IEC 60127-4:2005

(Main)Miniature fuses - Part 4: Universal modular fuse-links (UMF) - Through-hole and surface mount types

Miniature fuses - Part 4: Universal modular fuse-links (UMF) - Through-hole and surface mount types

This part of IEC 60127 relates to universal modular fuse-links (UMF) for printed circuits and other substrate systems, used for the protection of electric appliances, electronic equipment, and component parts thereof, normally intended to be used indoors. It does not apply to fuse-links for appliances intended to be used under special conditions, such as in a corrosive or explosive atmosphere. This standard applies in addition to the requirements of IEC 60127-1.

Coupe-circuit miniatures - Partie 4: Eléments de remplacement modulaires universels (UMF) - Types de montage en surface et montage par trous

La présente partie de la CEI 60127 s'applique aux éléments de remplacement modulaires universels (UMF) conçus pour le montage sur circuit imprimé et autres substrats, et employés pour la protection d'appareils électriques, de matériels électroniques et de leurs éléments constituants, normalement utilisés à l'intérieur. Elle n'est pas applicable aux éléments de remplacement pour les appareils destinés à être employés dans des conditions particulières, telles que des atmosphères corrosives ou explosives. La présente norme renvoie en outre aux exigences de la CEI 60127-1.

General Information

- Status

- Published

- Publication Date

- 06-Dec-2012

- Technical Committee

- SC 32C - Miniature fuses

- Drafting Committee

- WG 6 - TC 32/SC 32C/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Jan-2005

- Completion Date

- 31-May-2005

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60127-4:2005 is an international standard published by the International Electrotechnical Commission (IEC) that specifies the requirements for universal modular fuse-links (UMF) designed for printed circuit boards (PCBs) and other substrate systems. These miniature fuses are used primarily for the protection of electric appliances, electronic equipment, and related components intended for indoor applications. The standard covers both through-hole and surface mount types, providing guidance on design, ratings, electrical requirements, and testing procedures. It complements IEC 60127-1 by adding particular specifications for UMFs, notably focusing on non-interchangeability and the physical modularity of fuse-links.

Key Topics

Scope and Application

IEC 60127-4 applies to UMFs used indoors within a variety of electrical and electronic equipment, excluding those subjected to special conditions such as corrosive or explosive atmospheres. It defines requirements for fuse-links that are usually installed or replaced by skilled technicians using appropriate equipment.Design and Construction

The standard details dimensional requirements and construction methods for UMFs to ensure compatibility with printed circuit boards and substrate systems. Both through-hole and surface mount fuse-links are standardized to facilitate automated assembly and reliable mounting.Electrical Ratings and Characteristics

Rated voltages include 12.5 V, 25 V, 32 V, 50 V, 63 V, 125 V, and 250 V, covering a broad range of typical application needs. UMFs under this standard offer various tripping characteristics such as very quick acting (FF), quick acting (F), time-lag (T), and long time-lag (TT).Voltage Drop and Dissipation Limits

IEC 60127-4 specifies maximum permissible values for voltage drop and sustained power dissipation to ensure circuit protection without undue energy loss or overheating.Testing and Quality Assurance

The standard contains comprehensive test schedules, encompassing electrical, mechanical, and environmental evaluations including solderability, robustness of terminations, and breaking capacity. These tests validate fuse performance under typical operating conditions.Marking and Identification

Clear marking requirements identify the fuse ratings and types, incorporating unique identifying symbols specific to UMFs, assisting manufacturers and users in clear and reliable identification.

Applications

IEC 60127-4 UMFs are widely applied in:

Consumer Electronics

Protecting delicate electronic components in devices such as computers, entertainment systems, and household appliances.Industrial Electrical Equipment

Ensuring circuit safety within industrial control systems, machines, and instrumentation employing printed circuit boards.Telecommunication Devices

Providing overcurrent protection for telecommunication apparatus requiring miniature protective devices.Automotive Electronics

Applicable where surface mount or through-hole fuse-links protect embedded electronic control units inside vehicles.Medical Devices

Protecting sensitive electronic circuits in medical equipment that operate under controlled indoor environments.

The universal nature of these fuse-links allows flexibility across multiple sectors where miniaturized, reliable, and standard-compliant fuses are necessary.

Related Standards

IEC 60127-4 is part of the IEC 60127 series covering miniature fuses, including:

IEC 60127-1 – Definitions and general requirements for miniature fuse-links, providing the foundational concepts and requirements that support IEC 60127-4.

IEC 60127-2 – Cartridge fuse-links specification.

IEC 60127-3 – Sub-miniature fuse-links.

IEC 60127-5 – Guidelines for quality assessment of miniature fuse-links to ensure reliability and safety.

IEC 60127-6 – Fuse-holders for miniature fuse-links.

The standard also references critical environmental testing standards such as IEC 60068-2-20 and IEC 60068-2-58, which outline test methods for solderability and resistance to soldering heat, essential for surface mount device validation.

Keywords: IEC 60127-4, universal modular fuse-links, UMF, miniature fuses, through-hole fuse-links, surface mount fuse-links, printed circuit board fuses, electrical protection, fuse standards, fuse testing, electronic equipment protection

Buy Documents

IEC 60127-4:2005 - Miniature fuses - Part 4: Universal modular fuse-links (UMF) - Through-hole and surface mount types Released:1/27/2005

IEC 60127-4:2005+AMD1:2008+AMD2:2012 CSV - Miniature fuses - Part 4: Universal modular fuse-links (UMF) -Through-hole and surface mount types Released:12/7/2012

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60127-4:2005 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Miniature fuses - Part 4: Universal modular fuse-links (UMF) - Through-hole and surface mount types". This standard covers: This part of IEC 60127 relates to universal modular fuse-links (UMF) for printed circuits and other substrate systems, used for the protection of electric appliances, electronic equipment, and component parts thereof, normally intended to be used indoors. It does not apply to fuse-links for appliances intended to be used under special conditions, such as in a corrosive or explosive atmosphere. This standard applies in addition to the requirements of IEC 60127-1.

This part of IEC 60127 relates to universal modular fuse-links (UMF) for printed circuits and other substrate systems, used for the protection of electric appliances, electronic equipment, and component parts thereof, normally intended to be used indoors. It does not apply to fuse-links for appliances intended to be used under special conditions, such as in a corrosive or explosive atmosphere. This standard applies in addition to the requirements of IEC 60127-1.

