IEC 62341-5-2:2013

(Main)Organic light emitting diode (OLED) displays - Part 5-2: Mechanical endurance testing methods

Organic light emitting diode (OLED) displays - Part 5-2: Mechanical endurance testing methods

IEC 62341-5-2:2013 defines testing methods for evaluating mechanical endurance quality of Organic Light Emitting Diode (OLED) display panels and modules or their packaged form for transportation. It takes into account, wherever possible, the environmental testing methods outlined in specific parts of IEC 60068. The object of this standard is to establish uniform preferred test methods for judging the mechanical endurance properties of OLED display devices.

Afficheurs à diodes électroluminescentes organiques (OLED) - Partie 5-2: Méthodes d'essais d'endurance mécanique

La CEI 62341-5-2:2013 définit des méthodes d'essais pour évaluer la qualité de l'endurance mécanique de modules et de panneaux d'affichage à diodes électroluminescentes organiques (OLED) ou de leur emballage d'expédition. Elle tient compte, dans la mesure du possible, des méthodes d'essais d'environnement indiquées dans des parties spécifiques de la CEI 60068. La présente norme a pour objet d'établir des méthodes d'essais préférentielles uniformes pour juger les propriétés d'endurance mécanique des dispositifs d'affichage OLED.

General Information

- Status

- Published

- Publication Date

- 08-Jul-2013

- Technical Committee

- TC 110 - Electronic displays

- Drafting Committee

- WG 5 - TC 110/WG 5

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 18-Mar-2019

- Completion Date

- 31-Jan-2017

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62341-5-2:2013 is an international standard developed by the International Electrotechnical Commission (IEC) for mechanical endurance testing of Organic Light Emitting Diode (OLED) displays. Specifically, this standard defines uniform test methods to evaluate the mechanical durability of OLED display panels, modules, or their packaged forms, especially concerning transportation conditions. It references related environmental test methods from IEC 60068 where applicable to ensure comprehensive assessment of mechanical endurance. The goal is to establish consistent testing procedures that enable manufacturers, testers, and users to verify the robustness and quality of OLED display devices against mechanical stresses.

Key Topics

Scope and Purpose

Defines standardized mechanical endurance tests to assess vibration, shock, strength, bending, drop impacts, and peel strength of OLED displays and modules.Mechanical Endurance Test Methods

Includes detailed methodologies for several testing techniques:- Sinusoidal vibration tests to simulate operational and transport vibrational stresses

- Shock testing for sudden impact resistance

- Quasistatic strength measurements to assess resistance under gradual load

- Four-point bending tests to determine flexural strength and durability

- Transportation package drop tests simulating real-world handling and shipping

- Peel strength tests to assess adhesion quality of OLED layers and lamination

Evaluation and Reporting

Provides instructions on visual examination, dimensional verification, and systematic reporting of results after mechanical tests to ensure clear assessment criteria and comparability.Standard Conditions and Test Apparatus

Specifies standard atmospheric conditions and recommends appropriate test equipment and setup configurations to guarantee replicable and reliable results.

Applications

OLED Display Manufacturing

Manufacturers can apply IEC 62341-5-2 testing methods during production to ensure OLED display robustness, reduce product failures, and improve yield quality.Quality Assurance and Certification

Quality control labs and certification bodies use this standard to validate mechanical endurance claims and conformity with international benchmarks.Transportation and Logistics

Testing packaged OLED modules against standardized drop and vibration stress helps in designing protective packaging and optimizing shipping methods to minimize damages.Research and Development

R&D teams leverage these testing methods to evaluate new materials, flexible display technologies, or innovative packaging solutions for enhanced mechanical durability.Supplier and OEM Collaboration

Shared adherence to IEC 62341-5-2 fosters better communication and trust between component suppliers, OEMs, and integrators by ensuring standardized test results.

Related Standards

IEC 60068 Series

Provides environmental testing frameworks for electrical and electronic equipment, which are referenced within IEC 62341-5-2 for environmental conditions related to mechanical testing.IEC 62341 Series

The broader IEC 62341 family of standards covers all aspects of OLED display technology, including electrical, optical, and mechanical characteristics, ensuring comprehensive device evaluation.ISO/IEC Directives Part 2

Guidelines for the drafting and development of international standards ensuring consistency and clarity in IEC publication methodologies and formatting.

