IEC 60455-2:2023

(Main)Resin based reactive compounds used for electrical insulation - Part 2: Methods of test

Resin based reactive compounds used for electrical insulation - Part 2: Methods of test

IEC 60455-2:2023 specifies methods of test to be used for testing resin based reactive compounds, their components and cured compounds used for electrical insulation. This fourth edition cancels and replaces the third edition published in 2015. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) Introduction of test methods related to IEC 60455-3-8;

b) Additional and updated test methods for resins.

Composés réactifs à base de résines utilisés comme isolants électriques - Partie 2: Méthodes d'essai

L'IEC 60455-2:2023 spécifie les méthodes d'essai à utiliser pour vérifier les composés réactifs à base de résines, leurs composants et les composés durcis, utilisés pour l'isolation électrique. Cette quatrième édition annule et remplace la troisième édition parue en 2015. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) introduction des méthodes d'essai de l'IEC 60455-3-8;

b) ajout et mise à jour des méthodes d'essai pour les résines.

General Information

- Status

- Published

- Publication Date

- 26-Jul-2023

- Technical Committee

- TC 15 - Solid electrical insulating materials

- Drafting Committee

- WG 7 - TC 15/WG 7

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Jul-2023

- Completion Date

- 25-Aug-2023

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60455-2:2023 - Resin based reactive compounds used for electrical insulation - Part 2: Methods of test specifies standardized test methods for resin based reactive compounds, their components and cured compounds used in electrical insulation. This fourth edition (2023) cancels and replaces the 2015 edition and introduces technical revisions, including new test methods related to IEC 60455‑3‑8 and additional/updated resin test procedures. The standard is essential for consistent characterization of processing, mechanical, thermal, chemical and electrical properties of insulating resins (epoxy, unsaturated polyester and others).

Key Topics and Technical Requirements

IEC 60455-2:2023 defines methods of test across a broad range of material attributes. Major technical topics include:

- Preparing and conditioning of test specimens, sequence of tests and required test reporting.

- Raw component tests: flash point, density, viscosity, volatile organic content, water content (Karl Fischer), epoxide/isocyanate equivalents, hydroxyl/acid/amine values.

- Processing and cure behaviour: isothermal viscosity increase (processing time), pot life, gel time, shelf life, exothermic temperature rise, curing in presence of water, degree of cure.

- Cured-material properties:

- Mechanical: tensile, compressive, flexural, impact, hardness.

- Thermal: glass transition, thermal conductivity, thermal shock, loss of mass, temperature index.

- Chemical: water absorption, resistance to liquid chemicals, mould growth, water vapour permeability.

- Electrical: volume resistivity, dielectric dissipation factor (tan δ), relative permittivity, breakdown voltage/electric strength, proof tracking index (PTI), electrolytic corrosion.

- Special tests: curing in thick layers, emissions during curing, total volume shrinkage, filler/ash/chlorine content and flammability assessments.

- Health & safety guidance (informative annex).

Practical Applications - Who Uses This Standard

IEC 60455-2:2023 is used by:

- Manufacturer R&D and quality control teams to validate resin formulations, processing windows and batch consistency.

- Test laboratories and certification bodies for accredited testing and conformity assessments of insulating compounds.

- Cable accessory and electrical component designers to select materials that meet mechanical, thermal and dielectric performance requirements.

- Procurement and specifications engineers to define acceptance criteria in supplier contracts and product standards.

- Utilities and OEMs evaluating long-term reliability (hydrolytic stability, electrical aging).

Benefits include reproducible performance data, improved safety, reduced field failures and easier regulatory/contractual compliance.

Related Standards

- IEC 60455 series (other Parts) - complementary methods and product requirements.

- IEC 60455‑3‑8 - specifically referenced in this edition for newly introduced test methods.

Using IEC 60455-2:2023 helps ensure that resin based reactive compounds used for electrical insulation are tested consistently for dielectric properties, curing behaviour, thermal stability and mechanical integrity, supporting safe and reliable electrical systems.

Buy Documents

IEC 60455-2:2023 RLV - Resin based reactive compounds used for electrical insulation - Part 2: Methods of test Released:7/27/2023

IEC 60455-2:2023 - Resin based reactive compounds used for electrical insulation - Part 2: Methods of test Released:7/27/2023

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60455-2:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Resin based reactive compounds used for electrical insulation - Part 2: Methods of test". This standard covers: IEC 60455-2:2023 specifies methods of test to be used for testing resin based reactive compounds, their components and cured compounds used for electrical insulation. This fourth edition cancels and replaces the third edition published in 2015. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Introduction of test methods related to IEC 60455-3-8; b) Additional and updated test methods for resins.

IEC 60455-2:2023 specifies methods of test to be used for testing resin based reactive compounds, their components and cured compounds used for electrical insulation. This fourth edition cancels and replaces the third edition published in 2015. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Introduction of test methods related to IEC 60455-3-8; b) Additional and updated test methods for resins.

IEC 60455-2:2023 is classified under the following ICS (International Classification for Standards) categories: 17.220.99 - Other standards related to electricity and magnetism; 29.035.01 - Insulating materials in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60455-2:2023 has the following relationships with other standards: It is inter standard links to IEC 60455-2:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60455-2:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60455-2 ®

Edition 4.0 2023-07

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Resin based reactive compounds used for electrical insulation –

Part 2: Methods of test

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60455-2 ®

Edition 4.0 2023-07

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Resin based reactive compounds used for electrical insulation –

Part 2: Methods of test

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.220.99, 29.035.01 ISBN 978-2-8322-7342-5

