IEC 62532:2011

(Main)Fluorescent induction lamps - Safety specifications

Fluorescent induction lamps - Safety specifications

IEC 62532:2011 specifies the safety requirements for fluorescent induction lamps for general lighting purposes. It also specifies the method a manufacturer should use to show compliance with the requirements of this standard on the basis of whole production appraisal in association with his test records on finished products. This method can also be applied for certification purposes. Details of a batch test procedure, which can be used to make limited assessment of batches, are also given in this standard.

Lampes à fluorescence à induction - Spécifications de sécurité

La CEI 62532:2011 spécifie les exigences de sécurité pour les lampes à fluorescence à induction pour l'éclairage général. Elle spécifie aussi la méthode qu'il convient que le fabricant utilise pour démontrer la conformité de ses produits aux exigences de la présente norme, méthode basée sur l'évaluation de la qualité de la production globale, associée aux résultats d'essais enregistrés sur les produits finis. Cette méthode peut aussi être appliquée à des fins de certification. Des précisions sont également données dans la présente norme sur la procédure de contrôle par lots, qui peut être utilisée pour l'appréciation limitée de la qualité des lots.

General Information

- Status

- Published

- Publication Date

- 19-Jan-2016

- Technical Committee

- SC 34A - Electric light sources

- Current Stage

- PPUB - Publication issued

- Start Date

- 31-Jan-2011

- Completion Date

- 15-Feb-2011

Relations

- Amended By

IEC 62532:2011/AMD1:2016 - Amendment 1 - Fluorescent induction lamps - Safety specifications - Effective Date

- 05-Sep-2023

Overview

IEC 62532:2011 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies the safety requirements for fluorescent induction lamps used in general lighting applications. This standard outlines critical safety specifications, testing methods, and conformity assessment procedures to ensure that induction lamps meet stringent safety and performance criteria throughout production and usage.

The document also provides guidelines for manufacturers on demonstrating compliance via whole production appraisal combined with test records on finished products. Additionally, the standard includes batch testing procedures that enable limited assessment for quality control and certification purposes.

Key Topics

Scope and Purpose

IEC 62532 focuses on defining safety specifications applicable to fluorescent induction lamps, ensuring their reliable and safe operation in general lighting contexts.Safety Requirements

The standard elaborates on multiple safety aspects including:- Mechanical and electrical construction

- Marking and labeling requirements

- Insulation resistance and electric strength testing

- Prevention of accidental contact with live parts

- Resistance to heat and fire hazards

- Creepage distances and clearances for electrical safety

- Temperature rise limits under operation

- Endurance and durability criteria

- UV radiation safety considerations

Testing and Compliance Methods

IEC 62532 provides detailed test procedures for:- Measuring insulation resistance after exposure to humidity

- Electric strength tests for withstand voltage

- Thermal performance and maximum temperature rise measurements

- Photobiological safety concerning UV emission

Compliance demonstration involves whole production appraisal supported by routine testing of finished products, vital for certification.

Manufacturer Instructions

To assist manufacturers and product designers, the standard includes comprehensive annexes with:- Schematic drawings of different lamp types (internal and external coupled lamps)

- Information to optimize luminaire design and ballast compatibility

- Thermal test methods and temperature measurement points

Applications

IEC 62532:2011 is essential for manufacturers, designers, and certifiers involved in the production and evaluation of fluorescent induction lamps used in:

- Commercial and residential general lighting

- Industrial and public space illumination

- Architectural and decorative lighting where induction lamps are preferred for energy efficiency and longevity

By following this standard, stakeholders can ensure that induction lamps are manufactured and tested to prevent electrical hazards, overheating, fire risk, and UV radiation exposure. The clear guidance on mechanical and electrical safety features supports safer product development and enhanced consumer protection.

Related Standards

To complement IEC 62532, organizations and professionals may also refer to:

- IEC 60598 series – General requirements and testing of luminaires

- IEC 60065 – Safety requirements for audio, video, and similar electronic apparatus (for related electrical safety norms)

- IEC 62471 – Photobiological safety of lamps and lamp systems, important for UV radiation evaluation

- ISO/IEC Directives, Part 2 – Standardization processes for preparation and drafting of standards

These standards collectively ensure comprehensive safety and performance criteria across lighting equipment and components, facilitating international compliance and market access.