Summary

IEC 62341-5-2:2013 is essential for stakeholders in the OLED display industry aiming to maintain high mechanical endurance standards. Through standardized vibration, shock, bending, drop, and peel tests, this document supports the evaluation and improvement of OLED devices' durability. Its rigorous testing approaches help enhance product reliability during manufacturing, handling, transportation, and end-use, contributing to reduced failures and customer satisfaction. OEMs, manufacturers, testing labs, and logistics providers benefit from adopting the procedures detailed in this international standard to align with global quality and safety expectations.

Frequently Asked Questions

IEC 62341-5-2:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Organic light emitting diode (OLED) displays - Part 5-2: Mechanical endurance testing methods". This standard covers: IEC 62341-5-2:2013 defines testing methods for evaluating mechanical endurance quality of Organic Light Emitting Diode (OLED) display panels and modules or their packaged form for transportation. It takes into account, wherever possible, the environmental testing methods outlined in specific parts of IEC 60068. The object of this standard is to establish uniform preferred test methods for judging the mechanical endurance properties of OLED display devices.

IEC 62341-5-2:2013 defines testing methods for evaluating mechanical endurance quality of Organic Light Emitting Diode (OLED) display panels and modules or their packaged form for transportation. It takes into account, wherever possible, the environmental testing methods outlined in specific parts of IEC 60068. The object of this standard is to establish uniform preferred test methods for judging the mechanical endurance properties of OLED display devices.

IEC 62341-5-2:2013 is classified under the following ICS (International Classification for Standards) categories: 31.260 - Optoelectronics. Laser equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62341-5-2:2013 has the following relationships with other standards: It is inter standard links to IEC 62341-5-2:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62341-5-2:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62341-5-2 ®

Edition 1.0 2013-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Organic light emitting diode (OLED) displays –

Part 5-2: Mechanical endurance testing methods

Afficheurs à diodes électroluminescentes organiques (OLED) –

Partie 5-2: Méthodes d’essais d'endurance mécanique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62341-5-2 ®

Edition 1.0 2013-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Organic light emitting diode (OLED) displays –

Part 5-2: Mechanical endurance testing methods

Afficheurs à diodes électroluminescentes organiques (OLED) –

Partie 5-2: Méthodes d’essais d'endurance mécanique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX U

