IEC TS 62727:2012

(Main)Photovoltaic systems - Specification for solar trackers

Photovoltaic systems - Specification for solar trackers

IEC/TS 62727:2012(E) provides guidelines for the parameters to be specified for solar trackers for photovoltaic systems and provides recommendations for measurement techniques. The purpose of this test specification is to define the performance characteristics of trackers and describe the methods to calculate and/or measure critical parameters. This specification provides industry-wide definitions and parameters for solar trackers. Keywords: solar photovoltaic energy, solar trackers

General Information

- Status

- Withdrawn

- Publication Date

- 29-May-2012

- Withdrawal Date

- 24-Dec-2020

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 7 - TC 82/WG 7

- Current Stage

- WPUB - Publication withdrawn

- Start Date

- 04-Jan-2021

- Completion Date

- 31-Dec-2020

IEC TS 62727:2012 - Photovoltaic systems - Specification for solar trackers

IEC TS 62727:2012 - Photovoltaic systems - Specification for solar trackers Released:5/30/2012 Isbn:9782832201220

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC TS 62727:2012 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Photovoltaic systems - Specification for solar trackers". This standard covers: IEC/TS 62727:2012(E) provides guidelines for the parameters to be specified for solar trackers for photovoltaic systems and provides recommendations for measurement techniques. The purpose of this test specification is to define the performance characteristics of trackers and describe the methods to calculate and/or measure critical parameters. This specification provides industry-wide definitions and parameters for solar trackers. Keywords: solar photovoltaic energy, solar trackers

IEC/TS 62727:2012(E) provides guidelines for the parameters to be specified for solar trackers for photovoltaic systems and provides recommendations for measurement techniques. The purpose of this test specification is to define the performance characteristics of trackers and describe the methods to calculate and/or measure critical parameters. This specification provides industry-wide definitions and parameters for solar trackers. Keywords: solar photovoltaic energy, solar trackers

IEC TS 62727:2012 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62727:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TS 62727 ®

Edition 1.0 2012-05

TECHNICAL

SPECIFICATION

colour

inside

Photovoltaic systems – Specifications for solar trackers

IEC/TS 62727:2012(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

IEC/TS 62727 ®

Edition 1.0 2012-05

TECHNICAL

SPECIFICATION

colour

inside

Photovoltaic systems – Specifications for solar trackers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

U

ICS 27.160 ISBN 978-2-83220-122-0

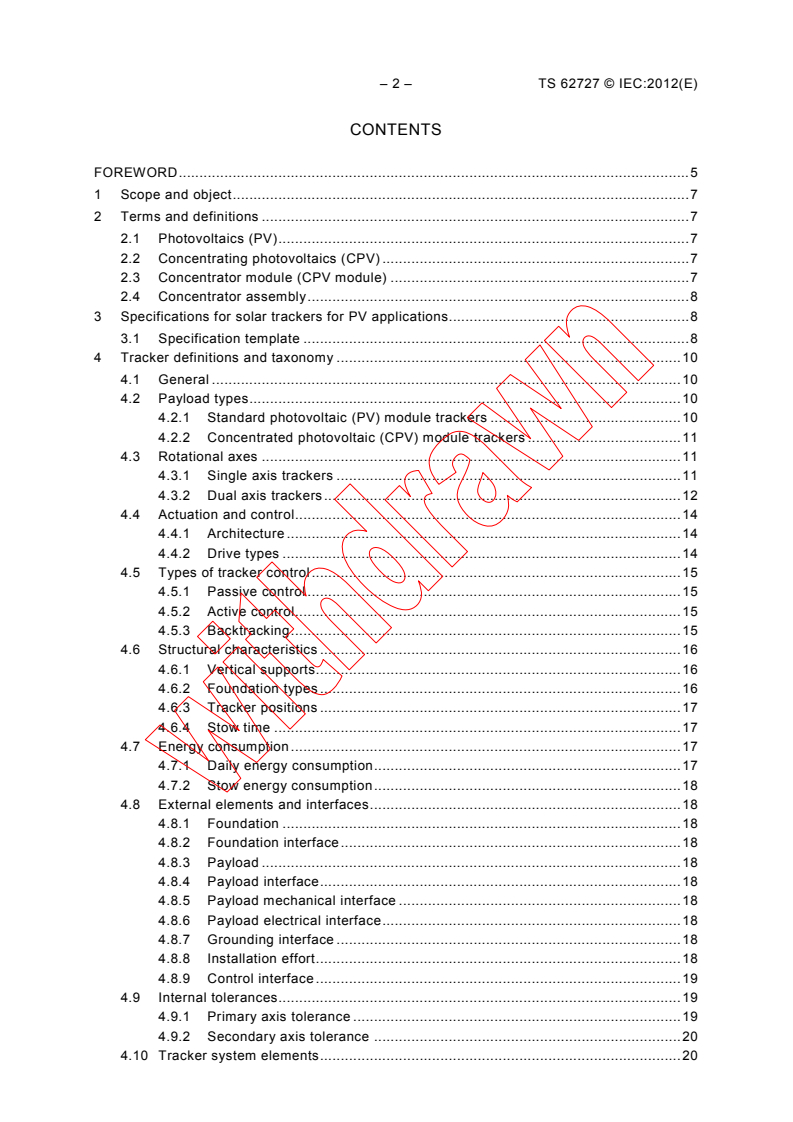

– 2 – TS 62727 © IEC:2012(E)

