IEC 60372:2020

(Main)Locking devices for ball and socket couplings of string insulator units - Dimensions and tests

Locking devices for ball and socket couplings of string insulator units - Dimensions and tests

IEC 60372:2020 is applicable to locking devices used with ball and socket couplings of string insulator units and used with the corresponding metal fittings standardized in IEC 60120, when they are supplied separately.The object of this document is

- to define the shapes and some standard dimensions for locking devices,

- to define the test methods for locking devices,

- to state the acceptance conditions for supply,

- to give other dimensions for guidance of manufacturing only.

This fourth edition cancels and replaces the third edition published in 1984. This edition includes the following significant technical changes with respect to the previous edition:

a. Two new designated size of couplings, 36 and 40, were introduced;

b. the relevant content of the 28B W-clip was deleted;

c. Annex A is informative, Annex B is normative, Annex C is informative.

Dispositifs de verrouillage pour les assemblages à rotule et logement de rotule des éléments de chaînes d'isolateurs - Dimensions et essais

l’IEC 60372:2020 est applicable aux dispositifs de verrouillage utilisés avec les assemblages à rotule des éléments de chaînes d'isolateurs et utilisés avec les accessoires métalliques correspondants normalisés dans l’IEC 60120, lorsqu'ils sont livrés séparément. Le présent document a pour objet:

- de définir les formes et certaines dimensions normalisées des dispositifs de verrouillage,

- de définir les méthodes d'essai des dispositifs de verrouillage,

- de fixer les conditions d'acceptation d'une fourniture,

- de donner d'autres dimensions, uniquement à titre de recommandation pour la fabrication.

Cette quatrième édition annule et remplace la troisième édition parue en 1984. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a. Deux nouvelles tailles d’assemblages normalisées, 36 et 40, sont présentées;

b. le contenu concernant l'agrafe 28B a été supprimé;

c. L’Annexe A est informative, l’Annexe B est normative, l’Annexe C est informative.

General Information

- Status

- Published

- Publication Date

- 21-Jul-2020

- Technical Committee

- TC 36 - Insulators

- Drafting Committee

- MT 21 - TC 36/MT 21

- Current Stage

- PPUB - Publication issued

- Start Date

- 22-Jul-2020

- Completion Date

- 10-Jul-2020

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60372:2020 is an international standard issued by the International Electrotechnical Commission (IEC) that specifies the dimensions and test methods for locking devices used with ball and socket couplings of string insulator units. This standard applies when locking devices are supplied separately from the metal fittings standardized under IEC 60120. It defines the shapes, standard dimensions, test procedures, and acceptance criteria crucial for ensuring the reliability and safety of these locking components. The fourth edition of the standard introduces new coupling sizes and updates previously published requirements, reflecting advancements and industry needs since the 1984 third edition.

Key Topics

Scope and Application

IEC 60372:2020 covers locking devices used with ball and socket couplings in string insulator units, commonly found in electrical transmission infrastructure. When these devices are supplied with insulators or fittings, they are treated as integral parts, with testing conducted as per related standards like IEC 60383-1 and IEC 61325.Locking Device Shapes and Dimensions

The standard defines two main types of locking devices:- Split-pin: Standard and alternative types with specified dimensions ensuring compatibility and secure fastening.

- W-clip: A locking device with detailed dimensional specifications, including a normative gauge described in Annex A to facilitate manufacturing and quality control.

Test Methods and Acceptance Conditions

The document outlines qualification and sample test procedures to verify:- Hardness (in accordance with ISO standards for Brinell, Vickers, and Rockwell hardness testing),

- Resistance to bending for split-pins,

- Corrosion resistance to prevent chemical reactions between locking devices and metal fittings.

Acceptance conditions for supply ensure that locking devices meet performance and durability criteria before being installed in the field.

Manufacturing Guidance

IEC 60372:2020 offers guidance on additional dimensions relevant for manufacturing processes, helping producers maintain consistency and compatibility across different batches and sizes.Recent Technical Updates

Key changes in the 2020 edition include introducing two new coupling sizes (36 and 40) and removing content related to the 28B W-clip based on industry feedback.

Applications

Electrical Transmission Systems

Locking devices conforming to IEC 60372:2020 are essential components in high-voltage overhead power lines, securing the ball and socket couplings of string insulator units used to support and electrically isolate conductors.Equipment Manufacturing

Manufacturers of insulators, ball and socket couplings, and related metal fittings rely on this standard to produce compatible and reliable locking devices that meet international quality and safety standards.Quality Control and Certification

Suppliers use the prescribed test methods and acceptance criteria to certify locking devices, ensuring conformity during procurement and installation processes.Maintenance and Replacement

Utilities engaged in maintenance of transmission lines can use IEC 60372:2020 as a reference for selecting proper locking devices during repair or replacement operations, promoting system reliability.

