IEC 61701:2011

(Main)Salt mist corrosion testing of photovoltaic (PV) modules

Salt mist corrosion testing of photovoltaic (PV) modules

IEC 61701:2011 describes test sequences useful to determine the resistance of different PV modules to corrosion from salt mist containing Cl- (NaCl, MgCl2, etc.). All tests included in the sequences, except the bypass diode functionality test, are fully described in IEC 61215, IEC 61646, IEC 62108, IEC 61730-2 and IEC 60068-2-52. This Standard can be applied to both flat plate PV modules and concentrator PV modules and assemblies. Salt mist test is based on IEC 60068-2-52 rather than IEC 60068-2-11 as in edition 1 since the former standard is much more widely used in the electronic component field. According to this change the new edition 2 includes a cycling testing sequence that combines in each cycle a salt fog exposure followed by humidity storage under controlled temperature and relative humidity conditions. This testing sequence is more suitable to reflect the corrosion processes that happen in PV modules subjected to permanent or temporary corrosive atmospheres.

Essai de corrosion au brouillard salin des modules photovoltaïques (PV)

La CEI 61701:2011 décrit des séquences d'essai pour déterminer la résistance de différents modules photovoltaïques à la corrosion due au brouillard salin contenant du Cl- (NaCl, MgCl2, etc.). Tous les essais inclus dans les séquences, à l'exception de l'essai de fonctionnalité des diodes de dérivation, sont décrits de façon détaillée dans les normes CEI 61215, CEI 61646, CEI 62108, CEI 61730-2 et CEI 60068-2-52. La présente Norme peut être appliquée à des modules photovoltaïques plans et à des modules et ensembles photovoltaïques à concentration. L'essai au brouillard salin est basé sur la CEI 60068-2-52 plutôt que sur la CEI 60068-2-11 comme dans l'édition 1 puisque l'ancienne norme est plus largement utilisée dans le domaine des composants électroniques. Conformément à ce changement, la nouvelle édition 2 inclut une séquence d'essai cyclique qui combine dans chaque cycle une exposition au brouillard salin suivie d'un stockage en milieu humide dans des conditions de température et d'humidité relative contrôlées. Cette séquence d'essai reflète mieux les processus de corrosion rencontrés par les modules photovoltaïques soumis à des atmosphères corrosives permanentes ou temporaires (NaCl).

General Information

- Status

- Published

- Publication Date

- 14-Dec-2011

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 2 - TC 82/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 11-Jun-2020

- Completion Date

- 28-Apr-2017

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61701:2011 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies test sequences for salt mist corrosion testing of photovoltaic (PV) modules. This standard is critical for assessing the corrosion resistance of PV modules exposed to salt mist environments, particularly in marine or coastal locations where chloride salts like sodium chloride (NaCl) and magnesium chloride (MgCl₂) are prevalent.

Its primary objective is to evaluate the durability and reliability of different types of PV modules-including flat plate and concentrator photovoltaic (CPV) modules-under corrosive salt mist conditions. The standardized testing ensures PV modules maintain their electrical performance and integrity throughout their operational lifetime in harsh environments.

Key Topics

Scope and Purpose

Designed to simulate the effects of salt-laden wet atmospheres on PV modules, this standard is applicable to both permanent marine exposure and temporary corrosive atmospheres (such as deicing salts on roads). It evaluates corrosion on metallic parts and deterioration of non-metallic materials like coatings and plastics.Test Basis and Procedures

IEC 61701:2011 bases its salt mist testing on IEC 60068-2-52 (salt mist, cyclic sodium chloride solution), which involves cycles of salt fog exposure followed by humidity storage under controlled temperature and relative humidity conditions. This cyclic test sequence more accurately reflects real-world corrosion mechanisms compared to previous editions relying on single exposure salt fog tests.PV Module Types Covered

- Crystalline silicon PV modules

- Thin-film PV modules

- Concentrator photovoltaic (CPV) modules and assemblies

Testing Components

The standard integrates tests from IEC 61215, IEC 61646, IEC 62108, IEC 61730-2, and IEC 60068-2-52, covering aspects such as:- Bypass diode functionality

- Electrical performance before and after testing

- Visual and mechanical inspections

- Corrosion effects on metallic and non-metallic materials

Sample Requirements

Three identical samples of the PV module model are used, with one serving as a control for comparison. For CPV modules, tests include primary and secondary optics when applicable. Smaller representative samples may be used if full-size modules cannot fit test chambers.