CONTENTS

FOREWORD . 5

1 Scope and object . 7

2 Terms and definitions . 7

2.1 Photovoltaics (PV) . 7

2.2 Concentrating photovoltaics (CPV) . 7

2.3 Concentrator module (CPV module) . 7

2.4 Concentrator assembly . 8

3 Specifications for solar trackers for PV applications . 8

3.1 Specification template . 8

4 Tracker definitions and taxonomy . 10

4.1 General . 10

4.2 Payload types . 10

4.2.1 Standard photovoltaic (PV) module trackers . 10

4.2.2 Concentrated photovoltaic (CPV) module trackers . 11

4.3 Rotational axes . 11

4.3.1 Single axis trackers . 11

4.3.2 Dual axis trackers . 12

4.4 Actuation and control . 14

4.4.1 Architecture . 14

4.4.2 Drive types . 14

4.5 Types of tracker control . 15

4.5.1 Passive control . 15

4.5.2 Active control. 15

4.5.3 Backtracking . 15

4.6 Structural characteristics . 16

4.6.1 Vertical supports. 16

4.6.2 Foundation types . 16

4.6.3 Tracker positions . 17

4.6.4 Stow time . 17

4.7 Energy consumption . 17

4.7.1 Daily energy consumption . 17

4.7.2 Stow energy consumption . 18

4.8 External elements and interfaces . 18

4.8.1 Foundation . 18

4.8.2 Foundation interface . 18

4.8.3 Payload . 18

4.8.4 Payload interface . 18

4.8.5 Payload mechanical interface . 18

4.8.6 Payload electrical interface . 18

4.8.7 Grounding interface . 18

4.8.8 Installation effort . 18

4.8.9 Control interface . 19

4.9 Internal tolerances . 19

4.9.1 Primary axis tolerance . 19

4.9.2 Secondary axis tolerance . 20

4.10 Tracker system elements . 20

TS 62727 © IEC:2012(E) – 3 –

4.10.1 Mechanical structure . 20

4.10.2 Tracker controller . 20

4.10.3 Sensors . 20

4.11 Reliability terminology . 20

4.11.1 Mean time between failures (MTBF) . 20

4.11.2 Mean time between critical failures (MTBCF) . 21

4.11.3 Mean time to repair (MTTR) . 21

4.12 Environmental conditions . 21

4.12.1 Operating temperature range . 21

4.12.2 Survival temperature range . 21

4.12.3 Maximum wind during operation . 21

4.12.4 Maximum wind during stow . 21

4.12.5 Snow load . 21

4.13 Functional tests . 22

4.13.1 Static load test . 22

4.13.2 Moment testing . 22

4.13.3 Limit switch operation . 22

4.13.4 Manual operation . 22

5 Tracker accuracy characterization . 22

5.1 Overview . 22

5.2 Pointing error (instantaneous) . 22

5.3 Measurement . 23

5.3.1 Overview . 23

5.3.2 Example of experimental method to measure pointing error . 23

5.3.3 Calibration of pointing error measurement tool . 24

5.4 Calculation of tracker accuracy . 24

5.4.1 Overview . 24

5.4.2 Data collection . 25

5.4.3 Data binning by wind speed . 25

5.4.4 Data filtering . 26

5.4.5 Data quantity . 26

5.4.6 Accuracy calculations . 26

6 Mechanical characterization . 27

6.1 General . 27

6.2 Backlash . 27

6.3 Stiffness . 27

7 Reliability testing . 28

7.1 Corrosion . 28

7.2 Component durability. 28

7.3 Extreme conditions tests . 28

8 Additional optional accuracy calculations . 28

8.1 Typical tracking accuracy range . 28

8.2 Tracking error histogram . 29

8.3 Percent of available irradiance as a function of pointing error . 29

Figure 1 – θ = Altitude angle = 0° (zenith angle = 90°) occurs when a vector normal to

the module face is pointing to the horizon. Altitude angle = 90° (zenith angle = 0°)

occurs when the module is facing the sky . 13

Figure 2 – Illustration of primary axis tolerance for a polar tracking axis . 19

– 4 – TS 62727 © IEC:2012(E)

Figure 3 – General illustration of pointing error . 23

Figure 4 – Two flat parallel plates at a specified distance, one having a pin hole for

sunlight to be tracked on specified-diameter circles that ultimately measure 0,1°, 0,2°,

and 0,3° accuracy rings (more if necessary) . 24

Figure 5 – Pointing error frequency distribution for the entire test period . 29

Figure 6 – Available irradiance as a function of pointing error . 30

Figure 7 – Available irradiance as a function of pointing error with binning by wind

speed . 30

Table 1 – Tracker specification template . 8

Table 2 – Alternate tracking accuracy reporting template . 27

TS 62727 © IEC:2012(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PHOTOVOLTAIC SYSTEMS –

SPECIFICATIONS FOR SOLAR TRACKERS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC 62727, which is a technical specification, has been prepared by IEC technical committee 82:

Solar photovoltaic energy systems.

– 6 – TS 62727 © IEC:2012(E)

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

82/651/DTS 82/711/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

TS 62727 © IEC:2012(E) – 7 –

PHOTOVOLTAIC SYSTEMS –

SPECIFICATIONS FOR SOLAR TRACKERS

1 Scope and object

This technical specification provides guidelines for the parameters to be specified for solar

trackers for photovoltaic systems and provides recommendations for measurement

techniques. No attempt is made to determine pass/fail criteria for trackers.

The purpose of this test specification is to define the performance characteristics of trackers

and describe the methods to calculate and/or measure critical parameters.

This specification provides industry-wide definitions and parameters for solar trackers. Each

vendor can design, build, and specify the functionality and accuracy with uniform definition.

This allows consistency in specifying the requirements for purchasing, comparing the products

from different vendors, and verifying the quality of the products. In addition, this specification

will clarify terminology and definitions for trackers and provide examples of measurement

techniques.

This technical specification will be a foundation for other standards to follow, including (but

not limited to) design qualification and reliability.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply. For additional

tracker-specific terminology, see Clause 5.

2.1

photovoltaics

PV

devices that use solar radiation to generate electrical energy

2.2

concentrating photovoltaics

CPV

devices that focus magnified sunlight on photovoltaics to generate electrical energy. The

sunlight could be magnified by various different methods, such as reflective or refractive

optics, in dish, trough, lens, or other configurations.

2.3

concentrator module

CPV module

a group of receivers (PV cells mounted in some way), optics, and other related components,

such as interconnections and mechanical enclosures, integrated together into a modular

package. The module is typically assembled in a factory and shipped to an installation site to

be installed along with other modules on a solar tracker.

Note 1 to entry: A CPV module typically does not have a field-adjustable focus point. In addition, a module could

be made of several sub-modules. The sub-module is a smaller, modular portion of the full-size module, which might

be assembled into the full module either in a factory or in the field.

– 8 – TS 62727 © IEC:2012(E)

2.4

concentrator assembly

a concentrator assembly consists of receivers, optics, and other related components that have

a field-adjustable focus point and are typically assembled and aligned in field

EXAMPLE: A system that combines a single large dish with a receiver unit which must be

aligned with the focal point of the disk.

Note 1 to entry: This term is used to differentiate certain CPV designs from the CPV modules mentioned above.

3 Specifications for solar trackers for PV applications

a) Specification template

All trackers complying with this specification should provide, as part of their product marking

and documentation, a table in the form specified below (see Table 1). See later clauses and

subclauses of this Technical Specification for further explanation of individual specifications.

Some of the specifications within the table are optional; however, if a tracker manufacturer

chooses to include optional information, it should be reported and measured in the specific

way shown in Table 1 (and in some cases, also described later in this Technical

Specification).

Engineering safety factors should be dictated by appropriate local standards and applications

details and documented by the tracker manufacturer.

The specification template below is a visual example only and should not be read as a list of

requirements.