Related Standards

- IEC 60120 – Standard for metal fittings for ball and socket couplings used in insulator strings; complements IEC 60372 by defining the main coupling components.

- IEC 60383-1 – Insulators for overhead lines – part 1 covers general requirements including testing of insulator units that may incorporate locking devices.

- IEC 61325 – Procedures for testing insulator units including mechanical and electrical performance, ensuring comprehensive assessment when locking devices are supplied as integrated parts.

- ISO 6506-1 / 6507-1 / 6508-1 – Relevant ISO standards referenced for metallic material hardness testing methods, used within IEC 60372 test procedures.

- IEC 60050-471 – International Electrotechnical Vocabulary providing standardized terms related to insulators for clarity and uniformity in documentation.

Keywords: IEC 60372, locking devices, ball and socket couplings, string insulator units, electrical insulators, dimensions, test methods, split-pin, W-clip, high-voltage transmission lines, IEC standards, corrosion resistance, hardness testing, quality control.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60372:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Locking devices for ball and socket couplings of string insulator units - Dimensions and tests". This standard covers: IEC 60372:2020 is applicable to locking devices used with ball and socket couplings of string insulator units and used with the corresponding metal fittings standardized in IEC 60120, when they are supplied separately.The object of this document is - to define the shapes and some standard dimensions for locking devices, - to define the test methods for locking devices, - to state the acceptance conditions for supply, - to give other dimensions for guidance of manufacturing only. This fourth edition cancels and replaces the third edition published in 1984. This edition includes the following significant technical changes with respect to the previous edition: a. Two new designated size of couplings, 36 and 40, were introduced; b. the relevant content of the 28B W-clip was deleted; c. Annex A is informative, Annex B is normative, Annex C is informative.

IEC 60372:2020 is applicable to locking devices used with ball and socket couplings of string insulator units and used with the corresponding metal fittings standardized in IEC 60120, when they are supplied separately.The object of this document is - to define the shapes and some standard dimensions for locking devices, - to define the test methods for locking devices, - to state the acceptance conditions for supply, - to give other dimensions for guidance of manufacturing only. This fourth edition cancels and replaces the third edition published in 1984. This edition includes the following significant technical changes with respect to the previous edition: a. Two new designated size of couplings, 36 and 40, were introduced; b. the relevant content of the 28B W-clip was deleted; c. Annex A is informative, Annex B is normative, Annex C is informative.

IEC 60372:2020 is classified under the following ICS (International Classification for Standards) categories: 29.080.10 - Insulators; 29.240.20 - Power transmission and distribution lines. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60372:2020 has the following relationships with other standards: It is inter standard links to IEC 60372:1984/AMD2:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60372:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60372 ®

Edition 4.0 2020-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Locking devices for ball and socket couplings of string insulator units –

Dimensions and tests

Dispositifs de verrouillage pour les assemblages à rotule et logement de rotule

des éléments de chaînes d'isolateurs – Dimensions et essais

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60372 ®

Edition 4.0 2020-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Locking devices for ball and socket couplings of string insulator units –

Dimensions and tests

Dispositifs de verrouillage pour les assemblages à rotule et logement de rotule

des éléments de chaînes d'isolateurs – Dimensions et essais

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.080.10; 29.240.20 ISBN 978-2-8322-8477-3