By adhering to IEC 62532:2011, manufacturers and testing bodies uphold high safety standards for fluorescent induction lamps, promoting efficiency and user safety while supporting sustainable lighting solutions worldwide.

Buy Documents

IEC 62532:2011 - Fluorescent induction lamps - Safety specifications Released:1/31/2011

IEC 62532:2011+AMD1:2016 CSV - Fluorescent induction lamps - Safety specifications Released:1/20/2016

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62532:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fluorescent induction lamps - Safety specifications". This standard covers: IEC 62532:2011 specifies the safety requirements for fluorescent induction lamps for general lighting purposes. It also specifies the method a manufacturer should use to show compliance with the requirements of this standard on the basis of whole production appraisal in association with his test records on finished products. This method can also be applied for certification purposes. Details of a batch test procedure, which can be used to make limited assessment of batches, are also given in this standard.

IEC 62532:2011 specifies the safety requirements for fluorescent induction lamps for general lighting purposes. It also specifies the method a manufacturer should use to show compliance with the requirements of this standard on the basis of whole production appraisal in association with his test records on finished products. This method can also be applied for certification purposes. Details of a batch test procedure, which can be used to make limited assessment of batches, are also given in this standard.

IEC 62532:2011 is classified under the following ICS (International Classification for Standards) categories: 29.140.30 - Fluorescent lamps. Discharge lamps. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62532:2011 has the following relationships with other standards: It is inter standard links to IEC 62532:2011/AMD1:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62532:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62532 ®

Edition 1.0 2011-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Fluorescent induction lamps – Safety specifications

Lampes à fluorescence à induction – Spécifications de sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62532 ®

Edition 1.0 2011-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Fluorescent induction lamps – Safety specifications

Lampes à fluorescence à induction – Spécifications de sécurité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX T