ICS 31.260 ISBN 978-2-8322-0964-6

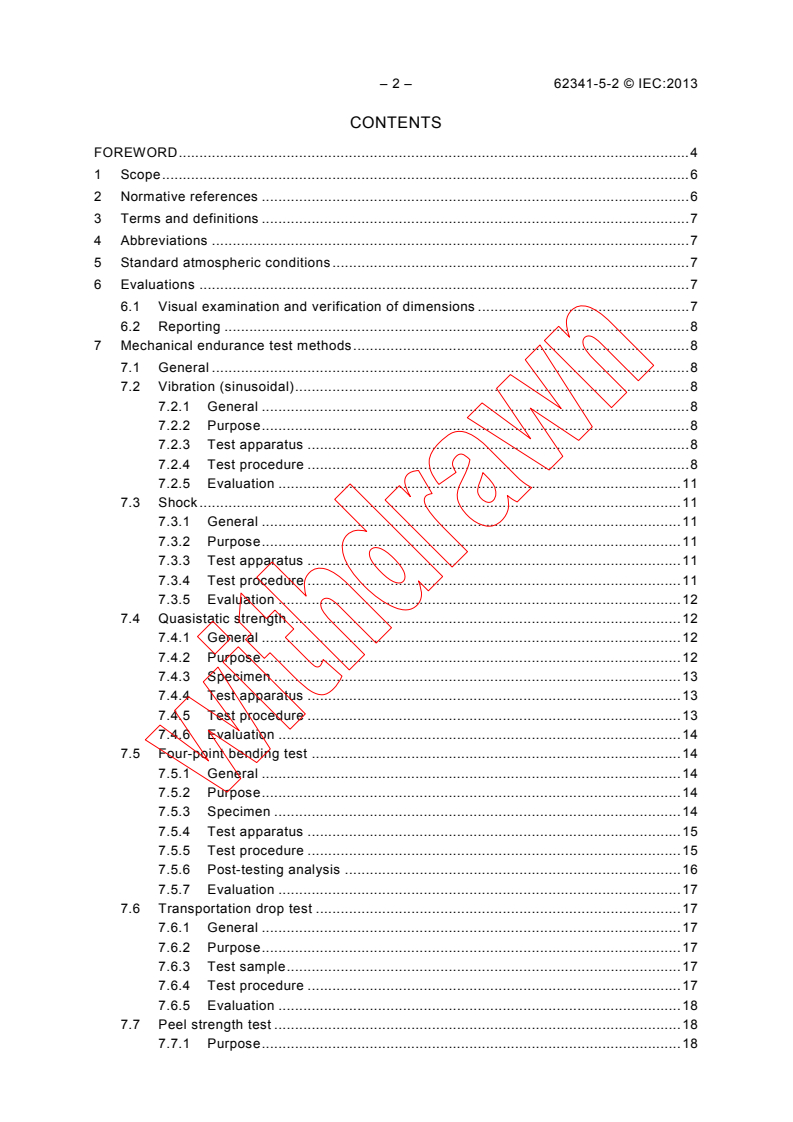

– 2 – 62341-5-2 © IEC:2013

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Abbreviations . 7

5 Standard atmospheric conditions . 7

6 Evaluations . 7

6.1 Visual examination and verification of dimensions . 7

6.2 Reporting . 8

7 Mechanical endurance test methods . 8

7.1 General . 8

7.2 Vibration (sinusoidal) . 8

7.2.1 General . 8

7.2.2 Purpose . 8

7.2.3 Test apparatus . 8

7.2.4 Test procedure . 8

7.2.5 Evaluation . 11

7.3 Shock . 11

7.3.1 General . 11

7.3.2 Purpose . 11

7.3.3 Test apparatus . 11

7.3.4 Test procedure . 11

7.3.5 Evaluation . 12

7.4 Quasistatic strength . 12

7.4.1 General . 12

7.4.2 Purpose . 12

7.4.3 Specimen . 13

7.4.4 Test apparatus . 13

7.4.5 Test procedure . 13

7.4.6 Evaluation . 14

7.5 Four-point bending test . 14

7.5.1 General . 14

7.5.2 Purpose . 14

7.5.3 Specimen . 14

7.5.4 Test apparatus . 15

7.5.5 Test procedure . 15

7.5.6 Post-testing analysis . 16

7.5.7 Evaluation . 17

7.6 Transportation drop test . 17

7.6.1 General . 17

7.6.2 Purpose . 17

7.6.3 Test sample . 17

7.6.4 Test procedure . 17

7.6.5 Evaluation . 18

7.7 Peel strength test . 18

7.7.1 Purpose . 18

62341-5-2 © IEC:2013 – 3 –

7.7.2 Test procedure . 18

7.7.3 Evaluation . 19

Annex A (informative) Example of the raw test data reduction for four-point bending

test . 20

Bibliography . 28

Figure 1 – Configuration of OLED shock test set-up . 11

Figure 2 – Schematic of quasistatic strength measurement apparatus example . 13

Figure 3 – Schematics of test apparatus and pinned bearing edges . 15

Figure 4 – Specimen configuration under four-point bending test . 15

Figure 5 – Order of transportation package drop . 18

Figure 6 – Example of peeling strength test . 19

Figure A.1 – Specimen dimensions used for sample test . 20

Figure A.3 – Finite element model of test specimen . 22

Figure A.4 – Displacement contour map after moving down loading-bar by 2 mm . 23

Figure A.5 – Contour map of maximum principal stress distribution . 23

Figure A.6 – Maximum principal stress and maximum stress along the edge . 24

Figure A.7 – Final relationship between panel strength and failure load . 24

Figure A.8 – Extraction of conversion factor by linear fitting . 25

Figure A.9 – Example of Weibull distribution of strength data and statistical outputs . 27

Figure A.10 – Fitted failure probability distribution of strength data . 27

Table 1 – Frequency range – Lower end . 9

Table 2 – Frequency range – Upper end . 9

Table 3 – Recommended frequency ranges . 10

Table 4 – Recommended vibration amplitudes . 10

Table 5 – Conditions for shock test . 12

Table 6 – Examples of test parameter combinations . 16

Table 7 – Example of package drop sequence . 18

Table A.1 – Results of raw test data . 21

Table A.2 – Example of conversion factor (t = 0,4 mm, test span = 20 mm/40 mm) . 25

Table A.3 – Failure load and converted strength data . 26

– 4 – 62341-5-2 © IEC:2013

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ORGANIC LIGHT EMITTING DIODE (OLED) DISPLAYS –

Part 5-2: Mechanical endurance testing methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62341-5-2 has been prepared by IEC technical committee 110:

Electronic display devices.