– 2 – IEC 60455-2:2023 RLV © IEC 2023

CONTENTS

FOREWORD . 5

INTRODUCTION . 2

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 11

4 General notes on methods of test . 11

4.1 Preparation and conditioning. 11

4.2 Sequence of tests . 12

4.3 Test report . 12

5 Methods of test for reactive compounds and their components . 12

5.1 Flash point . 12

5.2 Density . 12

5.3 Viscosity . 12

5.4 Viscosity after storing at elevated temperature . 12

5.5 Content of volatile organic components . 13

5.6 Isothermal increase of viscosity (processing time) . 13

5.7 Shelf life . 13

5.8 Colour . 14

5.9 Softening temperature . 14

5.10 Ash content . 14

5.11 Filler content . 14

5.12 Chlorine content. 14

5.12.1 Total chlorine content of unsaturated polyesters and epoxide resins . 14

5.12.2 Inorganic chlorine content of epoxide resins and glycidyl esters . 14

5.12.3 Easily saponifiable chlorine content of epoxide resins and related

materials . 14

5.13 Tendency of crystallisation . 14

5.14 Epoxide equivalent of epoxide resins . 14

5.15 Content of isocyanate . 14

5.16 Water content (Karl Fischer method) . 15

5.17 Hydroxyl value . 15

5.17.1 Polyester resins . 15

5.17.2 Resins other than polyester . 15

5.18 Acid value of polyester resins . 15

5.19 Amount of double bonds of unsaturated polyester and acrylate resins . 15

5.20 Acid and acid-anhydride content of acid-anhydride hardeners . 15

5.21 Amine value . 15

5.22 Pot life . 15

5.22.1 General . 15

5.22.2 Resinous compounds for cable accessories . 15

5.23 Gel time . 16

5.23.1 Unsaturated polyester based compounds . 16

5.23.2 Phenolic resin based compounds . 16

5.23.3 Other compounds . 16

5.24 Exothermic temperature rise . 16

5.24.1 Unsaturated polyester based compounds . 16

5.24.2 Resinous compounds for cable accessories . 16

5.24.3 Other compounds .

5.25 Total volume shrinkage of epoxide and unsaturated polyester based

compounds . 17

5.26 Curing in presence of water . 17

5.26.1 General . 17

5.26.2 Apparatus and materials . 17

5.26.3 Pouring device . 18

5.26.4 Procedure . 18

5.26.5 Test report . 18

5.27 Determination of the degree of curing . 19

5.28 Curing in thick layer and emissions during curing . 19

5.28.1 General . 20

5.28.2 Equipment . 20

5.28.3 Test specimen . 20

5.28.4 Procedure . 20

6 Methods of test for cured reactive compounds . 21

6.1 General . 22

6.2 Test specimens . 22

6.2.1 General . 22

6.2.2 Preparation of the reactive compound . 22

6.2.3 Preparation of test specimens. 22

6.2.4 Type and number of test specimens . 22

6.3 Density . 23

6.4 Mechanical properties . 23

6.4.1 Tensile properties . 23

6.4.2 Compressive properties . 23

6.4.3 Flexural properties . 23

6.4.4 Impact strength . 23

6.4.5 Hardness . 24

6.5 Thermal properties . 24

6.5.1 Bond strength at elevated temperature . 24

6.5.2 Linear thermal expansion . 24

6.5.3 Thermal conductivity . 24

6.5.4 Glass transition . 24

6.5.5 Flammability . 24

6.5.6 Thermal shock . 25

6.5.7 Dry heat resistance of resins for cable accessories – Method of test . 25

6.5.8 Wet heat resistance of resins for cable accessories . 26

6.5.9 Loss of mass . 28

6.5.10 Temperature index . 29

6.6 Chemical properties . 29

6.6.1 Water absorption . 29

6.6.2 Effect of liquid chemicals . 29

6.6.3 Resistance to mould growth . 30

6.6.4 Water vapour permeability . 30

6.7 Electrical properties . 30

6.7.1 Effect of water immersion on volume resistivity . 30

6.7.2 Dielectric dissipation factor (tan δ) and relative permittivity . 30

6.7.3 Break down voltage and electric strength . 31

– 4 – IEC 60455-2:2023 RLV © IEC 2023

6.7.4 Proof tracking index (PTI) . 33

6.7.5 Electrolytic corrosion . 33

Annex A (informative) Health and safety . 38

Bibliography . 39

Figure 1 – Test apparatus for curing in presence of water test .

Figure 2 – Test set-up for volume resistivity .

Figure 1 – Examination grid . 19

Figure 2 – Position of examination grid on the specimen . 19

Figure 3 – Example of electrode arrangement for flexible cured compound . 36

Figure 4 – Example of electrode arrangement for rigid cured compound . 37

Table 1 – Condition of the top side. 20

Table 2 – Condition of the bottom side . 21

Table 3 – Condition of the interior . 21

Table 4 – Voids . 21

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RESIN BASED REACTIVE COMPOUNDS USED

FOR ELECTRICAL INSULATION –

Part 2: Methods of test

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition IEC 60455-2:2015. A vertical bar appears in the margin

wherever a change has been made. Additions are in green text, deletions are in

strikethrough red text.

– 6 – IEC 60455-2:2023 RLV © IEC 2023

IEC 60455-2 has been prepared by IEC technical committee 15: Solid electrical insulating

materials. It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2015. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Introduction of test methods related to IEC 60455-3-8;

b) Additional and updated test methods for resins.

The text of this International Standard is based on the following documents:

Draft Report on voting

15/1006/FDIS 15/1015/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 60455 series, published under the general title Resin based reactive

compounds used for electrical insulation, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

INTRODUCTION

This part of IEC 60455 is one of a series which deals with solvent-free resin based reactive

compounds and their components used for electrical insulation.

The series consists of three parts:

• Part 1: Definitions and general requirements;

• Part 2: Methods of test;

• Part 3: Specifications for individual materials.

– 8 – IEC 60455-2:2023 RLV © IEC 2023

RESIN BASED REACTIVE COMPOUNDS USED

FOR ELECTRICAL INSULATION –

Part 2: Methods of test

1 Scope

This part of IEC 60455 specifies methods of test to be used for testing resin based reactive

compounds, their components and cured compounds used for electrical insulation.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050 (all parts), International Electrotechnical Vocabulary (available at

http://www.electropedia.org)

IEC 60068-2-10:2005, Environmental testing – Part 2-10: Tests – Test J and guidance: Mould

growth

IEC 60093:1980, Methods of test for volume resistivity and surface resistivity of solid electrical

insulating materials

IEC 60112:20032020, Method for the determination of the proof and the comparative tracking

indices of solid insulating materials

IEC 60216 (all parts), Electrical insulating materials – Thermal endurance properties

IEC 60243-1:19982013, Electrical strength of insulating materials – Test methods – Part 1:

Tests at power frequencies

IEC 60250:1969, Recommended methods for the determination of the permittivity and dielectric

dissipation factor of electrical insulating materials at power, audio and radio frequencies

including metre wavelengths

IEC 60296:20122020, Fluids for electrotechnical applications – Unused Mineral insulating oils

for transformers and switchgear electrical equipment

IEC 60426:2007, Electrical insulating materials – Determination of electrolytic corrosion caused

by insulating materials – Test methods

IEC 60455-1:1998, Resin based reactive compounds used for electrical insulation – Part 1:

Definitions and general requirements

IEC 60455-3 (all parts), Resin based reactive compounds used for electrical insulation – Part 3:

Specifications for individual materials

IEC 60455-3-8:20132021, Resin based reactive compounds used for electrical insulation – Part