IEC 60127-4:2005 is classified under the following ICS (International Classification for Standards) categories: 29.120.50 - Fuses and other overcurrent protection devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60127-4:2005 has the following relationships with other standards: It is inter standard links to IEC 60127-4:2005/AMD2:2012, IEC 60127-4:2005/AMD1:2008, IEC 60127-4:1996/AMD1:2002, IEC 60127-4:1996/AMD2:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60127-4:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

NORME CEI

INTERNATIONALE IEC

60127-4

INTERNATIONAL

Troisième édition

STANDARD

Third edition

2005-01

Coupe-circuit miniatures –

Partie 4:

Eléments de remplacement modulaires

universels (UMF) – Types de montage

en surface et montage par trous

Miniature fuses –

Part 4:

Universal modular fuse-links (UMF) –

Through-hole and surface mount types

Numéro de référence

Reference number

CEI/IEC 60127-4:2005

Numérotation des publications Publication numbering

Depuis le 1er janvier 1997, les publications de la CEI As from 1 January 1997 all IEC publications are

sont numérotées à partir de 60000. Ainsi, la CEI 34-1 issued with a designation in the 60000 series. For

devient la CEI 60034-1. example, IEC 34-1 is now referred to as IEC 60034-1.

Editions consolidées Consolidated editions

Les versions consolidées de certaines publications de la The IEC is now publishing consolidated versions of its

CEI incorporant les amendements sont disponibles. Par publications. For example, edition numbers 1.0, 1.1

exemple, les numéros d’édition 1.0, 1.1 et 1.2 indiquent and 1.2 refer, respectively, to the base publication,

respectivement la publication de base, la publication de the base publication incorporating amendment 1 and

base incorporant l’amendement 1, et la publication de the base publication incorporating amendments 1

base incorporant les amendements 1 et 2. and 2.

Informations supplémentaires Further information on IEC publications

sur les publications de la CEI

Le contenu technique des publications de la CEI est The technical content of IEC publications is kept

constamment revu par la CEI afin qu'il reflète l'état under constant review by the IEC, thus ensuring that

actuel de la technique. Des renseignements relatifs à the content reflects current technology. Information

cette publication, y compris sa validité, sont dispo- relating to this publication, including its validity, is

nibles dans le Catalogue des publications de la CEI available in the IEC Catalogue of publications

(voir ci-dessous) en plus des nouvelles éditions, (see below) in addition to new editions, amendments

amendements et corrigenda. Des informations sur les and corrigenda. Information on the subjects under

sujets à l’étude et l’avancement des travaux entrepris consideration and work in progress undertaken by the

par le comité d’études qui a élaboré cette publication, technical committee which has prepared this

ainsi que la liste des publications parues, sont publication, as well as the list of publications issued,

également disponibles par l’intermédiaire de: is also available from the following:

• Site web de la CEI (www.iec.ch) • IEC Web Site (www.iec.ch)

• Catalogue des publications de la CEI • Catalogue of IEC publications

Le catalogue en ligne sur le site web de la CEI The on-line catalogue on the IEC web site

(www.iec.ch/searchpub) vous permet de faire des (www.iec.ch/searchpub) enables you to search by a

recherches en utilisant de nombreux critères, variety of criteria including text searches,

comprenant des recherches textuelles, par comité technical committees and date of publication. On-

d’études ou date de publication. Des informations en line information is also available on recently

ligne sont également disponibles sur les nouvelles issued publications, withdrawn and replaced

publications, les publications remplacées ou retirées, publications, as well as corrigenda.

ainsi que sur les corrigenda.

• IEC Just Published • IEC Just Published

Ce résumé des dernières publications parues This summary of recently issued publications

(www.iec.ch/online_news/justpub) est aussi dispo- (www.iec.ch/online_news/justpub) is also available

nible par courrier électronique. Veuillez prendre by email. Please contact the Customer Service

contact avec le Service client (voir ci-dessous) Centre (see below) for further information.

pour plus d’informations.

• Service clients • Customer Service Centre

Si vous avez des questions au sujet de cette If you have any questions regarding this

publication ou avez besoin de renseignements publication or need further assistance, please

supplémentaires, prenez contact avec le Service contact the Customer Service Centre:

clients:

Email: custserv@iec.ch Email: custserv@iec.ch

Tél: +41 22 919 02 11 Tel: +41 22 919 02 11

Fax: +41 22 919 03 00 Fax: +41 22 919 03 00

.

NORME CEI

INTERNATIONALE IEC

60127-4

INTERNATIONAL

Troisième édition

STANDARD

Third edition

2005-01

Coupe-circuit miniatures –

Partie 4:

Eléments de remplacement modulaires

universels (UMF) – Types de montage

en surface et montage par trous

Miniature fuses –

Part 4:

Universal modular fuse-links (UMF) –

Through-hole and surface mount types

IEC 2005 Droits de reproduction réservés Copyright - all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in any

utilisée sous quelque forme que ce soit et par aucun procédé, form or by any means, electronic or mechanical, including

électronique ou mécanique, y compris la photocopie et les photocopying and microfilm, without permission in writing from

microfilms, sans l'accord écrit de l'éditeur. the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale PRICE CODE U

International Electrotechnical Commission

Международная Электротехническая Комиссия

Pour prix, voir catalogue en vigueur

For price, see current catalogue

− 2 − 60127-4 CEI:2005

SOMMAIRE

AVANT-PROPOS.4

INTRODUCTION .8

1 Domaine d'application et objet .10

2 Références normatives.10

3 Termes et définitions .12

4 Prescriptions générales .12

5 Valeurs assignées .12

6 Marquage.14

7 Généralités sur les essais .14

8 Dimensions et construction.16

9 Prescriptions d'ordre électrique .22

10 Feuilles de normes .46

Annexe A (informative) Montage des éléments de remplacement de type à montage

en surface .54

Bibliographie .58

Figure 1 – Symbole unique d’identification pour les UMFs .36

Figure 2 – Carte d'essai à circuit imprimé pour éléments de remplacement à montage

par trous.36

Figure 3 – Carte d'essai à circuit imprimé pour éléments de remplacement à montage

en surface .38

Figure 4 – Socle d'essai .40

Figure 5 – Dispositif de flexion pour éléments de remplacement de type à montage en

surface .42

Figure 6 – Circuit d'essai pour les essais du pouvoir de coupure .44

Tableau 1 – Valeurs maximales pour la chute de tension et la puissance dissipée.28