The text of this standard is based on the following documents:

FDIS Report on voting

110/472/FDIS 110/486/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62341 series, published under the general title Organic light

emitting diode (OLED) displays, can be found on the IEC website.

62341-5-2 © IEC:2013 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 62341-5-2 © IEC:2013

ORGANIC LIGHT EMITTING DIODE (OLED) DISPLAYS –

Part 5-2: Mechanical endurance testing methods

1 Scope

This part of IEC 62341 defines testing methods for evaluating mechanical endurance quality

of Organic Light Emitting Diode (OLED) display panels and modules or their packaged form

for transportation. It takes into account, wherever possible, the environmental testing methods

outlined in specific parts of IEC 60068. The object of this standard is to establish uniform

preferred test methods for judging the mechanical endurance properties of OLED display

devices.

There are generally two categories of mechanical endurance tests: those relating to the

product usage environment and those relating to the transportation environment in packaged

form. Vibration, shock, quasistatic strength, four-point bending test and peel strength test are

introduced here for usage environment, while transportation drop test is applicable to the

transportation environment. Mechanical endurance tests may also be categorized into mobile

application, notebook computer or monitor application and large size TV application. Special

considerations or limitations of test methods according to the size or application of the

specimen will be noted.

NOTE This standard is established separately from IEC 61747-5-3, because the technology of organic light

emitting diodes is considerably different from that of liquid crystal devices in such matters as:

– used materials and structure;

– operation principles;

– measuring methods.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-6:2007, Environmental testing – Part 2-6: Tests–Test Fc: Vibration (sinusoidal)

IEC 60068-2-27:2008, Environmental testing – Part 2-27: Tests–Test Ea and guidance: Shock

IEC 61747-5:1998, Liquid crystal and solid-state display devices – Part 5: Environmental,

endurance and mechanical test methods

IEC 61747-5-3:2009, Liquid crystal display devices – Part 5-3: Environmental, endurance and

mechanical test methods – Glass strength and reliability

IEC 62341-1-2:2007, Organic light emitting diode displays – Part 1-2: Terminology and letter

symbols

IEC 62341-5:2009, Organic light emitting diode (OLED) displays – Part 5: Environmental

testing methods

IEC 62341-6-1:2009, Organic light emitting diode (OLED) displays – Part 6-1: Measuring

methods of optical and electro-optical parameters

62341-5-2 © IEC:2013 – 7 –

IEC 62341-6-2:2012, Organic light emitting diode (OLED) displays – Part 6-2: Measuring

methods of visual quality and ambient performance

ISO 2206:1987, Packaging – Complete, filled transport packages – Identification of parts

when testing

ISO 2248:1985, Packaging – Complete, filled transport packages – Vertical impact test by

dropping

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62341-1-2 and the

following apply.

3.1

strength

stress at which a sample fails for a given loading condition

3.2

glass edge strength

measured stress at failure where the failure origin is known to have occurred at an edge

4 Abbreviations

FEA finite element analysis

FPCB flexible printed circuit board

B the value at lower 10 % position in the Weibull distribution [1]

TSP touch screen panel

5 Standard atmospheric conditions

The standard atmospheric conditions in IEC 62341-5:2009, 5.3, shall apply unless otherwise

specifically agreed between customer and supplier.

6 Evaluations

6.1 Visual examination and verification of dimensions

The specimen shall be submitted to the visual, dimensional checks in non-operation condition

and functional checks in operational condition prescribed by the following specification.

a) Visual checks of damage to exterior body of the specimen including marking,

encapsulation and terminals shall be examined as specified in IEC 61747-5:1998, 1.5.

b) Dimensions given in the customer’s specification shall be verified.

c) Visual and optical performance shall be checked as specified in IEC 62341-6-1.

Unless otherwise specified, visual inspection shall be performed under the conditions and

methods as specified in IEC 62341-6-2:2012, 6.2.

———————

Numbers in square brackets refer to the bibliography.