– 2 – IEC 60372:2020 © IEC 2020

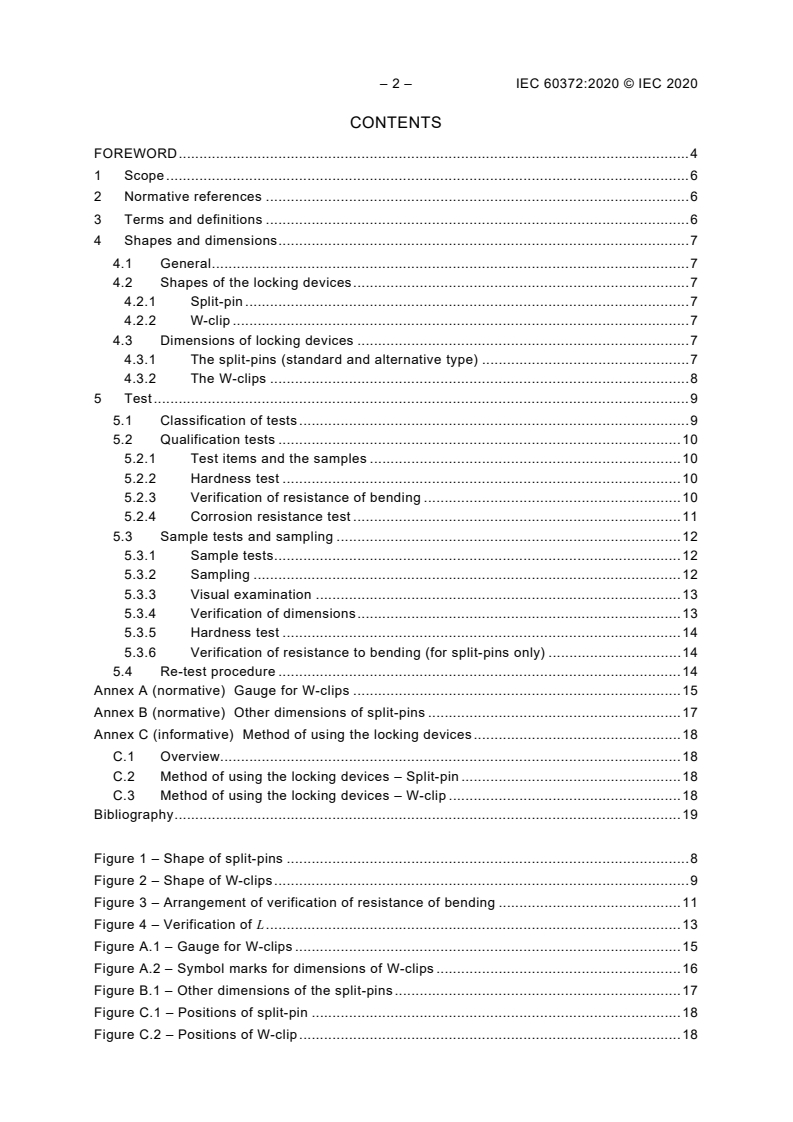

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Shapes and dimensions . 7

4.1 General . 7

4.2 Shapes of the locking devices . 7

4.2.1 Split-pin . 7

4.2.2 W-clip . 7

4.3 Dimensions of locking devices . 7

4.3.1 The split-pins (standard and alternative type) . 7

4.3.2 The W-clips . 8

5 Test . 9

5.1 Classification of tests . 9

5.2 Qualification tests . 10

5.2.1 Test items and the samples . 10

5.2.2 Hardness test . 10

5.2.3 Verification of resistance of bending . 10

5.2.4 Corrosion resistance test . 11

5.3 Sample tests and sampling . 12

5.3.1 Sample tests . 12

5.3.2 Sampling . 12

5.3.3 Visual examination . 13

5.3.4 Verification of dimensions . 13

5.3.5 Hardness test . 14

5.3.6 Verification of resistance to bending (for split-pins only) . 14

5.4 Re-test procedure . 14

Annex A (normative) Gauge for W-clips . 15

Annex B (normative) Other dimensions of split-pins . 17

Annex C (informative) Method of using the locking devices . 18

C.1 Overview. 18

C.2 Method of using the locking devices – Split-pin . 18

C.3 Method of using the locking devices – W-clip . 18

Bibliography . 19

Figure 1 – Shape of split-pins . 8

Figure 2 – Shape of W-clips . 9

Figure 3 – Arrangement of verification of resistance of bending . 11

Figure 4 – Verification of L . 13

Figure A.1 – Gauge for W-clips . 15

Figure A.2 – Symbol marks for dimensions of W-clips . 16

Figure B.1 – Other dimensions of the split-pins . 17

Figure C.1 – Positions of split-pin . 18

Figure C.2 – Positions of W-clip . 18

Table 1 – Dimensions of the split-pins . 8

Table 2 – Dimensions of W-clips . 9

Table 3 – Radii of verification of resistance of bending . 11

Table 4 – Size of the sample and acceptance number Ac . 12

Table 5 – Specifications of K and D in Figure 4 . 13

Table A.1 – Dimensions of the gauge for W-clips . 16

Table B.1 – Other dimensions of the split-pins . 17

– 4 – IEC 60372:2020 © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LOCKING DEVICES FOR BALL AND SOCKET COUPLINGS

OF STRING INSULATOR UNITS – DIMENSIONS AND TESTS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60372 has been prepared by IEC technical committee 36:

Insulators.

This fourth edition cancels and replaces the third edition published in 1984. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Two new designated size of couplings, 36 and 40, were introduced;

b) According to the results of the questionnaire (36/424/Q), the relevant content of the 28B

W-clip was deleted;

c) Annex A is informative, Annex B is normative, Annex C is informative.

