IEC 60079-10:2002

(Main)Electrical apparatus for explosive gas atmospheres - Part 10: Classification of hazardous areas

Electrical apparatus for explosive gas atmospheres - Part 10: Classification of hazardous areas

Is concerned with the classification of hazardous areas where flammable gas or vapour risks may arise, in order to permit the proper selection and installation of apparatus for use in such hazardous areas.

Matériel électrique pour atmosphères explosives gazeuses - Partie 10: Classement des emplacements dangereux

Est relative au classement des régions dangereuses dans lesquelles des risques dus à des gaz, ou vapeurs, inflammables peuvent apparaître, afin de permettre le choix et l'installation corrects du matériel à utiliser dans de telles régions dangereuses.

General Information

- Status

- Replaced

- Publication Date

- 18-Jun-2002

- Technical Committee

- SC 31J - Classification of hazardous areas and installation requirements

- Drafting Committee

- MT 4 - TC 14/MT 4

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 09-Dec-2008

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 10-Feb-2026

- Effective Date

- 05-Sep-2023

IEC 60079-10:2002 - Electrical apparatus for explosive gas atmospheres - Part 10: Classification of hazardous areas Released:6/19/2002

IEC 60079-10:2002 - Matériel électrique pour atmosphères explosives gazeuses - Partie 10: Classement des emplacements dangereux Released:6/19/2002

IEC 60079-10:2002 - Electrical apparatus for explosive gas atmospheres - Part 10: Classification of hazardous areas Released:6/19/2002 Isbn:2831863791

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60079-10:2002 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical apparatus for explosive gas atmospheres - Part 10: Classification of hazardous areas". This standard covers: Is concerned with the classification of hazardous areas where flammable gas or vapour risks may arise, in order to permit the proper selection and installation of apparatus for use in such hazardous areas.

Is concerned with the classification of hazardous areas where flammable gas or vapour risks may arise, in order to permit the proper selection and installation of apparatus for use in such hazardous areas.

IEC 60079-10:2002 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60079-10:2002 has the following relationships with other standards: It is inter standard links to IEC 60079-10-1:2008, EN 61800-2:2015, IEC 60079-10:1995. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60079-10:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

60079-10

Fourth edition

2002-06

Electrical apparatus for explosive gas

atmospheres –

Part 10:

Classification of hazardous areas

This English-language version is derived from the original

bilingual publication by leaving out all French-language

pages. Missing page numbers correspond to the French-

language pages.

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the base

publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to this

publication, including its validity, is available in the IEC Catalogue of publications

(see below) in addition to new editions, amendments and corrigenda. Information on

the subjects under consideration and work in progress undertaken by the technical

committee which has prepared this publication, as well as the list of publications

issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees and

date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub) is

also available by email. Please contact the Customer Service Centre (see below)

for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

60079-10

Fourth edition

2002-06

Electrical apparatus for explosive gas

atmospheres –

Part 10:

Classification of hazardous areas

IEC 2002 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical,

including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

XA

Commission Electrotechnique Internationale

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

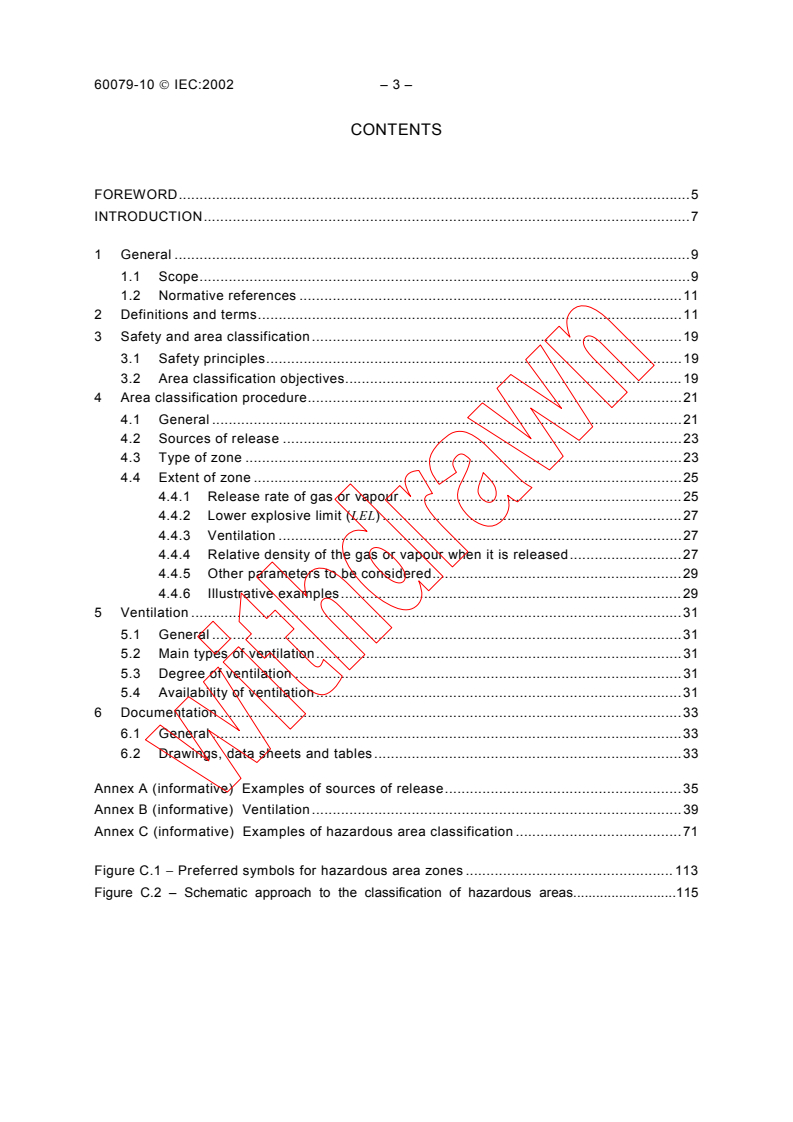

60079-10 IEC:2002 – 3 –

CONTENTS

FOREWORD.5

INTRODUCTION.7

1 General .9

1.1 Scope.9

1.2 Normative references .11

2 Definitions and terms.11

3 Safety and area classification .19

3.1 Safety principles.19

3.2 Area classification objectives.19

4 Area classification procedure.21

4.1 General .21

4.2 Sources of release .23

4.3 Type of zone .23

4.4 Extent of zone .25

4.4.1 Release rate of gas or vapour.25

4.4.2 Lower explosive limit (LEL) .27

4.4.3 Ventilation .27

4.4.4 Relative density of the gas or vapour when it is released.27

4.4.5 Other parameters to be considered.29

4.4.6 Illustrative examples.29

5 Ventilation .31

5.1 General .31

5.2 Main types of ventilation.31

5.3 Degree of ventilation .31

5.4 Availability of ventilation.31

6 Documentation .33

6.1 General .33

6.2 Drawings, data sheets and tables.33

Annex A (informative) Examples of sources of release.35

Annex B (informative) Ventilation.39

Annex C (informative) Examples of hazardous area classification .71

Figure C.1 − Preferred symbols for hazardous area zones .113

Figure C.2 – Schematic approach to the classification of hazardous areas.115

60079-10 IEC:2002 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL APPARATUS FOR EXPLOSIVE GAS ATMOSPHERES –

Part 10: Classification of hazardous areas

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60079-10 has been prepared by subcommittee 31J: Classification

of hazardous areas and installation requirements, of IEC technical committee 31: Electrical

apparatus for explosive atmospheres.