Tableau 2 − Programme des essais pour éléments de remplacement .30

Tableau 3 – Programme des essais pour le courant assigné maximal d’une série

homogène .32

Tableau 4 – Programme des essais pour le courant assigné minimal d’une série

homogène .34

60127-4 IEC:2005 – 3 –

CONTENTS

FOREWORD .5

INTRODUCTION .9

1 Scope and object.11

2 Normative references .11

3 Terms and definitions .13

4 General requirements.13

5 Standard ratings.13

6 Marking.15

7 General notes on tests .15

8 Dimensions and construction .17

9 Electrical requirements .23

10 Standard sheets .47

Annex A (informative) Mounting for surface mount fuse-links.55

Bibliography .59

Figure 1 – Unique identifying symbol for UMFs .37

Figure 2 – Test board for through-hole fuse-links .37

Figure 3 − Test board for surface mount fuse-links .39

Figure 4 – Test fuse base .41

Figure 5 – Bending jig for surface mount fuse-links .43

Figure 6 – Test circuits for breaking capacity tests .45

Table 1 – Maximum values of voltage drop and sustained dissipation .29

Table 2 − Testing schedule for individual ampere ratings.31

Table 3 – Testing schedule for maximum ampere rating of a homogeneous series.33

Table 4 – Testing schedule for minimum ampere rating of a homogeneous series.35

− 4 − 60127-4 CEI:2005

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

___________

COUPE-CIRCUIT MINIATURES –

Partie 4: Eléments de remplacement modulaires universels (UMF) –

Types de montage en surface et montage par trous

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60127-4 a été établie par le sous-comité 32C: Coupe-circuit à

fusibles miniatures, du comité d'études 32 de la CEI: Coupe-circuit à fusibles.

Cette troisième édition annule et remplace la deuxième édition (1996), ainsi que l’amende-

ment 1 (2002) et l’amendement 2 (2003), et constitue une révision technique.

Les modifications techniques majeures par rapport à l'édition précédente sont les suivantes:

introduction de dispositifs physiquement plus petits avec des tensions assignées inférieures.

L'essai de la température de l'élément de remplacement (9.7) est modifié.

60127-4 IEC:2005 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

_________

MINIATURE FUSES –

Part 4: Universal modular fuse-links (UMF) –

Through-hole and surface mount types

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60127-4 has been prepared by subcommittee 32C: Miniature

fuses, of IEC technical committee 32: Fuses.

This third edition cancels and replaces the second edition (1996), together with amendment 1

(2002) and amendment 2 (2003), and constitutes a technical revision.

The major technical changes with regard to the previous edition are as follows: introduction

of physically smaller devices with lower rated voltages. Fuse-link temperature test (9.7) is

modified.

− 6 − 60127-4 CEI:2005

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

32C/362/FDIS 32C/366/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote

ayant abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

Les articles de cette norme complètent, modifient ou remplacent les articles correspondants

de la CEI 60127-1.

Lorsqu'il n'y a pas d'article ou de paragraphe correspondants dans cette norme, l'article ou le

paragraphe de la CEI 60127-1 s'applique sans modification dans la mesure du possible.

Lorsque cette norme indique "addition", "modification" ou "remplacement", le texte corres-

pondant de la CEI 60127-1 doit être adapté en conséquence.

La série CEI 60127 est subdivisée comme suit:

Partie 1: Définitions pour coupe-circuit miniatures et prescriptions générales pour éléments

de remplacement miniatures

Partie 2: Cartouches

Partie 3: Eléments de remplacement subminiatures

Partie 4: Eléments de remplacement modulaires universels (UMF)

Partie 5: Directives pour l'évaluation de la qualité des éléments de remplacement

miniatures

Partie 6: Ensembles-porteurs pour éléments de remplacement miniatures

Partie 7: (Libre pour d'autres documents)

Partie 8: (Libre pour d'autres documents)

Partie 9: (Libre pour d'autres documents)

Partie 10: Guide d’utilisation pour coupe-circuit miniatures

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant la date de

maintenance indiquée sur le site web de la CEI sous «http://webstore.iec.ch» dans les

données relatives à la publication recherchée. A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

60127-4 IEC:2005 – 7 –

The text of this standard is based on the following documents:

FDIS Report on voting

32C/362/FDIS 32C/366/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The clauses of this standard supplement, modify or replace the corresponding clauses in

IEC 60127-1.

Where there is no corresponding clause or subclause in this standard, the clause or

subclause of IEC 60127-1 applies without modification as far as is reasonable. When this

standard states “addition”, “modification” or “replacement”, the relevant text in IEC 60127-1 is

to be adapted accordingly.

The IEC 60127 series is subdivided as follows:

Part 1: Definitions for miniature fuses and general requirements for miniature fuse-links

Part 2: Cartridge fuse-links

Part 3: Sub-miniature fuse-links

Part 4: Universal modular fuse-links (UMF)

Part 5: Guidelines for quality assessment of miniature fuse-links

Part 6: Fuse-holders for miniature fuse-links

Part 7: (Free for further documents)

Part 8: (Free for further documents)

Part 9: (Free for further documents)

Part 10: User guide for miniature fuses

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

− 8 − 60127-4 CEI:2005

INTRODUCTION

La tendance à la miniaturisation des équipements électroniques a conduit les utilisateurs à

exiger des éléments de remplacement de petites dimensions et de conception appropriée

pour les circuits imprimés ou les autres systèmes de substrats, si possible avec des moyens

automatiques. Il est recommandé que ces éléments de remplacement soient conçus pour

incorporer un degré de non-interchangeabilité.

Les tensions assignées de 12,5 V, 25 V, 32 V, 50 V, 63 V, 125 V et 250 V sont spécifiées

ainsi que les caractéristiques suivantes: la fusion très rapide (FF), la fusion rapide (F), la

fusion retardée (T) et la fusion très retardée (TT).

En raison de l’importance croissante de la limitation des surtensions transitoires dans la

nouvelle technologie, des recommandations sont incluses pour les limites des surtensions

produites par ces fusibles dans des conditions d’essai spécifiées relatives aux configurations

typiques des circuits.

Le choix est donné de spécifier le pouvoir de coupure en courant alternatif ou en courant

continu. Il est considéré que les fusibles satisfaisant aux exigences en courant continu

satisfont également au courant alternatif; cependant, des essais sont requis pour les valider.

Les fusibles peuvent avoir deux caractéristiques assignées, auquel cas il convient que la

documentation du constructeur y fasse référence.

Les utilisateurs de coupe-circuit miniatures expriment le voeu de n'avoir à considérer qu'un

seul numéro de publication pour toutes les normes, recommandations et autres documents

concernant les coupe-circuit miniatures, afin de faciliter tout renvoi aux coupe-circuit à

fusibles dans d'autres spécifications, par exemple celles relatives aux équipements.

De plus, un seul numéro de publication et une subdivision en parties faciliteront la mise en

oeuvre de nouvelles normes, car les articles et paragraphes comprenant des exigences

générales n'auront pas à être répétés.

60127-4 IEC:2005 – 9 –

INTRODUCTION

The trend towards miniaturization of electronic equipment has caused users to require fuse-

links of small dimensions, and of appropriate design for application to printed circuit boards

or other substrate systems, possibly by automatic means. These fuse-links should be

designed to incorporate a degree of non-interchangeability.