Applications

Marine and Coastal PV Installations

Provides essential assessment for PV modules intended for installation near seas and oceans, where continuous exposure to salt mist can cause rapid degradation.Roadside and Winter Salt Exposure

Suitable for PV systems located near roadways treated with deicing salts, which create temporary corrosive conditions affecting module longevity.Quality Assurance and Certification

Helps manufacturers meet rigorous type approval and design qualification requirements ensuring modules withstand environmental corrosion stresses.Product Development and Improvement

Assists R&D teams in understanding corrosion resistance of different PV materials and designs to innovate more durable photovoltaic products.Comparison of PV Technologies

Enables standardized evaluation across crystalline silicon, thin-film, and CPV technologies to select appropriate solutions based on environmental exposure risks.

Related Standards

- IEC 60068-2-52 – Environmental testing for salt mist, cyclic (sodium chloride solution)

- IEC 61215 – Design qualification for crystalline silicon terrestrial PV modules

- IEC 61646 – Design qualification for thin-film terrestrial PV modules

- IEC 61730-2 – PV module safety qualification and testing requirements

- IEC 62108 – Design qualification for concentrator photovoltaic modules and assemblies

- ISO/IEC 17025 – General requirements for the competence of testing and calibration laboratories

These normative references support IEC 61701 by providing detailed test methods or complementary criteria used during the salt mist corrosion testing sequences.

By adhering to IEC 61701:2011, stakeholders in the photovoltaic industry-including manufacturers, testing labs, and system designers-can ensure that PV modules meet internationally recognized standards for resistance to salt mist corrosion. This standard plays a vital role in enhancing the longevity, safety, and performance of solar power installations operating in corrosive environments worldwide.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 61701:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Salt mist corrosion testing of photovoltaic (PV) modules". This standard covers: IEC 61701:2011 describes test sequences useful to determine the resistance of different PV modules to corrosion from salt mist containing Cl- (NaCl, MgCl2, etc.). All tests included in the sequences, except the bypass diode functionality test, are fully described in IEC 61215, IEC 61646, IEC 62108, IEC 61730-2 and IEC 60068-2-52. This Standard can be applied to both flat plate PV modules and concentrator PV modules and assemblies. Salt mist test is based on IEC 60068-2-52 rather than IEC 60068-2-11 as in edition 1 since the former standard is much more widely used in the electronic component field. According to this change the new edition 2 includes a cycling testing sequence that combines in each cycle a salt fog exposure followed by humidity storage under controlled temperature and relative humidity conditions. This testing sequence is more suitable to reflect the corrosion processes that happen in PV modules subjected to permanent or temporary corrosive atmospheres.

IEC 61701:2011 describes test sequences useful to determine the resistance of different PV modules to corrosion from salt mist containing Cl- (NaCl, MgCl2, etc.). All tests included in the sequences, except the bypass diode functionality test, are fully described in IEC 61215, IEC 61646, IEC 62108, IEC 61730-2 and IEC 60068-2-52. This Standard can be applied to both flat plate PV modules and concentrator PV modules and assemblies. Salt mist test is based on IEC 60068-2-52 rather than IEC 60068-2-11 as in edition 1 since the former standard is much more widely used in the electronic component field. According to this change the new edition 2 includes a cycling testing sequence that combines in each cycle a salt fog exposure followed by humidity storage under controlled temperature and relative humidity conditions. This testing sequence is more suitable to reflect the corrosion processes that happen in PV modules subjected to permanent or temporary corrosive atmospheres.