– 8 – 62341-5-2 © IEC:2013

6.2 Reporting

For the main results in each test, generally the minimum and averaged values or B value

instead of minimum value shall be reported over the number of specimens depending on the

test purposes. The relevant specification shall provide the criteria upon which the acceptance

or rejection of the specimen is to be based.

7 Mechanical endurance test methods

7.1 General

Choice of the appropriate tests depends on the type of devices. The relevant specification

shall state which tests are applicable.

7.2 Vibration (sinusoidal)

7.2.1 General

Test Fc, specified in IEC 60068-2-6 and IEC 61747-5:1998, 2.3, are applicable with the

following specific conditions. In case of contradiction between these standards,

IEC 61747-5:1998, 2.3, shall govern.

7.2.2 Purpose

The purpose of this test is to investigate the behaviour of the specimen in a vibration

environment such as transportation or in actual use.

7.2.3 Test apparatus

The equipment shall be capable of maintaining the test conditions specified in 7.2.4. The

vibration testing table should not resonate within the test condition vibration frequency range.

The required characteristics apply to the complete vibration system, which includes the power

amplifier, vibrator, test fixture, specimen and control system when loaded for testing. The

body of the device shall be securely clamped during the test. If the device has a specified

method of installation, it shall be used to clamp the device. The specimen shall be tested

under the non-operational condition.

7.2.4 Test procedure

7.2.4.1 Test conditions

7.2.4.1.1 Basic motion

The basic motion shall be a sinusoidal function of time and such that the fixing points of the

specimen move substantially in phase and in straight parallel lines.

7.2.4.1.2 Spurious motion

The maximum amplitude of spurious transverse motion at the check points in any

perpendicular to the specified axis shall not exceed 25 %. In the case of large size or high

mass specimens, the occurrence of spurious rotational motion of the vibration table may be

important. If so, the relevant specification shall prescribe a tolerance level.

7.2.4.1.3 Signal tolerance

Unless otherwise stated in the relevant specification, acceleration signal tolerance

measurements shall be performed and signal tolerance shall not exceed 5 %.

62341-5-2 © IEC:2013 – 9 –

7.2.4.1.4 Vibration amplitude tolerance

Reference point: ± 15 %;

Check point: ± 25 %.

7.2.4.1.5 Frequency tolerances

7.2.4.1.5.1 Endurance by sweeping

± 1 Hz from 5 Hz to 50 Hz;

± 2 % above 50 Hz.

7.2.4.1.5.2 Endurance at critical frequencies

± 2 %.

7.2.4.2 Severities

7.2.4.2.1 General

A vibration severity is defined by the combination of the three parameters: frequency range,

vibration amplitude and duration of endurance (in sweep cycles or time).

7.2.4.2.2 Frequency range

The frequency range shall be given in the relevant specification by selecting a lower

frequency from Table 1 and an upper frequency from Table 2.

Table 1 – Frequency range – Lower end

Lower frequency f

Hz

Table 2 – Frequency range – Upper end

Upper frequency f

Hz

– 10 – 62341-5-2 © IEC:2013

The recommended ranges are shown in Table 3.

Table 3 – Recommended frequency ranges

Recommended frequency ranges, from

f to f

1 2

Hz

5 to 100

5 to 200

5 to 500

10 to 55

10 to 200

10 to 300

10 to 500

7.2.4.2.3 Vibration Amplitude

The vibration amplitude shall be stated in the relevant specification. Recommended vibration

amplitudes with cross-over frequency are shown in Table 4.

Table 4 – Recommended vibration amplitudes

Displacement amplitude

Acceleration amplitude above the cross-over frequency

below the cross-over

frequency

g

m/s

n

mm

0,035 4,9 0,5

0,075 9,8 1,0

0,10 14,7 1,5

0,15 19,6 2,0

0,20 2,4 3,0

NOTE The values listed apply in Table 4 for cross-over frequencies between 57 Hz and 62 Hz.

7.2.4.2.4 Duration of endurance

7.2.4.2.4.1 Endurance by sweeping

The duration of the endurance test in each axis shall be given as a number of sweep cycles

chosen from the list given below.

1, 5, 10, 20, 30, 45, 60, 120

The sweeping shall be continuous and the frequency shall change exponentially with time.

The endurance time associated with number of sweep cycles or sweep rate in octaves/minute

shall be specified. During the vibration response investigation, the specimen and the vibration

response data shall be examined in order to determine critical frequencies.

