IEC TS 62271-304:2008

(Main)High-voltage switchgear and controlgear - Part 304: Design classes for indoor enclosed switchgear and controlgear for rated voltages above 1 kV up to and includuing 52 kV to be used in severe climatic conditions

High-voltage switchgear and controlgear - Part 304: Design classes for indoor enclosed switchgear and controlgear for rated voltages above 1 kV up to and includuing 52 kV to be used in severe climatic conditions

IEC/TS 62271-304:2008 applies to indoor enclosed switchgear and controlgear complying with IEC 62271-200 and IEC 62271-201, intended to be used in service conditions more severe with respect to condensation and pollution than the normal service conditions specified in IEC 62271-1. This technical specification covers equipment where any of the insulation is exposed to indoor climatic conditions. This first edition of IEC/TS 62271-304 cancels and replaces the first edition of IEC/TS 60932, published in 1988, and constitutes a technical revision. This revised document has been basically changed to be updated to today's use of high-voltage switchgear and controlgear up to 52 kV. The contents of the corrigendum of January 2010 have been included in this copy.

Appareillage à haute tension - Partie 304: Classes de construction pour l'appareillage d'intérieur sous enveloppe pour tensions assignées à partir de 1 kV jusqu'à 52 kV inclus pour usage sous conditions climatiques sévères

La CEI/TS 62271-304:2008 s'applique à l'appareillage d'intérieur sous enveloppe conforme à la CEI 62271-200 et à la CEI 62271-201, destiné à être utilisé dans des conditions de service plus sévères en ce qui concerne la condensation et la pollution, que les conditions normales de service spécifiées dans la CEI 62271-1. Cette spécification technique couvre tous les équipements dans lesquelles il existe une partie isolante exposée aux conditions climatiques d'intérieur. Cette première édition de la CEI/TS 62271-304 annule et remplace la première édition de la CEI/TS 60932 parue en 1988 dont elle constitue une révision technique. Le fondement des modifications de ce document révisé consiste en la prise en compte du mode d'utilisation actuel de l'appareillage haute tension de moins de 52 kV. Le contenu du corrigendum de janvier 2010 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 26-May-2008

- Technical Committee

- SC 17C - Assemblies

- Drafting Committee

- MT 19 - TC 17/SC 17C/MT 19

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 21-Mar-2019

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62271-304:2008 is an important technical specification published by the International Electrotechnical Commission (IEC) that addresses the design classes for indoor enclosed high-voltage switchgear and controlgear. It applies to equipment with rated voltages above 1 kV and up to and including 52 kV, specifically for use in severe climatic conditions where condensation and pollution levels exceed normal indoor environments. This specification supplements IEC 62271-200 and IEC 62271-201 and replaces the earlier IEC/TS 60932 from 1988, reflecting modern technological advances and updated service conditions.

The scope focuses on the performance and reliability of electrical insulation exposed to challenging indoor climates featuring high humidity, temperature fluctuations, and pollution, ensuring switchgear and controlgear safety and functionality under such demanding conditions.

Key Topics

Severe Service Conditions Classification

Classification based on degrees of condensation and pollution:- Condensation Conditions:

- C_o: Rare condensation (not more than twice a year)

- C_L: Non-frequent condensation (not more than twice a month)

- C_H: Frequent condensation (more than twice a month)

- Pollution Levels:

- P_L: Light pollution, possibly requiring some precautions

- P_H: Heavy pollution without protective measures, excluding conductive or industrial deposits

- Condensation Conditions:

Test Procedures and Ageing Tests

Procedures simulate severe climatic conditions to evaluate the durability of electrical insulation and mechanical components.- Level 1 and Level 2 ageing tests assess long-term performance under cycles of temperature, humidity, and pollution stress.

- Diagnostic protocols include electrical withstand voltage tests and optional mechanical inspections.

Equipment Classification and Selection

The specification provides a detailed classification system to categorize switchgear based on environmental severity, enabling users and manufacturers to select or design equipment appropriate for specific indoor climates.Climatic Test Facilities

Specifications for climatic test rooms, control protocols, and energizing facilities ensure repeatable, standardized testing environments for verifying switchgear robustness during manufacturing and certification.