Rated voltages of 12,5 V, 25 V, 32 V, 50 V, 63 V, 125 V, and 250 V are specified together

with the following characteristics: very quick acting (FF), quick acting (F), time-lag (T) and

long time-lag (TT).

Because of the increasing importance of limitation of transient overvoltages in new

technology, recommendations are included for limits to the overvoltages produced by these

fuses under specified test conditions related to typical circuit configurations.

The option is given to specify the breaking capacity with alternating current or direct current;

it is considered that fuses that meet the d.c. requirement will meet the a.c. requirement;

however, testing is required to validate this. Fuses may be dual rated, in which case the

manufacturer's literature should be referred to.

The users of miniature fuses express the wish that all standards, recommendations and other

documents relating to miniature fuses should have the same publication number in order to

facilitate reference to fuses in other specifications, for example, equipment specifications.

Furthermore, a single publication number and subdivision into parts would facilitate the

establishment of new standards, because clauses and subclauses containing general

requirements need not be repeated.

− 10 − 60127-4 CEI:2005

COUPE-CIRCUIT MINIATURES –

Partie 4: Eléments de remplacement modulaires universels (UMF) –

Types de montage en surface et montage par trous

1 Domaine d'application et objet

La présente partie de la CEI 60127 s'applique aux éléments de remplacement modulaires

universels (UMF) conçus pour le montage sur circuit imprimé et autres substrats, et

employés pour la protection d'appareils électriques, de matériels électroniques et de leurs

éléments constituants, normalement utilisés à l'intérieur.

Elle n'est pas applicable aux éléments de remplacement pour les appareils destinés à être

employés dans des conditions particulières, telles que des atmosphères corrosives ou

explosives.

Ces coupe-circuit sont normalement destinés à être montés ou remplacés uniquement par

des personnes qualifiées, en utilisant des outils spéciaux.

Les éléments de remplacement pour utilisation dans les ensembles-porteurs sont à l’étude.

La présente norme renvoie en outre aux exigences de la CEI 60127-1.

L'objet de cette partie de la CEI 60127 est tel que donné dans la CEI 60127-1, avec

l’exigence supplémentaire d'un degré de non-interchangeabilité.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références

non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60068-2-20:1979, Essais fondamentaux climatiques et de robustesse mécanique −

Deuxième partie: Essais – Essai T: Soudure

Amendement 2 (1987)

CEI 60068-2-21:1999, Essais d'environnement – Partie 2-21: Essais – Essai U: Robustesse

des sorties et des dispositifs de montage incorporés

CEI 60068-2-58:2004, Essais d'environnement – Partie 2-58: Essais – Essai Td: Soudabilité,

résistance de la métallisation à la dissolution et résistance à la chaleur de soudage des

composants pour montage en surface (CMS) (en anglais seulement)

CEI 60127-1:1988, Coupe-circuit miniatures – Partie 1: Définitions pour coupe-circuit

miniatures et prescriptions générales pour éléments de remplacement miniatures

Amendement 1 (1999)

Amendement 2 (2002)

CEI 60194:1999, Conception, fabrication et assemblage des cartes imprimées – Termes et

définitions

___________

Il existe une version consolidée (2003).

60127-4 IEC:2005 – 11 –

MINIATURE FUSES –

Part 4: Universal modular fuse-links (UMF) –

Through-hole and surface mount types

1 Scope and object

This part of IEC 60127 relates to universal modular fuse-links (UMF) for printed circuits and

other substrate systems, used for the protection of electric appliances, electronic equipment,

and component parts thereof, normally intended to be used indoors.

It does not apply to fuse-links for appliances intended to be used under special conditions,

such as in a corrosive or explosive atmosphere.

These fuses are normally intended to be mounted or replaced only by appropriately skilled

persons using specialized equipment.

Fuse-links for use in fuse-holders are under consideration.

This standard applies in addition to the requirements of IEC 60127-1.

The objectives of this part of IEC 60127 are as given in IEC 60127-1, with the additional

requirement of a degree of non-interchangeability.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-2-20:1979, Basic environmental testing procedures – Part 2: Tests – Test T:

Soldering

Amendment 2 (1987)

IEC 60068-2-21:1999, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-58:2004, Environmental testing – Part 2-58: Tests – Test Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60127-1:1988, Miniature fuses – Part 1: Definitions for miniature fuses and general

requirements for miniature fuse-links

Amendment 1 (1999)

Amendment 2 (2002)

IEC 60194:1999, Printed board design, manufacture and assembly – Terms and definitions

___________

There exists a consolidated version (2003).

− 12 − 60127-4 CEI:2005

CEI 60664-1:1992, Coordination de l'isolement des matériels dans les systèmes (réseaux) à

basse tension – Partie 1: Principes, prescriptions et essais

Amendement 1 (2000)

Amendement 2 (2002)

CEI 61249-2-7:2002, Matériaux pour circuits imprimés et autres structures d'interconnexion –

Partie 2-7: Matériaux de base renforcés, plaqués et non plaqués – Feuille stratifiée tissée de

verre E avec de la résine époxyde, d'inflammabilité définie (essai de combustion verticale),

plaquée cuivre

ISO 3:1973, Nombres normaux – Séries de nombres normaux

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions donnés à l'Article 3 de la

CEI 60127-1 s’appliquent, ainsi que les suivants:

3.1

élément de remplacement de type à montage par trous

élément de remplacement modulaire universel (UMF) conçu pour le montage direct sur des

circuits imprimés par soudage, les sorties étant insérées dans des trous conçus pour un tel

montage

3.2

élément de remplacement de type à montage en surface

élément de remplacement modulaire universel (UMF) conçu pour la fixation conductrice

directe sur la surface d'un substrat par soudage ou d'autres méthodes, sans que les sorties

soient insérées dans des trous ou socles conçus pour un tel montage

3.3

pastille

partie d'impression conductrice utilisée usuellement – mais non exclusivement – pour la

connexion et/ou la fixation des composants (voir CEI 60194)

NOTE D'autres définitions applicables pour l'utilisation des éléments de remplacement de type à montage en

surface peuvent être trouvées dans la CEI 60115-1 et la CEI 60115-8 .

4 Prescriptions générales

Voir la CEI 60127-1.

5 Valeurs assignées

5.1 Tension assignée

Voir les feuilles de norme.

5.2 Courant assigné

Voir le Tableau 1 pour les caractéristiques assignées préférentielles.

5.3 Pouvoir de coupure assigné

Voir les feuilles de norme.

___________

Il existe une version consolidée (2002).

Cette norme a été supprimée.