IEC 61701:2011 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61701:2011 has the following relationships with other standards: It is inter standard links to IEC 61701:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61701:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61701 ®

Edition 2.0 2011-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Salt mist corrosion testing of photovoltaic (PV) modules

Essai de corrosion au brouillard salin des modules photovoltaïques (PV)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61701 ®

Edition 2.0 2011-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Salt mist corrosion testing of photovoltaic (PV) modules

Essai de corrosion au brouillard salin des modules photovoltaïques (PV)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX N

ICS 27.160 ISBN 978-2-88912-840-2

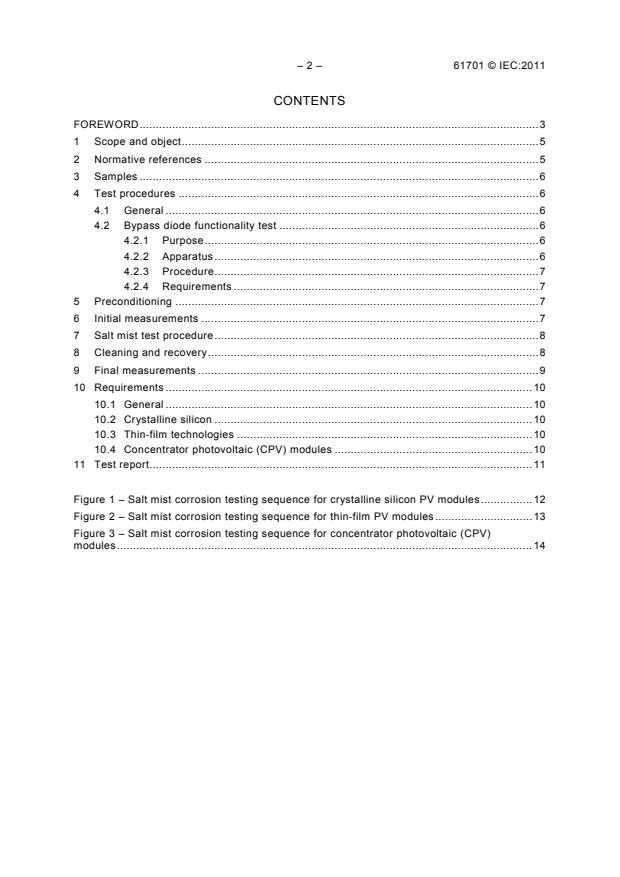

– 2 – 61701 © IEC:2011

CONTENTS

FOREWORD . 3

1 Scope and object . 5

2 Normative references . 5

3 Samples . 6

4 Test procedures . 6

4.1 General . 6

4.2 Bypass diode functionality test . 6

4.2.1 Purpose . 6

4.2.2 Apparatus . 6

4.2.3 Procedure . 7

4.2.4 Requirements . 7

5 Preconditioning . 7

6 Initial measurements . 7

7 Salt mist test procedure . 8

8 Cleaning and recovery . 8

9 Final measurements . 9

10 Requirements . 10

10.1 General . 10

10.2 Crystalline silicon . 10

10.3 Thin-film technologies . 10

10.4 Concentrator photovoltaic (CPV) modules . 10

11 Test report. 11

Figure 1 – Salt mist corrosion testing sequence for crystalline silicon PV modules . 12

Figure 2 – Salt mist corrosion testing sequence for thin-film PV modules . 13

Figure 3 – Salt mist corrosion testing sequence for concentrator photovoltaic (CPV)

modules . 14

61701 © IEC:2011 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SALT MIST CORROSION TESTING OF PHOTOVOLTAIC (PV) MODULES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61701 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

This second edition cancels and replaces the first edition issued in 1995. This edition

constitutes a technical revision.

The main technical changes with respect to the previous edition are as follows:

The scope has been updated to better reflect the applicability of the Standard.

Salt mist test is based on IEC 60068-2-52 rather than IEC 60068-2-11 as in edition 1 since

the former Standard is much more widely used in the electronic component field. According to

this change the new edition 2 includes a cycling testing sequence that combines in each cycle

a salt fog exposure followed by humidity storage under controlled temperature and relative

humidity conditions. This testing sequence is more suitable to reflect the corrosion processes

that happen in PV modules subjected to permanent or temporary corrosive atmospheres

(NaCl). In edition 1 only a salt fog exposure was considered.

– 4 – 61701 © IEC:2011

Additional tests have also been included to verify the effect of the salt mist test not only in the

PV module output but also in some of its components.

Different testing sequences are considered depending on the PV module technology involved:

crystalline silicon, thin-film and concentrator photovoltaic (CPV) modules.

A test report clause has also been included.