Applications

IEC TS 62271-304:2008 is essential for industries relying on reliable indoor electrical distribution and control in environments with challenging climatic conditions, such as:

- Industrial facilities with high humidity and airborne contaminants

- Power generation plants and substations located in tropical, coastal, or polluted urban areas

- Infrastructure environments with incomplete temperature and humidity control

- Environments where switchgear is exposed to frequent condensation or heavy dust and pollution from industrial processes

The standard helps manufacturers innovate and certify switchgear that withstands indoor climatic extremes, ensuring operational safety, longevity, and reduced maintenance.

Related Standards

- IEC 62271-1: Common specifications for high-voltage switchgear and controlgear

- IEC 62271-200: Specifications for AC metal-enclosed switchgear for 1 kV to 52 kV

- IEC 62271-201: Specifications for AC insulation-enclosed switchgear in the same voltage range

- IEC 60060-1: High-voltage test techniques – general definitions and test requirements

- IEC 60068: Environmental testing standards relevant for climatic and pollution testing

Compliance with this suite of IEC standards ensures comprehensive quality, safety, and performance criteria are met across a wide range of high-voltage electrical equipment used indoors.

Keywords: IEC TS 62271-304, high-voltage switchgear, controlgear, indoor enclosed switchgear, severe climatic conditions, condensation, pollution, insulation testing, high-voltage standards, electrical equipment design, IEC standards, rated voltages above 1 kV, 52 kV switchgear, ageing test, climatic test room, electrical insulation, switchgear classification.

Buy Documents

IEC TS 62271-304:2008 - High-voltage switchgear and controlgear - Part 304: Design classes for indoor enclosed switchgear and controlgear for rated voltages above 1 kV up to and includuing 52 kV to be used in severe climatic conditions Released:5/27/2008

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TS 62271-304:2008 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "High-voltage switchgear and controlgear - Part 304: Design classes for indoor enclosed switchgear and controlgear for rated voltages above 1 kV up to and includuing 52 kV to be used in severe climatic conditions". This standard covers: IEC/TS 62271-304:2008 applies to indoor enclosed switchgear and controlgear complying with IEC 62271-200 and IEC 62271-201, intended to be used in service conditions more severe with respect to condensation and pollution than the normal service conditions specified in IEC 62271-1. This technical specification covers equipment where any of the insulation is exposed to indoor climatic conditions. This first edition of IEC/TS 62271-304 cancels and replaces the first edition of IEC/TS 60932, published in 1988, and constitutes a technical revision. This revised document has been basically changed to be updated to today's use of high-voltage switchgear and controlgear up to 52 kV. The contents of the corrigendum of January 2010 have been included in this copy.

IEC/TS 62271-304:2008 applies to indoor enclosed switchgear and controlgear complying with IEC 62271-200 and IEC 62271-201, intended to be used in service conditions more severe with respect to condensation and pollution than the normal service conditions specified in IEC 62271-1. This technical specification covers equipment where any of the insulation is exposed to indoor climatic conditions. This first edition of IEC/TS 62271-304 cancels and replaces the first edition of IEC/TS 60932, published in 1988, and constitutes a technical revision. This revised document has been basically changed to be updated to today's use of high-voltage switchgear and controlgear up to 52 kV. The contents of the corrigendum of January 2010 have been included in this copy.

IEC TS 62271-304:2008 is classified under the following ICS (International Classification for Standards) categories: 29.130.10 - High voltage switchgear and controlgear. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62271-304:2008 has the following relationships with other standards: It is inter standard links to IEC TS 62271-304:2008/COR1:2010, IEC TS 62271-304:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62271-304:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TS 62271-304

Edition 1.0 2008-05

TECHNICAL

SPECIFICATION

SPÉCIFICATION

TECHNIQUE

High-voltage switchgear and controlgear –

Part 304: Design classes for indoor enclosed switchgear and controlgear for

rated voltages above 1 kV up to and including 52 kV to be used in severe

climatic conditions

Appareillage à haute tension –

Partie 304: Classes de construction pour l'appareillage d’intérieur sous

enveloppe pour tensions assignées à partir de 1 kV jusqu’à 52 kV inclus pour

usage sous conditions climatiques sévères

IEC/TS 62271-304:2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/TS 62271-304