ICS 29.140.30 ISBN 978-2-88912-352-0

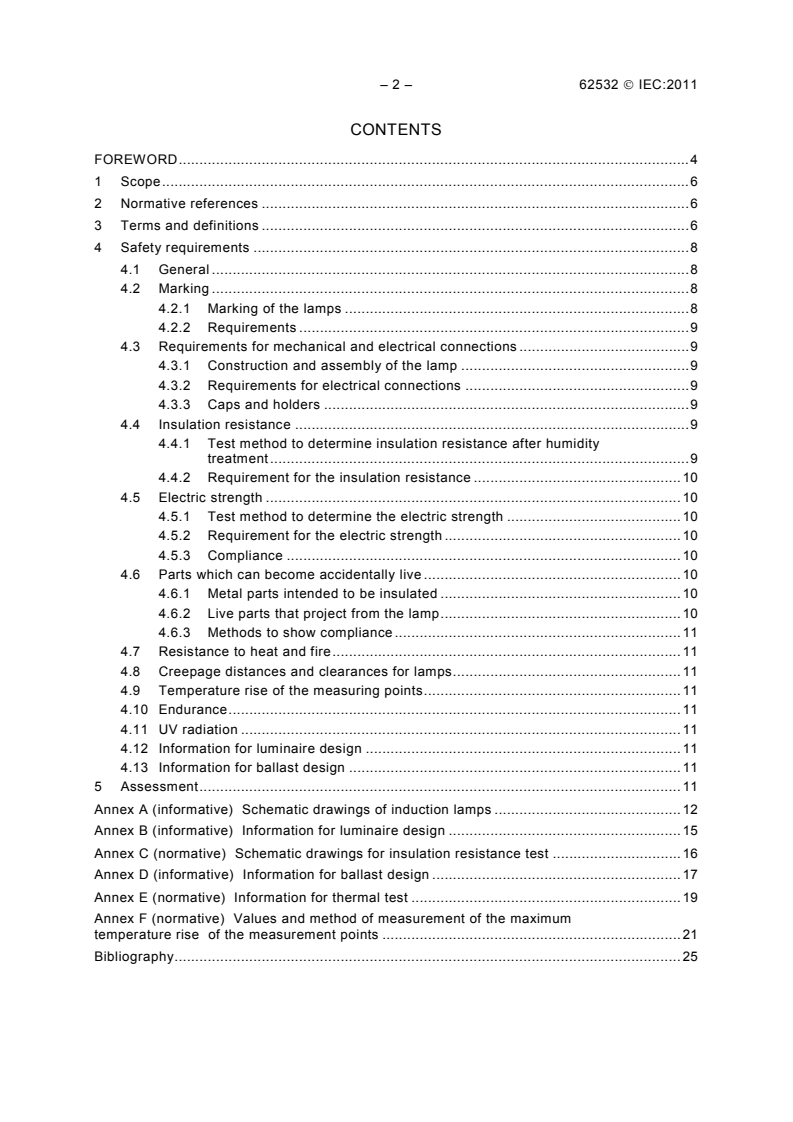

– 2 – 62532 IEC:2011

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Safety requirements . 8

4.1 General . 8

4.2 Marking . 8

4.2.1 Marking of the lamps . 8

4.2.2 Requirements . 9

4.3 Requirements for mechanical and electrical connections . 9

4.3.1 Construction and assembly of the lamp . 9

4.3.2 Requirements for electrical connections . 9

4.3.3 Caps and holders . 9

4.4 Insulation resistance . 9

4.4.1 Test method to determine insulation resistance after humidity

treatment . 9

4.4.2 Requirement for the insulation resistance . 10

4.5 Electric strength . 10

4.5.1 Test method to determine the electric strength . 10

4.5.2 Requirement for the electric strength . 10

4.5.3 Compliance . 10

4.6 Parts which can become accidentally live . 10

4.6.1 Metal parts intended to be insulated . 10

4.6.2 Live parts that project from the lamp . 10

4.6.3 Methods to show compliance . 11

4.7 Resistance to heat and fire . 11

4.8 Creepage distances and clearances for lamps . 11

4.9 Temperature rise of the measuring points . 11

4.10 Endurance . 11

4.11 UV radiation . 11

4.12 Information for luminaire design . 11

4.13 Information for ballast design . 11

5 Assessment . 11

Annex A (informative) Schematic drawings of induction lamps . 12

Annex B (informative) Information for luminaire design . 15

Annex C (normative) Schematic drawings for insulation resistance test . 16

Annex D (informative) Information for ballast design . 17

Annex E (normative) Information for thermal test . 19

Annex F (normative) Values and method of measurement of the maximum

temperature rise of the measurement points . 21

Bibliography . 25

62532 IEC:2011 – 3 –

Figure A.1 – Schematic drawing of an internal coupled induction lamp (operating

frequency 2 500 kHz to 3 000 kHz) . 12

Figure A.2 – Schematic drawing of an internal coupled induction lamp (operating

frequency 120 kHz to 145 kHz) . 13

Figure A.3 – Schematic drawing of an external coupled induction lamp (operating

frequency 225 kHz to 275 kHz) . 14

Figure C.1 – Test set up for measurement insulation resistance of internal coupled

induction lamp . 16

Figure C.2 – Test set up for measurement of insulation resistance external coupled

induction lamp . 16

Figure F.1 – Temperature test point of internal coupled induction lamp (operating

frequency 2 500 kHz to 3 000 kHz) . 22

Figure F.2 – Temperature test point of internal coupled induction lamp (operating

frequency 120 kHz to 145 kHz) . 23

Figure F.3 – Temperature test points of external coupled induction lamp (operating

frequency 225 kHz to 275 kHz) . 24

Table 1 – Requirements for the electric strength . 10

Table B.1 – Maximum temperature at measurement point(s) under operating condition . 15

Table D.1 – Maximum operating voltage of induction lamps between lamp terminals

and between lamp terminals and ground . 17

Table D.2 – Maximum voltage between lamp terminals . 18

Table E.1 – Heating test temperature levels . 19

Table F.1 – Maximum temperature rise of the lamp temperature test points . 21

Table F.2 – Dimensions of the heat sink of internally coupled induction lamps . 23

– 4 – 62532 IEC:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FLUORESCENT INDUCTION LAMPS –

SAFETY SPECIFICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62532 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

The text of this standard is based on the following documents:

FDIS Report on voting

34A/1422/FDIS 34A/1446/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

62532 IEC:2011 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 62532 IEC:2011

FLUORESCENT INDUCTION LAMPS –

SAFETY SPECIFICATIONS

1 Scope

This International Standard specifies the safety requirements for fluorescent induction lamps

for general lighting purposes.