3-8: Specifications for individual materials – Resins for cable accessories

IEC 60695-11-10:19992013, Fire hazard testing – Part 11-10: Test flames – 50 W horizontal

and vertical flame test methods

IEC 60814:1997, Insulating liquids – Oil-impregnated paper and pressboard – Determination of

water by automatic coulometric Karl Fischer titration

IEC 61033:1991, Test methods for the determination of bond strength of impregnating agents

to an enamelled wire substrate

IEC 61099:2010, Insulating liquids – Specifications for unused synthetic organic esters for

electrical purposes

ISO 37:2011, Rubber, vulcanized or thermoplastic – Determination of tensile stress-strain

properties

ISO 62:2008, Plastics – Determination of water absorption

ISO 75 (all parts), Plastics and ebonite – Determination of temperature of deflection under load

ISO 175:2010, Plastics – Methods of test for the determination of the effects of immersion in

liquid chemicals, including water

ISO 178:2010, Plastics – Determination of flexural properties

ISO 179-1:2010, Plastics – Determination of Charpy impact properties – Part 1: Non-

instrumented impact test

ISO 179-2:1997, Plastics – Determination of Charpy impact properties – Part 2: Instrumented

impact test

ISO 291, Plastics – Standard atmospheres for conditioning and testing

ISO 306:20042013, Plastics – Thermoplastic materials – Determination of Vicat softening

temperature (VST)

ISO 527 (all parts), Plastics – Determination of tensile properties

ISO 584:1982, Plastics – Unsaturated polyester resins – Determination of reactivity at

80 degrees C (conventional method)

ISO 604:2002, Plastics – Determination of compressive properties

ISO 868:2003, Plastics and ebonite – Determination of indentation hardness by means of a

durometer (Shore hardness)

ISO 1183-1:20122019, Plastics – Methods for determining the density of non-cellular plastics –

Part 1: Immersion method, liquid pycnometer method and titration method

ISO 1513:2010, Paints and varnishes – Examination and preparation of test samples for testing

ISO 1523:2002, Paints, varnishes, petroleum and related products – Determination of flash

point – Closed cup equilibrium method

ISO 1675:1985, Plastics – Liquid resins – Determination of density by the pycnometer method

– 10 – IEC 60455-2:2023 RLV © IEC 2023

ISO 2039-1:1993, Plastics – Determination of hardness – Part 1: Ball indentation method

ISO 2114:19962000, Plastics – Unsaturated (polyester resins) and paints and varnishes

(binders) – Determination of partial acid value and total acid value

ISO 2431:1993, Paints and varnishes – Determination of flow time by use of flow cups

ISO 2535:1997, Plastics – Unsaturated polyester resins – Measurement of gel time at

25 degrees C

ISO 2554:1997, Plastics – Unsaturated polyester resins – Determination of hydroxyl value

ISO 2555:1989, Plastics – Resins in the liquid state or as emulsions or dispersions –

Determination of apparent viscosity by the Brookfield test using a single cylinder type rotational

viscometer method

ISO 2592:1973, Petroleum products – Determination of flash and fire points – Cleveland open

cup method

ISO 3001:1997, Plastics – Epoxide Epoxy compounds – Determination of epoxide epoxy

equivalent

ISO 3219:1993, Plastics – Polymers/resins in the liquid state or as emulsions or dispersions –

Determination of viscosity using a rotational viscometer with defined shear rate

ISO 3451-1:1997, Plastics – Determination of ash – Part 1: General methods

ISO 3521:1997, Plastics – Unsaturated polyester and epoxy resins – Determination of overall

volume shrinkage

ISO 3679:1983, Paints, varnishes, petroleum and related products – Determination of flashpoint

– Rapid equilibrium method

ISO 4573:1978, Plastics – Epoxide resins and glycidyl esters – Determination of inorganic

chlorine

ISO 4583:1998, Plastics – Epoxide resins and related materials – Determination of easily

saponifiable chlorine

ISO 4615:1979, Plastics – Unsaturated polyesters and epoxide resins – Determination of total

chlorine content

ISO 4625:1980, Binders for paints and varnishes – Determination of softening point –

Ring-and-ball method

ISO 4895, Plastics – Liquid epoxy resins – Determination of tendency to crystallize

ISO 7056, Plastics laboratory ware – Beakers

ISO 9396:1997, Plastics – Phenolic resins – Determination of the gel time at a given

temperature of resols under specific conditions using automatic apparatus

ISO 11357-2:1999, Plastics – Differential scanning calorimetry (DSC) – Part 2: Determination

of glass transition temperature and step height

ISO 11359-2:1999, Plastics – Thermomechanical analysis (TMA) – Part 2: Determination of

coefficient of linear thermal expansion and glass transition temperature

ISO 11359-3:2002, Plastics – Thermomechanical analysis (TMA) – Part 3: Determination of

penetration temperature

ISO 14896:2009, Plastics – Polyurethane raw materials – Determination of isocyanate content

ISO 15528:2000, Paints, varnishes and raw materials for paints and varnishes – Sampling

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60455-1 and

IEC 60050 and the following shall apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

volume resistance

part of the insulation resistance which is due to conduction through the volume and excluding

surface current

3.2

volume resistivity

volume resistance reduced to a cubical unit volume

3.3

dielectric dissipation factor

tan δ

numerical value of the ratio of the imaginary to the real part of the complex permittivity

3.4

relative permittivity

ε

r

ratio of the absolute permittivity to the electric constant

Note 1 to entry: In practical engineering, it is usual to employ the term ‘permittivity’ when referring to relative

permittivity

4 General notes on methods of test

4.1 Preparation and conditioning

Unless otherwise specified in the relevant specification standard or in the method of test, all

tests shall be carried out at atmospheric conditions in a temperature range of between 21 °C

and 29 °C and a relative humidity range of between 45 % and 70 %. Before measurements are

made, the sample or test specimen shall be pre-conditioned under these atmospheric conditions

for a time sufficient to allow the sample or the test specimen to reach stability. For taking

samples in liquid or paste form, ISO 15528 shall be applied. For preparation of such samples

for testing, ISO 1513 shall be applied.

NOTE For definitions of terms for standard atmospheres, see ISO 558. The test atmosphere as specified above

does not comply with any of the two standard atmospheres as specified in ISO 291 but covers both ranges inclusive

of their tolerances

– 12 – IEC 60455-2:2023 RLV © IEC 2023

Normally, all requirements for a method of test are given in the description, and diagrams are

intended only to illustrate one possible arrangement for conducting the test. In case of

inconsistencies between this document and the specification sheets of the IEC 60455-3 series,

the latter shall prevail. When another standard is invoked for a test method, reference to that

standard shall be included in the report.