The text of this standard is based on the following documents:

FDIS Report on voting

82/667/FDIS 82/681/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

61701 © IEC:2011 – 5 –

SALT MIST CORROSION TESTING OF PHOTOVOLTAIC (PV) MODULES

1 Scope and object

Photovoltaic (PV) modules are electrical devices intended for continuous outdoor exposure

during their lifetime. Highly corrosive wet atmospheres, such as marine environments, could

eventually degrade some of the PV module components (corrosion of metallic parts,

deterioration of the properties of some non-metallic materials - such as protective coatings

and plastics - by assimilation of salts, etc.) causing permanent damages that could impair

their functioning. Temporary corrosive atmospheres are also present in places where salt is

used in winter periods to melt ice formations on streets and roads.

This Standard describes test sequences useful to determine the resistance of different PV

-

modules to corrosion from salt mist containing Cl (NaCl, MgCl , etc.). All tests included in the

sequences, except the bypass diode functionality test, are fully described in IEC 61215,

IEC 61646, IEC 62108, IEC 61730-2 and IEC 60068-2-52. They are combined in this Standard

to provide means to evaluate possible faults caused in PV modules when operating under wet

atmospheres having high concentration of dissolved salt (NaCl). Depending on the specific

nature of the surrounding atmosphere to which the module is exposed in real operation

several testing severities can be applied, as defined in IEC 60068-2-52. For example severity

(1) is intended to be used for PV modules used in a marine environment, or in close proximity

to the sea. Severities (3) to (6) are intended for PV modules operating in locations where

there could be a change between salt-laden and dry atmospheres, for examples in places

where salt is used to melt ice formations. Severity (2) is not suitable for PV modules as

testing conditions are too weak (this severity is originally intended for products exposed to

corrosive environments from time to time that are normally protected by an enclosure) and

should be avoided when applying this Standard.

This Standard can be applied to both flat plate PV modules and concentrator PV modules and

assemblies.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-52, Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium

chloride solution)

IEC 61215:2005, Crystalline silicon terrestrial photovoltaic (PV) modules – Design

qualification and type approval

IEC 61646:2008, Thin-film terrestrial photovoltaic (PV) modules – Design qualification and

type approval

IEC 61730-2:2004, Photovoltaic (PV) module safety qualification – Part 2: Requirements for

testing

IEC 62108:2007, Concentrator photovoltaic (CPV) modules and assemblies – Design

qualification and type approval

– 6 – 61701 © IEC:2011

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories

3 Samples

Three identical samples of the model of PV module or assembly of interest shall be subjected

to any of the testing sequences included in Figures 1, 2 or 3, depending on the PV technology

considered, namely crystalline silicon, thin-film or concentrator photovoltaic (CPV)

respectively. As the figures indicate one of these samples should be used as a control. The

control sample should be used as a check every time the test samples are measured to

evaluate the effect of the salt mist test.

In the case of CPV different situations for choosing the sample may occur. For non-field-

adjustable focus-point CPV systems or modules, 3 modules are required to complete the

testing sequence included in Figure 3. For field-adjustable focus-point CPV systems or

assemblies, 3 receivers (including secondary optics sections, if applicable) and 3 primary

optics sections are required to complete the testing sequence included in Figure 3. A

complete description of the different types and components of CPV modules and assemblies

can be found in IEC 62108.

If a full-size sample is too large to fit into the environmental chambers required for the salt

mist test then a smaller representative sample may be specially designed and manufactured

for this test. The representative sample should be carefully designed so that it can reveal

similar failure mechanisms as the full-size one, and the fabrication process of the

representative sample should be as identical as possible to the process of the full-size ones.

The fact that the test has been made on representative samples and not on the full-size

samples has to be indicated and reported in the test report under item g), see Clause 11.

If the PV module is provided with means for grounding then they constitute a part of the test

sample.

4 Test procedures

4.1 General

All tests included in Figures 1, 2 or 3, except the bypass diode functionality test, are fully

described (including purpose, apparatus, procedure and requirements) in the IEC Standards

from where the specific tests are taken (see notes in the Figures). Tests included in Figures

1, 2 or 3 shall be performed in the specified order. In the case of CPV if some test procedures

included in this Standard are not applicable to a specific design configuration, the

manufacturer should discuss this with the testing agency to develop a comparable test

program, based on the principles described in this Standard. Any changes and deviations

shall be recorded and reported in detail, as required in Clause 11, item l).

4.2 Bypass diode functionality test

4.2.1 Purpose

To verify that the bypass diode(s) of the test samples remains functional following the salt fog

exposure.