It also specifies the method a manufacturer should use to show compliance with the

requirements of this standard on the basis of whole production appraisal in association with

his test records on finished products. This method can also be applied for certification

purposes.

Details of a batch test procedure, which can be used to make limited assessment of batches,

are also given in this standard.

The schematic drawings of the systems are shown in Annex A.

NOTE Self-ballasted induction lamps (where the discharge vessel, the power coupler and the control gear are

integrated in the same product) are excluded from the scope of this standard.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60061, Lamp caps and holders together with gauges for the control of interchangeability

and safety

IEC 60360:1998, Standard method of measurement of lamp cap temperature rise

IEC 60598-1:2008, Luminaires – Part 1: General requirements and tests

IEC 60901, Single-capped fluorescent lamps. Performance specifications

IEC 60695-2-10, Fire Hazard testing – Part 2-10: Glowing/hot-wire based test methods –

Glow-wire apparatus and common test procedure

IEC 60695-2-11, Fire hazard testing – Part 2-11: Glowing/hot-wire based test methods –

Glow-wire flammability test method for end-products

IEC 61347-1, Lamp control gear – Part 1: General and safety requirements

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

induction lamp

assembly of a low pressure mercury discharge vessel and an inductive power coupler

62532 IEC:2011 – 7 –

3.2

discharge vessel (closed containment description)

vessel containing at least a low pressure mercury vapour, which will be energized by means

of the inductive coupler

NOTE 1 The ultra violet radiation from the resulting discharge is converted by a layer of fluorescent material into

visible light.

NOTE 2 The discharge vessel may have means of mechanical fixation to position it to the inductive power

coupler.

3.3

inductive power coupler

component to transform high frequency electrical energy, by means of induction, in order to

energize the low pressure mercury in the discharge vessel

NOTE 1 The component includes electrical connection.

NOTE 2 The inductive power coupler can contain a means to fixate and position the discharge vessel.

3.4

mechanical interface

means to fixate and position the induction lamp

3.5

internally coupled induction lamp

induction lamp where the coupler is partly surrounded by the discharge vessel

3.6

externally coupled induction lamp

induction lamp where the discharge vessel is partly surrounded by the coupler

3.7

group

lamps having the same electrical characteristics and physical dimensions

3.8

type

lamps of the same group having the same photometric and colour characteristics

3.9

family

lamp groups which have common features of materials, components, and/or method of

processing

3.10

nominal wattage

wattage used to designate the lamp

3.11

working voltage

highest RMS voltage which may occur across any insulation at rated supply voltage,

transients being neglected, in open-circuit conditions or during normal operation

3.12

equilibrium temperature

steady-state temperature of a lamp reached after a sufficient operating time

– 8 – 62532 IEC:2011

3.13

design test

test made on a sample for the purpose of checking compliance of the design of a family,

group or a number of groups with the requirements of the relevant clause

3.14

periodic test

test, or series of tests, repeated at intervals in order to check that a product does not deviate

in certain respects from the given design

3.15

running test

test repeated at frequent intervals to provide data for assessment

3.16

batch

all lamps of one family and/or group and identified as such and put forward at one time for

test or checking compliance

3.17

whole production

production during a period of twelve months of all types of lamps within the scope of this

standard and nominated in a list of the manufacturer for inclusion in the certificate

4 Safety requirements

4.1 General

In this document, the term “lamp” stands for “induction lamp”.

Lamps shall be so designed and constructed that in normal use they present no danger to the

user or the surroundings if operated with a ballast complying with IEC 61347-1.

In general, compliance is checked by carrying out all the tests specified.

All plastic materials shall meet all safety requirements of this standard after exposure to UV

and temperature over the claimed lifetime of the lamp. Any accelerated test shall correspond

to the real lifetime effect. The allowed temperature range for the use of the lamp as given by

the lamp manufacturer or responsible vendor shall be noticed.

Plastic material which is directly exposed to UV by the lamp shall be tested at a wavelength of

254 nm. UV irradiance, temperature and testing time are under consideration.

Schematic drawings of the construction of internally and externally coupled induction lamps

are given in Annex A.

4.2 Marking

4.2.1 Marking of the lamps

The following information shall be legibly and durably marked on the lamps:

a) mark of origin (this may take the form of a trade mark, the manufacturer's name or the

name of the responsible vendor);

b) the nominal wattage (marked "W" or "watts") or any other indication which identifies the

lamp.