This fourth edition cancels and replaces the third edition published in 1995, and constitutes a

technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

31J/82/FDIS 31J/84/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annexes A, B and C are for information only.

The committee has decided that the contents of this publication will remain unchanged

until 2007. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

60079-10 IEC:2002 – 7 –

INTRODUCTION

In areas where dangerous quantities and concentrations of flammable gas or vapour may

arise, protective measures are to be applied in order to reduce the risk of explosions. This

part of IEC 60079 sets out the essential criteria against which the risk of ignition can be

assessed, and gives guidance on the design and control parameters which can be used in

order to reduce such a risk.

This standard can be used as a basis for the proper selection and installation of apparatus for

use in a hazardous area.

60079-10 IEC:2002 – 9 –

ELECTRICAL APPARATUS FOR EXPLOSIVE GAS ATMOSPHERES –

Part 10: Classification of hazardous areas

1 General

1.1 Scope

This part of IEC 60079 is concerned with the classification of hazardous areas where

flammable gas or vapour risks may arise, in order to permit the proper selection and

installation of apparatus for use in such hazardous areas.

It is intended to be applied where there may be a risk of ignition due to the presence of

flammable gas or vapour, mixed with air under normal atmospheric conditions (see note 2),

but it does not apply to

a) mines susceptible to firedamp;

b) the processing and manufacture of explosives;

c) areas where a risk may arise due to the presence of ignitable dusts or fibres;

d) catastrophic failures which are beyond the concept of abnormality dealt with in this

standard (see note 3);

e) rooms used for medical purposes;

f) areas where the presence of flammable mist may give rise to an unpredictable risk and

which require special consideration (see note 5);

g) domestic premises.

This standard does not take into account the effects of consequential damage.

Definitions and explanations of terms are given together with the main principles and

procedures relating to hazardous area classification.

For detailed recommendations regarding the extent of the hazardous areas in specific

industries or applications, reference may be made to the codes relating to those industries or

applications.

NOTE 1 For the purpose of this standard, an area is a three-dimensional region or space.

NOTE 2 Atmospheric conditions include variations above and below reference levels of 101,3 kPa (1 013 mbar)

and 20 °C (293 K), provided that the variations have a negligible effect on the explosion properties of the

flammable materials.

NOTE 3 Catastrophic failure in this context is applied, for example, to the rupture of a process vessel or pipeline

and events that are not predictable.

NOTE 4 In any process plant, irrespective of size, there may be numerous sources of ignition apart from those

associated with electrical apparatus. Appropriate precautions will be necessary to ensure safety in this context.

This standard may be used with judgement for other ignition sources.

NOTE 5 Mists may form or be present at the same time as flammable vapours. This may affect the way flammable

material disperses and the extent of any hazardous areas. The strict application of area classification for gases

and vapours may not be appropriate because the flammability characteristics of mists are not always predictable.

Whilst it can be difficult to decide upon the type and extent of zones, the criteria applicable to gases and vapours

will, in most cases, give a safe result. However, special consideration should always be given to the danger of

ignition of flammable mists.

60079-10 IEC:2002 – 11 –

1.2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050(426):1990, International Electrotechnical Vocabulary (IEV) – Chapter 426:

Electrical apparatus for explosive atmospheres

IEC 60079-4:1975, Electrical apparatus for explosive gas atmospheres – Part 4: Method of

test for ignition temperature

IEC 60079-4A:1970, First supplement to IEC 60079-4 (1966), Electrical apparatus for

explosive gas atmospheres – Part 4: Method of test for ignition temperature

IEC 60079-20:1996, Electrical apparatus for explosive gas atmospheres – Part 20: Data for

flammable gases and vapours, relating to the use of electrical apparatus

2 Definitions and terms

For the purpose of this part of IEC 60079, the following definitions and terms apply.

NOTE Where a definition appears in this clause and in IEC 60050(426), the definition given in this clause is

applicable.

2.1

explosive atmosphere

mixture with air, under atmospheric conditions, of flammable substances in the form of gas,

vapour, mist or dust, in which after ignition, combustion spreads throughout the unconsumed

mixture

[IEV 426-02-02, modified]

2.2

explosive gas atmosphere

mixture with air, under atmospheric conditions, of flammable substances in the form of gas or

vapour in which, after ignition, combustion spreads throughout the unconsumed mixture

[IEV 426-02-03, modified]

NOTE Although a mixture which has a concentration above the upper explosive limit (UEL) is not an explosive

gas atmosphere, it can readily become so and, in certain cases for area classification purposes, it is advisable to

consider it as an explosive gas atmosphere.

2.3

hazardous area

area in which an explosive gas atmosphere is present, or may be expected to be present, in

quantities such as to require special precautions for the construction, installation and use of

apparatus

[IEV 426-03-01, modified]

2.4

non-hazardous area

area in which an explosive gas atmosphere is not expected to be present in quantities such

as to require special precautions for the construction, installation and use of apparatus

[IEV 426-03-02, modified]

60079-10 IEC:2002 – 13 –

2.5

zones

hazardous areas are classified into zones based upon the frequency of the occurrence and

duration of an explosive gas atmosphere, as follows:

2.5.1

zone 0

place in which an explosive atmosphere consisting of a mixture with air of flammable

substances in the form of gas, vapour or mist is present continuously or for long periods or

frequently

[IEV 426-03-03, modified]

2.5.2

zone 1

place in which an explosive atmosphere consisting of a mixture with air of flammable

substances in the form of gas, vapour or mist is likely to occur in normal operation

occasionally

[IEV 426-03-04, modified]

2.5.3

zone 2

place in which an explosive atmosphere consisting of a mixture with air of flammable

substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it

does occur, will persist for a short period only

[IEV 426-03-05, modified]

NOTE 1 In this definition, the word "persist" means the total time for which the flammable atmosphere will exist.

This will normally comprise the total of the duration of the release, plus the time taken for the flammable

atmosphere to disperse after the release has stopped. (The term "persistence time" as used in annex B refers

specifically to only one part of the total time for which the flammable atmosphere will exist.)

NOTE 2 Indications of the frequency of the occurrence and duration may be taken from codes relating to specific

industries or applications.

2.6

source of release

point or location from which a flammable gas, vapour, or liquid may be released into the

atmosphere in such a way that an explosive gas atmosphere could be formed

[IEV 426-03-06, modified]

2.7

grades of release

there are three basic grades of release, as listed below in order of decreasing frequency and

likelihood of the explosive gas atmosphere being present:

a) continuous grade;

b) primary grade;

c) secondary grade.

A source of release may give rise to any one of these grades of release, or to a combination

of more than one

2.7.1

continuous grade of release

release which is continuous or is expected to occur frequently or for long periods

60079-10 IEC:2002 – 15 –

2.7.2

primary grade of release

release which can be expected to occur periodically or occasionally during normal operation

2.7.3

secondary grade of release

release which is not expected to occur in normal operation and, if it does occur, is likely to do

so only infrequently and for short periods

2.8

release rate

quantity of flammable gas or vapour emitted per unit time from the source of release

2.9

normal operation

situation when the equipment is operating within its design parameters

NOTE 1 Minor releases of flammable material may be part of normal operation. For example, releases from seals

which rely on wetting by the fluid which is being pumped are considered to be minor releases.

NOTE 2 Failures (such as the breakdown of pump seals, flange gaskets or spillages caused by accidents) which

involve urgent repair or shut-down are not considered to be part of normal operation nor are they considered to be

catastrophic.

NOTE 3 Normal operation includes start-up and shut-down conditions.