NOTE If in the test sample there are no bypass diodes or the bypass diodes do not have any metallic parts then

this test is omitted.

4.2.2 Apparatus

a) DC power source capable of applying a current up to 1,25 times the standard test

conditions (STC) short-circuit current of the sample under test and means for monitoring

the flow of current through the test sample during the test period.

61701 © IEC:2011 – 7 –

b) Equipment for measuring the voltage drop across the test sample at an accuracy of

± 0,5 % of reading.

c) Equipment for measuring test current at an accuracy of ± 0,5 % of reading.

4.2.3 Procedure

This procedure can be conducted in any ambient within 25 °C ± 10 °C. During the test the

sample shall not be subjected to illumination.

a) Electrically short any blocking diodes incorporated to the test sample.

b) Determine the rated STC short-circuit current of the test sample from its label or

instruction sheet.

c) Connect the DC power source’s positive output to the test sample negative lead, and the

DC power source’s negative output to the test sample positive lead by using wires of the

manufacturer’s minimum recommended wire gauge. Follow the manufacturer’s

recommendations for wire entry into the wiring compartment. With this configuration the

current shall pass through the cells in the reverse direction and through the diode(s) in the

forward direction.

NOTE Some modules have overlapping bypass diode circuits. In this case it may be necessary to install a jumper

cable to ensure that all of the current is flowing through one bypass diode.

d) Apply a current equal to of 1,25 times (± 5 %) the STC short-circuit current of the test

sample for a period of 1 h.

4.2.4 Requirements

After the 1 h of current flow check that the bypass diode(s) remains operational. A possible

method is to again pass a forward current through the diode(s) by passing a reverse current

through the cells and then monitor the temperature of the diode(s) with the aid of a thermal IR

camera. Diode(s) shall reach thermal equilibrium with the environment after step d) above

before applying this procedure. Another option is to shade a solar cell protected by each

diode (one per string, step by step) in the PV module and verify the characteristics of the

resulting I-V curve (under illumination close to STC) to check if the bypass diode(s) is(are)

working.

5 Preconditioning

All test samples shall be preconditioned with either global or direct normal sunlight (natural or

simulated) according to the specifications given in the applicable design qualification and type

approval IEC Standard applicable to the PV module technology considered, i.e., IEC 61215

for crystalline silicon, IEC 61646 for thin-film materials and IEC 62108 for concentrator

photovoltaic (CPV). At the time of writing this Standard no preconditioning is specified for

thin-film technologies in IEC 61646.

6 Initial measurements

6.1 The following initial measurements shall be performed on the selected samples

depending on the PV module technology being evaluated.

6.2 Crystalline silicon. The test order is included in Figure 1.

– Tests according to IEC 61215:

a) 10.2: Maximum power determination

b) 10.15: Wet leakage current test

– Tests according to IEC 61730-2

c) MST 01: Visual inspection

– 8 – 61701 © IEC:2011

d) MST 13: Ground continuity test

e) MST 16: Dielectric withstand test

NOTE The reference before each test corresponds to its identification in the relevant IEC Standard.

6.3 Thin-film technologies. The test order is included in Figure 2.

– Tests according to IEC 61646:

a) 10.2: Maximum power determination.

NOTE 1 The only purpose of this test is to verify that the PV module is operational before being subjected to the

subsequent tests of the sequence.

b) 10.15: Wet leakage current test

– Tests according to IEC 61730-2

c) MST 01: Visual inspection

d) MST 13: Ground continuity test

e) MST 16: Dielectric withstand test

NOTE 2 The reference before each test corresponds to its identification in the relevant IEC Standard.

6.4 Concentrator photovoltaic (CPV) modules. The test order is included in Figure 3.

– Tests according to IEC 62108:

a) 10.1: Visual inspection

b) 10.2: Electrical performance measurement

c) 10.3: Ground path continuity test

d) 10.4: Electrical insulation test

e) 10.5: Wet insulation test

NOTE The reference before each test correspond to its identification in IEC 62108.