4.2 Sequence of tests

To avoid unnecessary efforts, tests shall be carried out on the samples in the following

sequence:

1) tests on individual components prior to mixing;

2) tests on reactive compound just after mixing (ready to use);

3) tests on cured compound;

4) tests on cured compound after pre treatment (thermal, humidity, water etc.).

If the sample under test fails a test the following tests may become obsolete.

4.3 Test report

If not otherwise specified, the test report shall include the following data:

1) resin designation and identification;

2) lot number or other identification;

3) confirmation of marking and labelling according to the material safety data sheet (MSDS);

4) test results;

5) major test parameters, including conditioning and calibration, if any;

6) processing conditions used to reactive compound;

7) copy of the technical data sheet (TDS) and (MSDS).

5 Methods of test for reactive compounds and their components

5.1 Flash point

For flash point temperatures of 79 °C and above, the method given in ISO 2592 shall be used.

For flash point temperatures below 79 °C, the method given in ISO 1523 shall be used with any

of the closed-cup apparatus as described in Annex A of ISO 1523:2002. ISO 1523 shall be read

in conjunction with ISO 3679. Two measurements shall be made on two separate samples, and

the two results of the flash point shall be reported along with reference to the standards applied.

5.2 Density

The method given in ISO 1675 shall be used. Two measurements shall be made, and the two

results of the density shall be reported.

5.3 Viscosity

The viscosity shall be determined with a suitable device at (23 ± 0,5) °C if not otherwise

specified. If a rotating type of device is used, it shall be in accordance with ISO 2555 (Brookfield

type) or with ISO 3219 (a type working at a defined shear rate). If an efflux type of equipment

is used, the method of test and the flow cup shall be in accordance with ISO 2431. Two

measurements shall be made, and the two results of the viscosity shall be reported, along with

reference to the standards applied.

5.4 Viscosity after storing at elevated temperature

This method is not applicable to one-component systems or components containing hardener.

If not otherwise specified, a sample of sufficient amount is stored for (20 ± 0,5) h at a

temperature of (100 ± 3) °C in a sealed container. After cooling down to room temperature the

viscosity is measured according to 5.3. The increase of viscosity is calculated using the

following equation:

Increase of viscosity in % = (η – η ) × 100 / η

2 1 1

where

η dynamic viscosity before storing

η dynamic viscosity after storing

5.5 Content of volatile organic components

This method is not applicable to one-component systems or components containing hardener.

If not otherwise specified, the test shall be carried out in the following way:

The mass of an empty weighing bottle (about 80 mm × 30 mm) is taken to 0,001 g (m m1). A

mass of 0,4 g to 0,5 g resin (m m2) is weighed to 0,001 g into the weighing bottle (well closed

during weighing). Some drops of toluene are added to dilute the resin. The liquid is spread on

the floor of the weighing bottle with a slight twist.

The open weighing bottle is placed into an oven with forced air circulation for at least 2 h at

(110 ± 2) °C. After cooling down to room temperature in a desiccator the weighing bottle is

weighed again to 0,001 g (m3).

Volatile organic components = 100 × (m – (m – m )) / m .

2 3 1 2

Volatile organic components = 100 × (m2 – (m3 – m1)) / m2

where:

m1 mass of an empty weighing bottle (g)

m2 mass of resin before heating (g)

m3 mass of an empty weighing bottle with resin after heating and cooling (g)

5.6 Isothermal increase of viscosity (processing time)

This method is designed for PUR and EP resins. For UP resins gel time shall be used. If not

otherwise specified, the test shall be carried out in the following way:

All components and equipment shall be at room temperature. The components of the resin are

mixed according to the manufacturer’s instructions. The mixing procedure shall not take more

than 3 min. The time measurement starts after adding and mixing of the last component. After

10 min the first viscosity measurement is taken as the initial value. The measurement is

repeated until the specified maximum viscosity is reached. The time between the initial value

and the maximum value is reported as processing time.

5.7 Shelf life

The shelf life shall be determined by measurement of the change in a specified characteristic

property after a certain storage time and temperature. Experience has shown that viscosity

according to 5.3 and gel time according to 5.23 are appropriate characteristics. To assess shelf

life, viscosity and/or gel time shall be determined according to 5.3 and/or 5.23 respectively, at

a temperature and with an end-point as agreed upon between supplier and purchaser. Two

measurements shall be made on both fresh material and on material stored for a time and at a

temperature as agreed between supplier and purchaser. The two results of shelf life shall be

reported, along with reference to the standards applied. The results shall contain the viscosity

– 14 – IEC 60455-2:2023 RLV © IEC 2023

and/or the gel time before and after storing, the storing time and temperature and the test

temperature.

5.8 Colour

The method given in ISO 6271 shall be used. Two measurements shall be made, and the two

results of colour shall be reported along with reference to the standard applied.

5.9 Softening temperature

The method given in ISO 306 or ISO 4625 shall be used. Two measurements shall be made,

and the two results of softening temperature shall be reported along with reference to the

standard applied.

5.10 Ash content

The method given in ISO 3451-1, method A, shall be used. Two measurements shall be made,

and the two results of the ash content shall be reported.

5.11 Filler content

To be agreed between supplier and purchaser.

5.12 Chlorine content

5.12.1 Total chlorine content of unsaturated polyesters and epoxide resins

The method given in ISO 4615 shall be used. Two measurements shall be made, and the two

results of the total chlorine content shall be reported.

5.12.2 Inorganic chlorine content of epoxide resins and glycidyl esters

The method given in ISO 4573 shall be used. Two measurements shall be made, and the two

results of the inorganic chlorine content shall be reported.

5.12.3 Easily saponifiable chlorine content of epoxide resins and related materials

The method given in ISO 4583 shall be used. Two measurements shall be made, and the two

results of the saponifiable chlorine content shall be reported.

5.13 Tendency of crystallisation

This method is applicable to epoxy resins only.

The method given in ISO 4895 shall be used. Two measurements shall be made, and the two

results shall be reported.

5.14 Epoxide equivalent of epoxide resins

The method given in ISO 3001 shall be used. Two measurements shall be made, and the two

results of the epoxide equivalent shall be reported.

5.15 Content of isocyanate

This method is applicable to polyurethane hardeners only.

The method given in ISO 14896 shall be used. Two measurements shall be made, and the two

results shall be reported.

5.16 Water content (Karl Fischer method)

The method given in IEC 60814 shall be used. Two measurements shall be made, and the two

results of the water content shall be reported.

5.17 Hydroxyl value

5.17.1 Polyester resins

The method given in ISO 2554 shall be used. Two measurements shall be made, and the two

results of the hydroxyl value shall be reported.

5.17.2 Resins other than polyester

To be agreed between supplier and purchaser.

5.18 Acid value of polyester resins

The method given in ISO 2114 shall be used. Two measurements shall be made, and the two

results of the acid value shall be reported.