The text of this International Standard is based on the following documents:

FDIS Report on voting

36/485/FDIS 36/493/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60372:2020 © IEC 2020

LOCKING DEVICES FOR BALL AND SOCKET COUPLINGS

OF STRING INSULATOR UNITS – DIMENSIONS AND TESTS

1 Scope

This international standard is applicable to locking devices used with ball and socket

couplings of string insulator units and used with the corresponding metal fittings standardized

in IEC 60120, when they are supplied separately.

When these locking devices are supplied with an insulator or fitting, they are considered as an

integral part of it. In this case, the relevant test is to be included with those of insulators, as

specified in IEC 60383-1 and IEC 61325. On request, a certificate is to be delivered

confirming that the tests on locking devices as specified in this document have been carried

out. The locking devices are usually supplied with the insulator or corresponding metal fittings.

The object of this document is

• to define the shapes and some standard dimensions for locking devices,

• to define the test methods for locking devices,

• to state the acceptance conditions for supply,

• to give other dimensions for guidance of manufacturing only.

The object of this document does not include the specification of the nature of the material,

and the material covered by the scope of this document does not have a surface coating for

corrosion protection. However, the material which will give rise to significant contact

corrosion(chemical reaction) between the locking device and the ball and socket coupling

does not covered by this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-471, International Electrotechnical Vocabulary (IEV) – Part 471: Insulators

ISO 6506-1, Metallic materials – Brinell Hardness – Test Part 1: Test Method

ISO 6507-1, Metallic materials – Vickers Hardness – Test Part 1: Test Method

ISO 6508-1, Metallic materials – Rockwell Hardness – Test Part 1: Test Method

3 Terms and definitions

For the purposes of this document, the terms and definitions of IEC 60050-471 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

locking device (for ball and socket coupling)

component which prevents pin ball decoupling from socket, when it is in locking position, by

using its shape and material properties

Note 1 to entry: See schematic of locking position in Annex C.

4 Shapes and dimensions

4.1 General

Two types of locking devices are standardized, one using a split-pin, the other a W- shaped

clip.

The first type requires a circular hole and the second a rectangular hole.

Two split-pins are proposed.

• standard split-pin this split-pin is a tight-fit in the socket-hole,

• alternative split-pin this split-pin is a loose fit in the socket-hole.

This alternative may be used by agreement between the manufacturer and the purchaser

when the problems of stress corrosion are possible for the split-pin metal due to the

permanent stress in the tight-fit system, e.g. when certain types of stainless steel are used.

The socket-hole into which the locking device fits is the same for both the standard and

alternative split-pin, so it is possible to use the alternative split-pin in a socket designed for

the standard split-pin.

4.2 Shapes of the locking devices

4.2.1 Split-pin

One of the legs of the split-pin has a hump and the free ends are bent outwards after insertion

into the socket. These features provide two distinct positions for the split-pin when operated

for locking and coupling, and complete withdrawal from the socket is effectively prevented

(see Annex C).

4.2.2 W-clip

The W-clip is so shaped that it will remain in two distinct positions when operated for coupling

and locking. The shape of the W-clip is such that complete withdrawal from the socket when

moving from the locking to the coupling position is prevented (see Annex C).

4.3 Dimensions of locking devices

4.3.1 The split-pins (standard and alternative type)

The shape of split-pins is given in Figure 1. The dimensions of split-pins are given in Table 1.

– 8 – IEC 60372:2020 © IEC 2020

Figure 1 – Shape of split-pins

Table 1 – Dimensions of the split-pins

Dimensions in millimetres

Alternative split-

Standard split-pins

a

pins

Designated size of

coupling

′

S T R F R L F

2 2Min Min Min 2 Max

+0,2

2,2± 0,1

11 4,8 3,3 8,2 2,5 29 7,3

+0,2

b c

A 5,5 3,8 10,3 43 9,2

16 3,2± 0,1 3,0

+0,2

b

7,9

B 4,8 10,7 38 9,7

+0,2

20 3,2± 0,1 7,0 4,8 10,7 3,0 49 9,7

+0,2

4,0± 0,1 8,7

24 5,7 12,8 3,5 60 11,7

+0,2

28 4,5± 0,1 10,0 6,2 13,8 3,5 71 12,7

+0,2

5,2± 0,1

32 11,5 7,2 15,8 3,5 81 14,7

+0,2

36 6,5± 0,1 11,5 8,7 17,8 4,0 91 16,7

+0,2

6,5± 0,1 11,5

40 8,7 17,8 4,0 102 16,7

a ′

All the dimensions are the same as for standard split-pins, except the value F replaced by F

2Min 2 Max

b

See Clause 6 of IEC 60120:2020.

c

Many existing designs of the inside of the socket still prevent uncoupling with lower values of L . In this

min

case L can be reduced to 38 mm.

min

The dimension L shall be specified by the purchaser of the split-pin (see 5.3.4.1)

max

4.3.2 The W-clips

The shape of W-clips is given in Figure 2. The dimensions of W-clips are given in Table 2.