60127-4 IEC:2005 – 13 –

IEC 60664-1:1992, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

Amendment 1 (2000)

Amendment 2 (2002)

IEC 61249-2-7:2002, Materials for printed boards and other interconnecting structures –

Part 2-7: Reinforced base materials clad and unclad - Epoxide woven E-glass laminated

sheet of defined flammability (vertical burning test), copper-clad

ISO 3:1973, Preferred numbers – Series of preferred numbers

3 Terms and definitions

For the purposes of this document, the terms and definitions given in Clause 3 of IEC 60127-

1, together with the following definitions, apply.

3.1

through-hole fuse-link

UMF designed for soldering directly into a printed wiring board, with insertion of its leads in

suitably designed holes

3.2

surface mount fuse-link

UMF designed for direct conductive attachment by solder or other means on to the surface of

a substrate, without insertion of its leads in suitably designed holes or sockets

3.3

land

portion of a conductive pattern usually but not exclusively used for the connection and/or

attachment of components (see IEC 60194)

NOTE Further definitions which may be useful in the application of surface mount fuse-links may be found in

3.

IEC 60115-1 and IEC 60115-8

4 General requirements

See IEC 60127-1.

5 Standard ratings

5.1 Rated voltage

See standard sheets.

5.2 Rated current

See Table 1 for preferred ratings.

5.3 Rated breaking capacity

See standard sheets.

___________

There exists a consolidated version (2002).

This standard has been withdrawn.

− 14 − 60127-4 CEI:2005

6 Marquage

En plus des exigences données à l'Article 6 de la CEI 60127-1, les critères suivants

concernant un UMF doivent être respectés et marqués:

6.1 Supplément

e) pour les éléments de remplacement d'une tension assignée de 250 V, un symbole

indiquant le pouvoir de coupure doit figurer. Ce symbole doit être placé entre l'indication

du courant assigné et celle de la tension assignée.

Ces symboles sont les suivants:

H: à haut pouvoir de coupure;

I: à pouvoir de coupure intermédiaire;

L: à faible pouvoir de coupure.

f) le symbole distinctif donné à la Figure 1;

g) les lettres c.a. avant la tension pour éléments de remplacement conçus uniquement pour

des applications en courant alternatif.

6.4 Codage des éléments de remplacement modulaires universels par bandes de

couleur

A l'étude.

6.5 Si le marquage est impossible en raison de leur taille réduite, il est recommandé que les

informations correspondantes apparaissent sur le plus petit emballage et dans la documen-

tation technique du constructeur.

7 Généralités sur les essais

En plus des exigences données à l'Article 7 de la CEI 60127-1, les règles suivantes sont à

respecter:

7.2 Supplément:

7.2.1 Pour les essais des courants assignés individuels des fusibles selon les feuilles de

norme 1 et 2, voir le Tableau 2. Pour des éléments de remplacement définis et assignés à la

fois pour les courants alternatif et continu, le nombre d'éléments de remplacement requis est

de 63. Pour des éléments de remplacement définis uniquement pour le courant alternatif, le

nombre d'éléments de remplacement requis est de 48. Neuf sont gardés en réserve.

Pour le courant assigné maximal d'une série homogène selon les feuilles de norme 1 et 2,

voir le Tableau 3. Pour des éléments de remplacement définis et assignés à la fois pour les

courants alternatif et continu, le nombre d'éléments de remplacement requis est de 53. Pour

des éléments de remplacement définis uniquement pour le courant alternatif, le nombre

d'éléments de remplacement requis est de 48. 19 sont gardés en réserve.

Pour le courant assigné minimal d’une série homogène selon les feuilles de norme 1 et 2,

voir le Tableau 4. Pour des éléments de remplacement définis et assignés à la fois pour les

courants alternatif et continu, le nombre d'éléments de remplacement requis est de 38. Pour

des éléments de remplacement définis uniquement pour le courant alternatif, le nombre

d'éléments de remplacement requis est de 33. 16 sont gardés en réserve.

60127-4 IEC:2005 – 15 –

6 Marking

In addition to the requirements of Clause 6 in IEC 60127-1, the following criteria concerning

UMF shall be observed and marked:

6.1 Addition:

e) For fuse-links rated at 250 V, a symbol denoting the breaking capacity. This symbol shall

be placed between the marking for rated current and the marking for rated voltage.

These symbols are as follows:

H: denoting high-breaking capacity;

I: denoting intermediate-breaking capacity;

L: denoting low-breaking capacity.

f) The distinctive symbol shown in Figure 1.

g) The letters a.c. before the voltage for devices designed solely for alternating current

application.

6.4 Colour coding for universal modular fuse-links

Under consideration.

6.5 Where marking is impractical due to space limitations, the relevant information should

appear on the smallest package and in the manufacturer’s technical literature.

7 General notes on tests

In addition to the requirements of Clause 7 in IEC 60127-1, the following criteria shall be

observed:

7.2 Addition:

7.2.1 For testing of individual fuse ratings according to standard sheets 1 and 2, see Table

2. For fuse-links designed and rated both for a.c. and d.c., the number of fuse-links required

is 63. For fuse-links designed only for a.c., the number of fuse-links required is 48. There are

nine spares.

For the maximum ampere rating of a homogeneous series according to standard sheets 1

and 2, see Table 3. For fuse-links designed and rated both for a.c. and d.c., the number of

fuse-links required is 53. For fuse-links designed only for a.c., the number of fuse-links

required is 48. There are 19 spares.

For the minimum ampere rating of a homogeneous series according to standard sheets 1 and

2, see Table 4. For fuse-links designed and rated both for a.c. and d.c., the number of fuse-

links required is 38. For fuse-links designed only for a.c., the number of fuse-links required

is 33. There are 16 spares.

− 16 − 60127-4 CEI:2005

7.3 Socles d'essai

7.3.1 Exigences générales

Les éléments de remplacement doivent être montés sur un circuit imprimé d'essai approprié

(voir 7.3.2 ou 7.3.3, selon le cas) par soudage.

Ce circuit imprimé d'essai doit ensuite être monté sur le socle d'essai (Figure 4). Le circuit

imprimé d'essai doit être réalisé en feuille stratifiée de tissu de verre époxyde recouverte de

cuivre telle que définie dans la CEI 61249-2-7:

− l'épaisseur nominale de la feuille doit être de 1,6 mm;

− l'épaisseur nominale de la couche de cuivre doit être de 0,035 mm (0,070 mm au-dessus

de 6,3 A).

Les pièces métalliques du socle doivent être en laiton avec une teneur en cuivre comprise

entre 58 % et 70 %. Les contacts doivent être argentés.

Si deux éléments de remplacement ou plus sont essayés en série, les socles d'essai doivent

être disposés de manière qu'une distance de 50 mm au moins sépare deux éléments de

remplacement en essai. Les fils conducteurs raccordant les socles d'essai entre eux et

servant au raccordement des socles d'essai à l'ampèremètre et à la source de courant

doivent être réalisés en fil de cuivre isolé. Chaque conducteur doit avoir une longueur de

250 mm et une section de 1 mm² environ.