2.10

ventilation

movement of air and its replacement with fresh air due to the effects of wind, temperature

gradients, or artificial means (for example, fans or extractors)

2.11

explosive limits

NOTE The terms "explosive limit" and "flammable limit" are equivalent. IEC 60079-20 and IEC 61779-1 use the

term "flammable limit" whilst all the other standards use the more widely accepted term "explosive limit".

2.11.1

lower explosive limit (LEL)

concentration of flammable gas or vapour in air, below which the gas atmosphere is not

explosive

[IEV 426-02-09, modified]

2.11.2

upper explosive limit (UEL)

concentration of flammable gas or vapour in air, above which the gas atmosphere is not

explosive

[IEV 426-02-10, modified]

2.12

relative density of a gas or a vapour

density of a gas or a vapour relative to the density of air at the same pressure and at the

same temperature (air is equal to 1,0)

60079-10 IEC:2002 – 17 –

2.13

flammable material (flammable substance)

material which is flammable of itself, or is capable of producing a flammable gas, vapour or

mist

2.14

flammable liquid

liquid capable of producing a flammable vapour under any foreseeable operating conditions

2.15

flammable gas or vapour

gas or vapour which, when mixed with air in certain proportions, will form an explosive gas

atmosphere

2.16

flammable mist

droplets of flammable liquid, dispersed in air so as to form an explosive atmosphere

2.17

flashpoint

lowest liquid temperature at which, under certain standardized conditions, a liquid gives off

vapours in a quantity such as to be capable of forming an ignitable vapour/air mixture

[IEV 426-02-14]

2.18

boiling point

temperature of a liquid boiling at an ambient pressure of 101,3 kPa (1 013 mbar)

NOTE The initial boiling point that should be used for liquid mixtures is to indicate the lowest value of the boiling

point for the range of liquids present, as determined in a standard laboratory distillation without fractionation.

2.19

vapour pressure

pressure exerted when a solid or liquid is in equilibrium with its own vapour. It is a function of

the substance and of the temperature

2.20

ignition temperature of an explosive gas atmosphere

lowest temperature of a heated surface at which, under specified conditions, the ignition of a

flammable substance in the form of a gas or vapour mixture with air will occur

[IEV 426-02-01, modified]

NOTE IEC 60079-4 and IEC 60079-4A standardize a method for the determination of this temperature.

2.21

extent of zone

distance in any direction from the source of release to the point where the gas/air mixture has

been diluted by air to a value below the lower explosive limit

2.22

liquefied flammable gas

flammable material which is stored or handled as a liquid and which at ambient temperature

and atmospheric pressure is a flammable gas

60079-10 IEC:2002 – 19 –

3 Safety and area classification

3.1 Safety principles

Installations in which flammable materials are handled or stored should be designed, operated

and maintained so that any releases of flammable material, and consequently the extent of

hazardous areas, are kept to a minimum, whether in normal operation or otherwise, with

regard to frequency, duration and quantity.

It is important to examine those parts of process equipment and systems from which release

of flammable material may arise and to consider modifying the design to minimize the

likelihood and frequency of such releases and the quantity and rate of release of material.

These fundamental considerations should be examined at an early stage of the design

development of any process plant and should also receive prime attention in carrying out the

area classification study.

In the case of maintenance activities other than those of normal operation, the extent of the

zone may be affected but it is expected that this would be dealt with by a permit-to-work

system.

In a situation in which there may be an explosive gas atmosphere, the following steps should

be taken:

a) eliminate the likelihood of an explosive gas atmosphere occurring around the source of

ignition, or

b) eliminate the source of ignition.

Where this is not possible, protective measures, process equipment, systems and procedures

should be selected and prepared so the likelihood of the coincidence of a) and b) is so small

as to be acceptable. Such measures may be used singly, if they are recognized as being

highly reliable, or in combination to achieve an equivalent level of safety.

3.2 Area classification objectives

Area classification is a method of analysing and classifying the environment where explosive

gas atmospheres may occur so as to facilitate the proper selection and installation of appa-

ratus to be used safely in that environment, taking into account gas groups and temperature

classes.

In most practical situations where flammable materials are used, it is difficult to ensure that an

explosive gas atmosphere will never occur. It may also be difficult to ensure that apparatus

will never give rise to a source of ignition. Therefore, in situations where an explosive gas

atmosphere has a high likelihood of occurring, reliance is placed on using apparatus which

has a low likelihood of creating a source of ignition. Conversely, where the likelihood of an

explosive gas atmosphere occurring is reduced, apparatus constructed to a less rigorous

standard may be used.

It is rarely possible by a simple examination of a plant or plant design to decide which parts of

the plant can be equated to the three zonal definitions (zones 0, 1 and 2). A more detailed

approach is therefore necessary and this involves the analysis of the basic possibility of an

explosive gas atmosphere occurring.

60079-10 IEC:2002 – 21 –

The first step is to assess the likelihood of this, in accordance with the definitions of zone 0,

zone 1 and zone 2. Once the likely frequency and duration of release (and hence the grade of

release), the release rate, concentration, velocity, ventilation and other factors which affect

the type and/or extent of the zone have been determined, there is then a firm basis on which

to determine the likely presence of an explosive gas atmosphere in the surrounding areas.

This approach therefore requires detailed consideration to be given to each item of process

equipment which contains a flammable material, and which could therefore be a source of

release.

In particular, zone 0 or zone 1 areas should be minimized in number and extent by design or

suitable operating procedures. In other words, plants and installations should be mainly

zone 2 or non-hazardous. Where release of flammable material is unavoidable, process

equipment items should be limited to those which give secondary grade releases or, failing

this (that is where primary or continuous grade releases are unavoidable), the releases should

be of very limited quantity and rate. In carrying out area classification, these principles should

receive prime consideration. Where necessary, the design, operation and location of process

equipment should ensure that, even when it is operating abnormally, the amount of flammable

material released into the atmosphere is minimized, so as to reduce the extent of the

hazardous area.

Once a plant has been classified and all necessary records made, it is important that no

modification to equipment or operating procedures is made without discussion with those

responsible for the area classification. Unauthorized action may invalidate the area

classification. It is necessary to ensure that all equipment affecting the area classification

which has been subjected to maintenance is carefully checked during and after re-assembly

to ensure that the integrity of the original design, as it affects safety, has been maintained

before it is returned to service.

4 Area classification procedure

4.1 General

The area classification should be carried out by those who have knowledge of the properties

of flammable materials, the process and the equipment, in consultation, as appropriate, with

safety, electrical, mechanical and other engineering personnel.

The following subclauses give guidance on the procedure for classifying areas in which there

may be an explosive gas atmosphere and on the extent of zones 0, 1 and 2. An example of a

schematic approach to the classification of hazardous areas is given in figure C.1.

The area classification should be carried out when the initial process and instrumentation line

diagrams and initial layout plans are available and confirmed before plant start-up. Reviews

should be carried out during the life of the plant.

60079-10 IEC:2002 – 23 –

4.2 Sources of release

The basic elements for establishing the hazardous zone types are the identification of the

source of release and the determination of the grade of release.

Since an explosive gas atmosphere can exist only if a flammable gas or vapour is present

with air, it is necessary to decide if any of these flammable materials can exist in the area

concerned. Generally speaking, such gases and vapours (and flammable liquids and solids

which may give rise to them) are contained within process equipment which may or may not

be totally enclosed. It is necessary to identify where a flammable atmosphere can exist inside

a process plant, or where a release of flammable materials can create a flammable

atmosphere outside a process plant.

Each item of process equipment (for example, tank, pump, pipeline, vessel, etc.) should be

considered as a potential source of release of flammable material. If the item cannot contain

flammable material, it will clearly not give rise to a hazardous area around it. The same will

apply if the item contains a flammable material but cannot release it into the atmosphere (for

example, an all-welded pipeline is not considered to be a source of release).