Figure 2 – Shape of W-clips

Table 2 – Dimensions of W-clips

Dimensions in millimetres

Designated

size of F F F F F F L L L L L R R R S T

1 2 3 4 5 6 1 2 3 4 5 1 2 3(max)

coupling

+0,6 +0,2 +0,2

11 15 20 4 13 19 4 37± 1,5 12,0 24± 1,5 8.0 3 2,5 3,0 1,5 1,2 4,8

0 0 0

+0,2

a

5,5

A 3,0

+1 +0,2

5 50± 1,5 36± 1,5 1,5

16 22 28 5 19 24 15,5 10.5 3 2,5 2,5

0 0

+0,2

a

B 4,5 7,9

+1 +0,2 +0,2

62± 1,5 42± 1,5

20 22 30 5 19 24 5 15,5 10.5 3 2,5 4,5 2,5 2,0 7,0

0 0 0

+1 +0,2 +0,2

24 22 30 5 19 25 5 72± 1,5 15,5 50± 1,5 10.5 3 2,5 5,0 2,5 2,0 8,7

0 0 0

+1 +0,2 +0,2

83± 1,5 62± 1,5

28 24 32 6 21 28 6 16,0 12.5 4 3,0 6,0 3,0 2,2 10,0

0 0 0

+1 +0,2 +0,2

32 26 36 6 24 33 7 96± 1,5 18,0 71± 1,5 16.0 4 3,0 7,0 3,0 2,6 11,5

0 0 0

a

See Clause 6 of IEC 60120:2020.

5 Test

5.1 Classification of tests

The tests are divided into two groups:

– Group I qualification tests

The qualification tests are made in order to verify the suitability of the type of material to be

used in the manufacture of locking device.

– Group II sample tests

Sample tests are made in order to verify the quality of a manufacture, they are made on

samples taken at random from each lot.

– 10 – IEC 60372:2020 © IEC 2020

5.2 Qualification tests

5.2.1 Test items and the samples

Qualification tests consist of

– hardness test,

– verification of resistance to bending (for split-pins only),

– corrosion resistance test.

They are each made on five samples of material. It shall not be necessary to repeat these

tests if a certificate of qualification test is available and if the locking-device manufacturer

gives proof that the profiled material used is the same.

5.2.2 Hardness test

The hardness test shall be carried out according to ISO 6507-1:2005 for copper alloy locking

devices and for steel locking device. It shall be carried out on one of the flat surfaces of the

locking device (the side opposite the rounding in the case of split-pin types). A series of three

measurements shall be effected on each locking device.

The average of the three measurements shall be greater than or equal to 150.

Upon agreement between the purchaser and the manufacturer, other methods may be used

for measurement of hardness. ISO 6506-1:2014 or ISO 6508-1:2016. In this case, the values

shall be agreed.

5.2.3 Verification of resistance of bending

The test applies only to split-pin. The test shall be carried out on a piece taken from the

straight part of a leg of the split-pin, or on a sample selected from the profiled material from

which the pins have been manufactured.

The test consists of bending the test piece around a specified radius, as shown in Figure 3.

One end of the test piece is inserted into a vice, one of the jaws of which is covered with a

lining piece made of steel with its surface at about 75° from the vertical position. By means of

a wooden mallet, the test piece is bent against the inclined surface.

After this bending, no splits or cracks must appear.

Figure 3 – Arrangement of verification of resistance of bending

Table 3 – Radii of verification of resistance of bending

Dimensions in millimetres

Designated 16

size of 11 20 24 28 32 36 40

a a

A B

coupling

r 2 3 4 4 5 6 7 8 8

a

See Clause 6 of IEC 60120:2020.

5.2.4 Corrosion resistance test

This test concerns stress corrosion cracking. This corrosion can only appear if there is,

simultaneously, a mechanical stress associated with a corrosive atmosphere.

This test concerns neither external corrosion due to corrosive atmospheric conditions nor

contact corrosion which can occur between different metals.

The need for a test for resistance to stress corrosion cracking depends on the material used

for the manufacture of the locking devices.

For the following materials, no test is required:

– bronze and phosphor-bronze;

– copper alloys with not more than 15 % zinc content having undergone a suitable

stabilizing annealing treatment;

– austenitic stainless steels having undergone the standard thermal treatment on the

original profiled material.

For other materials, such as other types of stainless steels and copper alloys with more than

15 % zinc content, a suitable test shall be agreed upon in advance by the manufacturer and

the purchaser, avoiding, for copper alloys, methods requiring the use of mercury nitrate.

