability: design reliability and field reliability. Design reliability is

generally estimated by accelerated test results and/or calculated by a cumulative total of fit

rates of the parts and materials. Field reliability is generally calculated by the total failures

and the total operating hour volume in the field.

The following shows the standard approach to design reliability:

– Conducting a failure mode analysis and analysing the performance of the parts which

degrade and the factors that accelerate degradation;

– Determining the acceleration test conditions and the pass/fail criteria based on the results

of failure analysis;

– Carrying out acceleration tests under different conditions and obtaining the appropriate

functions to indicate the lifetime (i.e. the failure function (Weibull distribution, lognormal

distribution)) and the acceleration factor;

– Carrying out lifetime tests under suitable conditions of the accelerated tests to obtain more

accurate parameters for the lifetime distribution function and calculating the failure rate

and the accumulated failure rate.

Besides the reliability estimate obtained in the procedures based on the failure mode analysis

described above, conventional reliability qualification tests have been used for many types of

optical components and modules that consider the component environment. In particular,

– 8 – TR 62721 IEC:2012(E)

merchantability is often determined by the result of reliability qualification tests for modules

that are composed of several components and other functional components for which the

failure mode is difficult to identify.

4 IEC documents on reliability in TC86

4.1 General

TC86 (Fibre optics) consists of three Subcommittees: SC86A (Fibres and cables), SC86B

(Fibre optic interconnecting devices and passive optical components) and SC86C (Fibre optic

systems and active devices).

There are different approaches to failure mode and reliability depending on the products

handled by each Subcommittee.

It is generally known that a failure mode for silica-based optical fibres is where a small crack

on the surface and/or inside the fibre grows by constant stress and leads to fibre breaks.

The degradation mode and degradation accelerating factors for optical connectors and optical

passive components are very complex, as these optical components are fabricated by several

types of parts made from different materials. Reliability is determined by failure mode analysis

and based on the acceleration rate and reliability estimate result obtained by such analysis.

Another approach to ensure reliability is to conduct a reliability qualification test in the user

environment.

For a laser diode it is known that optical output power is decreased by the increase of

electrical current leakage in the active layers in the LD chip. It is caused by dislocation growth

and formation of dark spots and dark lines in the active area of the laser diode. This

degradation mode is one of the typical wear-out failures and information on this failure has

been sufficiently collected. In order to evaluate the reliability of the LD module, not the LD

chip itself, the test methods for passive optical components are generally applied.

Optical fibre amplifiers and dynamic modules are typically modules or sub-systems composed

of optical passive and active components. Reliability of these modules or sub-systems is

reliant on the reliability of the parts of the modules or sub-systems. Reliability (fit rates) of

modules is generally calculated by the cumulative sum of the fit rates of individual optical

component parts. Besides the estimation of the failure fit rate, some types of aging (long-term

operation) tests and mechanical tests are required to check the effect after mounting the

component parts.

Information on reliability includes failure mode analysis, lifetime estimate by acceleration tests,

and reliability qualification tests in addition to the general items on quality and reliability.

TC86 SCs and WGs have developed and published various documents relating to quality and

reliability in each product group.

Table 1 shows the TC86 classification mentioned above. Measuring methods are described in

the table, as the application of these in each test is important to confirm the reliability and

performance.

Failure and degradation relating to higher power is also of interest although different from the

issue of long-term reliability. Annex A gives a list of documents relating to higher power that

are published or in process within TC 86.

TR 62721 IEC:2012(E) – 9 –

Table 1 – IEC documents on reliability of fibre optic devices

Types of Optical fibre Optical passive Optical Optical active Dynamic modules

contents and cable components amplifiers devices

Generic of None IEC 62005-1 IEC 61291-5-2 IEC 62572-3 IEC 62343-2

reliability and IEC 62005-4

a)

quality IEC 62005-5

IEC 62005-7

Failure mode TR 62048 IEC 62005-3 None IEC/TR 62572-2 IEC/TR 62343-6-6

and/or

degradation

analysis

Lifetime TR 62048 IEC 62005-2 IEC 61291-5-2 IEC/TR 62572-2 IEC 62343-2

estimation and/or IEC/TR 62627-03-01

fit rate calculation

a

Reliability 60793-1-30 IEC 62005-9-1 IEC 61291-5-2 IEC 62572-3 IEC 62343-2

qualification test IEC 62005-9-2

a

IEC 62005-9-4

Test and 60793-1 series IEC 61300 series IEC 61290 IEC 60068 series IEC 62343-5 series

measurement 60794-1-2 series IEC 60749 series

IEC 62007-2

IEC series

a

To be published.

Details of reliability documents for each optical device are given in 4.2 to 4.6.

4.2 Reliability documents for optical fibres and cables

4.2.1 General

The reliability for silica optical fibre is described in IEC/TR 62048, which indicates how to

estimate and calculate the reliability of optical fibre under constant stress.

Break modes are roughly classified into dynamic fatigue and static fatigue. Test methods of

dynamic fatigue and static fatigue are defined by IEC 60793-1-33. The characteristics of

dynamic fatigue can be obtained by measuring the stress rate dependency of the break stress.

The characteristics of static fatigue are obtained by measuring the static stress dependency

found during the time to break.

Lifetime is estimated from the static fatigue measurement. A W

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...