If it is established that the item may release flammable material into the atmosphere, it is

necessary, first of all, to determine the grade of release in accordance with the definitions, by

establishing the likely frequency and duration of the release. It should be recognized that the

opening-up of parts of enclosed process systems (for example, during filter changing or batch

filling) should also be considered as sources of release when developing the area

classification. By means of this procedure, each release will be graded either "continuous",

"primary" or "secondary".

Having established the grade of the release, it is necessary to determine the release rate and

other factors which may influence the type and extent of the zone.

If the total quantity of flammable material available for release is "small", for example, labo-

ratory use, whilst a potential hazard may exist, it may not be appropriate to use this area

classification procedure. In such cases, account shall be taken of the particular risks involved.

The area classification of process equipment in which flammable material is burned, for

example, fired heaters, furnaces, boilers, gas turbines etc., should take into account purge

cycle, start-up and shut-down conditions.

4.3 Type of zone

The likelihood of the presence of an explosive gas atmosphere and hence the type of zone

depends mainly on the grade of release and the ventilation.

NOTE 1 A continuous grade of release normally leads to a zone 0, a primary grade to zone 1 and a secondary

grade to zone 2 (see annex B).

NOTE 2 Where zones created by adjacent sources of release overlap and are of different zonal classification, the

higher risk classification will apply in the area of overlap. Where overlapping zones are of the same classification,

this common classification will normally apply.

However, care needs to be taken where the overlapping zones relate to flammable materials which have different

apparatus groups and/or temperature class. So, for example, if a zone 1 IIA T3 area overlapped a zone 2 IIC T1

area, then classifying the overlap as zone 1 IIC T3 may be over-restrictive but classifying it as zone 1 IIA T3 or

zone 1 IIC T1 would not be acceptable. In this situation, the area classification should be recorded as zone 1 IIA T3

and zone 2 IIC T1.

60079-10 IEC:2002 – 25 –

4.4 Extent of zone

The extent of the zone depends on the estimated or calculated distance over which an

explosive atmosphere exists before it disperses to a concentration in air below its lower

explosive limit. When assessing the area of spread of gas or vapour before dilution to below

its lower explosive limit, expert advice should be sought.

Consideration should always be given to the possibility that a gas which is heavier than air

may flow into areas below ground level (for example, pits or depressions) and that a gas

which is lighter than air may be retained at high level (for example, in a roof space).

Where the source of release is situated outside an area or in an adjoining area, the pene-

tration of a significant quantity of flammable gas or vapour into the area can be prevented by

suitable means such as:

a) physical barriers;

b) maintaining a sufficient overpressure in the area relative to the adjacent hazardous areas,

so preventing the ingress of the explosive gas atmosphere;

c) purging the area with sufficient flow of fresh air, so ensuring that the air escapes from all

openings where the flammable gas or vapour may enter.

The extent of the zone is mainly affected by the following chemical and physical parameters,

some of which are intrinsic properties of the flammable material; others are specific to the

process. For simplicity, the effect of each parameter listed below assumes that the other

parameters remain unchanged.

4.4.1 Release rate of gas or vapour

The greater the release rate, the larger the extent of the zone. The release rate depends itself

on other parameters, namely

a) Geometry of the source of release

This is related to the physical characteristics of the source of release, for example, an

open surface, leaking flange, etc. (see annex A).

b) Release velocity

For a given source of release, the release rate increases with the release velocity. In the

case of a product contained within process equipment, the release velocity is related to

the process pressure and the geometry of the source of release. The size of a cloud of

flammable gas or vapour is determined by the rate of flammable vapour release and the

rate of dispersion. Gas and vapour flowing from a leak at high velocity will develop a cone-

shaped jet which will entrain air and be self-diluting. The extent of the explosive gas

atmosphere will be almost independent of wind velocity. If the material is released at low

velocity or if its velocity is reduced by impingement on a solid object, it will be carried by

the wind and its dilution and extent will depend on wind velocity.

c) Concentration

The release rate increases with the concentration of flammable vapour or gas in the

released mixture.

d) Volatility of a flammable liquid

This is related principally to the vapour pressure, and the enthalpy ("heat") of vaporization.

If the vapour pressure is not known, the boiling point and flashpoint can be used as a

guide.

60079-10 IEC:2002 – 27 –

An explosive gas atmosphere cannot exist if the flashpoint is above the relevant maximum

temperature of the flammable liquid. The lower the flashpoint, the greater may be the

extent of the zone. If a flammable material is released in a way that forms a mist (for

example, by spraying) an explosive atmosphere may be formed below the flashpoint of the

material, for example.

NOTE 1 Flashpoints of flammable liquids are not precise physical quantities, particularly where mixtures are

involved.

NOTE 2 Some liquids (for example, certain halogenated hydrocarbons) do not possess a flashpoint although

they are capable of producing an explosive gas atmosphere. In these cases, the equilibrium liquid temperature

which corresponds to the saturated concentration at the lower explosive limit should be compared with the

relevant maximum liquid temperature.

e) Liquid temperature

The vapour pressure increases with temperature, thus increasing the release rate due to

evaporation.

NOTE The temperature of the liquid after it has been released may be increased, for example, by a hot

surface or by a high ambient temperature.

4.4.2 Lower explosive limit (LEL)

For a given release volume, the lower the LEL the greater will be the extent of the zone.

Experience has shown that a release of ammonia, with an LEL of 15 % by volume, will

dissipate rapidly in the open air, so an explosive gas atmosphere will normally be of negligible

extent.

4.4.3 Ventilation

With increased ventilation, the extent of the zone will normally be reduced. Obstacles which

impede the ventilation may increase the extent of the zone. On the other hand, some

obstacles, for example, dykes, walls or ceilings, may limit the extent. A compressor shelter

with a large roof-ventilator and with the sides open sufficient, to allow free passage of air

through all parts of the building is considered well ventilated and should be treated as an

outdoor area (i.e. "medium" degree and "good" availability).

4.4.4 Relative density of the gas or vapour when it is released

If the gas or vapour is significantly lighter than air, it will tend to move upwards. If significantly

heavier, it will tend to accumulate at ground level. The horizontal extent of the zone at ground

level will increase with increasing relative density and the vertical extent above the source will

increase with decreasing relative density.

NOTE 1 For practical applications, a gas or vapour which has a relative density below 0,8 is regarded as being

lighter than air. If the relative density is above 1,2, it is regarded as being heavier than air. Between these values,

both of these possibilities should be considered.

NOTE 2 With gases or vapours lighter than air, an escape at low velocity will disperse fairly rapidly upwards; the

presence of a roof will, however, inevitably increase the area of spread under it. If the escape is at high velocity in

a free jet the action of the jet, although entraining air which dilutes the gas or vapour, may increase the distance

over which the gas/air mixture remains above its lower flammable limit.

NOTE 3 With gases or vapours heavier than air, an escape at low velocity will tend to flow downward and may

travel long distances over the ground before it is safely dispersed by atmospheric diffusion. Special regard

therefore needs to be paid to the topography of any site under consideration and also to surrounding areas in order

to determine where gases or vapours might collect in hollows or run down inclines to lower levels. If the escape is

at high velocity in a free jet the jet-mixing action by entraining air may well reduce the gas/air mixture to below its

lower flammable limit in a much shorter distance than in the case of a low-velocity escape.

NOTE 4 Care needs to be taken when classifying areas containing cryogenic flammable gases such as liquefied

natural gas. Vapours emitted can be heavier than air at low temperatures and become lighter than air on

approaching ambient temperature.