– 12 – IEC 60372:2020 © IEC 2020

5.3 Sample tests and sampling

5.3.1 Sample tests

The sample tests consist of:

– visual examination,

– verification of dimensions,

– hardness test,

– verification of resistance to bending.

5.3.2 Sampling

5.3.2.1 Sampling for visual examination

The inspection shall be made by attributes. The following control method shall be applied:

– single sampling,

– size of the sample and acceptance number Ac as given in Table 4.

Table 4 – Size of the sample and acceptance number Ac

Devices in the lot Size of the sample Acceptance number Ac

N n AQL = 1,5 % AQL = 6,5 %

N ≤ 500 50 Ac = 2 Ac = 7

500 < N ≤ 1 200 80 Ac = 3 Ac = 10

1 200 < N ≤ 3 200 125 Ac = 5 Ac = 14

3 200 < N ≤ 10 000 200 Ac = 7 Ac = 21

10 000 < N ≤ 35 000 315 Ac = 10 Ac = 21

35 000 < N ≤ 150 000 500 Ac = 14 Ac = 21

NOTE A lot is the quantity of locking devices manufactured or produced under conditions which are presumed

uniform and offered for acceptance.

5.3.2.2 Sampling for the other tests

The number p of locking devices selected for testing shall be the nearest even number greater

than the one given by the following formulae (N being the number of locking devices in the lot):

N < 500 p shall be subject of agreement between the parties;

0,75N

500 ≤ N ≤ 20000 p = 2 + ;

1 000

0,35N

N > 20000 p = 10 +

1 000

The group of selected samples is submitted to the verification of dimensions test. Then it is

divided into two equal parts, the first being used for the hardness test, the second for the

bending test.

In the event of a sample failing to pass one of the above tests, a re-test procedure according

to 6.4 is permissible.

5.3.3 Visual examination

5.3.3.1 Requirements

The locking device shall not have any defects prejudicial to satisfactory behaviour in service:

a) defects to which an AQL of 1,5 % applies are surface cracking or incipient cracks;

b) defects to which an AQL of 6,5 % applies are rough surface(orange-peel surface), blisters.

5.3.3.2 Acceptance criteria

Acceptance number Ac is given in Table 4.

The lot shall be considered as complying with this standard if the number of defectives is less

than or equal to the acceptance number Ac.

If the lot does not comply, it may be withdrawn and re-examined by the manufacturer.

Following this, it may be submitted again for inspection.

5.3.4 Verification of dimensions

5.3.4.1 Split-pins

For split-pins, the following dimensions shall be checked: S, T, F , R, L.

Verification of dimension L.

To check the dimensions L and L , the split-pin is placed in a jig as shown in Figure 4,

min max

the split-pin being in contact with A. The values for K and D are given in Table 5:

Figure 4 – Verification of L

Table 5 – Specifications of K and D in Figure 4

Dimensions in millimetres

Designated 16

size of 11 20 24 28 32 36 40

a a

A B

coupling

3,5± 0,6 4,0± 0,7 5,0± 1,0 5,0± 1,0 6,0± 1,0 7,0± 1,2 8,0± 1,4 9,0± 1,4 10,0± 1,4

K

D 7,5± 0,4 9,5± 0,5 10.0± 0.5 10,0± 0,5 12,0± 0,5 13,0± 0,5 15,0± 0,5 17,0± 0,5 17,0± 0,5

a

See Clause 6 of IEC 60120:2020.

– 14 – IEC 60372:2020 © IEC 2020

The split-pin, when in the locking position, shall not extend beyond the face AA of the socket

entry, as shown in Figure C.1.

NOTE For 11 standard coupling, it is permitted that the split-pin can extend beyond the socket entry by no more

than 5 mm.

5.3.4.2 W-clips

For W-clips, all dimensions shall be checked.

It is important that, in forming the W-clips, extremity F is approximately perpendicular to the

axis when the clip is in the locking position.

The Annex A shows the gauges which may be used to check the dimensions for W-clips.

5.3.5 Hardness test

The test shall be carried out as described in 5.2.2.

5.3.6 Verification of resistance to bending (for split-pins only)

The test shall be carried out as described in 5.2.3.

5.4 Re-test procedure

In the case of failure to meet the requirements of 5.3.4,agreement may be reached to

withdraw the batch for further examination by manufacturer. The tests of 5.3.4 may then be

repeated, taking three times the number of samples originally submitted to these tests.

If only one locking device fails to comply with one of the tests given in 5.3.5 and 5.3.6, a re-

test concerning this test may be carried out, taking twice the number of samples originally

submitted to this test.