7.2.4.2.4.2 Endurance at critical frequencies

The duration of the endurance test in each axis at the critical frequencies found during the

vibration response investigation shall be chosen from the list given below. This test shall be

repeated for the number of critical frequencies as specified by the relevant specification.

10 min, 15 min, 30 min, 90 min.

62341-5-2 © IEC:2013 – 11 –

7.2.5 Evaluation

After the test, visual, dimensional and functional checks shall be performed and compared as

described in 6.1.

7.3 Shock

7.3.1 General

IEC 60068-2-27 and 61747-5:1998, 2.4, shall be applied with the following specific conditions.

In case of contradiction between these standards, IEC 61747-5:1998, 2.4, shall govern.

7.3.2 Purpose

This test is to provide a standard procedure for determining the ability of an OLED panel or

module to withstand specified severities of shock. During transportation or in use, an OLED

panel or module may be subjected to conditions involving relatively non-repetitive shocks.

7.3.3 Test apparatus

The body of the specimen shall be securely clamped during the test in the test direction

aligning with the z-axis of the test machine; for example, Figure 1 depicts shock test along the

y’-direction of the specimen. If the device has a specified method of installation, it shall be

used to clamp the device.

Clamp

OLED

OLED

module

module

y′

OLED

module

y′

z

y

x′

x

z′

IEC 1686/13

a) Example of a shock test machine b) Test direction of a specimen

Figure 1 – Configuration of OLED shock test set-up

7.3.4 Test procedure

Test Ea, specified in IEC 60068-2-27, is applicable, with the following specific requirements.

The conditions shall be selected from Table 5, taking into consideration the mass of the

device and its internal construction.

– 12 – 62341-5-2 © IEC:2013

Table 5 – Conditions for shock test

Peak amplitude A Corresponding velocity change

Corresponding duration D of the

ΔV

nominal pulse

Half-sine Trapezoidal

m/s (g ) ms m/s m/s

n

50 (5) 30 1,0 -

150 (15) 11 1,0 1,5

300 (30) 18 3,4 4,8

300 (30) 11 2,1 2,9

300 (30) 6 1,1 1,6

500 (50) 11 3,4 4,9

500 (50) 3 0,9 1,3

1 000 (100) 11 6,9 9,7

1 000 (100) 6 3,7 5,3

2 000 (200) 6 7,5 10,6

2 000 (200) 3 3,7 5,3

5 000 (500) 1 3,1 -

10 000 (1 000) 1 6,2 -

NOTE Preferred values are underlined.

The choice of waveform to be used depends on a number of factors, and difficulties inherent

in making such a choice preclude a preferred order being given in the standard (see

IEC 60068-2-27:2008, Clause A.3). The relevant specification shall state the waveform

utilized.

Unless otherwise prescribed by the relevant specification, three successive shocks shall be

applied in each direction of three mutually perpendicular axes of the specimen, for a total of

18 shocks. Depending on the number of identical devices available and the mounting

arrangements, particularly in the case of components, they may be oriented such that the

multiple axis/direction requirements of the relevant specification can be met by the application

of three shocks in one direction only (see IEC 60068-2-27:2008, Clause A.7).

7.3.5 Evaluation

Visual, dimensional and functional checks shall be performed and compared as described in

6.1 to the relevant specification.

7.4 Quasistatic strength

7.4.1 General

IEC 61747-5-3:2009, 5.4, is applicable with the following specific conditions.

7.4.2 Purpose

The objective of this standard is to establish uniform requirements for accurate and reliable

measurements of the quasistatic strength of OLED panels or modules. The quasistatic

strength of OLED module may be specified to ensure the mechanical endurance level from

the quasistatic external loadings in and around the display area in normal use, such as sitting

on the product or touching/pushing fingertip in the display area.

62341-5-2 © IEC:2013 – 13 –

7.4.3 Specimen

This standard applies to the OLED panels or modules for mobile and IT application. OLED

module products incorporating additional components, e.g. TSP, protective film and window

cover may be used as an acceptable form of the specimen. In all cases a minimum sample

size of at least 6 panels or modules shall be used to obtain a statistically significant strength

distribution representative of quasistatic resistance of the specimen to external loadings

induced by handling, processing and fabrication of the specimen specified as a part of the end

product.