Table 1 – Tracker specification template

Characteristic Example Notes/Clause/Subclause

Manufacturer The XYZ Company

Model number XX1090

Type of tracker CPV Tracker, Dual Axis 4.2, 4.3

Payload characteristics

Minimum/maximum mass 100/1 025 kg 4.8.3

supported

Payload center of mass 0-30 cm distance perpendicular to 4.8.3

restrictions mounting surface

Maximum dynamic torques Azimuth (Θ ): 10 kN⋅m 4.13.2, 7.3

z

allowed while moving

Θ , Θ : 5 kN⋅m

x y

[ should provide a set of diagrams to

clarify torques and which axes they

are relative to ]

Maximum static torques allowed [ should provide a set of diagrams ] 4.13.1, 7.3

while in stow position

Installation characteristics

Allowable foundation Reinforced concrete 4.6.2

Foundation tolerance in primary 4.9

± 0,5°

axis

Foundation tolerance in secondary ± 0,5° 4.9

axis

Electrical characteristics

Includes backup power? No N/A

TS 62727 © IEC:2012(E) – 9 –

Characteristic Example Notes/Clause/Subclause

Daily energy consumption 1 kWh typical 4.7.1

5 kWh maximum

Stow energy consumption kWh typical 4.7.2

1 kWh maximum

Input power requirements 100-240 VAC, 50-60 Hz, 5 A No specifics defined

Tracking accuracy

Accuracy, typical 0,1° 5.4.6

(low wind, min deflect point)

Accuracy, typical 0,3° 5.4.6

(low wind, max deflect point)

th

Accuracy, 95 percentile 0,5° 5.4.6

(low wind, min deflect point)

th

Accuracy, 95 percentile 0,8° 5.4.6

(low wind, max deflect point)

Mean wind speed during the “low 3 km/h 5.4.6

wind” test conditions

Accuracy, typical 0,7° 5.4.6

(high wind, min deflect point)

Accuracy, typical 1,0° 5.4.6

(high wind, max deflect point)

th

Accuracy, 95 percentile 1,1 5.4.6

(high wind, min deflect point)

th

Accuracy, 95 percentile 1,6° 5.4.6

(high wind, max deflect point)

Mean wind speed during the “high 12 km/h 5.4.6

wind” test conditions

Weight and area of payload 500 kg payload evenly distributed 5.4.2.1

installed during testing over a 50 m area

Payload center of mass installed Payload center of mass 20 cm above 5.4.2.1

during testing the module mounting surface

Control characteristics

Control algorithm Hybrid 4.5

Control interface None 4.8.9

External communication interface Ethernet/TCP-IP No specific description

Emergency stow provided? Yes, at wind speeds 100 km/h 4.6.4, 4.12.3

Stow time 4 minutes 4.6.4

Clock accuracy 1 second per year N/A

Mechanical design

Range of motion, primary axis ± 160° azimuth 4.6.3.3

Range of motion, secondary axis 10°-90° elevation 4.6.3.3

System stiffness Azimuth (Θ ): 0,05º / 1 000 N⋅m, Θ : 6.3

z x

0,1º / 1 000 N⋅m

Diagrams attached show applied

loads and observed deflection

Backlash 0,1° maximum 6.2

Environmental conditions

Maximum allowable wind speed Design values: 4.12.3

– 10 – TS 62727 © IEC:2012(E)

Characteristic Example Notes/Clause/Subclause

during tracking

80 km/h with 0 % terrain slope, open

country,

60 km/h with 8 % terrain slope,

suburban, urban

Tested to:

60 km/h with 0 % terrain slope, open

country

Maximum allowable wind speed in Design values: 4.12.4

stow

150 km/h horizontal wind,

120 km/h with 10 % slope

Tested to:

80 km/h with 0 % slope

Temperature operational range –20 °C to +50 °C 4.12.1

Temperature survival range –40 °C to +60 °C 4.12.2

Snow rating Up to 20 kg/m of snow load allowed 4.12.5

For an alternate template for the presentation of accuracy specifications see Table 2.

4 Tracker definitions and taxonomy

4.1 General

Solar trackers are mechanical devices used to point PV modules towards the sun or to direct

sunlight on PV cells or modules. Photovoltaic trackers can be classified into two types:

standard photovoltaic (PV) trackers and concentrated photovoltaic (CPV) trackers. Each of

these tracker types can be further categorized by the number and orientation of their axes,

their actuation architecture and drive type, their intended applications, and their vertical

supports and foundation type.

4.2 Payload types

4.2.1 Standard photovoltaic (PV) module trackers

4.2.1.1 Uses

Standard photovoltaic trackers are used to minimize the angle of incidence between incoming

light and a photovoltaic module. This increases the amount of energy produced from a fixed

amount of power generating capacity.

4.2.1.2 Type of light accepted

Photovoltaic modules accept both direct and diffuse light from all angles. This means that

systems implementing standard photovoltaic trackers produce energy even when not directly

pointed at the sun. Tracking in standard photovoltaic systems is used to increase the amount

of energy produced by the direct component of the incoming light.

4.2.1.3 Accuracy requirements

In standard photovoltaic systems, the energy contributed by the direct beam drops off with the

cosine of the angle between the incoming light and the module. Thus trackers that have

accuracies of ± 5° can deliver more than 99,6 % of the energy supplied by the direct beam. As

a result, high-accuracy tracking is not typically used.

TS 62727 © IEC:2012(E) – 11 –

4.2.2 Concentrated photovoltaic (CPV) module trackers

4.2.2.1 Uses

Concentrated photovoltaic trackers are used to enable the optics used in CPV systems. These

trackers point the concentrator modules at the sun or focus sunlight on PV collectors.

4.2.2.2 Type of light accepted

Direct solar radiation, as opposed to diffuse solar radiation, is the primary energy source for

CPV modules. Optics are designed specifically to focus the direct radiation on photovoltaic

cells. If this focus is not maintained, power output drops substantially.

If the CPV module concentrates in one dimension, then single axis tracking is required. If the

CPV module concentrates in two dimensions, then two axis tracking is required.

4.2.2.3 Accuracy requirements

In concentrator modules, tracking accuracy requirements are typically related to energy

production through the module acceptance angle. When the sun-pointing error is less than the

acceptance angle, the modules will typically deliver 90 % or more of the rated power output.

4.3 Rotational axes

4.3.1 General

Photovoltaic trackers can be grouped into classes by the number and orientation of the

tracker’s axes.

4.3.2 Single axis trackers

4.3.2.1 General

Single axis trackers have one degree of freedom that acts as an axis of rotation.

4.3.2.2 Single axis tracker implementations

4.3.2.2.1 General

There are several common implementations of single axis trackers. These include horizontal

single axis trackers, vertical single axis trackers, and tilted single axis trackers.

4.3.2.2.2 Horizontal single axis tracker (HSAT)

The axis of rotation for a horizontal single axis tracker is horizontal with respect to the ground.

IEC 1028/12

4.3.2.2.3 Vertical single axis tracker (VSAT)

The axis of rotation for vertical single axis trackers is vertical with respect to the ground.

These trackers rotate from east to west over the course of the day.

– 12 – TS 62727 © IEC:2012(E)

IEC 1029 /12

4.3.2.2.4 Tilted single axis tracker (TSAT)

All trackers with axes of rotation between horizontal and vertical are considered tilted single

axis trackers. Tracker tilt angles are often limited to reduce the wind profile and decrease the

elevated end’s height off the ground.

The polar aligned single axis tracker (PASAT) is a specific version of the tilted single axis

tracker. In this particular implementation, the tilt angle is equal to the latitude of the

installation. This aligns the tracker’s axis of rotation with the earth’s axis of rotation.

IEC 1030/12

4.3.2.3 Orientation – cardinal direction

The axis of rotation of single axis trackers is typically aligned along a true North meridian. It is

possible to align them in any cardinal direction with advanced tracking algorithms.

4.3.2.4 Module orientation with respect to rotational axis

The orientation of the module with respect to the tracker axis is important when modelling

performance.

Horizontal and tilted single axis trackers typically have the face of the module oriented

parallel to the axis of rotation. As a module tracks, it sweeps a cylinder that is rotationally

symmetric around the axis of rotation.