60079-10 IEC:2002 – 29 –

4.4.5 Other parameters to be considered

a) Climatic conditions

The rate of gas or vapour dispersion in the atmosphere increases with wind speed but

there is a minimum speed of 2 m/s – 3 m/s required to initiate turbulent diffusion; below

this, layering of the gas or vapour occurs and the distance for safe dispersal is greatly

increased. In plant areas sheltered by large vessels and structures, the speed of air

movement may be substantially below that of the wind; however, obstruction of air

movement by items of equipment tends to maintain turbulence even at low wind speeds.

NOTE 1 In annex B (clause B.4), 0,5 m/s wind speed is considered to be appropriate for determining the

rates at which ventilation in an outdoor situation dilutes a flammable release. This lower value of wind speed is

appropriate for that purpose, in order to maintain a conservative approach, even though it is recognized that

the tendency of layering may compromise the calculation.

NOTE 2 In normal practice the tendency of layering is not taken into account in area classification because

the conditions which give rise to this tendency are rare and occur for short periods only. However, if prolonged

periods of low wind speed are expected for the specific circumstance then the extent of the zone should take

account of the additional distance required to achieve dispersion.

b) Topography

Some liquids are less dense than water and do not readily mix with water: such liquids can

spread on the surface of water (whether it be on the ground, in plant drains or in pipe

trenches) and then be ignited at a point remote from the original spillage, therefore putting

at risk a large area of plant.

The layout of the plant, where possible, should be designed to aid the rapid dispersal of

explosive gas atmospheres. An area with restricted ventilation (for example, in pits or

trenches) that would otherwise be Zone 2 may require Zone 1 classification; on the other

hand, wide shallow depressions used for pumping complexes or pipe reservations may not

require such rigorous treatment.

4.4.6 Illustrative examples

Some ways in which the above-mentioned parameters affect the vapour or gas release rate

and hence the extent of the zone are demonstrated in the examples in annex C.

a) Source of release: open surface of liquid

In most cases, the liquid temperature will be below the boiling point and the vapour

release rate will depend principally on the following parameters:

− liquid temperature;

− vapour pressure of the liquid at its surface temperature;

− dimensions of the evaporation surface;

− ventilation.

b) Source of release: virtually instantaneous evaporation of a liquid (for example, from a jet

or spray)

Since the discharged liquid vaporizes virtually instantaneously, the vapour release rate is

equal to the liquid flow rate and this depends on the following parameters:

− liquid pressure;

− geometry of the source of release.

Where the liquid is not instantaneously vaporized, the situation is complex because

droplets, liquid jets and pools may create separate sources of release.

60079-10 IEC:2002 – 31 –

c) Source of release: leakage of a gas mixture

The gas release rate is affected by the following parameters:

− pressure within the equipment which contains the gas;

− geometry of the source of release;

− concentration of flammable gas in the released mixture.

For examples, of sources of release, see clause A.2.

5 Ventilation

5.1 General

Gas or vapour released into the atmosphere can be diluted by dispersion or diffusion into the

air until its concentration is below the lower explosive limit. Ventilation, i.e. air movement

leading to replacement of the atmosphere in a (hypothetical) volume around the source of

release by fresh air, will promote dispersion. Suitable ventilation rates can also avoid

persistence of an explosive gas atmosphere thus influencing the type of zone.

5.2 Main types of ventilation

Ventilation can be accomplished by the movement of air due to the wind and/or by

temperature gradients or by artificial means such as fans. So two main types of ventilation are

thus recognized:

a) natural ventilation;

b) artificial ventilation, general or local.

5.3 Degree of ventilation

The most important factor is that the degree or amount of ventilation is directly related to the

types of sources of release and their corresponding release rates. This is irrespective of the

type of ventilation, whether it be wind speed or the number of air changes per time unit. Thus

optimal ventilation conditions in the hazardous area can be achieved, and the higher the

amount of ventilation in respect of the possible release rates, the smaller will be the extent of

the zones (hazardous areas), in some cases reducing them to a negligible extent (non-

hazardous area).

Practical examples for guidance on the degree of ventilation which may used are given in

annex B.

5.4 Availability of ventilation

The availability of ventilation has an influence on the presence or formation of an explosive

gas atmosphere and thus also on the type of zone. Guidance on availability is given in

annex B.

NOTE Combining the concepts of degree of ventilation and level of availability results in a quantitative method

...

NORME CEI

INTERNATIONALE

60079-10

Quatrième édition

2002-06

Matériel électrique pour atmosphères

explosives gazeuses –

Partie 10:

Classement des emplacements dangereux

Cette version française découle de la publication d’origine

bilingue dont les pages anglaises ont été supprimées.

Les numéros de page manquants sont ceux des pages

supprimées.

Numéro de référence

CEI 60079-10:2002(F)

Numérotation des publications

Depuis le 1er janvier 1997, les publications de la CEI sont numérotées à partir de

60000. Ainsi, la CEI 34-1 devient la CEI 60034-1.

Editions consolidées

Les versions consolidées de certaines publications de la CEI incorporant les

amendements sont disponibles. Par exemple, les numéros d’édition 1.0, 1.1 et 1.2

indiquent respectivement la publication de base, la publication de base incorporant

l’amendement 1, et la publication de base incorporant les amendements 1 et 2

Informations supplémentaires sur les publications de la CEI

Le contenu technique des publications de la CEI est constamment revu par la CEI

afin qu'il reflète l'état actuel de la technique. Des renseignements relatifs à cette

publication, y compris sa validité, sont disponibles dans le Catalogue des

publications de la CEI (voir ci-dessous) en plus des nouvelles éditions, amende-

ments et corrigenda. Des informations sur les sujets à l’étude et l’avancement des

travaux entrepris par le comité d’études qui a élaboré cette publication, ainsi que la

liste des publications parues, sont également disponibles par l’intermédiaire de:

• Site web de la CEI (www.iec.ch)

• Catalogue des publications de la CEI

Le catalogue en ligne sur le site web de la CEI (www.iec.ch/searchpub) vous permet

de faire des recherches en utilisant de nombreux critères, comprenant des

recherches textuelles, par comité d’études ou date de publication. Des informations

en ligne sont également disponibles sur les nouvelles publications, les publications

remplacées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published

Ce résumé des dernières publications parues (www.iec.ch/online_news/justpub)

est aussi disponible par courrier électronique. Veuillez prendre contact avec le

Service client (voir ci-dessous) pour plus d’informations.

• Service clients

Si vous avez des questions au sujet de cette publication ou avez besoin de

renseignements supplémentaires, prenez contact avec le Service clients:

Email: custserv@iec.ch

Tél: +41 22 919 02 11

Fax: +41 22 919 03 00

NORME CEI

INTERNATIONALE

60079-10

Quatrième édition

2002-06

Matériel électrique pour atmosphères

explosives gazeuses –

Partie 10:

Classement des emplacements dangereux

IEC 2002 Droits de reproduction réservés

Aucune partie de cette publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun

procédé, électronique ou mécanique, y compris la photocopie et les microfilms, sans l'accord écrit de l'éditeur.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