Edition 1.0 2008-05

TECHNICAL

SPECIFICATION

SPÉCIFICATION

TECHNIQUE

High-voltage switchgear and controlgear –

Part 304: Design classes for indoor enclosed switchgear and controlgear for

rated voltages above 1 kV up to and including 52 kV to be used in severe

climatic conditions

Appareillage à haute tension –

Partie 304: Classes de construction pour l'appareillage d’intérieur sous

enveloppe pour tensions assignées à partir de 1 kV jusqu’à 52 kV inclus pour

usage sous conditions climatiques sévères

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

P

CODE PRIX

ICS 29.130.10 ISBN 2-8318-9828-5

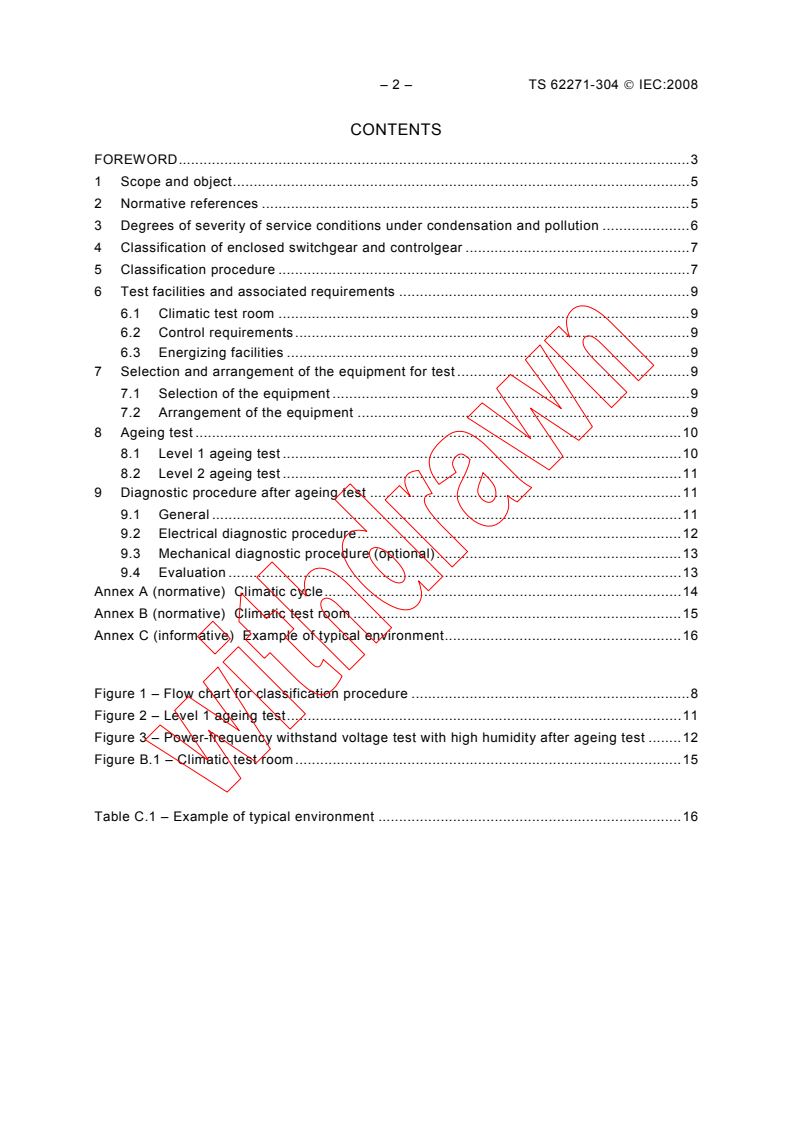

– 2 – TS 62271-304 © IEC:2008

CONTENTS

FOREWORD.3

1 Scope and object.5

2 Normative references .5

3 Degrees of severity of service conditions under condensation and pollution .6

4 Classification of enclosed switchgear and controlgear .7

5 Classification procedure .7

6 Test facilities and associated requirements .9

6.1 Climatic test room .9

6.2 Control requirements.9

6.3 Energizing facilities .9

7 Selection and arrangement of the equipment for test .9

7.1 Selection of the equipment .9

7.2 Arrangement of the equipment .9

8 Ageing test .10

8.1 Level 1 ageing test .10

8.2 Level 2 ageing test .11

9 Diagnostic procedure after ageing test .11

9.1 General .11

9.2 Electrical diagnostic procedure.12

9.3 Mechanical diagnostic procedure (optional).13

9.4 Evaluation .13

Annex A (normative) Climatic cycle.14

Annex B (normative) Climatic test room .15

Annex C (informative) Example of typical environment.16

Figure 1 – Flow chart for classification procedure .8

Figure 2 – Level 1 ageing test.11

Figure 3 – Power-frequency withstand voltage test with high humidity after ageing test .12

Figure B.1 – Climatic test room.15

Table C.1 – Example of typical environment .16

TS 62271-304 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

Part 304: Design classes for indoor enclosed

switchgear and controlgear for rated voltages above 1 kV up to and

including 52 kV to be used in severe climatic conditions

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

– 4 – TS 62271-304 © IEC:2008

IEC 62771-304, which is a technical specification, has been prepared by subcommittee 17C:

High-voltage switchgear and controlgear assemblies, of IEC technical committee 17:

Switchgear and controlgear.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

17C/402/DTS 17C/422A/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This first edition of IEC/TS 62271-304 cancels and replaces the first edition of IEC/TR 60932,

published in 1988, and constitutes a technical revision.

This revised document has been basically changed to be updated to today’s use of high-

voltage switchgear and controlgear up to 52 kV.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62271 series, under the general title High-voltage switchgear

and controlgear, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of January 2010 have been included in this copy.

TS 62271-304 © IEC:2008 – 5 –

HIGH-VOLTAGE SWITCHGEAR AND CONTROLGEAR –

Part 304: Design classes for indoor enclosed