Vertical single axis trackers typically have the face of the module oriented at an angle with

respect to the axis of rotation. As a module tracks, it sweeps a cone that is rotationally

symmetric around the axis of rotation.

4.3.3 Dual axis trackers

4.3.3.1 General

Dual axis trackers have two degrees of freedom that act as axes of rotation. These axes are

typically normal to one another. The axis that is fixed with respect to the ground can be

considered the primary axis. The axis that is referenced to the primary axis can be considered

the secondary axis.

TS 62727 © IEC:2012(E) – 13 –

4.3.3.2 Dual axis tracker implementations

4.3.3.2.1 General

There are several common implementations of dual axis trackers. They are classified by the

orientation of their primary axes with respect to the ground. Two common implementations are

tip-tilt trackers and azimuth-altitude trackers (see Figure 1).

One convention for azimuth angle is “degrees east of north” (e.g. 0° azimuth is pointing north,

and 90° azimuth is pointing east).

One convention for altitude angle is “degrees up from the horizon” as illustrated below. Zenith

angle is the complement of altitude angle (zenith = 90° – altitude).

θθ = 0 = °

θ = 90°

θ =

IEC 1031/12

Figure 1 – θ = Altitude angle = 0° (zenith angle = 90°) occurs

when a vector normal to the module face is pointing to the horizon.

Altitude angle = 90° (zenith angle = 0°) occurs

when the module is facing the sky

The above sign conventions are assumed to be the ones used to describe angles, but a

different convention can be used as long as it is described. For example, the range of motion

of a tracker could be described as “azimuth from +20° to +340°,” or alternately, “azimuth

± 160° from south”.

4.3.3.2.2 Tip-tilt dual axis tracker

A tip- tilt dual axis tracker (TTDAT) has its primary axis horizontal to the ground. The

secondary axis is then typically normal to the primary axis.

The polar-style dual axis tracker is a particular type of TTDAT.

IEC 1032/12

– 14 – TS 62727 © IEC:2012(E)

4.3.3.2.3 Azimuth-altitude dual axis tracker

An azimuth-altitude dual axis tracker (AADAT) has its primary axis vertical to the ground. The

secondary axis is then typically normal to the primary axis.

IEC 1033/12

4.3.3.3 Orientation – cardinal direction

The axes of rotation of tip-tilt dual axis trackers are typically aligned either along a true north

meridian or an east-west line of latitude. It is possible to align them in any cardinal direction

with advanced tracking algorithms.

4.3.3.4 Module orientation with respect to rotational axes

The orientation of the module with respect to the tracker axis is important when modelling

performance. Dual axis trackers typically have modules oriented parallel to the secondary axis

of rotation.

4.4 Actuation and control

4.4.1 Architecture

4.4.1.1 General

There are two common actuation and control architectures: distributed actuation and ganged

actuation. These are implemented in many ways.

4.4.1.2 Distributed actuation

In a distributed actuation architecture, each tracker and each axis of rotation is independently

actuated and controlled.

4.4.1.3 Ganged actuation

In a ganged actuation architecture, many axes of rotation are simultaneously driven with a

single actuation system. This can be multiple axes on a single tracker or multiple trackers in

an array.

4.4.2 Drive types

4.4.2.1 General

There are three drive types used with solar trackers.

4.4.2.2 Electric drive

Electric drive systems transfer electrical energy to AC motors, DC brushed motors, or DC

brushless motors to create rotational motion. These motors interface with gearboxes that

reduce the rotational speed in exchange for additional torque. The final gearbox stage

delivers either rotary or linear motion that is used to drive a tracker axis.

TS 62727 © IEC:2012(E) – 15 –

4.4.2.3 Hydraulic drive

Hydraulic drive systems use pumps to generate hydraulic pressure. The hydraulic pressure is

transferred through valves, pipes, and hoses to a hydraulic motor or cylinder. The hydraulic

motor and cylinder adjust the mechanical advantage as needed to deliver the rotary or linear

motion to drive a tracker axis.

4.4.2.4 Passive drive

Passive drive systems use differential fluid pressure to drive a tracker axis. The pressure

differential is created by thermal gradients created by differential shading. The tracker moves

to bring the pressure differentials to equilibrium.

4.5 Types of tracker control

4.5.1 Passive control

Passive solar tracking typically relies on environmental forces to produce changes in fluid

density, which provide internal forces that can be used for mechanical advantage to position

the payload.

4.5.2 Active control

4.5.2.1 General

Active solar tracking uses supplied power to drive circuitry and actuators (motors, hydraulics,

and others) to position the payload.

4.5.2.2 Open loop control

Open loop control is an active method of tracking that does not use direct sensing of the sun

position, module power, et cetera as feedback. It uses mathematical calculations of the sun

position (based on the time of day, date, location, and so on) to determine where the tracker

should be pointing and drives actuators accordingly.

Note that open loop control in this context does not imply that the actuators themselves do not

provide feedback; the actuators could be servo motors with encoders and could themselves

be controlled via a closed-loop PID or similar controller.

Open loop in the context of tracker control refers to the control algorithm having no direct

feedback on the actual tracking error.

4.5.2.3 Closed loop control

This is an active method of tracking that utilizes some sort of feedback (such as an optical

sun position sensor or the module power output) to determine how to drive the actuators and

position the payload.

4.5.2.4 Hybrid control

This is an active method of tracking that combines the mathematical sun position calculations

(open loop ephemeris code) with the type of sensor data used in a closed feedback loop.

There are many different approaches to hybrid control.

4.5.3 Backtracking

Backtracking refers to intentionally positioning trackers somewhat off-sun, typically to reduce

shading from adjacent trackers in a close-packed installation during the early morning and

late afternoon when the sun is low on the horizon.

– 16 – TS 62727 © IEC:2012(E)

One method involves moving all the trackers in a field to a slightly higher elevation angle to

avoid shading. Another approach is for every other row to be inactive and positioned at 0°

(pointing at the sky) to allow the other rows clear line-of-sight to the sun without shading. This

is useful mainly in designs that do not have access to enough land area to be spaced far

enough apart to avoid shading in the early morning and late afternoon. Backtracking is

typically not applicable to CPV.

4.6 Structural characteristics

4.6.1 Vertical supports

4.6.1.1 General

Vertical supports transfer the load of the structure to the foundation. There are two common

types of vertical supports.

4.6.1.2 Pole-mounted trackers

A pole-mounted tracker transfers the load to the foundation via one or more poles. These

poles attach to or continue into one or more foundations.

All types of trackers (single axis and dual axis) can be mounted on poles.

4.6.1.3 Carousel-mounted trackers

A carousel-mounted tracker transfers the load to the foundation via a ring. This ring is then

attached to the foundation at multiple points.

Vertical single axis trackers and azimuth-altitude dual axis trackers are the only trackers that

can be carousel mounted.

4.6.2 Foundation types

4.6.2.1 General

The load placed on the tracker structure shall be sustained through its foundation.

Trackers can be mounted on roofs, ground/earth, and water and will be subject to location-

specific loading. As a result, there are many types of foundations used with trackers. The

foundation type used will depend on site-specific characteristics and the codes of the local

jurisdiction.