XA

Commission Electrotechnique Internationale

International Electrotechnical Commission

Международная Электротехническая Комиссия

Pour prix, voir catalogue en vigueur

– 2 – 60079-10 © CEI:2002

SOMMAIRE

AVANT-PROPOS .4

INTRODUCTION.6

1 Généralités.8

1.1 Domaine d'application.8

1.2 Références normatives .10

2 Définitions et terminologie.10

3 Sécurité et classement des emplacements dangereux.18

3.1 Principes de sécurité .18

3.2 Objectifs du classement des emplacements dangereux.18

4 Procédure de classement des emplacements dangereux.20

4.1 Généralités.20

4.2 Sources de dégagement .22

4.3 Type de la zone .22

4.4 Etendue de la zone.24

4.4.1 Taux de dégagement de gaz ou vapeur.24

4.4.2 Limite inférieure d'explosivité (LIE).26

4.4.3 Ventilation .26

4.4.4 Densité relative du gaz ou de la vapeur au moment de son

dégagement.26

4.4.5 Autres paramètres à considérer .28

4.4.6 Exemples.28

5 Ventilation .30

5.1 Généralités.30

5.2 Principaux types de ventilation.30

5.3 Degré de ventilation.30

5.4 Disponibilité de la ventilation.30

6 Documentation .32

6.1 Généralités.32

6.2 Plans, feuilles de données et tableaux .32

Annexe A (informative) Exemples de sources de dégagement .34

Annexe B (informative) Ventilation.38

Annexe C (informative) Exemples de classement des emplacements dangereux.70

Figure C.1 – Symboles préférés pour les zones des emplacements dangereux . 112

Figure C.2 – Approche schématique pour le classement des emplacements dangereux .114

– 4 – 60079-10 © CEI:2002

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

MATÉRIEL ÉLECTRIQUE POUR ATMOSPHÈRES EXPLOSIVES GAZEUSES –

Partie 10: Classement des emplacements dangereux

AVANT-PROPOS

1) La CEI (Commission Electrotechnique Internationale) est une organisation mondiale de normalisation composée

de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a pour objet de

favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines de

l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes internationales.

Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national intéressé par le

sujet traité peut participer. Les organisations internationales, gouvernementales et non gouvernementales, en

liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement avec l'Organisation

Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides et agréés comme tels par les Comités

nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les Normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente Norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60079-10 a été établie par le sous-comité 31J: Classification des

emplacements dangereux et règles d’installation, du comité d’études 31 de la CEI: Matériel

électrique pour atmosphères explosives.

Cette quatrième édition annule et remplace la troisième édition parue en 1995, et constitue une

révision technique.

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

31J/82/FDIS 31J/84/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

La présente publication a été rédigée conformément à la Partie 3 des Directives ISO/CEI.

Les annexes A, B, et C sont données uniquement à titre d’information.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2007. A cette

date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

– 6 – 60079-10 © CEI:2002

INTRODUCTION

Dans les emplacements où des quantités et concentrations dangereuses de gaz ou vapeurs

inflammables peuvent apparaître, on appliquera des mesures préventives pour réduire le

risque d'explosions. La présente partie de la CEI 60079 expose les critères essentiels par

rapport auxquels le risque d'inflammation peut être évalué et donne des conseils, relatifs aux

paramètres de conception et d'exploitation, que l'on peut utiliser pour réduire ce risque.

La présente norme peut servir de base pour le choix et l’installation corrects de matériel

utilisable dans un emplacement dangereux.

– 8 – 60079-10 © CEI:2002

MATÉRIEL ÉLECTRIQUE POUR ATMOSPHÈRES EXPLOSIVES GAZEUSES –

Partie 10: Classement des emplacements dangereux

1 Généralités

1.1 Domaine d'application

La présente partie de la CEI 60079 est relative au classement des emplacements dangereux

dans lesquels des risques dus à des gaz ou vapeurs inflammables peuvent apparaître, afin de

permettre le choix et l’installation corrects du matériel à utiliser dans de tels emplacements.

Elle est destinée à être appliquée là où il peut exister un risque d'inflammation du fait de la

présence de gaz ou vapeurs inflammables, en mélange avec l'air, dans les conditions

atmosphériques habituelles (voir note 2); mais elle ne s'applique pas

a) aux mines grisouteuses;

b) au traitement et à la fabrication des explosifs;

c) aux emplacements dans lesquels un risque dû à la présence de poussières ou fibres

inflammables peut apparaître;

d) aux défaillances catastrophiques, qui dépassent le concept d'anormalité traité dans la

présente norme (voir note 3);

e) aux salles utilisées à des fins médicales;

f) aux emplacements dans lesquels la présence de brouillard inflammable peut créer un

risque imprévisible et qui requièrent une attention particulière (voir note 5);

g) aux locaux à usage domestique.

La présente norme ne prend pas en compte les effets de sinistres en cascade.

Des définitions et explications de termes y sont données ainsi que les grands principes et

procédures relatifs au classement des emplacements dangereux.

On pourra se référer aux codes relatifs à des industries ou applications particulières pour

trouver des recommandations détaillées quant à l'étendue des emplacements dangereux dans

ces industries ou applications.

NOTE 1 Pour les besoins de la présente norme, un emplacement désigne un secteur ou un espace

tridimensionnel.

NOTE 2 Les conditions atmosphériques englobent les écarts au-dessus et au-dessous des niveaux de référence

de 101,3 kPa (1 013 mbar) et 20 °C (293 K) à condition que cela ait un effet négligeable sur les propriétés

explosives des matières inflammables.

NOTE 3 Le terme «défaillance catastrophique» s'applique ici, par exemple, à l’éclatement d’une cuve ou d'une

canalisation et aux événements imprévisibles.

NOTE 4 Dans toute usine, quelle que soit son importance, il peut y avoir de nombreuses sources d'inflammation

en dehors de celles qui sont associées au matériel électrique. Il sera nécessaire dès lors de prendre les

précautions appropriées pour garantir la sécurité. On pourra utiliser avec prudence la présente norme pour ces

autres sources d'inflammation.

NOTE 5 Des brouillards peuvent se former à partir de vapeurs inflammables ou être présents en même temps que

de telles vapeurs. Cela peut affecter la façon dont les matières inflammables se dispersent et l'étendue de tout

emplacement dangereux. Par ailleurs, l'application stricte du classement d’emplacements pour les gaz et vapeurs

peut ne pas convenir, car les caractéristiques d'inflammabilité des brouillards ne sont pas toujours prévisibles.

Quoiqu'il soit difficile d'arrêter le type et l'étendue des zones, les critères applicables aux gaz et vapeurs donneront,

dans la plupart des cas, un résultat sans danger. Néanmoins, il convient toujours de porter une attention

particulière au danger d'inflammation des brouillards inflammables.

– 10 – 60079-10 © CEI:2002

1.2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références non

datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60050(426):1990, Vocabulaire Electrotechnique International (VEI) – Chapitre 426:

Matériel électrique pour atmosphères explosives

CEI 60079-4:1975, Matériel électrique pour atmosphères explosives gazeuses – Quatrième

partie: Méthode d’essai pour la détermination de la température d’inflammation

CEI 60079-4A:1970, Premier complément à la CEI 60079-4 (1966), Matériel électrique pour

atmosphères explosives gazeuses – Quatrième partie: Méthode d’essai pour la détermination

de la température d’inflammation

CEI 60079-20:1996, Matériel électrique pour atmosphères explosives gazeuses – Partie 20:

Données pour gaz et vapeurs inflammables, en relation avec l'utilisation des matériels

électriques

2 Définitions et terminologie

Pour les besoins de la présente partie de la CEI 60079, les définitions et la terminologie

suivantes s’appliquent.

NOTE Lorsqu'une définition est donnée conjointement dans le présent article et dans la CEI 60050(426), c'est la

définition du présent article qui s'applique.