switchgear and controlgear for rated voltages above 1 kV up to and

including 52 kV to be used in severe climatic conditions

1 Scope and object

This part of IEC 62271 applies to indoor enclosed switchgear and controlgear complying with

IEC 62271-200 and IEC 62271-201, intended to be used in service conditions more severe

with respect to condensation and pollution than the normal service conditions specified in

IEC 62271-1.

This technical specification covers equipment where any of the insulation is exposed to indoor

climatic conditions.

The test detailed in this technical specification has been designed primarily to investigate the

behaviour of electrical insulation and not corrosion on equipments. Nevertheless, the

performance of mechanical components, such as mechanisms, interlocks and enclosures may

also be recorded.

This technical specification proposes definitions for two degrees of severe service conditions

with respect to condensation and pollution. It also proposes test procedures for assessing the

performance of enclosed switchgear and controlgear under specified conditions so that

conclusions may be drawn concerning their suitability for service under those severe service

conditions.

In this technical specification, the term "equipment" is used in accordance with the scope for

an "enclosed assembly of switchgear and controlgear" (see IEC 60050-441, definition 441-12-

02).

NOTE The testing procedures described in this technical specification may also be applied to internal insulation of

outdoor equipment.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60060-1: High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60068 (all parts), Environmental testing

IEC 62271-1:2007, High-voltage switchgear and controlgear – Part 1: Common specifications

– 6 – TS 62271-304 © IEC:2008

IEC 62271-200, High-voltage switchgear and controlgear – Part 200: A.C. metal-enclosed

switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV

IEC 62271-201, High-voltage switchgear and controlgear – Part 201: AC insulation-enclosed

switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV

3 Degrees of severity of service conditions under condensation and pollution

Indoor equipment installed inside a building or room and thus normally protected against the

outdoor climatic conditions may be subjected to condensation due to rapid temperature

changes and to pollution due to the environment inside the building.

The service conditions with respect to condensation and pollution around the enclosed

switchgear and controlgear are designated and characterized as follows:

C : Condensation does not normally occur (not more than twice a year)

o

• Equipment to be used in locations with humidity and/or temperature control in

order to avoid condensation. The building or room provides protection from daily

variations of outside climate.

C : Non-frequent condensation (not more than twice a month)

L

• Equipment to be used in locations without humidity and/or temperature control.

The building or room provides protection from daily variations of outside climate,

but condensation cannot be excluded.