If two or more locking devices fail to comply with one of the tests given in the above clause, or

if the result of the re-test is not satisfactory, the complete batch is considered as not

complying with this document.

Annex A

(normative)

Gauge for W-clips

Gauge for W-clips and its dimensions are given in Figure A.1 and Table A.1, the symbol

marks for dimensions of W-clips are given in Figure A.2.

Dimensions in millimetres

Figure A.1 – Gauge for W-clips

– 16 – IEC 60372:2020 © IEC 2020

Table A.1 – Dimensions of the gauge for W-clips

Dimensions in millimetres

Designated

size of

A B C D E F G H J K L M N P R S

coupling

11 0,6 23 15 20 4 50 3,0 19 18 24 4,5 32 12 3 9 32

a

A

16 1,0 32 22 28 5 60 2,5 24 20 30 8,0 44 15 4 9 32

a

B

20 1,0 32 22 30 5 60 2,5 24 20 30 8,0 55 15 4 9 40

24 1,0 32 22 30 5 60 3,0 25 20 30 8,0 65 15 4 9 42

28 1,0 36 24 32 6 65 3,5 28 22 30 8,0 75 15 5 12 42

32 1,0 40 26 36 6 70 4,5 33 22 35 10,0 85 15 5 12 45

a

See Clause 6 of IEC 60120:2020.

Figure A.2 – Symbol marks for dimensions of W-clips

Notes on the use of gauges for W-clips

• The clip is mounted in the gauge in the position shown so that the nominal dimensions F

and F are maintained by the pegs and stops respectively.

• The grooves of width A correspond to the allowed tolerances of dimension F .The ends of

“ears” of the clip shall lie within the zone defined by these grooves.

• Dimension D corresponds to the nominal overall width F of the clip. The two recesses

allow comparison between the clip and the nominal dimension.

• Dimension E corresponds to the nominal width F of the internal loop. The recess allows

comparison between the clip and the nominal dimension.

• The recesses of width G correspond to the difference between the nominal dimensions F

and F . The internal edges of these recesses allow comparison between the clip and the

nominal dimension F .

• Comparison of the clip with the nominal dimensions L , L , L , and L is made by direct

1 2 3 4

measurement.

• Dimensions S and T on the clip are verified by direct measurement.

Annex B

(normative)

Other dimensions of split-pins

Other dimensions of split-pins, given for guidance of manufacturing only, are given in

Figure B.1 and Table B.1.

Figure B.1 – Other dimensions of the split-pins

Table B.1 – Other dimensions of the split-pins

Dimensions in millimetres

Alternative

Standard split-pins

a

Designated

split-pins

size of

coupling

b b b

F F F F L L L L L F R V F ′

1 3 4 5 1 2 3 4 5 6 3 3

11 11,9 4,5 3,5 2,5 55 16,0 4,6 16 2 1,0 6,0 8 4,8

c d

A 14,5 3,0 70 19,0 5,2 18 6,5 5,7

16 5,5 4,5 3 1,5 12

c

B 16,4 3,5 65 18,5 6,5 22 8,5 6,2

20 16,4 6,0 4,5 3,5 80 22,5 6,5 22 3 1,5 8,5 12 6,2

24 20,0 7,0 7,0 4,0 100 29,5 7,7 28 4 2,0 10,0 12 7,4

28 22,5 7,4 7,5 4,5 115 32,5 8,7 31 5 2,0 12,0 15 7,9

32 26,0 8,4 8,5 5,0 130 37,0 10,0 36 6 2,5 14,0 15 9,2

36 31,0 9,4 9,5 5,5 145 41,5 11,0 39 7 2,5 16,0 18 9,9

40 31,0 9,4 10,0 6,0 160 46,0 12,0 42 7 2,5 16,0 18 9,9

a

All the dimensions are the same as for standard split-pins, except the value F replaced by F ′.

3 3

b

Approximative values given when the split-pins are supplied on insulator or fittings. The angle α can vary from

35°to 50°.

c

See Clause 6 of IEC 60120:2020.

d

If the value of L (see 4.3.1) is reduced to 38 mm, then the value of L can be reduced to 65 mm.

min 1

NOTE 1 The length L can be reduced provided that the eye of the split-pin protrudes sufficiently to allow easy

use of a live-line working tool to operate the split-pin. In this case, the total length L can be reduced accordingly.

NOTE 2 The tips of split-pin legs can be cut straight or chamfered on one or both sides, shown in Figure B.1.

NOTE 3 The radius R indicated in the figure is to be defined by agreement between the manufacture and the

purchaser.

NOTE 4 In order to make the bending of the split-pin legs easier, a notch can be made at a distance "V" from the

tip of the legs.