2.1

atmosphère explosive

mélange avec l'air, dans les conditions atmosphériques, de substances inflammables sous forme de

gaz, vapeur, brouillard ou poussière dans lequel, après inflammation, la combustion s'étend à

tout le mélange non brûlé

[VEI 426-02-02, modifié]

2.2

atmosphère explosive gazeuse

mélange avec l'air, dans les conditions atmosphériques, de substances inflammables sous

forme de gaz ou vapeur dans lequel, après inflammation, la combustion s'étend à tout le

mélange non brûlé

[VEI 426-02-03, modifié]

NOTE Bien qu'un mélange où la concentration est supérieure à la limite supérieure d'explosivité (LSE) ne soit pas

une atmosphère explosive gazeuse, il peut aisément le devenir et il est recommandé de le considérer comme tel

dans certains cas aux fins de classement des emplacements dangereux.

2.3

emplacement dangereux

emplacement dans lequel une atmosphère explosive gazeuse est présente, ou dans lequel on

peut s'attendre qu'elle soit présente, en quantités suffisantes pour nécessiter des précautions

particulières pour la construction, l'installation et l'utilisation de matériel

[VEI 426-03-01, modifié]

2.4

emplacement non dangereux

emplacement dans lequel on ne s'attend pas à ce qu'une atmosphère explosive gazeuse soit

présente en quantités suffisantes pour nécessiter des précautions particulières pour la

construction, l'installation et l'utilisation de matériel

[VEI 426-03-02, modifié]

– 12 – 60079-10 © CEI:2002

2.5

zones

les emplacements dangereux sont classés en zones, d'après la fréquence et la durée de la

présence d'une atmosphère explosive gazeuse, comme suit:

2.5.1

zone 0

emplacement dans lequel une atmosphère explosive constituée d'un mélange d'air de

substances inflammables sous forme de gaz, de vapeur ou de brouillard est présente en

permanence, ou pendant de longues périodes ou encore fréquemment

[VEI 426-03-03, modifié]

2.5.2

zone 1

emplacement dans lequel il est probable qu'une atmosphère explosive constituée d'un mélange

d'air de substances inflammables sous forme de gaz, de vapeur ou de brouillard, apparaîtra

occasionnellement en fonctionnement normal

[VEI 426-03-04, modifié]

2.5.3

zone 2

emplacement dans lequel il n'est pas probable qu'une atmosphère explosive constituée d'un

mélange d'air de substances inflammables sous forme de gaz, de vapeur ou de brouillard

apparaisse en fonctionnement normal mais où, si elle apparaît, il est probable qu'elle

persistera seulement pour une courte période

[VEI 426-03-05, modifié]

NOTE 1 Dans cette définition, le mot «persistera» fait référence à la durée totale pour laquelle l'atmosphère

inflammable existe. Cela comprend normalement la durée totale de dégagement à laquelle s'ajoute le temps

de dispersion de l'atmosphère inflammable après dégagement. (Le terme «durée de persistance» employé à

l'annexe B fait spécifiquement référence à une partie seulement de la durée totale pendant laquelle l'atmosphère

inflammable existe.)

NOTE 2 On peut tirer des indications intéressant la fréquence d’apparition et la durée des codes propres à

certaines industries ou applications.

2.6

source de dégagement

point ou endroit d'où un gaz, une vapeur ou un liquide inflammable peut être libéré dans

l'atmosphère, de telle sorte qu'une atmosphère explosive gazeuse soit créée

[VEI 426-03-06, modifié]

2.7

degrés de dégagement

il y a trois degrés de dégagement de base, énumérés ci-dessous par ordre décroissant de

probabilité de présence d'une atmosphère explosive gazeuse:

a) degré continu;

b) premier degré;

c) deuxième degré.

Une source de dégagement peut donner lieu à n'importe lequel de ces degrés de dégagement

ou à une combinaison de plusieurs d'entre eux

2.7.1

dégagement de degré continu

dégagement qui se produit en permanence ou dont on s'attend à ce qu'il se produise pendant

de longues périodes

– 14 – 60079-10 © CEI:2002

2.7.2

dégagement de premier degré

dégagement dont on peut s'attendre à ce qu'il se produise de façon périodique ou occasion-

nelle en fonctionnement normal

2.7.3

dégagement de deuxième degré

dégagement dont on ne s'attend pas à ce qu'il se produise en fonctionnement normal et dont il

est probable que, s'il se produit, ce sera seulement à une faible fréquence et pour de courtes

périodes

2.8

taux de dégagement

quantité de gaz ou vapeur inflammable émise par unité de temps par la source de dégagement

2.9

fonctionnement normal

situation dans laquelle l'installation fonctionne selon ses paramètres nominaux

NOTE 1 De petits dégagements de matière inflammable peuvent faire partie du fonctionnement normal. Par

exemple, des fuites des garnitures d'étanchéité lubrifiées par le liquide pompé sont considérées comme de petits

dégagements.

NOTE 2 Des défaillances (telles que la rupture de garnitures d'étanchéité de pompe ou de joints de brides ou des

épandages provoqués par des accidents) qui entraînent une réparation ou un arrêt urgent, ne sont pas considérées

comme faisant partie du fonctionnement normal, ni comme étant catastrophiques.

NOTE 3 Un fonctionnement normal comprend des conditions de démarrage et de fermeture.

2.10

ventilation

mouvement de l'air et remplacement de cet air par de l'air frais sous l'action du vent et de

gradients de température ou de moyens artificiels (par exemple ventilateurs ou extracteurs)

2.11

limites d'explosivité

NOTE Les termes «limite d'explosivité» et «limite d'inflammabilité» sont équivalents. Le terme «limite

d'inflammabilité» est utilisé dans la CEI 60079-20 et la CEI 61779-1 alors que le terme «limite d'explosivité», plus

généralement accepté, est utilisé dans toutes les autres normes.

2.11.1

limite inférieure d'explosivité (LIE)

concentration dans l'air de gaz ou vapeur inflammable, au-dessous de laquelle l'atmosphère

gazeuse n'est pas explosive

[VEI 426-02-09, modifié]

2.11.2

limite supérieure d'explosivité (LSE)

concentration dans l'air de gaz ou vapeur inflammable, au-dessus de laquelle l'atmosphère

gazeuse n'est pas explosive

[VEI 426-02-10, modifié]

2.12

densité relative d'un gaz ou d'une vapeur

rapport de la densité d'un gaz ou d'une vapeur à la densité de l'air à la même pression et à la

même température (elle est égale à 1,0 pour l'air)

– 16 – 60079-10 © CEI:2002

2.13

matière inflammable (substance inflammable)

matière inflammable par elle-même ou capable de produire un gaz, une vapeur, ou un

brouillard inflammable

2.14

liquide inflammable

liquide capable de produire une vapeur inflammable dans toutes les conditions d'exploitation

prévisibles

2.15

gaz ou vapeur inflammable

gaz ou vapeur, qui, mélangé à l'air dans certaines proportions, formera une atmosphère

explosive gazeuse

2.16

brouillard inflammable

gouttelettes de liquide inflammable dispersées dans l'air de façon à former une atmosphère

explosive gazeuse

2.17

point d'éclair

température la plus basse d'un liquide à laquelle, dans certaines conditions normalisées, ce

liquide libère des vapeurs en quantité telle qu’un mélange vapeur/air inflammable puisse se former

[VEI 426-02-14]

2.18

point d'ébullition

température à laquelle un liquide bout à la pression ambiante de 101,3 kPa (1 013 mbar).

NOTE Le point d'ébullition initial qu'il convient d'utiliser dans les mélanges de liquides sert à indiquer la valeur la

plus basse du point d'ébullition de la gamme des liquides présents dans le mélange, telle que cette valeur est

déterminée par distillation en laboratoire normalisée sans fractionnement.