C : Frequent condensation (more than twice a month)

H

• Equipment to be used in locations without temperature control. The building or

room provides only minimal protection from daily variations of outside climate, so

that frequent condensation may occur.

P : Light pollution (as given in 2.1.1, item d) of IEC 62271-1) (see note 2 below)

L

• In order to reach light pollution in heavy polluted locations precautions may be

necessary.

P : Heavy pollution (any value exceeding P )

H L

P does not include areas subject to conductive dust and/or to industrial smoke,

H

producing thick conductive deposits.

• The location has no special precautions to minimize the presence of deposits, or

the equipment is situated in close proximity to pollution sources.

NOTE 1 Absence of pollution is considered as unrealistic. At least light pollution is assumed.

NOTE 2 IEC 62271-1, 2.1.1, item d): “The ambient air is not significantly polluted by dust, smoke, corrosive

and/or flammable gases, vapours or salt. The manufacturer will assume that, in absence of specific requirements

from the user, there are none.”

NOTE 3 Precautions to minimize the amount of deposits inside the enclosure of the equipment may be taken by

the choice of an appropriate degree of protection of the enclosed switchgear and controlgear.

Taking into account the fact that the equipment is especially influenced by the combination of

humidity and pollution, three degrees of severity of service conditions are defined as follows:

TS 62271-304 © IEC:2008 – 7 –

Degree 0: C P

o L

Degree 1: C P or C P

L L o H

Degree 2: C P or C P or C P

L H H L H H

NOTE 4 Degree 0 correspond to normal service condition as described in 2.1.1 of IEC 62271-1.

4 Classification of enclosed switchgear and controlgear

Three design classes 0, 1 and 2 are defined. They essentially correspond to the three

degrees of severity of service conditions according to Clause 3.

5 Classification procedure

For the normal service conditions specified in IEC 62271-200 and IEC 62271-201, no

additional test is required. Standardized switchgear and controlgear complying with these

publications is considered as belonging to Design Class 0.

Satisfactory performance under severe service conditions of equipment complying with

Design Class 1 or 2 is verified by testing the equipment.

Enclosed switchgear and controlgear is considered to belong to Design Class 1 if it is

subjected to the level 1 ageing test according to 8.1 and satisfies the evaluation criteria of the

diagnostic procedure described in Clause 9.

Enclosed switchgear and controlgear is considered to belong to Design Class 2 if it is

submitted to the level 2 ageing test according to 8.2 and satisfies the evaluation criteria of the

diagnostic procedure described in Clause 9.

The level 1 and level 2 ageing tests require the repeated application of identical climatic

cycles followed by the diagnostic procedures specified in Clause 9. The level 2 ageing test is

identical to the level 1 ageing test except that for level 2 a greater number of climatic cycles is

to be applied.

This classification procedure is illustrated in the flow chart, Figure 1.

– 8 – TS 62271-304 © IEC:2008

Design Class 0

Level 1

Ageing test

Diagnostic

procedure

(See clause 9)

Fail

Pass

Design Class 1

Level 2

Ageing test

Diagnostic

procedure

(See clause 9) Fail

Pass

Design Class 2 Design Class 1 Design Class 0

IEC 845/08

Figure 1 – Flow chart for classification procedure

TS 62271-304 © IEC:2008 – 9 –

6 Test facilities and associated requirements

6.1 Climatic test room

A climatic test room is required which shall be of sufficient size to accommodate the

equipment to be tested. The equipment shall be installed in the climatic test room at a height

of not less than 0,5 m from the ground in a manner to permit the circulation of the ambient air.

The distance between walls and ceiling of the test room and walls and the top of the

enclosure of the equipment shall be more than 1,0 m. Precautions shall be taken to insure

that no condensed water from the walls and ceiling of the test chamber can fall on the

equipment.

Figure B.1 is an explanatory figure for the test room.

6.2 Control requirements

The temperature needs to be controlled within limits of less than ±3 K. During the tests, it

shall be varied cyclically between 30 °C to 50 °C. The temperature gradient shall be at least

0,5 K/min. The distribution of temperature in the whole volume of the chamber should be

within the same tolerances.

The humidity also needs to be controlled within close limits over a range from below 80 % to

over 95 % of relative humidity.