7.3.2 Eléments de remplacement de type à montage par trous (feuille de norme 1)

Pour les essais électriques sur les éléments de remplacement conformes à la feuille de

norme 1, l'élément de remplacement doit être monté dans le circuit imprimé d'essai donné à

la Figure 2 dans les deux trous appropriés à l'espacement entre les sorties.

7.3.3 Eléments de remplacement de type à montage en surface (feuille de norme 2)

Pour les essais électriques sur les éléments de remplacement conformes à la feuille de

norme 2, l'élément de remplacement doit être monté sur le circuit imprimé d'essai donné à la

Figure 3. Voir l’Annexe A pour les informations.

8 Dimensions et construction

8.1 Dimensions

Les dimensions des UMFs doivent être conformes aux exigences des feuilles de norme

correspondantes.

La conformité est vérifiée par la mesure de la longueur, de l'épaisseur et de la hauteur.

Pour les éléments de remplacement conformes à la feuille de norme 1, l'espacement entre

les sorties est vérifié. La sortie doit aussi passer à travers un trou de 1 mm. La longueur de

la sortie n'est pas spécifiée car elle dépend du mode de conditionnement.

8.2 Construction

L’élément fusible doit être complètement enfermé.

L’UMF doit résister à la chaleur et à l’exposition chimique d'un circuit imprimé ou autres

opérations d'assemblage du substrat sans altération de ses performances.

La conformité est vérifiée par l'essai de la résistance à la chaleur de soudage (voir 8.7).

60127-4 IEC:2005 – 17 –

7.3 Fuse-bases for tests

7.3.1 General requirements

Fuse-links shall be mounted upon the appropriate test board (see 7.3.2 or 7.3.3 as

appropriate) by soldering.

This test board shall then be mounted on the test fuse-base (Figure 4). The test board shall

be made of epoxide woven glass fabric copper-clad laminated sheet, as defined in

IEC 61249-2-7:

− the nominal sheet thickness shall be 1,6 mm;

− the nominal thickness of copper layer shall be 0,035 mm (0,070 mm above 6,3 A).

Metal parts of the fuse-base shall be made of brass with a copper content between 58 % and

70 %. Contact parts shall be silver-plated.

When two or more fuse-links are tested in series, the test fuse-bases shall be located so that

there will be a spacing of not less than 50 mm between any two fuse-links under test. The

conductor connecting the test fuse-bases together, and connecting the test fuse-bases to the

ammeter and the source of supply shall be insulated copper wir

...

IEC 60127-4 ®

Edition 3.2 2012-12

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Miniature fuses –

Part 4: Universal modular fuse-links (UMF) – Through-hole and surface mount

types

Coupe-circuit miniatures –

Partie 4: Eléments de remplacement modulaires universels (UMF) – Types de

montage en surface et montage par trous

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC

65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte,

et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les

publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées.

antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Restez informé sur les nouvelles publications IEC. Just Service Clients - webstore.iec.ch/csc

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60127-4 ®

Edition 3.2 2012-12

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Miniature fuses –

Part 4: Universal modular fuse-links (UMF) – Through-hole and surface mount

types

Coupe-circuit miniatures –

Partie 4: Eléments de remplacement modulaires universels (UMF) – Types de

montage en surface et montage par trous

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.120.50 ISBN 978-2-8322-0554-9

– 2 – 60127-4 IEC:2005+A1:2008+A2:2012

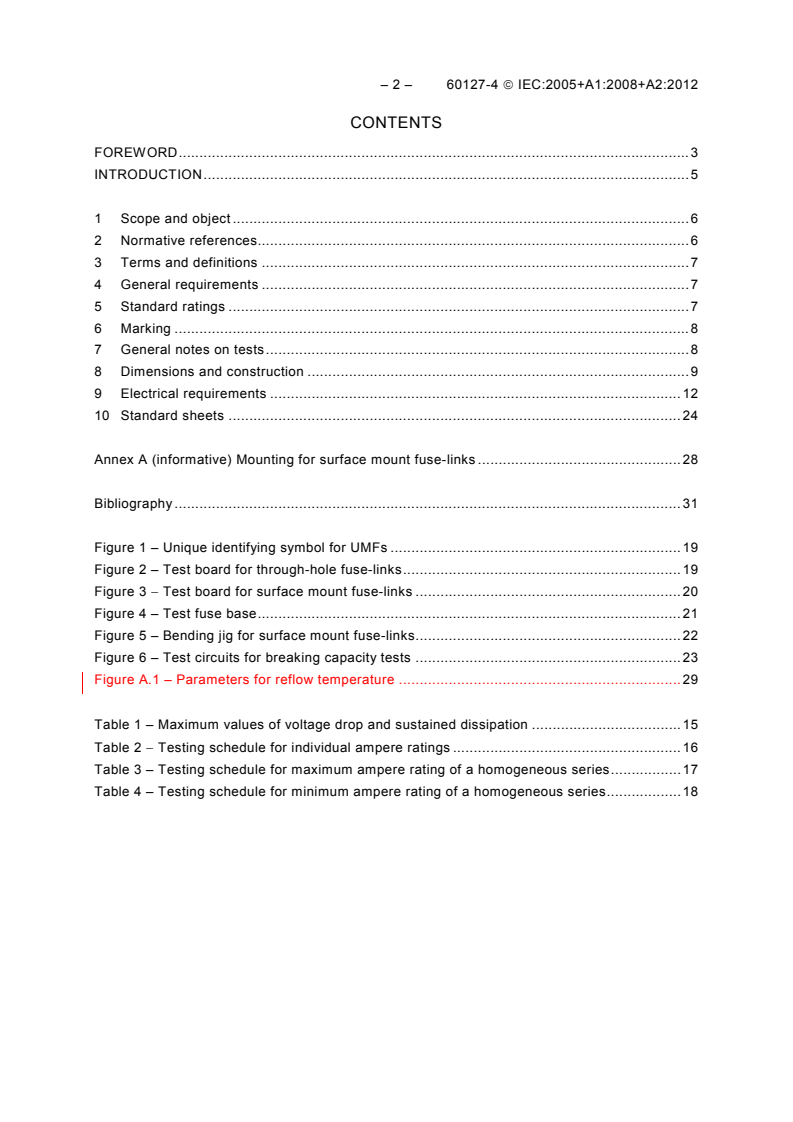

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope and object . 6

2 Normative references. 6

3 Terms and definitions . 7

4 General requirements . 7

5 Standard ratings . 7

6 Marking . 8

7 General notes on tests . 8

8 Dimensions and construction . 9

9 Electrical requirements . 12

10 Standard sheets . 24

Annex A (informative) Mounting for surface mount fuse-links . 28

Bibliography . 31

Figure 1 – Unique identifying symbol for UMFs . 19

Figure 2 – Test board for through-hole fuse-links . 19

Figure 3 − Test board for surface mount fuse-links . 20

Figure 4 – Test fuse base . 21

Figure 5 – Bending jig for surface mount fuse-links . 22

Figure 6 – Test circuits for breaking capacity tests . 23

Figure A.1 – Parameters for reflow temperature . 29

Table 1 – Maximum values of voltage drop and sustained dissipation . 15

Table 2 − Testing schedule for individual ampere ratings . 16

Table 3 – Testing schedule for maximum ampere rating of a homogeneous series . 17

Table 4 – Testing schedule for minimum ampere rating of a homogeneous series . 18

60127-4 IEC:2005+A1:2008+A2:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

_________

MINIATURE FUSES –

Part 4: Universal modular fuse-links (UMF) –

Through-hole and surface mount types

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendments has been prepared

for user convenience.