Foundation types are often categorized by whether or not they penetrate into the mounting

surface.

4.6.2.2 Penetrating foundations

4.6.2.2.1 Pile foundations

Pile foundations (also known as deep foundations) come in a wide variety of types. These

include but are not limited to concrete piles, driven piles, and drilled piles.

Pile foundations are common in ground-mounted and water-mounted applications. Hole

diameters, depth, concrete mixtures, rebar requirements, thread type, and other

characteristics are all determined by local site conditions.

TS 62727 © IEC:2012(E) – 17 –

4.6.2.3 Non-penetrating foundations

4.6.2.3.1 Ballasted foundations

Ballasted foundations (also known as shallow foundations) come in a wide variety of types.

Ballasted foundations are found in ground mount and roof mount applications. The area in

contact with the surface, total mass, material type, rebar requirements, and other

characteristics are all determined by local site conditions.

4.6.3 Tracker positions

4.6.3.1 Stow

The stow position is the position the tracker moves to when adverse weather conditions (e.g.,

high wind or heavy snow) are present or expected in order to avoid loads that might damage

the tracker or payload. Not all trackers will have a stow position, and the exact position will

vary depending on the tracker design.

4.6.3.2 Maintenance

The maintenance position is the position the tracker moves to for operations such as cleaning,

module installation, servicing, and so on. It could be the same position as the stow position or

a different position, and there could be multiple maintenance positions. When in this position,

there should be a safety interlock preventing sudden tracker motion without operator

interaction.

4.6.3.3 Range of motion

The range of motion is defined by the maximum motion of the tracker in each direction, in

each axis.

For example, a turret-style primary axis might have a range of motion of ± 135° from true

south [or in the reference frames defined above, +45° to +315° azimuth (east of north)]. An

elevation-style secondary axis might have a range of motion of 0° to 90°.

The range of motion specified in the requirements of Table 1 shall be tested and documented.

Note that the range of motion is not only defined by any mechanical limits: the presence of

electronic limit switches or software settings may be used to further restrict the range of

motion for reasons such as safety or reduction of shading.

If the tracker includes a controller, the range of motion should refer to the maximum range of

motion that can be commanded by the combination of hardware and software.

4.6.4 Stow time

The stow time is the time for the tracker with a standard payload to move from the position

farthest from the stow position to the stow position.

4.7 Energy consumption

4.7.1 Daily energy consumption

The daily energy consumption of a tracker is defined as the amount of energy in kWh that is

required to perform a full 24 h day of tracking (from start to stop at a typical tracking speed

and back to start by whatever speed is standard for that tracker) carrying a standard load.

The energy consumption will likely vary based on the wind loading and possibly also on cloud

cover and other weather conditions. The energy consumption

...

IEC/TS 62727 ®

Edition 1.0 2012-05

TECHNICAL

SPECIFICATION

colour

inside

Photovoltaic systems – Specifications for solar trackers

IEC/TS 62727:2012(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

IEC/TS 62727 ®

Edition 1.0 2012-05

TECHNICAL

SPECIFICATION

colour

inside

Photovoltaic systems – Specifications for solar trackers

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

U

ICS 27.160 ISBN 978-2-83220-122-0

– 2 – TS 62727 © IEC:2012(E)

CONTENTS

FOREWORD . 5

1 Scope and object . 7

2 Terms and definitions . 7

2.1 Photovoltaics (PV) . 7

2.2 Concentrating photovoltaics (CPV) . 7

2.3 Concentrator module (CPV module) . 7

2.4 Concentrator assembly . 8

3 Specifications for solar trackers for PV applications . 8

3.1 Specification template . 8

4 Tracker definitions and taxonomy . 10

4.1 General . 10

4.2 Payload types . 10

4.2.1 Standard photovoltaic (PV) module trackers . 10

4.2.2 Concentrated photovoltaic (CPV) module trackers . 11

4.3 Rotational axes . 11

4.3.1 Single axis trackers . 11

4.3.2 Dual axis trackers . 12

4.4 Actuation and control . 14

4.4.1 Architecture . 14

4.4.2 Drive types . 14

4.5 Types of tracker control . 15

4.5.1 Passive control . 15

4.5.2 Active control. 15

4.5.3 Backtracking . 15

4.6 Structural characteristics . 16

4.6.1 Vertical supports. 16

4.6.2 Foundation types . 16

4.6.3 Tracker positions . 17

4.6.4 Stow time . 17

4.7 Energy consumption . 17

4.7.1 Daily energy consumption . 17

4.7.2 Stow energy consumption . 18

4.8 External elements and interfaces . 18

4.8.1 Foundation . 18

4.8.2 Foundation interface . 18

4.8.3 Payload . 18

4.8.4 Payload interface . 18

4.8.5 Payload mechanical interface . 18

4.8.6 Payload electrical interface . 18

4.8.7 Grounding interface . 18

4.8.8 Installation effort . 18

4.8.9 Control interface . 19

4.9 Internal tolerances . 19

4.9.1 Primary axis tolerance . 19

4.9.2 Secondary axis tolerance . 20

4.10 Tracker system elements . 20

TS 62727 © IEC:2012(E) – 3 –

4.10.1 Mechanical structure . 20

4.10.2 Tracker controller . 20

4.10.3 Sensors . 20

4.11 Reliability terminology . 20

4.11.1 Mean time between failures (MTBF) . 20

4.11.2 Mean time between critical failures (MTBCF) . 21

4.11.3 Mean time to repair (MTTR) . 21

4.12 Environmental conditions . 21

4.12.1 Operating temperature range . 21

4.12.2 Survival temperature range . 21

4.12.3 Maximum wind during operation . 21

4.12.4 Maximum wind during stow . 21

4.12.5 Snow load . 21

4.13 Functional tests . 22

4.13.1 Static load test . 22

4.13.2 Moment testing . 22

4.13.3 Limit switch operation . 22

4.13.4 Manual operation . 22

5 Tracker accuracy characterization . 22

5.1 Overview . 22

5.2 Pointing error (instantaneous) . 22

5.3 Measurement . 23

5.3.1 Overview . 23

5.3.2 Example of experimental method to measure pointing error . 23

5.3.3 Calibration of pointing error measurement tool . 24

5.4 Calculation of tracker accuracy . 24

5.4.1 Overview . 24

5.4.2 Data collection . 25

5.4.3 Data binning by wind speed . 25

5.4.4 Data filtering . 26

5.4.5 Data quantity . 26

5.4.6 Accuracy calculations . 26

6 Mechanical characterization . 27

6.1 General . 27

6.2 Backlash . 27

6.3 Stiffness . 27

7 Reliability testing . 28

7.1 Corrosion . 28

7.2 Component durability. 28

7.3 Extreme conditions tests . 28

8 Additional optional accuracy calculations . 28

8.1 Typical tracking accuracy range . 28

8.2 Tracking error histogram . 29

8.3 Percent of available irradiance as a function of pointing error . 29

Figure 1 – θ = Altitude angle = 0° (zenith angle = 90°) occurs when a vector normal to

the module face is pointing to the horizon. Altitude angle = 90° (zenith angle = 0°)

occurs when the module is facing the sky . 13

Figure 2 – Illustration of primary axis tolerance for a polar tracking axis . 19

– 4 – TS 62727 © IEC:2012(E)

Figure 3 – General illustration of pointing error . 23

Figure 4 – Two flat parallel plates at a specified distance, one having a pin hole for

sunlight to be tracked on specified-diameter circles that ultimately measure 0,1°, 0,2°,

and 0,3° accuracy rings (more if necessary) . 24

Figure 5 – Pointing error frequency distribution for the entire test period . 29

Figure 6 – Available irradiance as a function of pointing error . 30

Figure 7 – Available irradiance as a function of pointing error with binning by wind

speed . 30

Table 1 – Tracker specification template . 8

Table 2 – Alternate tracking accuracy reporting template . 27

TS 62727 © IEC:2012(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PHOTOVOLTAIC SYSTEMS –

SPECIFICATIONS FOR SOLAR TRACKERS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC 62727, which is a technical specification, has been prepared by IEC technical committee 82:

Solar photovoltaic energy systems.