5.19 Amount of double bonds of unsaturated polyester and acrylate resins

To be agreed between supplier and purchaser.

5.20 Acid and acid-anhydride content of acid-anhydride hardeners

The method given in ISO 2114 shall be used for acid content. The method given in ISO 7327

shall be used for anhydride content. Two measurements shall be made, and the two results of

the acid value and/or anhydride content shall be reported.

5.21 Amine value

The method given in ISO 9702 shall be used if not otherwise agreed between supplier and

purchaser.

5.22 Pot life

5.22.1 General

The time which a particular method requires to achieve a viscosity of 50 Pas is measured.

The viscosity can be determined in any viscosimeter.

5.22.2 Resinous compounds for cable accessories

5.22.2.1 Apparatus and materials

Equipment to be used:

• beaker in accordance with ISO 7056, polyethylene, polypropylene or glass with dimensions:

70 mm to 100 mm diameter and 70 mm to 130 mm high;

• environmental chamber;

• time measuring device;

• viscosimeter.

5.22.2.2 Preparation of the sample

The beaker shall be marked to a volume of (300 ± 25) ml.

– 16 – IEC 60455-2:2023 RLV © IEC 2023

The beaker and a standard manufacturer pack shall be stored in an environmental chamber for

24 h at the temperature specified with a tolerance of K.

–2

5.22.2.3 Procedure

The components shall be removed from the environmental chamber and start mixing

immediately according to the supplier´s instructions. The time starts at the commencement of

mixing the components.

Remove the beaker from the environmental chamber, and pour the mixed compound into the

beaker up to the mark previously made.

5.22.2.4 Test report

The test report shall include the following information:

• the time is determined from the start of mixing until a viscosity of 50 Pas is reached. The

pot life shall be rounded to the nearest of a second;

• the viscosimeter, test parameters and system used (e.g. spindle size, rotation speed etc.).

The viscosimeter with the system used shall be calibrated at 50 Pas.

5.23 Gel time

5.23.1 Unsaturated polyester based compounds

Gel time is the period of time after which the reactive compound reaches the gel state. The

method given in ISO 2535 shall be used at a test temperature as agreed upon between supplier

and purchaser. Two measurements shall be made, and the two results of the gel time shall be

reported along with the test temperature.

5.23.2 Phenolic resin based compounds

The method given in ISO 9396 shall be used. Two measurements shall be made, and the two

results of the gel time shall be reported.

5.23.3 Other compounds

If applicable, the methods given in ISO 2535 or ISO 9696 ISO 9396, or ISO 8987 shall be used.

5.24 Exothermic temperature rise

5.24.1 Unsaturated polyester based compounds

The method given in ISO 584 shall be used. Two measurements shall be made, and the two

results of the exothermic temperature rise shall be reported.

5.24.2 Resinous compounds for cable accessories

5.24.2.1 Apparatus and materials

Equipment to be used:

• beaker in accordance with ISO 7056, polyethylene, polypropylene or glass with dimensions:

70 mm to 100 mm diameter and 70 mm to 130 mm high;

• thermocouple made with twisted wires;

• temperature recorder;

• time measurement device.

5.24.2.2 Preparation of the sample: Test at 23 °C

The beaker shall be marked to a volume of (300 ± 25) ml. The beaker and a sufficient amount

of resin

...

IEC 60455-2 ®

Edition 4.0 2023-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Resin based reactive compounds used for electrical insulation –

Part 2: Methods of test

Composés réactifs à base de résines utilisés comme isolants électriques –

Partie 2: Méthodes d'essai

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur les adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 300 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 19 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60455-2 ®

Edition 4.0 2023-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Resin based reactive compounds used for electrical insulation –

Part 2: Methods of test

Composés réactifs à base de résines utilisés comme isolants électriques –

Partie 2: Méthodes d'essai

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220.99, 29.035.01 ISBN 978-2-8322-7283-1