IEC 60127-4 edition 3.2 contains the third edition (2005) [documents 32C/362/FDIS and 32C/366/

RVD], its amendment 1 (2008) [documents 32C/411/FDIS and 32C/412/RVD] and its amendment

2 (2012) [documents 32C/456/CDV and 32C/463/RVC].

A vertical line in the margin shows where the base publication has been modified by

amendments 1 and 2. Additions and deletions are displayed in red, with deletions being struck

through.

– 4 – 60127-4 IEC:2005+A1:2008+A2:2012

International Standard IEC 60127-4 has been prepared by subcommittee 32C: Miniature fuses,

of IEC technical committee 32: Fuses.

The major technical changes with regard to the previous edition are as follows: introduction of

physically smaller devices with lower rated voltages. Fuse-link temperature test (9.7) is

modified.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The clauses of this standard supplement, modify or replace the corresponding clauses in

IEC 60127-1.

Where there is no corresponding clause or subclause in this standard, the clause or subclause

of IEC 60127-1 applies without modification as far as is reasonable. When this standard states

“addition”, “modification” or “replacement”, the relevant text in IEC 60127-1 is to be adapted

accordingly.

The IEC 60127 series is subdivided as follows:

Part 1: Definitions for miniature fuses and general requirements for miniature fuse-links

Part 2: Cartridge fuse-links

Part 3: Sub-miniature fuse-links

Part 4: Universal modular fuse-links (UMF)

Part 5: Guidelines for quality assessment of miniature fuse-links

Part 6: Fuse-holders for miniature fuse-links

Part 7: (Free for further documents)

Part 8: (Free for further documents)

Part 9: (Free for further documents)

Part 10: User guide for miniature fuses

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The “colour inside” logo on the cover page of this publication indicates

IMPORTANT –

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

60127-4 IEC:2005+A1:2008+A2:2012 – 5 –

INTRODUCTION

The trend towards miniaturization of electronic equipment has caused users to require fuse-

links of small dimensions, and of appropriate design for application to printed circuit boards or

other substrate systems, possibly by automatic means. These fuse-links should be designed to

incorporate a degree of non-interchangeability.

Rated voltages of 12,5 V, 25 V, 32 V, 50 V, 63 V, 125 V, and 250 V are specified together with

the following characteristics: very quick acting (FF), quick acting (F), time-lag (T) and long

time-lag (TT).

Because of the increasing importance of limitation of transient overvoltages in new technology,

recommendations are included for limits to the overvoltages produced by these fuses under

specified test conditions related to typical circuit configurations.

The option is given to specify the breaking capacity with alternating current or direct current;

it is considered that fuses that meet the d.c. requirement will meet the a.c. requirement;

however, testing is required to validate this. Fuses may be dual rated, in which case the

manufacturer's literature should be referred to.

The users of miniature fuses express the wish that all standards, recommendations and other

documents relating to miniature fuses should have the same publication number in order to

facilitate reference to fuses in other specifications, for example, equipment specifications.

Furthermore, a single publication number and subdivision into parts would facilitate the

establishment of new standards, because clauses and subclauses containing general require-

ments need not be repeated.

– 6 – 60127-4 IEC:2005+A1:2008+A2:2012

MINIATURE FUSES –

Part 4: Universal modular fuse-links (UMF) –

Through-hole and surface mount types

1 Scope and object

This part of IEC 60127 relates to universal modular fuse-links (UMF) for printed circuits and

other substrate systems, used for the protection of electric appliances, electronic equipment,

and component parts thereof, normally intended to be used indoors.

It does not apply to fuse-links for appliances intended to be used under special conditions,

such as in a corrosive or explosive atmosphere.

These fuses are normally intended to be mounted or replaced only by appropriately skilled

persons using specialized equipment.

Fuse-links for use in fuse-holders are under consideration.

This standard applies in addition to the requirements of IEC 60127-1.

The objectives of this part of IEC 60127 are as given in IEC 60127-1, with the additional

requirement of a degree of non-interchangeability.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60068-2-20:1979, Basic environmental testing procedures – Part 2: Tests – Test T:

Soldering

Amendment 2 (1987)

IEC 60068-2-20:2008, Environmental testing – Part 2-20: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-21:1999, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-58:2004, Environmental testing – Part 2-58: Tests – Test Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60127-1:1988, Miniature fuses – Part 1: Definitions for miniature fuses and general

requirements for miniature fuse-links

Amendment 1 (1999)

Amendment 2 (2002)

IEC 60194:1999, Printed board design, manufacture and assembly – Terms and definitions

___________

There exists a consolidated version (2003).

60127-4 IEC:2005+A1:2008+A2:2012 – 7 –

IEC 60664-1:1992, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

Amendment 1 (2000)

Amendment 2 (2002)

IEC 61249-2-7:2002, Materials for printed boards and other interconnecting structures –

Part 2-7: Reinforced base materials clad and unclad - Epoxide woven E-glass laminated sheet

of defined flammability (vertical burning test), copper-clad

ISO 3:1973, Preferred numbers – Series of preferred numbers

3 Terms and definitions

For the purposes of this document, the terms and definitions given in Clause 3 of IEC 60127-1,

together with the following definitions, apply.

3.1

through-hole fuse-link

UMF designed for soldering directly into a printed wiring board, with insertion of its leads in

suitably designed holes

3.2

surface mount fuse-link

UMF designed for direct conductive attachment by solder or other means on to the surface of a

substrate, without insertion of its leads in suitably designed holes or sockets

3.3

land

portion of a conductive pattern usually but not exclusively used for the connection and/or

attachment of components (see IEC 60194)

NOTE Further definitions which may be useful in the application of surface mount fuse-links may be found in

3.

IEC 60115-1 and IEC 60115-8

4 General requirements

See IEC 60127-1.