– 6 – TS 62727 © IEC:2012(E)

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

82/651/DTS 82/711/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

TS 62727 © IEC:2012(E) – 7 –

PHOTOVOLTAIC SYSTEMS –

SPECIFICATIONS FOR SOLAR TRACKERS

1 Scope and object

This technical specification provides guidelines for the parameters to be specified for solar

trackers for photovoltaic systems and provides recommendations for measurement

techniques. No attempt is made to determine pass/fail criteria for trackers.

The purpose of this test specification is to define the performance characteristics of trackers

and describe the methods to calculate and/or measure critical parameters.

This specification provides industry-wide definitions and parameters for solar trackers. Each

vendor can design, build, and specify the functionality and accuracy with uniform definition.

This allows consistency in specifying the requirements for purchasing, comparing the products

from different vendors, and verifying the quality of the products. In addition, this specification

will clarify terminology and definitions for trackers and provide examples of measurement

techniques.

This technical specification will be a foundation for other standards to follow, including (but

not limited to) design qualification and reliability.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply. For additional

tracker-specific terminology, see Clause 5.

2.1

photovoltaics

PV

devices that use solar radiation to generate electrical energy

2.2

concentrating photovoltaics

CPV

devices that focus magnified sunlight on photovoltaics to generate electrical energy. The

sunlight could be magnified by various different methods, such as reflective or refractive

optics, in dish, trough, lens, or other configurations.

2.3

concentrator module

CPV module

a group of receivers (PV cells mounted in some way), optics, and other related components,

such as interconnections and mechanical enclosures, integrated together into a modular

package. The module is typically assembled in a factory and shipped to an installation site to

be installed along with other modules on a solar tracker.

Note 1 to entry: A CPV module typically does not have a field-adjustable focus point. In addition, a module could

be made of several sub-modules. The sub-module is a smaller, modular portion of the full-size module, which might

be assembled into the full module either in a factory or in the field.

– 8 – TS 62727 © IEC:2012(E)

2.4

concentrator assembly

a concentrator assembly consists of receivers, optics, and other related components that have

a field-adjustable focus point and are typically assembled and aligned in field

EXAMPLE: A system that combines a single large dish with a receiver unit which must be

aligned with the focal point of the disk.

Note 1 to entry: This term is used to differentiate certain CPV designs from the CPV modules mentioned above.

3 Specifications for solar trackers for PV applications

a) Specification template

All trackers complying with this specification should provide, as part of their product marking

and documentation, a table in the form specified below (see Table 1). See later clauses and

subclauses of this Technical Specification for further explanation of individual specifications.

Some of the specifications within the table are optional; however, if a tracker manufacturer

chooses to include optional information, it should be reported and measured in the specific

way shown in Table 1 (and in some cases, also described later in this Technical

Specification).

Engineering safety factors should be dictated by appropriate local standards and applications

details and documented by the tracker manufacturer.

The specification template below is a visual example only and should not be read as a list of

requirements.

Table 1 – Tracker specification template

Characteristic Example Notes/Clause/Subclause

Manufacturer The XYZ Company

Model number XX1090

Type of tracker CPV Tracker, Dual Axis 4.2, 4.3

Payload characteristics

Minimum/maximum mass 100/1 025 kg 4.8.3

supported

Payload center of mass 0-30 cm distance perpendicular to 4.8.3

restrictions mounting surface

Maximum dynamic torques Azimuth (Θ ): 10 kN⋅m 4.13.2, 7.3

z

allowed while moving

Θ , Θ : 5 kN⋅m

x y

[ should provide a set of diagrams to

clarify torques and which axes they

are relative to ]

Maximum static torques allowed [ should provide a set of diagrams ] 4.13.1, 7.3

while in stow position

Installation characteristics

Allowable foundation Reinforced concrete 4.6.2

Foundation tolerance in primary 4.9

± 0,5°

axis

Foundation tolerance in secondary ± 0,5° 4.9

axis

Electrical characteristics

Includes backup power? No N/A

TS 62727 © IEC:2012(E) – 9 –

Characteristic Example Notes/Clause/Subclause

Daily energy consumption 1 kWh typical 4.7.1

5 kWh maximum

Stow energy consumption kWh typical 4.7.2

1 kWh maximum

Input power requirements 100-240 VAC, 50-60 Hz, 5 A No specifics defined

Tracking accuracy

Accuracy, typical 0,1° 5.4.6

(low wind, min deflect point)

Accuracy, typical 0,3° 5.4.6

(low wind, max deflect point)

th

Accuracy, 95 percentile 0,5° 5.4.6

(low wind, min deflect point)

th

Accuracy, 95 percentile 0,8° 5.4.6

(low wind, max deflect point)

Mean wind speed during the “low 3 km/h 5.4.6

wind” test conditions

Accuracy, typical 0,7° 5.4.6

(high wind, min deflect point)

Accuracy, typical 1,0° 5.4.6

(high wind, max deflect point)

th

Accuracy, 95 percentile 1,1 5.4.6

(high wind, min deflect point)

th

Accuracy, 95 percentile 1,6° 5.4.6

(high wind, max deflect point)

Mean wind speed during the “high 12 km/h 5.4.6

wind” test conditions

Weight and area of payload 500 kg payload evenly distributed 5.4.2.1

installed during testing over a 50 m area

Payload center of mass installed Payload center of mass 20 cm above 5.4.2.1

during testing the module mounting surface

Control characteristics

Control algorithm Hybrid 4.5

Control interface None 4.8.9

External communication interface Ethernet/TCP-IP No specific description

Emergency stow provided? Yes, at wind speeds 100 km/h 4.6.4, 4.12.3

Stow time 4 minutes 4.6.4

Clock accuracy 1 second per year N/A

Mechanical design

Range of motion, primary axis ± 160° azimuth 4.6.3.3

Range of motion, secondary axis 10°-90° elevation 4.6.3.3

System stiffness Azimuth (Θ ): 0,05º / 1 000 N⋅m, Θ : 6.3

z x

0,1º / 1 000 N⋅m

Diagrams attached show applied

loads and observed deflection

Backlash 0,1° maximum 6.2

Environmental conditions

Maximum allowable wind speed Design values: 4.12.3

– 10 – TS 62727 © IEC:2012(E)

Characteristic Example Notes/Clause/Subclause

during tracking

80 km/h with 0 % terrain slope, open

country,

60 km/h with 8 % terrain slope,

suburban, urban

Tested to:

60 km/h with 0 % terrain slope, open

country

Maximum allowable wind speed in Design values: 4.12.4

stow

150 km/h horizontal wind,

120 km/h with 10 % slope

Tested to:

80 km/h with 0 % slope

Temperature operational range –20 °C to +50 °C 4.12.1

Temperature survival range –40 °C to +60 °C 4.12.2

Snow rating Up to 20 kg/m of snow load allowed 4.12.5

For an alternate template for the presentation of accuracy specifications see Table 2.