6.3 Energizing facilities

A three-phase high-voltage source shall be provided so that the equipment to be tested can

be energised during the test. The source used for this purpose shall be able to maintain the

rated voltage with a tolerance of 0 to –5 % during the climatic cycles. The voltage shall be

recorded continuously during the whole duration of the tests for the purpose of checking

possible disruptive discharges.

A source is required for applying diagnostic test voltages up to at least the dry power-

frequency withstand voltage of the equipment to be tested. This source shall have a protective

device operating in less than 0,1 s in the event of a disruptive discharge.

The sources shall comply with IEC 60060-1.

7 Selection and arrangement of the equipment for test

7.1 Selection of the equipment

Ageing test is to be made on a functional unit completely assembled and fitted with all its

components as for service, measuring transformers included. The functional unit and its

components shall be new and clean.

7.2 Arrangement of the equipment

The equipment to be tested shall be installed in the climatic test room, as given in 6.1, in its

normal service position. The test arrangement of the functional unit shall not be more

favourable than the normal service arrangement, especially in respect of the external

connections.

– 10 – TS 62271-304 © IEC:2008

Connection shall be made so that the functional unit can be energized from a three-phase

supply at its rated voltage.

8 Ageing test

8.1 Level 1 ageing test

The equipment shall be installed in the climatic test room and subjected during three identical

test periods of seven days, to 2 h damp heat cycles as follows (see Figure 2).

The temperature of the climatic test room is raised from 30 °C to 50 °C in 40 min, with the

relative humidity constantly above 95 %. These conditions are maintained for 20 min, and the

temperature is then lowered to 30 °C in 40 min, at any convenient value of humidity.

The temperature is then maintained at 30 °C for 20 min, and throughout this period the

relative humidity is kept above 80 %.

The test period of seven days duration is made up as follows:

For five days, the equipment to be tested is energised at its rated voltage and subjected to 60

damp heat cycles.The application of rated voltage means U between phases and U / 3

r

r

between phase and earth. After these five days the test is stopped at the end of the last cycle

at 30 °C. The equipment is de-energized. A visual inspection is made as far as possible

without dismantling the equipment in order to detect the inception of trackings on insulating

surfaces.

For two days, the equipment shall be maintained in an ambient climate close to the reference

atmosphere mentioned in IEC 60060-1.

After the completion of three test periods, the performance of the equipment shall be

evaluated in accordance with the diagnostic procedure specified in 9.2.

TS 62271-304 © IEC:2008 – 11 –

IEC 846/08

Figure 2 – Level 1 ageing test

8.2 Level 2 ageing test

The level 2 ageing test comprises a total of seven identical test periods of seven days,

followed by the diagnostic procedure specified in 9.2.

NOTE In the case where equipment has already been successfully subjected to the level 1 ageing test it is

permitted to continue the test immediately after the diagnostic test, applying four additional test periods.

9 Diagnostic procedure after ageing test

9.1 General

After the conclusion of the ageing tests, and reaching ambient temperature, the equipment

shall be subjected to dielectric tests as follows without any special treatment like cleaning,

extra drying, etc. The voltage transformers shall be disconnected.

Relative humidity uncontrolled

Relative humidity uncontrolled

Visual inspection Visual inspection

Relative humidity uncontrolled

Visual inspection

Visual inspection

(Dry) Power-frequency voltage test

Power-frequency voltage test at high humidity

(see figure 3)

– 12 – TS 62271-304 © IEC:2008

9.2 Electrical diagnostic procedure

The equipment is first subjected to the dry 1 min power-frequency withstand voltage test at its

rated value according to IEC 62271-1.

The voltage shall be removed and the temperature in the climatic test room shall be increased

to 30 °C and the humidity at least to 95 %. After 3 h in these conditions, the following

dielectric test is performed (see Figure 3).

One phase is energized at U / 3 , where U is the rated voltage of the equipment, the other

r

r

two phases being earthed and connected to the protective conductor of the equipment. After

1 h, the voltage is raised to 3 U for 30 s (voltage rise in accordance with 6.3.1 of

r

IEC 60060-1).

The test is repeated successively on the other two phases, the interval between the tests

being as short as possible. If the configuration permits, phase A and C may be energised

together. If all 3 phases are screened (fully separated by earthed partitions), they can be

energised together.