62532 IEC:2011 – 9 –

4.2.2 Requirements

Compliance is checked by the following:

a) presence and legibility of the marking by visual inspection;

b) durability of marking by applying the following test on unused lamps.

The area of the marking on the lamp shall be rubbed by hand with a smooth cloth damped

with water for a period of 15 s.

After this test, the marking shall still be legible.

4.3 Requirements for mechanical and electrical connections

4.3.1 Construction and assembly of the lamp

The construction shall be such that the whole assembly remains safe during and after

operation.

Wiring and cables shall be so situated or protected that they cannot be damaged by sharp

edges, rivets, screws and similar components. Wiring and cables shall not be twisted through

an angle exceeding 360°.

Compliance is checked by visual inspection.

Minimum bending radius, as specified in the manufacturer’s documentation, of the applied

cables and wiring should be observed.

Compliance is checked by measurement of the radii.

4.3.2 Requirements for electrical connections

Electrical connections shall have adequate electrical performance and mechanical strength.

Compliance is checked by carrying out the same kind of tests as given in section 15 of

IEC 60598-1.

4.3.3 Caps and holders

If applicable, the requirements of IEC 60061 apply.

4.4 Insulation resistance

4.4.1 Test method to determine insulation resistance after humidity treatment

Wrap a copper foil around the lamp and connect it to metal parts if any. For schematic

drawing, see Annex c. The lamp shall be conditioned for 48 h in a cabinet containing air with

a relative humidity between 91 % and 95 %. The temperature of the air, t, is maintained within

1 °C of any convenient value between 20 °C and 30 °C.

Before being placed in the humidity cabinet, the lamp wrapped with copper foil is brought to a

temperature between t and (t + 4) °C.

Before the insulation test, visible drops of water, if any, are removed by means of blotting

paper.

Immediately after the moisture treatment, the insulation resistance shall be measured with a

d.c. voltage of 500 V, 1 min after application of the voltage.

– 10 – 62532 IEC:2011

4.4.2 Requirement for the insulation resistance

The insulation resistance between the foil and all lamp connections connected together shall

not be less than 2 MΩ.

4.5 Electric strength

4.5.1 Test method to determine the electric strength

Immediately after the insulation resistance test, the same parts as those referred to in 4.4

shall withstand the test voltage of 4.5.2.

The high-voltage transformer used for the test shall be so designed that when the output

terminals are short-circuited after the output voltage has been adjusted to the appropriate test

voltage, the output current is at least 200 mA.

The overcurrent relay shall not trip when the output current is less than 100 mA.

The r.m.s. value of the test voltage applied shall be measured to within ±3 %.

The metal foil referred to in 4.4 shall be placed so that no flashover occurs at the edges of the

insulation.

4.5.2 Requirement for the electric strength

Compliance is checked with a test voltage of substantially sine-wave form, see Table 1, with a

frequency of 50 Hz or 60 Hz and applied for 1 min. Initially, not more than half the prescribed

voltage shall be applied; it shall then be raised rapidly to the full value. The working voltage

shall be given in the manufacturer’s documentation.

Table 1 – Requirements for the electric strength

Test voltage

Working voltage U

V

Up to and including 42 V 500

Above 42 V up to and including 1 000 V 2U + 1 000

4.5.3 Compliance

No flashover or breakdown shall occur during the test.

Glow discharges without a drop in voltage are neglected.

4.6 Parts which can become accidentally live

4.6.1 Metal parts intended to be insulated

Metal parts, if any, intended to be insulated from live parts shall not be or become live.

4.6.2 Live parts that project from the lamp

With the exception of the electrical connection, no live part shall project from any part of the

lamp.

62532 IEC:2011 – 11 –

4.6.3 Methods to show compliance

Compliance is checked by a suitable measuring system, which may include visual inspection

where appropriate. It shall be safeguarded that during assembly damage to insulation cannot

occur.

4.7 Resistance to heat and fire

The lamp shall be sufficiently resistant to heat.

Compliance is checked by the test in Annex E.

4.8 Creepage distances and clearances for lamps

The same requirements apply as in section 11 of IEC 60598-1.

4.9 Temperature rise of the measuring points

The values and measurement methods of the maximum temperature rises of the measuring

points are given in Annex F.