4 Tracker definitions and taxonomy

4.1 General

Solar trackers are mechanical devices used to point PV modules towards the sun or to direct

sunlight on PV cells or modules. Photovoltaic trackers can be classified into two types:

standard photovoltaic (PV) trackers and concentrated photovoltaic (CPV) trackers. Each of

these tracker types can be further categorized by the number and orientation of their axes,

their actuation architecture and drive type, their intended applications, and their vertical

supports and foundation type.

4.2 Payload types

4.2.1 Standard photovoltaic (PV) module trackers

4.2.1.1 Uses

Standard photovoltaic trackers are used to minimize the angle of incidence between incoming

light and a photovoltaic module. This increases the amount of energy produced from a fixed

amount of power generating capacity.

4.2.1.2 Type of light accepted

Photovoltaic modules accept both direct and diffuse light from all angles. This means that

systems implementing standard photovoltaic trackers produce energy even when not directly

pointed at the sun. Tracking in standard photovoltaic systems is used to increase the amount

of energy produced by the direct component of the incoming light.

4.2.1.3 Accuracy requirements

In standard photovoltaic systems, the energy contributed by the direct beam drops off with the

cosine of the angle between the incoming light and the module. Thus trackers that have

accuracies of ± 5° can deliver more than 99,6 % of the energy supplied by the direct beam. As

a result, high-accuracy tracking is not typically used.

TS 62727 © IEC:2012(E) – 11 –

4.2.2 Concentrated photovoltaic (CPV) module trackers

4.2.2.1 Uses

Concentrated photovoltaic trackers are used to enable the optics used in CPV systems. These

trackers point the concentrator modules at the sun or focus sunlight on PV collectors.

4.2.2.2 Type of light accepted

Direct solar radiation, as opposed to diffuse solar radiation, is the primary energy source for

CPV modules. Optics are designed specifically to focus the direct radiation on photovoltaic

cells. If this focus is not maintained, power output drops substantially.

If the CPV module concentrates in one dimension, then single axis tracking is required. If the

CPV module concentrates in two dimensions, then two axis tracking is required.

4.2.2.3 Accuracy requirements

In concentrator modules, tracking accuracy requirements are typically related to energy

production through the module acceptance angle. When the sun-pointing error is less than the

acceptance angle, the modules will typically deliver 90 % or more of the rated power output.

4.3 Rotational axes

4.3.1 General

Photovoltaic trackers can be grouped into classes by the number and orientation of the

tracker’s axes.

4.3.2 Single axis trackers

4.3.2.1 General

Single axis trackers have one degree of freedom that acts as an axis of rotation.

4.3.2.2 Single axis tracker implementations

4.3.2.2.1 General

There are several common implementations of single axis trackers. These include horizontal

single axis trackers, vertical single axis trackers, and tilted single axis trackers.

4.3.2.2.2 Horizontal single axis tracker (HSAT)

The axis of rotation for a horizontal single axis tracker is horizontal with respect to the ground.

IEC 1028/12

4.3.2.2.3 Vertical single axis tracker (VSAT)

The axis of rotation for vertical single axis trackers is vertical with respect to the ground.

These trackers rotate from east to west over the course of the day.

– 12 – TS 62727 © IEC:2012(E)

IEC 1029 /12

4.3.2.2.4 Tilted single axis tracker (TSAT)

All trackers with axes of rotation between horizontal and vertical are considered tilted single

axis trackers. Tracker tilt angles are often limited to reduce the wind profile and decrease the

elevated end’s height off the ground.

The polar aligned single axis tracker (PASAT) is a specific version of the tilted single axis

tracker. In this particular implementation, the tilt angle is equal to the latitude of the

installation. This aligns the tracker’s axis of rotation with the earth’s axis of rotation.

IEC 1030/12

4.3.2.3 Orientation – cardinal direction

The axis of rotation of single axis trackers is typically aligned along a true North meridian. It is

possible to align them in any cardinal direction with advanced tracking algorithms.

4.3.2.4 Module orientation with respect to rotational axis

The orientation of the module with respect to the tracker axis is important when modelling

performance.

Horizontal and tilted single axis trackers typically have the face of the module oriented

parallel to the axis of rotation. As a module tracks, it sweeps a cylinder that is rotationally

symmetric around the axis of rotation.

Vertical single axis trackers typically have the face of the module oriented at an angle with

respect to the axis of rotation. As a module tracks, it sweeps a cone that is rotationally

symmetric around the axis of rotation.

4.3.3 Dual axis trackers

4.3.3.1 General

Dual axis trackers have two degrees of freedom that act as axes of rotation. These axes are

typically normal to one another. The axis that is fixed with respect to the ground can be

considered the primary axis. The axis that is referenced to the primary axis can be considered

the secondary axis.

TS 62727 © IEC:2012(E) – 13 –

4.3.3.2 Dual axis tracker implementations

4.3.3.2.1 General

There are several common implementations of dual axis trackers. They are classified by the

orientation of their primary axes with respect to the ground. Two common implementations are

tip-tilt trackers and azimuth-altitude trackers (see Figure 1).

One convention for azimuth angle is “degrees east of north” (e.g. 0° azimuth is pointing north,

and 90° azimuth is pointing east).

One convention for altitude angle is “degrees up from the horizon” as illustrated below. Zenith

angle is the complement of altitude angle (zenith = 90° – altitude).

θθ = 0 = °

θ = 90°

θ =

IEC 1031/12

Figure 1 – θ = Altitude angle = 0° (zenith angle = 90°) occurs

when a vector normal to the module face is pointing to the horizon.

Altitude angle = 90° (zenith angle = 0°) occurs

when the module is facing the sky

The above sign conventions are assumed to be the ones used to describe angles, but a

different convention can be used as long as it is described. For example, the range of motion

of a tracker could be described as “azimuth from +20° to +340°,” or alternately, “azimuth

± 160° from south”.

4.3.3.2.2 Tip-tilt dual axis tracker

A tip- tilt dual axis tracker (TTDAT) has its primary axis horizontal to the ground. The

secondary axis is then typically normal to the primary axis.

The polar-style dual axis tracker is a particular type of TTDAT.

IEC 1032/12

– 14 – TS 62727 © IEC:2012(E)

4.3.3.2.3 Azimuth-altitude dual axis tracker

An azimuth-altitude dual axis tracker (AADAT) has its primary axis vertical to the ground. The

secondary axis is then typically normal to the primary axis.