7 Salt mist test procedure

Apply to the test samples under study the salt mist test as described in IEC 60068-2-52

following the general conditions, apparatus, characteristics of the salt solution, severities and

other specifications included. The severity of the salt mist test shall be chosen according to

the atmospheric conditions prevailing in the place where the installation of the PV modules is

intended. Severity (2) is not suitable for PV modules as testing conditions are too weak (it is

intended for products exposed to corrosive environments from time to time that are normally

protected by an enclosure) and should be avoided when applying this Standard. During

testing the face of the PV module normally exposed to solar irradiance shall be inclined 15° to

30° from vertical inside the salt fog chamber. The module can be placed vertically in the

humidity chamber used for the humidity storage portion of the test.

8 Cleaning and recovery

After the salt mist test all samples shall be washed to remove the adherent salt using running

tap water (not artificially pressurised) for a maximum time of 5 min per square metre of area

of the sample. Once the washing is finished distilled or demineralized water shall be used to

rinse the samples, followed by complete drying at room temperature. To accelerate drying it is

allowed to shake the test sample by hand or to use air blasts with the aid of a fan. The

temperature of the water used for washing shall not exceed 35 °C. During cleaning or drying

the use of cloths, gauzes or any other woven material shall be avoided and no scraping is

allowed. After drying, the recovery time shall be minimised and the applicable testing

sequence shall be continued as soon as possible to avoid further damage produced by salt

depositions.

61701 © IEC:2011 – 9 –

9 Final measurements

9.1 After the salt mist test the test samples shall be subjected to the following tests

depending on the PV module technology.

9.2 Crystalline silicon. The test order is included in Figure 1.

– Tests according to IEC 61215:

a) 10.2: Maximum power determination

b) 10.15: Wet leakage current test

– Tests according to IEC 61730-2:

c) MST 01: Visual inspection

d) MST 13: Ground continuity test

e) MST 16: Dielectric withstand test

NOTE The reference before each test corresponds to its identification in the relevant IEC Standard.

– Test according to this Standard:

f) Bypass diode functionality test

9.3 Thin-film technologies. The test order is included in Figure 2.

– Tests according to IEC 61646:

a) 10.6: Performance at STC (not NOCT)

b) 10.15: Wet leakage current test

c) 10.19: Light soaking

– Tests according to IEC 61730-2

d) MST 01: Visual inspection

e) MST 13: Ground continuity test

f) MST 16: Dielectric withstand test

NOTE The reference before each test corresponds to its identification in the relevant IEC Standard.

– Test according to this Standard:

g) Bypass diode functionality test

9.4 Concentrator photovoltaic (CPV) module. The test order is included in Figure 3.

– Tests according to IEC 62108:

a) 10.1: Visual inspection

b) 10.2: Electrical performance measurement

c) 10.3: Ground path continuity test

d) 10.4: Electrical insulation test

e) 10.5: Wet insulation test

NOTE The reference before each test corresponds to its identification in IEC 62108.

– Test according to this Standard:

f) Bypass diode functionality test

– 10 – 61701 © IEC:2011

10 Requirements

10.1 General

The following requirements shall be fulfilled by the two PV samples that undergo the testing

sequences included in Figures 1, 2 or 3:

10.2 Crystalline silicon

– After the salt mist test there shall be no evidence of major visual defects as described in

IEC 61730-2 including also no mechanical deterioration or corrosion of module

components which would significantly impair their function during their intended life.

– After the salt mist test the maximum power shall not decrease by more than 5 % of the

initial value.

NOTE The pass/fail criteria should consider the laboratory uncertainty of measurement.

– All pass fail criteria corresponding to tests 10.15, MST 13 and MST 16 shall be fulfilled

according to what is specified in IEC 61215 and IEC 61730-2 for these specific tests.

– The requirement for the bypass diode functionality test shall be also fulfilled.

10.3 Thin-film technologies

– After the salt mist test there shall be no evidence of major visual defects as described in

IEC 61730-2 including also no mechanical deterioration or corrosion of module

components which would significantly impair their function during their intended life.

– After the light soaking the maximum power at Standard Test Conditions (STC) shall not be

less than 90 % of the minimum value specified by the manufacturer in the marking of the

PV module.

NOTE 1 The pass/fail criteria should consider the laboratory uncertainty of measurement.

– All pass fail criteria corresponding to tests 10.15, 10.19, MST 13 and MST 16 shall be

fulfilled according to what is specified in IEC 61646 and IEC 61730-2 for these specific

tests.