– 18 – IEC 60372:2020 © IEC 2020

Annex C

(informative)

Method of using the locking devices

C.1 Overview

A locking device shall never be separated from its socket and replaced by a locking device of

different design even if, in both cases, the locking devices are in agreement with the height

T required by IEC 60120.

min

C.2 Method of using the locking devices – Split-pin

The split-pin is inserted through the hole and afterwards the legs are bent as shown in

Figure C.1. It can then be operated between the locking and coupling positions.

a) Split-pin in locking position b) Split-pin in coupling position

Figure C.1 – Positions of split-pin

C.3 Method of using the locking devices – W-clip

The W-clip is inserted through the socket entry and can be operated between the locking and

coupling positions, as shown in Figure C.2.

a) W-clip in locking position b) W-clip in coupling position

Figure C.2 – Positions of W-clip

Bibliography

[1] IEC 60120:2020, Ball and socket couplings of string insulator units - Dimensions

[2] IEC 61325:1995, Insulators for overhead lines with a nominal voltage above 1 000 V –

Ceramic or glass insulator units for DC systems – Definitions, test methods and

acceptance criteria

[3] ISO 2859-1:1999/Amd1:2011, Sampling procedures for inspection by attributes –

Part 1: Sampling schemes indexed by acceptance quality limit(AQL) for lot-by-lot

inspection

_____________

– 20 – IEC 60372:2020 © IEC 2020

SOMMAIRE

AVANT-PROPOS . 22

1 Domaine d’application . 24

2 Références normatives . 24

3 Termes et définitions . 24

4 Formes et dimensions . 25

4.1 Généralités . 25

4.2 Formes des dispositifs de verrouillage . 25

4.2.1 Goupille . 25

4.2.2 Agrafe . 25

4.3 Dimensions des dispositifs de verrouillage . 26

4.3.1 Les goupilles (type normalisé et variante) . 26

4.3.2 Les agrafes . 26

5 Essai . 27

5.1 Classification des essais . 27

5.2 Essais de qualification . 28

5.2.1 Entités soumises à l’essai et échantillons . 28

5.2.2 Essai de dureté . 28

5.2.3 Vérification de la tenue au pliage . 28

5.2.4 Essai de résistance à la corrosion . 29

5.3 Essais sur prélèvements et échantillonnage . 30

5.3.1 Essais sur prélèvements . 30

5.3.2 Échantillonnage . 30

5.3.3 Examen visuel . 31

5.3.4 Vérification des dimensions . 31

5.3.5 Essai de dureté . 32

5.3.6 Vérification de la tenue au pliage (uniquement pour les goupilles) . 32

5.4 Contre-épreuve . 32

Annexe A (normative) Calibre d’agrafes . 33

Annexe B (normative) Autres dimensions de goupilles . 35

Annexe C (informative) Méthode d’utilisation des dispositifs de verrouillage . 36

C.1 Vue d’ensemble . 36

C.2 Méthode d’utilisation des dispositifs de verrouillage – Goupille . 36

C.3 Méthode d’utilisation des dispositifs de verrouillage – Agrafe . 36

Bibliographie . 37

Figure 1 – Forme des goupilles . 26

Figure 2 – Forme des agrafes . 27

Figure 3 – Disposition de vérification de la tenue au pliage . 29

Figure 4 – Vérification de la dimension L . 31

Figure A.1 – Calibre d’agrafes . 33

Figure A.2 – Marques de symbole des dimensions d’agrafes . 34

Figure B.1 – Autres dimensions de goupilles . 35

Figure C.1 – Positions de la goupille . 36

Figure C.2 – Positions de l’agrafe . 36

Tableau 1 – Dimensions des goupilles . 26

Tableau 2 – Dimensions des agrafes . 27

Tableau 3 – Angles de vérification de la tenue au pliage . 29

Tableau 4 – Effectif de l’échantillon et critère d’acceptation Ac . 30

Tableau 5 – Spécifications de K et D à la Figure 4 . 32

Tableau A.1 – Dimensions du calibre d’agrafes . 34

Tableau B.1 – Autres dimensions de goupilles . 35

– 22 – IEC 60372:2020 © IEC 2020

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

DISPOSITIFS DE VERROUILLAGE POUR LES ASSEMBLAGES À ROTULE

ET LOGEMENT DE ROTULE DES ÉLÉMENTS DE CHAÎNES D'ISOLATEURS

– DIMENSIONS ET ESSAIS

AVANT-PROPOS

1) La Commission Électrotechnique Internationale (IEC) est une organisation mondiale de normalisation composée

de l'ensemble des comités électrotechniques nationaux (Comités nationau

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...