IEC 1033/12

4.3.3.3 Orientation – cardinal direction

The axes of rotation of tip-tilt dual axis trackers are typically aligned either along a true north

meridian or an east-west line of latitude. It is possible to align them in any cardinal direction

with advanced tracking algorithms.

4.3.3.4 Module orientation with respect to rotational axes

The orientation of the module with respect to the tracker axis is important when modelling

performance. Dual axis trackers typically have modules oriented parallel to the secondary axis

of rotation.

4.4 Actuation and control

4.4.1 Architecture

4.4.1.1 General

There are two common actuation and control architectures: distributed actuation and ganged

actuation. These are implemented in many ways.

4.4.1.2 Distributed actuation

In a distributed actuation architecture, each tracker and each axis of rotation is independently

actuated and controlled.

4.4.1.3 Ganged actuation

In a ganged actuation architecture, many axes of rotation are simultaneously driven with a

single actuation system. This can be multiple axes on a single tracker or multiple trackers in

an array.

4.4.2 Drive types

4.4.2.1 General

There are three drive types used with solar trackers.

4.4.2.2 Electric drive

Electric drive systems transfer electrical energy to AC motors, DC brushed motors, or DC

brushless motors to create rotational motion. These motors interface with gearboxes that

reduce the rotational speed in exchange for additional torque. The final gearbox stage

delivers either rotary or linear motion that is used to drive a tracker axis.

TS 62727 © IEC:2012(E) – 15 –

4.4.2.3 Hydraulic drive

Hydraulic drive systems use pumps to generate hydraulic pressure. The hydraulic pressure is

transferred through valves, pipes, and hoses to a hydraulic motor or cylinder. The hydraulic

motor and cylinder adjust the mechanical advantage as needed to deliver the rotary or linear

motion to drive a tracker axis.

4.4.2.4 Passive drive

Passive drive systems use differential fluid pressure to drive a tracker axis. The pressure

differential is created by thermal gradients created by differential shading. The tracker moves

to bring the pressure differentials to equilibrium.

4.5 Types of tracker control

4.5.1 Passive control

Passive solar tracking typically relies on environmental forces to produce changes in fluid

density, which provide internal forces that can be used for mechanical advantage to position

the payload.

4.5.2 Active control

4.5.2.1 General

Active solar tracking uses supplied power to drive circuitry and actuators (motors, hydraulics,

and others) to position the payload.

4.5.2.2 Open loop control

Open loop control is an active method of tracking that does not use direct sensing of the sun

position, module power, et cetera as feedback. It uses mathematical calculations of the sun

position (based on the time of day, date, location, and so on) to determine where the tracker

should be pointing and drives actuators accordingly.

Note that open loop control in this context does not imply that the actuators themselves do not

provide feedback; the actuators could be servo motors with encoders and could themselves

be controlled via a closed-loop PID or similar controller.

Open loop in the context of tracker control refers to the control algorithm having no direct

feedback on the actual tracking error.

4.5.2.3 Closed loop control

This is an active method of tracking that utilizes some sort of feedback (such as an optical

sun position sensor or the module power output) to determine how to drive the actuators and

position the payload.

4.5.2.4 Hybrid control

This is an active method of tracking that combines the mathematical sun position calculations

(open loop ephemeris code) with the type of sensor data used in a closed feedback loop.

There are many different approaches to hybrid control.

4.5.3 Backtracking

Backtracking refers to intentionally positioning trackers somewhat off-sun, typically to reduce

shading from adjacent trackers in a close-packed installation during the early morning and

late afternoon when the sun is low on the horizon.

– 16 – TS 62727 © IEC:2012(E)

One method involves moving all the trackers in a field to a slightly higher elevation angle to

avoid shading. Another approach is for every other row to be inactive and positioned at 0°

(pointing at the sky) to allow the other rows clear line-of-sight to the sun without shading. This

is useful mainly in designs that do not have access to enough land area to be spaced far

enough apart to avoid shading in the early morning and late afternoon. Backtracking is

typically not applicable to CPV.

4.6 Structural characteristics

4.6.1 Vertical supports

4.6.1.1 General

Vertical supports transfer the load of the structure to the foundation. There are two common

types of vertical supports.

4.6.1.2 Pole-mounted trackers

A pole-mounted tracker transfers the load to the foundation via one or more poles. These

poles attach to or continue into one or more foundations.

All types of trackers (single axis and dual axis) can be mounted on poles.

4.6.1.3 Carousel-mounted trackers

A carousel-mounted tracker transfers the load to the foundation via a ring. This ring is then

attached to the foundation at multiple points.

Vertical single axis trackers and azimuth-altitude dual axis trackers are the only trackers that

can be carousel mounted.

4.6.2 Foundation types

4.6.2.1 General

The load placed on the tracker structure shall be sustained through its foundation.

Trackers can be mounted on roofs, ground/earth, and water and will be subject to location-

specific loading. As a result, there are many types of foundations used with trackers. The

foundation type used will depend on site-specific characteristics and the codes of the local

jurisdiction.

Foundation types are often categorized by whether or not they penetrate into the mounting

surface.

4.6.2.2 Penetrating foundations

4.6.2.2.1 Pile foundations

Pile foundations (also known as deep foundations) come in a wide variety of types. These

include but are not limited to concrete piles, driven piles, and drilled piles.

Pile foundations are common in ground-mounted and water-mounted applications. Hole

diameters, depth, concrete mixtures, rebar requirements, thread type, and other

characteristics are all determined by local site conditions.

TS 62727 © IEC:2012(E) – 17 –

4.6.2.3 Non-penetrating foundations

4.6.2.3.1 Ballasted foundations

Ballasted foundations (also known as shallow foundations) come in a wide variety of types.

Ballasted foundations are found in ground mount and roof mount applications. The area in

contact with the surface, total mass, material type, rebar requirements, and other

characteristics are all determined by local site conditions.

4.6.3 Tracker positions

4.6.3.1 Stow

The stow position is the position the tracker moves to when adverse weather conditions (e.g.,

high wind or heavy snow) are present or expected in order to avoid loads that might damage

the tracker or payload. Not all trackers will have a stow position, and the exact position will

vary depending on the tracker design.

4.6.3.2 Maintenance

The maintenance position is the position the tracker moves to for operations such as cleaning,

module installation, servicing, and so on. It could be the same position as the stow position or

a different position, and there could be multiple maintenance positions. When in this position,

there should be a safety interlock preventing sudden tracker motion without operator

interaction.

4.6.3.3 Range of motion

The range of motion is defined by the maximum motion of the tracker in each direction, in

each axis.

For example, a turret-style primary axis might have a range of motion of ± 135° from true

south [or in the reference frames defined above, +45° to +315° azimuth (east of north)]. An

elevation-style secondary axis might have a range of motion of 0° to 90°.

The range of motion specified in the requirements of Table 1 shall be tested and documented.

Note that the range of motion is not only defined by any mechanical limits: the presence of

electronic limit switches or software settings may be used to further restrict the range of

motion for reasons such as safety or reduction of shading.

If the tracker includes a controller, the range of motion should refer to the maximum range of