– 2 – IEC 60455-2:2023 © IEC 2023

CONTENTS

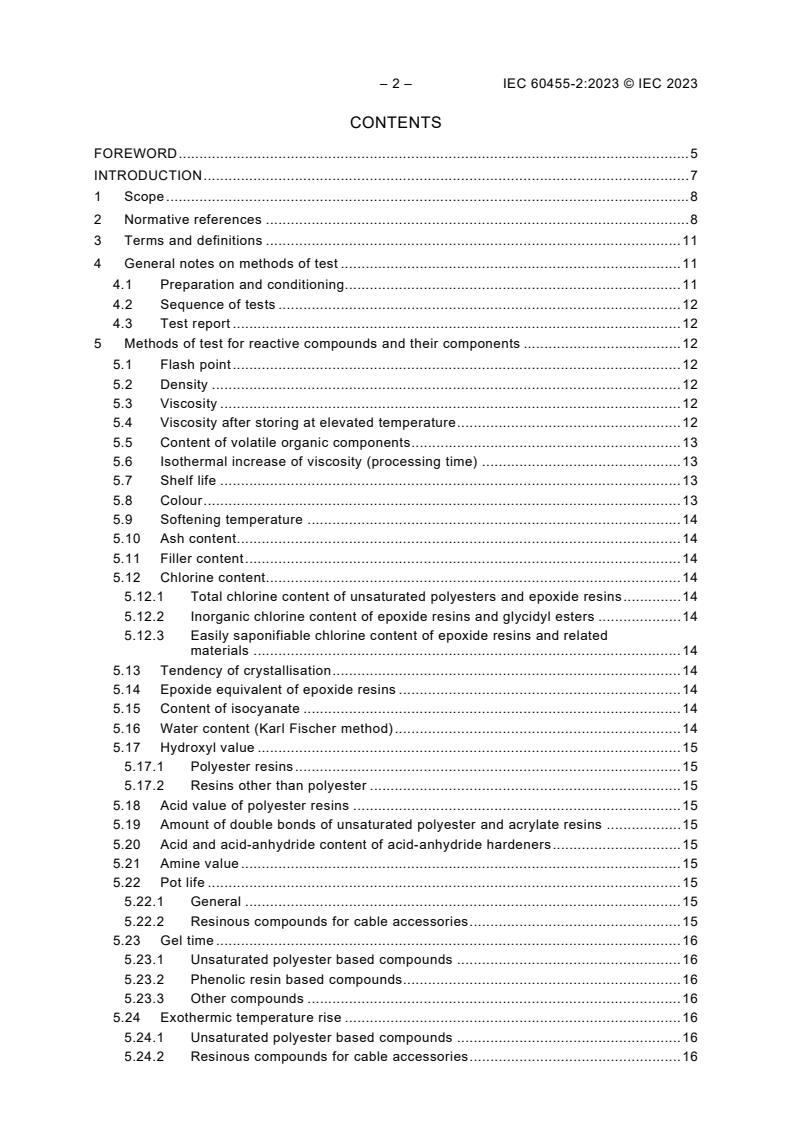

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 11

4 General notes on methods of test . 11

4.1 Preparation and conditioning. 11

4.2 Sequence of tests . 12

4.3 Test report . 12

5 Methods of test for reactive compounds and their components . 12

5.1 Flash point . 12

5.2 Density . 12

5.3 Viscosity . 12

5.4 Viscosity after storing at elevated temperature . 12

5.5 Content of volatile organic components . 13

5.6 Isothermal increase of viscosity (processing time) . 13

5.7 Shelf life . 13

5.8 Colour . 13

5.9 Softening temperature . 14

5.10 Ash content . 14

5.11 Filler content . 14

5.12 Chlorine content. 14

5.12.1 Total chlorine content of unsaturated polyesters and epoxide resins . 14

5.12.2 Inorganic chlorine content of epoxide resins and glycidyl esters . 14

5.12.3 Easily saponifiable chlorine content of epoxide resins and related

materials . 14

5.13 Tendency of crystallisation . 14

5.14 Epoxide equivalent of epoxide resins . 14

5.15 Content of isocyanate . 14

5.16 Water content (Karl Fischer method) . 14

5.17 Hydroxyl value . 15

5.17.1 Polyester resins . 15

5.17.2 Resins other than polyester . 15

5.18 Acid value of polyester resins . 15

5.19 Amount of double bonds of unsaturated polyester and acrylate resins . 15

5.20 Acid and acid-anhydride content of acid-anhydride hardeners . 15

5.21 Amine value . 15

5.22 Pot life . 15

5.22.1 General . 15

5.22.2 Resinous compounds for cable accessories . 15

5.23 Gel time . 16

5.23.1 Unsaturated polyester based compounds . 16

5.23.2 Phenolic resin based compounds . 16

5.23.3 Other compounds . 16

5.24 Exothermic temperature rise . 16

5.24.1 Unsaturated polyester based compounds . 16

5.24.2 Resinous compounds for cable accessories . 16

5.25 Total volume shrinkage of epoxide and unsaturated polyester based

compounds . 17

5.26 Curing in presence of water . 17

5.26.1 General . 17

5.26.2 Apparatus and materials . 17

5.26.3 Pouring device . 17

5.26.4 Procedure . 17

5.26.5 Test report . 18

5.27 Determination of the degree of curing . 19

5.28 Curing in thick layer and emissions during curing . 19

5.28.1 General . 19

5.28.2 Equipment . 20

5.28.3 Test specimen . 20

5.28.4 Procedure . 20

6 Methods of test for cured reactive compounds . 21

6.1 General . 21

6.2 Test specimens . 21

6.2.1 General . 21

6.2.2 Preparation of the reactive compound . 21

6.2.3 Preparation of test specimens. 22

6.2.4 Type and number of test specimens . 22

6.3 Density . 22

6.4 Mechanical properties . 22

6.4.1 Tensile properties . 22

6.4.2 Compressive properties . 22

6.4.3 Flexural properties . 23

6.4.4 Impact strength . 23

6.4.5 Hardness . 23

6.5 Thermal properties . 23

6.5.1 Bond strength at elevated temperature . 23

6.5.2 Linear thermal expansion . 23

6.5.3 Thermal conductivity . 23

6.5.4 Glass transition . 24

6.5.5 Flammability . 24

6.5.6 Thermal shock . 24

6.5.7 Dry heat resistance of resins for cable accessories – Method of test . 24

6.5.8 Wet heat resistance of resins for cable accessories . 25

6.5.9 Loss of mass . 27

6.5.10 Temperature index . 28

6.6 Chemical properties . 29

6.6.1 Water absorption . 29

6.6.2 Effect of liquid chemicals . 29

6.6.3 Resistance to mould growth . 29

6.6.4 Water vapour permeability . 29

6.7 Electrical properties . 29

6.7.1 Effect of water immersion on volume resistivity . 29

6.7.2 Dielectric dissipation factor (tan δ) and relative permittivity . 29

6.7.3 Break down voltage and electric strength . 29

6.7.4 Proof tracking index (PTI) . 31

– 4 – IEC 60455-2:2023 © IEC 2023

6.7.5 Electrolytic corrosion . 31

Annex A (informative) Health and safety . 34

Bibliography . 35

Figure 1 – Examination grid . 18

Figure 2 – Position of examination grid on the specimen . 19

Figure 3 – Example of electrode arrangement for flexible cured compound . 32

Figure 4 – Example of electrode arrangement for rigid cured compound . 33

Table 1 – Condition of the top side. 20

Table 2 – Condition of the bottom side . 20

Table 3 – Condition of the interior . 20

Table 4 – Voids . 21

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RESIN BASED REACTIVE COMPOUNDS USED

FOR ELECTRICAL INSULATION –

Part 2: Methods of test

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 60455-2 has been prepared by IEC technical committee 15: Solid electrical insulating

materials. It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2015. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Introduction of test methods related to IEC 60455-3-8;

b) Additional and updated test methods for resins.

– 6 – IEC 60455-2:2023 © IEC 2023

The text of this International Standard is based on the following documents:

Draft Report on voting

15/1006/FDIS 15/1015/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 60455 series, published under the general title Resin based reactive

compounds used for electrical insulation, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

This part of IEC 60455 is one of a series which deals with solvent-free resin based reactive

compounds and their components used for electrical insulation.

The series consists of three parts:

• Part 1: Definitions and general requirements;

• Part 2: Methods of test;

• Part 3: Specifications for individual materials.