F

Metal rod

Specimen

Frame with

cavity

Hard plate

IEC 1687/13

a) Boundary support with cavity b) Side support

Figure 2 – Schematic of quasistatic strength measurement apparatus example

7.4.4 Test apparatus

The quasistatic strength of a specimen is measured by supporting the specimen on the

mounting frame and loading it at the center as shown in Figure 2. The specimen shall be put

on the frame with the rectangular cavity as shown in Figure 2a) or on side supports as shown

in Figure 2b). The size of a rectangular cavity in the frame (Figure 2a)) shall be specified by

the relevant specification and shall be as big as the edge of the supporting area allows. It is

recommended to set the cavity to be around the active area size for mobile application. The

tip of metal loading bar shall be rounded in shape and the diameter of the metal rod varies

according to the specimen size under testing. It is recommended to use a metal rod of 10 mm

in diameter for the samples up to 101,6 mm (4 inches) display diagonal length. For larger

modules, such as for notebook computer or monitor applications, a rod of 19 mm diameter is

recommended. The same apparatus may also be used for loading the OLED module off-

center and obtaining its strength at different locations. For TV applications, this quasistatic

strength test is generally not applicable.

7.4.5 Test procedure

7.4.5.1 General

The displacement rate should be slow enough so that there is no significant dynamic

response from the loading such that the maximum strain rate upon specimen shall be of the

-4 -1

order of 1,0 × 10 s [3]. Typical loading rate or crosshead speed is 3 mm/min or 5 mm/min

for small size displays such that failure may occur within the measurement time of 30 s to

45 s. Depending on the purpose of the test, the following test procedure may be applied.

– 14 – 62341-5-2 © IEC:2013

7.4.5.2 Static loading resistance

For this test, a specified load is set to assess module resistance to external static load from

the relevant specification. A specified load is set and load is applied on the surface of the

specimen by lowering the metal rod as shown in Figure 2. After reaching the specified load,

the rod is set to return back to starting position. Multiple loads may be applied in steps. The

loading position of the specimen shall be the center of the active area of the display, but

multiple loading positions including off-center position may also be applied depending on the

area of interest.

7.4.5.3 Quasistatic failure load

In the continuation of the specified load test in 7.4.5.2, this test is intended to measure the

failure load. The metal rod is lowered to push the surface of the specimen until the specimen

breaks. The specimen is categorized as a failure when the applied load starts to drop by more

than a designated portion, e.g. 2 % of the peak load value.

7.4.6 Evaluation

For the static load test, the relevant specification shall provide the specified load level upon

which the acceptance or rejection of the resistance of specimen is to be based. For the failure

load test in 7.4.5.3, the average, maximum and minimum values along with failure load of

each test specimen are reported. It shall be noted in the test reporting about the specimen if it

incorporates any additional component.

7.5 Four-point bending test

7.5.1 General

This standard is established separately from IEC 61747-5-3, where the characterization of

glass component is particularly emphasized. Quasistatic strength of the edges of glass or

simply flexural strength of OLED panels and the integrity of the panel structure are assessed

in the four-point bending test configuration. Even though there is no limitation in use of four-

point bending test on the size of display panel, this test is generally applicable for mobile

applications, which is at most 101,6 mm in diagonal size.

7.5.2 Purpose

The four-point bending test is important since the result of this test can be used as an

indicator of the mechanical endurance level when either panel sample or module sample is

exposed to various mechanical loadings under hostile usage conditions, such as twisting a

handset, etc. For the purpose of this test, glasses in OLED display panels are considered

brittle and to have the property that fracture normally occurs at the surface of the glass from

the maximum tensile stress. The failure strength of display module is determined when a

weakest component in the specimen fails. Depending on the panel structure, the weakest link

could be inferior edge of glass or other failure origins, such as disintegration of sealing

material. The four-point bending test is recommended since it distributes the maximum tensile

stress over a larger volume or area in comparison to the three-point bending test.

7.5.3 Specimen

The specimen is a display panel consisting of rear and front glasses. The test specimen may

contain a polarizer; however, it is not necessary if the testing is done at production phase

where the polarizers have not yet been placed. The use of polarizer or other low elastic

modulus tape is permitted on the specimen surface to hold the cracked fragments and permit

observation of crack origin. At least 10 specimens shall be used for the purpose of estimating

the mean. A minimum of 20 specimens shall be necessary if estimates regarding the form of

strength distribution are to be reported. Unless otherwise taken for specific purpose, the

samples shall be taken from several sheets or regions of a single sheet from which the

display panels are made. Any specimen may be rejected prior to testing for defects

62341-5-2 © IEC:2013 – 15 –

considered likely to affect the quasistatic strength of the edges of glass. The variation in width

or thickness shall not exceed 5 % over the length of the specimen equal to the support span.