The degree of tracking shall be recorded in the test report.

Voltage

Phase A Phase B Phase C

30 s 30 s 30 s

3 U

r

1 h 1 h 1 h

U / 3

r

Time

IEC 215/10

Figure 3 – Power-frequency withstand voltage test with high humidity after ageing test

TS 62271-304 © IEC:2008 – 13 –

9.3 Mechanical diagnostic procedure (optional)

This diagnostic procedure is not set up to prove the mechanical and corrosion performances.

Nevertheless, the results of the test can give useful information. Specific procedures are

foreseen in the IEC 60068 series.

Mechanical operations shall be performed on the switching devices and on the doors of the

functional unit.

The following mechanical diagnostics may be applied if applicable: operating times, torque,

contact speeds, operation of interlocks, etc., and shall be recorded according to IEC 62271-1.

The degree of corrosion shall be recorded in the test report.

9.4 Evaluation

The equipment complies with the Design Class 1 or 2 if the following conditions are satisfied:

• no disruptive discharge has occurred during the climatic cycles according to the ageing

test;

• no disruptive discharge has occurred during the diagnostic procedure;

• if the option of 9.3 is chosen, the mechanical functional performances of the equipment

shall be within the permitted tolerances given by the manufacturer.

– 14 – TS 62271-304 © IEC:2008

Annex A

(normative)

Climatic cycle

A.1 Remarks on the climatic cycle

The climatic cycle described in this technical specification is the same described in the first

edition of IEC 60932. This climatic cycle has proved satisfactory for more than 15 years.

The aim of this climatic cycle is to produce condensation on the insulation parts of the

switchgear in order to prove the dielectric behaviour under this condition.

Condensation always occurs immediately when the temperature of the object is lower than the

dew point of the ambient air. The object described in 7.1 consists of several components with

their own thermal time constants. If the time constants of all components are long in

comparison with the half of the climatic cycle, the temperature of all components alternates

slightly around the mean temperature of the climatic cycles. Therefore the temperature of the

object is nearly half of the cycle below the dew point of the ambient air and condensation

occurs for this time at least.

A.2 Origin of the apparition of a conductive layer, produced by the cyclic

presence of condensation on insulating parts of high voltage switchgear

This explanation has been given by competent chemists working in collaboration HV test

laboratories, after proceeding to several analysis of deposits from insulating services having

been naturally exposed to condensation for years (in the network) or artificially for weeks

(method A of the first edition of IEC 60932).

Atmospheric air is essentially (78%) composed of nitrogen (N ). In presence of high voltage

(surface) discharges, and catalysed by UV radiation due to corona effect, some N combines

with H O from condensation, to produce small quantities of HNO and HNO .These acids

2 2 3

dissolved in H O react with metals like Al, Ag, Cu, or Fe and produce conductive nitrous salts,

which are deposited and concentrated in some places during drying. The presence of those

irregular conductive paths give way to tracking of the insulating surfaces. Nitrous salts have

been detected by spectrographic analysis of deposits on insulating surfaces after the

application of the method A.

When using method B of the first edition of IEC 60932, spectrographic analysis mainly

showed the presence of deposits of NaCl, small amounts of metal chloride salts and traces of

nitride salts. Chemical concentration was higher, but exposure time was much less.

Inter-laboratory comparison focused on usual epoxy insulating parts showed a good

relationship between the final results of application of method A and method B of first edition

of IEC 60932.

TS 62271-304 © IEC:2008 – 15 –

Annex B

(normative)

Climatic test room

The test object shall be placed in the test room with minimum distances to the walls as shown

in Figure B.1.

≥ 1,0 m

≥ 1,0 m ≥ 1,0 m

Test object

≥ 0,5 m

IEC 848/08

Figure B.1 – Climatic test room

– 16 – TS 62271-304 © IEC:2008

Annex C

(informative)

Example of typical environment

The following Table C.1 is intended to give examples of determination of the pollution level of

typical environment.