– 8 – IEC 60455-2:2023 © IEC 2023

RESIN BASED REACTIVE COMPOUNDS USED

FOR ELECTRICAL INSULATION –

Part 2: Methods of test

1 Scope

This part of IEC 60455 specifies methods of test to be used for testing resin based reactive

compounds, their components and cured compounds used for electrical insulation.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050 (all parts), International Electrotechnical Vocabulary (available at

http://www.electropedia.org)

IEC 60068-2-10:2005, Environmental testing – Part 2-10: Tests – Test J and guidance: Mould

growth

IEC 60112:2020, Method for the determination of the proof and the comparative tracking indices

of solid insulating materials

IEC 60216 (all parts), Electrical insulating materials – Thermal endurance properties

IEC 60243-1:2013, Electric strength of insulating materials – Test methods – Part 1: Tests at

power frequencies

IEC 60296:2020, Fluids for electrotechnical applications – Mineral insulating oils for electrical

equipment

IEC 60426:2007, Electrical insulating materials – Determination of electrolytic corrosion caused

by insulating materials – Test methods

IEC 60455-1:1998, Resin based reactive compounds used for electrical insulation – Part 1:

Definitions and general requirements

IEC 60455-3 (all parts), Resin based reactive compounds used for electrical insulation – Part 3:

Specifications for individual materials

IEC 60455-3-8:2021, Resin based reactive compounds used for electrical insulation – Part 3-8:

Specifications for individual materials – Resins for cable accessories

IEC 60695-11-10:2013, Fire hazard testing – Part 11-10: Test flames – 50 W horizontal and

vertical flame test methods

IEC 60814:1997, Insulating liquids – Oil-impregnated paper and pressboard – Determination of

water by automatic coulometric Karl Fischer titration

IEC 61033:1991, Test methods for the determination of bond strength of impregnating agents

to an enamelled wire substrate

IEC 61099:2010, Insulating liquids – Specifications for unused synthetic organic esters for

electrical purposes

ISO 37:2011, Rubber, vulcanized or thermoplastic – Determination of tensile stress-strain

properties

ISO 62:2008, Plastics – Determination of water absorption

ISO 75 (all parts), Plastics and ebonite – Determination of temperature of deflection under load

ISO 175:2010, Plastics – Methods of test for the determination of the effects of immersion in

liquid chemicals

ISO 178:2010, Plastics – Determination of flexural properties

ISO 179-1:2010, Plastics – Determination of Charpy impact properties – Part 1: Non-

instrumented impact test

ISO 179-2:1997, Plastics – Determination of Charpy impact properties – Part 2: Instrumented

impact test

ISO 291, Plastics – Standard atmospheres for conditioning and testing

ISO 306:2013, Plastics – Thermoplastic materials – Determination of Vicat softening

temperature (VST)

ISO 527 (all parts), Plastics – Determination of tensile properties

ISO 584:1982, Plastics – Unsaturated polyester resins – Determination of reactivity at

80 degrees C (conventional method)

ISO 604:2002, Plastics – Determination of compressive properties

ISO 868:2003, Plastics and ebonite – Determination of indentation hardness by means of a

durometer (Shore hardness)

ISO 1183-1:2019, Plastics – Methods for determining the density of non-cellular plastics –

Part 1: Immersion method, liquid pycnometer method and titration method

ISO 1513:2010, Paints and varnishes – Examination and preparation of test samples

ISO 1523:2002, Determination of flash point – Closed cup equilibrium method

ISO 1675:1985, Plastics – Liquid resins – Determination of density by the pycnometer method

ISO 2039-1:1993, Plastics – Determination of hardness – Part 1: Ball indentation method

ISO 2114:2000, Plastics (polyester resins) and paints and varnishes (binders) – Determination

of partial acid value and total acid value

ISO 2431:1993, Paints and varnishes – Determination of flow time by use of flow cups

– 10 – IEC 60455-2:2023 © IEC 2023

ISO 2535:1997, Plastics – Unsaturated polyester resins – Measurement of gel time at

25 degrees C

ISO 2554:1997, Plastics – Unsaturated polyester resins – Determination of hydroxyl value

ISO 2555:1989, Plastics – Resins in the liquid state or as emulsions or dispersions –

Determination of apparent viscosity using a single cylinder type rotational viscometer method

ISO 2592:1973, Petroleum products – Determination of flash and fire points – Cleveland open

cup method

ISO 3001:1997, Plastics – Epoxy compounds – Determination of epoxy equivalent

ISO 3219:1993, Plastics – Polymers/resins in the liquid state or as emulsions or dispersions –

Determination of viscosity using a rotational viscometer with defined shear rate

ISO 3451-1:1997, Plastics – Determination of ash – Part 1: General methods

ISO 3521:1997, Plastics – Unsaturated polyester and epoxy resins – Determination of overall

volume shrinkage

ISO 3679:1983, Paints, varnishes, petroleum and related products – Determination of flashpoint

– Rapid equilibrium method

ISO 4573:1978, Plastics – Epoxide resins and glycidyl esters – Determination of inorganic

chlorine

ISO 4583:1998, Plastics – Epoxide resins and related materials – Determination of easily

saponifiable chlorine

ISO 4615:1979, Plastics – Unsaturated polyesters and epoxide resins – Determination of total

chlorine content

ISO 4625:1980, Binders for paints and varnishes – Determination of softening point –

Ring-and-ball method

ISO 4895, Plastics – Liquid epoxy resins – Determination of tendency to crystallize

ISO 7056, Plastics laboratory ware – Beakers

ISO 9396:1997, Plastics – Phenolic resins – Determination of the gel time of resols under

specific conditions using automatic apparatus

ISO 11357-2:1999, Plastics – Differential scanning calorimetry (DSC) – Part 2: Determination

of glass transition temperature and step height

ISO 11359-2:1999, Plastics – Thermomechanical analysis (TMA) – Part 2: Determination of

coefficient of linear thermal expansion and glass transition temperature

ISO 11359-3:2002, Plastics – Thermomechanical analysis (TMA) – Part 3: Determination of

penetration temperature

ISO 14896:2009, Plastics – Polyurethane raw materials – Determination of isocyanate content

ISO 15528:2000, Paints, varnishes and raw materials for paints and varnishes – Sampling

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60455-1 and

IEC 60050 and the following shall apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

volume resistance

part of the insulation resistance which is due to conduction through the volume and excluding

surface current

3.2

volume resistivity

volume resistance reduced to a cubical unit volume

3.3

dielectric dissipation factor

tan δ

numerical value of the ratio of the imaginary to the real part of the complex permittivity

3.4

relative permittivity

ε

r

ratio of the absolute permittivity to the electric constant

Note 1 to entry: In practical engineering, it is usual to employ the term ‘permittivity’ when referring to relative

permittivity

4 General notes on methods of test

4.1 Preparation and conditioning

Unless otherwise specified in the relevant specification standard or in the method of test, all

tests shall be carried out at atmospheric conditions in a temperature range of between 21 °C

and 29 °C and a relative humidity range of between 45 % and 70 %. Before measurements are

made, the sample or test specimen shall be pre-conditioned under these atmospheric conditions

for a time sufficient to allow the sample or the test specimen to reach stability. For taking

samples in liquid or paste form, ISO 15528 shall be applied. For preparation of such samples

for testing, ISO 1513 shall be applied.