7.5.4 Test apparatus

7.5.4.1 Testing machine

The testing machine consists of a test frame and a four-point bending test fixture. Figure 3

illustrates an example of four-point bending test fixture with an OLED panel specimen. The

test frame consists of a vertical loading machine, which could be electromechanical, servo-

hydraulic or pneumatic driven, a load cell mounted and controller software. It is assumed that

the fixtures are relatively rigid and that most of the testing-machine crosshead travel is

imposed as strain on the specimen. There are also several requirements for a four-point

bending apparatus to be met in order to ensure reliable data with minimal variation [2].

7.5.4.2 Bearing cylinders

Cylindrical bearing edges shall be used for the support of the specimen and for the

application of the load. The bearing cylinder radius shall be approximately 2 mm to 5 mm

depending on the thickness of the specimen [3]. The cylinders shall be made of sufficiently

hardened steel to prevent excessive deformation under load and free to roll in order to relieve

frictional constraints. Moreover two loading bearings and one support bearing cylinder also

shall be provided to rotate laterally to compensate for any irregular surface contact with

specimen and to ensure uniform and even distribution of load between the two inner bearing

edges. Figure 3 shows a suitable arrangement using pinned bearing assemblies.

d d

Bearing

Panel

cylinders

front

Test

fixture

IEC 1688/13

b) Front view

a) Side view

Figure 3 – Schematics of test apparatus and pinned bearing edges

S

L

S

L

z

z

y y

x

S

S

S

S

x

L

L

IEC 1689/13

b) Y-direction bending

a) X-direction bending

Figure 4 – Specimen configuration under four-point bending test

7.5.5 Test procedure

The specimen length, L is determined as the length of either the long side or short side of the

front glass as described in Figure 4a) and Figure 4b), respectively. The amount of overhang

of the specimen, d in Figure 3 shall be at least 2 mm beyond the outer bearings to allow the

– 16 – 62341-5-2 © IEC:2013

specimen to slide over the support and to eliminate the effect of the specimen’s end condition.

Slowly apply the load at right angles to the fixture. The maximum permissible stress in the

specimen due to initial load shall not exceed 25 % of the mean strength. In four-point bending

test, a specimen is loaded at constant displacement rate until rupture. The displacement rate

to be used depends on the chosen spans and it is chosen such that the time to complete one

test cycle would be sufficiently long as described in 7.4.5.1 while times to failure for a typical

specimen range from 30 s to 45 s. In Table 6 some examples of the combinations of test

configurations and displacement rates are given.

Table 6 – Examples of test parameter combinations

Displacement rate

S (mm) S (mm)

L (mm)

S L

(mm/min)

25 20 10 3

45 40 20 5

85 80 40 10

Specifically the span between the test jig and loading rollers needs to be adjusted for a

) and load span (S ) to cover most

different specimen size with a specified support span (S

S L

part of panel edge under bending. On the other hand, to prevent the effect of bending area

size on glass edge strength and to test under the same strength criteria regardless of the

specimen sizes tested, a constant load span and support span may be specified. In any case,

the load span shall be the half of the support span [3]. The bearing cylinders shall be carefully

positioned such that the spans are accurate within ± 0,10 mm.

7.5.6 Post-testing analysis

7.5.6.1 Breakage origin analysis

Since OLED panels may have different structures for various emission mechanisms and

encapsulation schemes, potentially they may exhibit unique fracture mechanisms. And hence,

fracture origin of a specimen under four-point bending test may be different. Therefore, it is

required and important to ensure this four-point bending test method is valid for assessing the

mechanical endurance in the area of interest. Frequently, break origin analysis through

fractography is conducted to review the failure origin of the panel. Potential failure modes

include inferior edge quality, or weak integrity of adhesion material, and/or other structure

weaknesses.

7.5.6.2 Test result analysis

The mechanical testing unit used for four-point bending test reports failure load when a

specimen under the test procedures described in this test method fails. It is very important to

convert these failure load values into a standardized expression of failure stress,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...