5 Standard ratings

5.1 Rated voltage

See standard sheets.

5.2 Rated current

See Table 1 for preferred ratings.

5.3 Rated breaking capacity

See standard sheets.

___________

There exists a consolidated version (2002).

This standard has been withdrawn.

– 8 – 60127-4 IEC:2005+A1:2008+A2:2012

6 Marking

In addition to the requirements of Clause 6 in IEC 60127-1, the following criteria concerning

UMF shall be observed and marked:

6.1 Addition:

e) For fuse-links rated at 250 V, a symbol denoting the breaking capacity. This symbol shall

be placed between the marking for rated current and the marking for rated voltage.

These symbols are as follows:

H: denoting high-breaking capacity;

I: denoting intermediate-breaking capacity;

L: denoting low-breaking capacity.

f) The distinctive symbol shown in Figure 1.

g) The letters a.c. before the voltage for devices designed solely for alternating current

application.

6.4 Colour coding for universal modular fuse-links

Under consideration.

6.5 Where marking is impractical due to space limitations, the relevant information should

appear on the smallest package and in the manufacturer’s technical literature.

7 General notes on tests

In addition to the requirements of Clause 7 in IEC 60127-1, the following criteria shall be

observed:

7.2 Addition:

7.2.1 For testing of individual fuse ratings according to standard sheets 1 and 2, see Table 2.

For fuse-links designed and rated both for a.c. and d.c., the number of fuse-links required

is 63. For fuse-links designed only for a.c., the number of fuse-links required is 48. There are

nine spares.

For the maximum ampere rating of a homogeneous series according to standard sheets 1

and 2, see Table 3. For fuse-links designed and rated both for a.c. and d.c., the number of

fuse-links required is 53. For fuse-links designed only for a.c., the number of fuse-links

required is 48. There are 19 spares.

For the minimum ampere rating of a homogeneous series according to standard sheets 1 and

2, see Table 4. For fuse-links designed and rated both for a.c. and d.c., the number of fuse-

links required is 38. For fuse-links designed only for a.c., the number of fuse-links required

is 33. There are 16 spares.

60127-4 IEC:2005+A1:2008+A2:2012 – 9 –

7.3 Fuse-bases for tests

7.3.1 General requirements

Fuse-links shall be mounted upon the appropriate test board (see 7.3.2 or 7.3.3 as appropriate)

by soldering.

This test board shall then be mounted on the test fuse-base (Figure 4). The test board shall be

made of epoxide woven glass fabric copper-clad laminated sheet, as defined in IEC 61249-2-7:

− the nominal sheet thickness shall be 1,6 mm;

− the nominal thickness of copper layer shall be 0,035 mm (0,070 mm above 6,3 A for rated

currents above 5 A).

Metal parts of the fuse-base shall be made of brass with a copper content between 58 % and

70 %. Contact parts shall be silver-plated.

When two or more fuse-links are tested in series, the test fuse-bases shall be located so that

there will be a spacing of not less than 50 mm between any two fuse-links under test. The

conductor connecting the test fuse-bases together, and connecting the test fuse-bases to the

ammeter and the source of supply shall be insulated copper wire. The length of each conductor

shall be 250 mm, and the cross-sectional area of the wire shall be approximately 1 mm².

7.3.2 Through-hole fuse-links (standard sheet 1)

For electrical tests upon fuse-links covered by standard sheet 1, the fuse-link shall be mounted

on the test board, as shown in Figure 2 in the pair of holes appropriate to the spacing of the

terminations.

7.3.3 Surface mount fuse-links (standard sheet 2)

For electrical tests upon fuse-links covered by standard sheet 2, the fuse-link shall be mounted

on the test board, as shown in Figure 3. See Annex A for guidance.

8 Dimensions and construction

8.1 Dimensions

The dimensions of the UMFs shall comply with the relevant standard sheets.

Compliance is checked by measurement of length, width and height.

For fuse-links to standard sheet 1, the termination spacing is checked. The termination shall

also pass through a 1 mm hole. The length of the termination is not specified as this is subject

to the method of packaging.

8.2 Construction

The fuse-element shall be completely enclosed.

The UMF shall withstand the heat and chemical exposure of a printed circuit board or other

substrate assembly operations with its performance unimpaired.

Compliance is checked by the resistance to soldering heat test as specified in 8.7.

– 10 – 60127-4 IEC:2005+A1:2008+A2:2012

8.3 Terminations

8.3.1 Through-hole fuse-links

Terminations shall be firmly attached so that it is not possible to remove them without

damaging the UMF.

Compliance is checked by carrying out the following test.

The samples are preconditioned by immersion in water for 24 h at a temperature between

15 °C and 35 °C.

The tests are carried out in accordance with IEC 60068-2-21.

The following tests shall be applied:

− tensile test Ua , applied force 10 N;

− thrust test Ua , applied force 2 N;

− bending test Ub, applied force 5 N, number of bends: 1.

The sample size is two fuses for each test. After testing, the terminations shall remain firmly

attached. The voltage drop shall be measured in accordance with 9.1, and shall not exceed the

maximum allowed in Table 1. Bending test Ub is omitted if the terminations are less than

5 mm.

8.3.2 Surface mount fuse-links

The fuse-links shall be mounted on the test board as shown in Figure 3. The test board, with

the fuse-links on the underside, shall be placed in the bending jig as shown in Figure 5. The

board shall then be bent by 1 mm at a rate of 1 mm/s. The test board shall be allowed to

recover from the bent position, and then be removed from the test jig.

After the test, the terminations shall remain firmly attached, and the voltage drop shall be

measured in accordance with 9.1, and shall not exceed the maximum allowed in Table 1.

8.4 Alignment and configuration of terminations

The termination configuration and spacing shall be as specified in the standard sheets.

NOTE 1 Through-hole fuse-links

For through-hole mounting of UMFs (standard sheet 1), the dimensions shown on the standard sheets are such as

to permit installation on printed circuit boards having a grid system of holes located on centres of distance

e = 2,5 mm. Attention is drawn to the fact that in some parts of the world the value e = 2,54 mm is still in use by

printed circuit designers.

Electrical and electronic circuit designers are advised to apply the requirements of IEC 60326-3.

NOTE 2 Surface mount fuse-links

For surface mounting of UMFs (standard sheet 2), electrical and electronic circuit designers are advised to design

substrate land areas to receive UMFs with due consideration for achieving the maximum area of contact in the

application, taking into account the tolerance applied to mechanical placing of the component and the dimensions

and tolerances for terminals in this standard.

8.5 Soldered joints

See IEC 60127-1.

60127-4 IEC:2005+A1:2008+A2:2012 – 11 –

8.6 Solderability of terminations

8.6.1 Through-hole fuse-links