NOTE 2 In the case of the requirements corresponding to test 10.19 (light soaking) MST 01 of IEC 61730-2

should be applied instead of test 10.1 of IEC 61646 and MST 16 of IEC 61730-2 should be applied instead of test

10.3 of IEC 61646.

– The requirement for the bypass diode functionality test shall be also fulfilled.

10.4 Concentrator photovoltaic (CPV) modules

– After the salt mist test there shall be no evidence of major visual defects as described in

IEC 62108 including also no mechanical deterioration or corrosion of test sample

components which would significantly impair their function during their intended life. No

significant amount of water should remain inside the test sample after the salt mist test

(the depth of the remaining water should not reach any electrically active parts in any

possible position).

– After the salt mist test the relative power degradation shall not exceed 7 % if the I-V

measurement is under outdoor natural sunlight, or 5 % if the I-V measurement is under

solar simulator.

NOTE The pass/fail criteria should consider the laboratory uncertainty of measurement.

– All pass fail criteria corresponding to tests 10.3, 10.4 and 10.5 shall be fulfilled according

to what is specified in IEC 62108 for these specific tests.

– The requirement for the bypass diode functionality test shall be also fulfilled.

61701 © IEC:2011 – 11 –

11 Test report

A test report with measured performance characteristics and test results shall be prepared by

the test agency in accordance with ISO/IEC 17025. The test report shall contain the following

data:

a) a title;

b) name and address of the test laboratory and location where the tests were carried out;

c) unique identification of the certification or report and of each page, and a clear

identification of the purpose of the test report;

d) name and address of client, where appropriate;

e) reference to sampling procedure, where relevant;

f) date of receipt of test items and date(s) of test, where appropriate;

g) description and identification of the items tested. If the test has been made on

representative samples and not on the full-size samples this has to be clearly indicated;

h) characterization and condition of the test items;

i) identification of test method used;

j) characteristics of the salt solution used;

k) severity applied for the salt mist test according to IEC 60068-2-52;

l) any deviations from, additions to or exclusions from the test method, and any other

information relevant to a specific test, such as environmental conditions;

m) measurements, examinations and derived results supported by tables, graphs, sketches

and photographs as appropriate including any failures observed;

n) a statement of the estimated uncertainty of the test results (where relevant);

o) a signature and title, or equivalent identification of the person(s) accepting responsibility

for the content of the certificate or report, and the date of issue;

p) where relevant, a statement to the effect that the results relate only to the items tested;

q) a statement that the report shall not be reproduced except in full, without the written

approval of the laboratory.

A copy of this report shall be kept by the laboratory and manufacturer for reference purposes.

– 12 – 61701 © IEC:2011

3 modules

Preconditioning

MST 01

Visual inspection

10.2

Maximum power determination

MST 16

Dielectric withstand test

10.15

Wet leakage current test

MST 13

Ground continuity test

2 modules

1 module

Salt mist test according to any one of the severities included in IEC 60068-2-52, except severity 2

Cleaning and recovery

MST 01

Visual inspection

10.2

Maximum power determination

C

o

MST 16

n

Dielectric withstand tes t

t

r

o

l

10.15

Wet leakage current test

MST 13

Ground continuity test

Bypass diode functionality test

IEC 2751/11

NOTE 1 Preconditioning and tests 10.2 and 10.15 are taken from IEC 61215. Tests MST 01, MST 13 and MST 16 are taken

from IEC 61730-2.

NOTE 2 The control module should be used as a check every time the test modules are measured to evaluate the effect of

the salt mist test.

Figure 1 – Salt mist corrosion testing sequence for crystalline silicon PV modules

61701 © IEC:2011 – 13 –

3 modules

MST 01

Visual inpection

10.2

Maximum power determination

MST 16

Dielectric withstand test

10.15

Wet leakage current test

MST 13

Ground continuity test

2 modules

Salt mist test according to any one of the severities included in IEC 60068-2-52, except severity 2

1 module

Cleaning and recovery

MST 01

Visual inspection

MST 16

Dielectric withstand test

10.15

C

Wet leakage current test

o

n

t

r

MST 13

o

Ground continuity test

l

Bypass diode functionality test

10.19

Light soaking

10.6

Performance at STC (not NOCT)

IEC 2752/11

NOTE 1 Tests 10.2, 10.6, 10.15 and 10.19 are taken from IEC 61646. Tests MST 01, MST 13 and MST 16 are taken from

IEC 61730-2.