NOTE For definitions of terms for standard atmospheres, see ISO 558. The test atmosphere as specified above

does not comply with any of the two standard atmospheres as specified in ISO 291 but covers both ranges inclusive

of their tolerances

Normally, all requirements for a method of test are given in the description, and diagrams are

intended only to illustrate one possible arrangement for conducting the test. In case of

inconsistencies between this document and the specification sheets of the IEC 60455-3 series,

the latter shall prevail. When another standard is invoked for a test method, reference to that

standard shall be included in the report.

– 12 – IEC 60455-2:2023 © IEC 2023

4.2 Sequence of tests

To avoid unnecessary efforts, tests shall be carried out on the samples in the following

sequence:

1) tests on individual components prior to mixing;

2) tests on reactive compound just after mixing (ready to use);

3) tests on cured compound;

4) tests on cured compound after pre treatment (thermal, humidity, water etc.).

If the sample under test fails a test the following tests may become obsolete.

4.3 Test report

If not otherwise specified, the test report shall include the following data:

1) resin designation and identification;

2) lot number or other identification;

3) confirmation of marking and labelling according to the material safety data sheet (MSDS);

4) test results;

5) major test parameters, including conditioning and calibration, if any;

6) processing conditions used to reactive compound;

7) copy of the technical data sheet (TDS) and (MSDS).

5 Methods of test for reactive compounds and their components

5.1 Flash point

For flash point temperatures of 79 °C and above, the method given in ISO 2592 shall be used.

For flash point temperatures below 79 °C, the method given in ISO 1523 shall be used with any

of the closed-cup apparatus as described in Annex A of ISO 1523:2002. ISO 1523 shall be read

in conjunction with ISO 3679. Two measurements shall be made on two separate samples, and

the two results of the flash point shall be reported along with reference to the standards applied.

5.2 Density

The method given in ISO 1675 shall be used. Two measurements shall be made, and the two

results of the density shall be reported.

5.3 Viscosity

The viscosity shall be determined with a suitable device at (23 ± 0,5) °C if not otherwise

specified. If a rotating type of device is used, it shall be in accordance with ISO 2555 (Brookfield

type) or with ISO 3219 (a type working at a defined shear rate). If an efflux type of equipment

is used, the method of test and the flow cup shall be in accordance with ISO 2431. Two

measurements shall be made, and the two results of the viscosity shall be reported, along with

reference to the standards applied.

5.4 Viscosity after storing at elevated temperature

This method is not applicable to one-component systems or components containing hardener.

If not otherwise specified, a sample of sufficient amount is stored for (20 ± 0,5) h at a

temperature of (100 ± 3) °C in a sealed container. After cooling down to room temperature the

viscosity is measured according to 5.3. The increase of viscosity is calculated using the

following equation:

Increase of viscosity in % = (η – η ) × 100 / η

2 1 1

where

η dynamic viscosity before storing

η dynamic viscosity after storing

5.5 Content of volatile organic components

This method is not applicable to one-component systems or components containing hardener.

If not otherwise specified, the test shall be carried out in the following way:

The mass of an empty weighing bottle (about 80 mm × 30 mm) is taken to 0,001 g (m1). A mass

of 0,4 g to 0,5 g resin (m2) is weighed to 0,001 g into the weighing bottle (well closed during

weighing). Some drops of toluene are added to dilute the resin. The liquid is spread on the floor

of the weighing bottle with a slight twist.

The open weighing bottle is placed into an oven with forced air circulation for at least 2 h at

(110 ± 2) °C. After cooling down to room temperature in a desiccator the weighing bottle is

weighed again to 0,001 g (m3).

Volatile organic components = 100 × (m2 – (m3 – m1)) / m2

where:

m1 mass of an empty weighing bottle (g)

m2 mass of resin before heating (g)

m3 mass of an empty weighing bottle with resin after heating and cooling (g)

5.6 Isothermal increase of viscosity (processing time)

This method is designed for PUR and EP resins. For UP resins gel time shall be used. If not

otherwise specified, the test shall be carried out in the following way:

All components and equipment shall be at room temperature. The components of the resin are

mixed according to the manufacturer’s instructions. The mixing procedure shall not take more

than 3 min. The time measurement starts after adding and mixing of the last component. After

10 min the first viscosity measurement is taken as the initial value. The measurement is

repeated until the specified maximum viscosity is reached. The time between the initial value

and the maximum value is reported as processing time.

5.7 Shelf life

The shelf life shall be determined by measurement of the change in a specified characteristic

property after a certain storage time and temperature. Experience has shown that viscosity

according to 5.3 and gel time according to 5.23 are appropriate characteristics. To assess shelf

life, viscosity and/or gel time shall be determined according to 5.3 and/or 5.23 respectively, at

a temperature and with an end-point as agreed upon between supplier and purchaser. Two

measurements shall be made on both fresh material and on material stored for a time and at a

temperature as agreed between supplier and purchaser. The two results of shelf life shall be

reported, along with reference to the standards applied. The results shall contain the viscosity

and/or the gel time before and after storing, the storing time and temperature and the test

temperature.

5.8 Colour

The method given in ISO 6271 shall be used. Two measurements shall be made, and the two

results of colour shall be reported along with reference to the standard applied.

– 14 – IEC 60455-2:2023 © IEC 2023

5.9 Softening temperature

The method given in ISO 306 or ISO 4625 shall be used. Two measurements shall be made,

and the two results of softening temperature shall be reported along with reference to the

standard applied.

5.10 Ash content

The method given in ISO 3451-1, method A, shall be used. Two measurements shall be made,

and the two results of the ash content shall be reported.

5.11 Filler content

To be agreed between supplier and purchaser.

5.12 Chlorine content

5.12.1 Total chlorine content of unsaturated polyesters and epoxide resins

The method given in ISO 4615 shall be used. Two measurements shall be made, and the two

results of the total chlorine content shall be reported.

5.12.2 Inorganic chlorine content of epoxide resins and glycidyl esters

The method given in ISO 4573 shall be used. Two measurements shall be made, and the two

results of the inorganic chlorine content shall be reported.

5.12.3 Easily saponifiable chlorine content of epoxide resins and related materials

The method given in ISO 4583 shall be used. Two measurements shall be made, and the two

results of the saponifiable chlorine content shall be reported.

5.13 Tendency of crystallisation

This method is applicable to epoxy resins only.

The method given in ISO 4895 shall be used. Two measurements shall be made, and the two

results shall be reported.

5.14 Epoxide equivalent of epoxide resins

The method given in ISO 3001 shall be used. Two measurements shall be made, and the two

results of the epoxide equivalent shall be reported.

5.15 Content of isocyanate

This method is applicable to polyurethane hardeners only.

The method given in ISO 14896 shall be used. Two measurements shall be made, and the two

results shall be reported.

5.16 Water content (Karl Fischer method)

The method given in IEC 60814 shall be used. Two measurements shall be made, and the two