Table C.1 – Example of typical environment

Pollution level Example of typical environments

Light - Areas without industries and with low density of houses

equipped with heating plants

- Agricultural areas

All these areas shall be situated at least

- Mountainous areas

10 km to 20 km from the sea and shall not

be exposed to winds directly from the sea

Heavy - Areas with industries not particularly producing pollution smoke

and/or with average density of houses equipped with heating

plants

- Areas exposed to wind from the sea but not too close to the

coast (at least several kilometres distant)

- Areas with high density of industries and suburbs of large cities

with high density of heating plants producing pollution

- Areas close to the sea

___________

– 18 – TS 62271-304 © CEI:2008

SOMMAIRE

AVANT-PROPOS.19

1 Domaine d'application et objet.21

2 Références normatives.21

3 Degrés de sévérité des conditions de service sous condensation et pollution .22

4 Classification de l'appareillage sous enveloppe .23

5 Procédure de classification.23

6 Moyens d'essais et exigences correspondantes.25

6.1 Chambre d'essai climatique.25

6.2 Exigences de contrôle .25

6.3 Moyens d’alimentation.25

7 Choix et disposition de l'appareillage pour l'essai .25

7.1 Choix de l'appareillage .25

7.2 Disposition de l'appareillage.25

8 Essai de vieillissement .26

8.1 Essai de vieillissement de niveau 1 .26

8.2 Essai de vieillissement de niveau 2 .27

9 Méthode de diagnostic après l'essai de vieillissement .27

9.1 Généralités.27

9.2 Méthode de diagnostic électrique .28

9.3 Méthode de diagnostic mécanique (option).28

9.4 Evaluation .29

Annexe A (normative) Cycles climatiques .30

Annexe B (normative) Chambre climatique .31

Annexe C (informative) Exemple d’environnements typiques .32

Figure 1 – Diagramme de la procédure de classification .24

Figure 2 – Essai de vieillissement de niveau 1.27

Figure 3 – Essai de tension de tenue à fréquence industrielle sous forte humidité,

après essai de vieillissement .28

Figure B.1 – Chambre d’essai climatique .31

Tableau C.1 – Exemples d’environnement typiques .32

TS 62271-304 © CEI:2008 – 19 –

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

APPAREILLAGE À HAUTE TENSION –

Partie 304: Classes de construction pour l'appareillage

d’intérieur sous enveloppe pour tensions assignées à partir de 1 kV

jusqu’à 52 kV inclus

pour usage sous conditions climatiques sévères

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI elle-même ne fournit aucune attestation de conformité. Des organismes de certification indépendants

fournissent des services d'évaluation de conformité et, dans certains secteurs, accèdent aux marques de

conformité de la CEI. La CEI n'est responsable d'aucun des services effectués par les organismes de

certification indépendants.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La tâche principale des comités d’études de la CEI est l’élaboration des Normes

internationales. Exceptionnellement, un comité d’études peut proposer la publication d’une

spécification technique

• lorsqu’en dépit de maints efforts, l’accord requis ne peut être réalisé en faveur de la

publication d’une Norme internationale, ou

• lorsque le sujet en question est encore en cours de développement technique ou quand,

pour une raison quelconque, la possibilité d’un accord pour la publication d’une Norme

internationale peut être envisagée pour l’avenir mais pas dans l’immédiat.

– 20 – TS 62271-304 © CEI:2008

Les spécifications techniques font l’objet d’un nouvel examen trois ans au plus tard après leur

publication afin de décider éventuellement de leur transformation en Normes internationales.

La CEI 62271-304, qui est une spécification technique, a été établie par le sous-comité 17C:

Ensembles d’appareillages à haute tension, du comité d’études 17 de la CEI: Appareillage.

Le texte de cette spécification technique est issu des documents suivants:

Projet d’enquête Rapport de vote

17C/402/DTS 17C/422A/RVC

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette spécification technique.

Cette première édition de la CEI/TS 62271-304 annule et remplace la première édition de la

CEI/TR 60932 parue en 1988 dont elle constitue une révision technique.

Le fondement des modifications de ce document révisé consiste en la prise en compte du

mode d’utilisation actuel de l’appareillage haute tension de moins de 52 kV

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

Une liste de toutes les parties de la série CEI 62271, présentée sous le titre général

Appareillage à haute tension, peut être consultée sur le site web de la CEI.

Le comité a décidé que le contenu de cette publication ne sera pas modifié ava

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...