NOTE 2 The control module should be used as check every time the test modules are measured to evaluate the effect of

the salt mist test.

NOTE 3 Maximum power determination after salt mist test according to test 10.2 of IEC 61646 could eventually be made

for diagnostic purpose only.

NOTE 4 Test 10.6 is performed as a part of the requirements corresponding to test 10.19 a described in IEC 61646. For

the remaining requirements use test MST 01 instead of 10.1 and MST 16 instead of 10.3.

Figure 2 – Salt mist corrosion testing sequence for thin-film PV modules

– 14 – 61701 © IEC:2011

3 modules (m) (for CPV modules)

3 receivers (r) + 3 mirrors (mir) (for CPV assemblies)

Preconditioning

10.1

3m

Visual inspection

3r + 3mir

10.2

3m

Electrical performance measurement

3r + 3mir

10.4 3m

Electrical insulation test 3r + 3mir

10.5 3m

Wet insulation test 3r + 3mir

10.3 3m

Ground path continuity test 3r + 3mir

1m (for CPV modules) 2m (for CPV modules)

1r + 1mir (for CPV assemblies) 2r + 2mir (for CPV assemblies)

2m

Salt mist test according to any one of the severities included in IEC 60068-2-52, except severity 2

2r + 2mir

Cleaning and recovery

10.1 2m

Visual inspection 2r + 2mir

10.2

2m

Electrical performance measurement

2r + 2mir

C

o

10.4

n 2m

t Electrical insulation test 2r + 2mir

r

o

10.5

l 2m

Wet insulation test

2r + 2mir

10.3

2m

Ground path continuity test

2r + 2mir

2m

Bypass diode functionality test

2r

IEC 2753/11

NOTE 1 Tests 10.1, 10.2, 10.3, 10.4 and 10.5 are taken from IEC 62108.

NOTE 2 The control sample should be used as a check every time the test sample are measured to evaluate the effect

of the salt mist test.

Figure 3 – Salt mist corrosion testing sequence

for concentrator photovoltaic (CPV) modules

____________

– 16 – 61701 © CEI:2011

SOMMAIRE

AVANT-PROPOS . 17

1 Domaine d’application et objet . 19

2 Références normatives . 19

3 Echantillons . 20

4 Procédures d’essai . 20

4.1 Généralités. 20

4.2 Essai de fonctionnalité des diodes de dérivation . 21

4.2.1 But . 21

4.2.2 Appareillage . 21

4.2.3 Procédure . 21

4.2.4 Exigences . 21

5 Préconditionnement . 21

6 Mesures initiales . 22

7 Procédure d’essai au brouillard salin . 22

8 Nettoyage et rétablissement . 23

9 Mesures finales . 23

10 Exigences . 24

10.1 Généralités. 24

10.2 Silicium cristallin . 24

10.3 Technologies de type couches minces . 24

10.4 Modules photovoltaïques à concentration . 25

11 Rapport d’essai . 25

Figure 1 – Séquence d'essais de corrosion au brouillard salin pour des modules

photovoltaïques (PV) au silicium cristallin . 27

Figure 2 – Séquence d'essais de corrosion au brouillard salin pour des modules

photovoltaïques (PV) en couches minces . 28

Figure 3 – Séquence d'essais de corrosion au brouillard salin pour des modules

photovoltaïques à concentration (CPV) . 29

61701 © CEI:2011 – 17 –

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

ESSAI DE CORROSION AU BROUILLARD SALIN

DES MODULES PHOTOVOLTAÏQUES (PV)

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI elle-même ne fournit aucune attestation de conformité. Des organismes de certification indépendants

fournissent des services d'évaluation de conformité et, dans certains secteurs, accèdent aux marques de

conformité de la CEI. La CEI n'est responsable d'aucun des services effectués par les organismes de

certification indépendants.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de brevet. La CEI ne saurait être tenue pour responsable de ne pas avoir identifié de tels droits

de brevets et de ne pas avoir signalé leur existence.

La Norme internationale CEI 61701 a été établie par le comité d'études 82 de la CEI:

Systèmes de conversion photovoltaïque de l'énergie solaire.

Cette deuxième édition annule et remplace la première édition publiée en 1995.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...