2.19

pression de vapeur

pression exercée quand un solide ou un liquide est en équilibre avec sa propre vapeur. Elle est

fonction de la substance et de la température

2.20

température d'inflammation d’une atmosphère explosive gazeuse

température la plus basse d'une surface chaude à laquelle, dans des conditions spécifiées,

l'inflammation d'une substance inflammable sous la forme d'un mélange de gaz ou de vapeur

avec l'air peut se produire

[VEI 426-02-01, modifié]

NOTE La CEI 60079-4 et la CEI 60079-4A normalisent une méthode de détermination de cette température.

2.21

étendue de zone

distance en tout sens de la source de dégagement au point où le mélange air/gaz a été dilué

par l'air à une valeur inférieure à la valeur au-dessous de la limite inférieure d'explosivité

2.22

gaz inflammable liquéfié

matériau inflammable qui est stocké et manipulé comme un liquide et qui, à température

ambiante et pression atmosphérique, est un gaz inflammable

– 18 – 60079-10 © CEI:2002

3 Sécurité et classement des emplacements dangereux

3.1 Principes de sécurité

Il convient que les installations dans lesquelles des matières inflammables sont manipulées ou

stockées soient conçues, exploitées et entretenues de façon que tous les dégagements de

matières inflammables, et, par conséquent, l'étendue des emplacements dangereux soient

maintenus les plus réduits possibles, que ce soit en fonctionnement normal ou non, en ce qui

concerne la fréquence, la durée et l'importance de ces dégagements.

Il importe d'examiner les parties de l'équipement de production et les systèmes d'où peut

survenir le dégagement de matériau inflammable et d'envisager la modification de la concep-

tion pour minimiser à la fois la probabilité et la fréquence de tels dégagements ainsi que la

quantité et le taux de dégagement du matériau.

Il convient d'examiner ces considérations fondamentales à un stade précoce du développe-

ment de la conception de toute usine et il convient également de leur accorder une extrême

attention lors de la réalisation de l'étude du classement des emplacements dangereux.

Dans le cas des opérations de maintenance autres que celles qui sont relatives au fonctionne-

ment normal, elles peuvent avoir un effet sur l'étendue de la zone mais on a supposé que la

question serait réglée par un système de permis de travail.

Dans les situations où il peut y avoir une atmosphère explosive gazeuse, il convient de prendre

les mesures suivantes:

a) éliminer la probabilité d'apparition d'une atmosphère explosive gazeuse à proximité de la

source d'inflammation, ou bien

b) éliminer la source d'inflammation.

Lorsque cela n'est pas possible, il convient de choisir et de préparer des mesures préventives,

des équipements de production, des systèmes et des procédures tels que la probabilité de la

simultanéité de a) et b) soit ramenée à un niveau suffisamment faible pour être acceptable. De

telles mesures peuvent être utilisées isolément, s'il est reconnu qu'elles ont une grande

fiabilité, ou en combinaison de façon à réaliser un niveau de sécurité équivalent.

3.2 Objectifs du classement des emplacements dangereux

Le classement des emplacements dangereux est une méthode d'analyse et de classement du

milieu dans lequel peuvent apparaître des atmosphères explosives gazeuses, de façon à

faciliter le choix et l’installation corrects du matériel électrique utilisable sans danger dans ce

milieu, compte tenu des groupes de gaz et des classes de température des gaz.

En pratique, dans la plupart des cas où l'on utilise des matières inflammables, il est difficile de

garantir qu'une atmosphère explosive gazeuse n'apparaîtra jamais. Il peut aussi être difficile

de garantir que le matériel électrique ne produira jamais de source d'inflammation. C'est pour-

quoi, lorsque la présence d'une atmosphère explosive gazeuse est hautement probable, on

recourra à l'utilisation d'un matériel électrique ayant une faible probabilité de créer une source

d'inflammation. Inversement, si la probabilité de présence d'une atmosphère explosive gazeuse

est faible, on pourra utiliser un matériel électrique répondant à des exigences moins sévères.

Il est rarement possible de déterminer par simple examen d'une usine ou de ses plans quelles

sont les parties de cette usine auxquelles peuvent s'appliquer les définitions des zones 0,

1 ou 2. Une étude plus détaillée est par conséquent nécessaire, ce qui implique une analyse

de la possibilité élémentaire d'apparition d'une atmosphère explosive gazeuse.

– 20 – 60079-10 © CEI:2002

La première étape consiste à évaluer la probabilité de cette apparition, conformément aux

définitions des zones 0, 1 et 2. Une fois que la fréquence et la durée probables de dégagement

(et, par suite, le degré de dégagement), le taux de dégagement, la concentration, la vitesse du

dégagement, la ventilation et les autres facteurs qui ont une influence sur le type et/ou

l'étendue de la zone ont été déterminés, on dispose d'une base solide pour décider si la

présence d'une atmosphère explosive gazeuse dans les emplacements avoisinants est

probable.

Cette approche exige, par conséquent, qu'on examine de façon détaillée chaque équipement

de production qui contient une matière inflammable et qui, par conséquent, pourrait constituer

une source de dégagement.

Il convient, en particulier, de réduire au minimum, grâce à la conception ou au moyen de

procédures d'exploitation appropriées, le nombre et l'étendue des emplacements classés

zones 0 et 1. En d'autres termes, il convient que les usines ou installations soient

principalement de zone 2 ou zone non dangereuse. Là où le dégagement de matière

inflammable est inévitable, il convient que les équipements de production soient limités à ceux

qui donnent lieu à des dégagements de deuxième degré, ou, à défaut (c'est-à-dire lorsque les

dégagements de degré continu ou de premier degré sont inévitables), il convient que les

dégagements soient d'importance ou de taux de dégagement très limités. Lorsqu'on effectue le

classement des emplacements dangereux, il convient de prendre ces principes en

considération en priorité. Si nécessaire, il convient que la conception, l'exploitation ou

l'implantation de l'équipement de production garantissent que, même en cas de fonctionnement

anormal de cet équipement, la quantité de matière inflammable dégagée dans l'atmosphère

sera la plus faible possible, de façon à réduire l'étendue de l’emplacement dangereux.

Lorsqu'une usine a fait l'objet d'un classement des emplacements dangereux et que tous les

éléments nécessaires à ce titre ont été notés, il est important qu'aucune modification ne soit

apportée à l'équipement ou aux procédures d'exploitation sans en avoir discuté avec les

responsables du classement des emplacements dangereux. Une intervention non autorisée

peut invalider le classement. Avant remise en service d’un équipement de production sur

lequel on a effectué des opérations de maintenance, il est nécessaire de s'assurer, par un

contrôle attentif pendant et après le remontage, que sa conception d'origine a été

intégralement maintenue, pour autant qu’elle affecte la sécurité.

4 Procédure de classement des emplacements dangereux

4.1 Généralités

Il convient que le classement des emplacements dangereux soit effectué par des personnes

qui connaissent les propriétés des matières inflammables, les procédés et les équipements,

moyennant consultation chaque fois qu’il y a lieu, du personnel de sécurité, des

électriciens, des techniciens en mécanique et des autres spécialistes concernés.

Les paragraphes suivants donnent des conseils relatifs à la procédure pour le classement

des emplacements où il peut y avoir une atmosphère explosive et pour l'étendue des zones 0,

1 et 2. La figure C.1 donne une approche schématique du classement des emplacements

dangereux.

Il convient d'effectuer le classement des emplacements dangereux lorsque les schémas

initiaux de lignes de production et d'instrumentation et les plans initiaux d'implantation sont

disponibles et confirmés avant le démarrage d'usine. Il convient d'effectuer des examens au