4.10 Endurance

Under consideration.

4.11 UV radiation

The specific effective radiant UV power emitted by the lamp shall not exceed the value of

2 mW/klm. For reflector lamps, it shall not exceed the value of 2 mW/(m klx).

NOTE 1 In IEC 62471, exposure limits are given as effective irradiance values (unit:W/m ) and for risk group

classification, the values for general lighting lamps are reported at an illuminance level of 500 lx. The borderline for

risk group exempt is 0,001 W/m at an illuminance level of 500 lx. This means the specific value, related to the

2 2 2

illuminance, is 0,001 divided by 500 in W/(m lx), which is 2 mW/(m klx). Since lx = lm/m this equals 2 mW/klm

specific UV power.

NOTE 2 Compliance is checked by spectroradiometric measurement, under the same conditions as for the lamp’s

electrical and photometric characteristics as given in IEC 60901 or in Annex B of the forthcoming performance

standard for induction lamps.

4.12 Information for luminaire design

The luminaire manufacturer should observe the maximum temperature(s) specified in

Annex B.

4.13 Information for ballast design

The ballast manufacturer should observe the requirements in Annex D.

5 Assessment

Under consideration.

– 12 – 62532 IEC:2011

Annex A

(informative)

Schematic drawings of induction lamps

To clarify the construction of an internally and an externally coupled induction lamp,

schematic drawings are given in Figures A.1 to A.3.

Figure A.1 – Schematic drawing of an internal coupled induction lamp

(operating frequency 2 500 kHz to 3 000 kHz)

62532 IEC:2011 – 13 –

A

B

A discharge vessel B inductive power coupler

IEC 234/11

Figure A.2 – Schematic drawing of an internal coupled induction lamp

(operating frequency 120 kHz to 145 kHz)

– 14 – 62532 IEC:2011

Power coupler

Mounting bracket

Connector

Discharge vessel

Power coupler

IEC 235/11

Figure A.3 – Schematic drawing of an external coupled induction lamp

(operating frequency 225 kHz to 275 kHz)

62532 IEC:2011 – 15 –

Annex B

(informative)

Information for luminaire design

To ensure safe lamp operation, it is essential to observe the following recommendations.

– Maximum temperature at the measurement point(s) under operating conditions

The luminaire designer should ensure that the temperature at the measurement point(s),

under operating conditions, should not exceed the maximum temperature value as given in

Table B.1.

Table B.1 – Maximum temperature at measurement point(s) under operating condition

Lamp type Frequency Maximum operating temperature at the

measurement point

kHz

Internally coupled induction lamp - 55 W 2 500 to 3 000 105 °C (see Annex F)

Internally coupled induction lamp - 85 W 2 500 to 3 000 105 °C (see Annex F)

Internally coupled induction lamp - 165 W 2 500 to 3 000 105 °C (see Annex F)

Internally coupled induction lamp - 30 W 120 to 145 95 °C (see Annex F)

Internally coupled induction lamp - 50 W 120 to 145 95 °C (see Annex F)

Internally coupled induction lamp - 150 W 120 to 145 95 °C (see Annex F)

Internally coupled induction lamp - 240 W 120 to 145 95 °C (see Annex F)

Externally coupled induction lamp - 70 W 225 to 275 150 °C/150 °C point 1 / 2 (see Annex F)

Externally coupled induction lamp - 100 W 225 to 275 150 °C/150 °C point 1 / 2 (see Annex F)

Externally coupled induction lamp - 150 W 225 to 275 150 °C/150 °C point 1 / 2 (see Annex F)

– Specific effective radiant UV power

The specific effective radiant UV power of the lamp should not exceed 2 mW/klm.

NOTE The effective power of the UV radiation is obtained by weighting the spectral power distribution of ht

lamp with the UV hazard function S (λ). Information about the relevant UV hazard function is given in

uv

IEC 62471. It only relates to possible hazards regarding UV exposure of human being. It does not deal with the

possible influence of optical radiation on materials, like mechanical damage or discoloration.

– 16 – 62532 IEC:2011

Annex C

(normative)

Schematic drawings for insulation resistance test

This annex gives schematic drawings of the test set-up for measuring the insulation

resistance as described in Subclause 4.4.

Cu-foil

IEC 236/11

Figure C.1 – Test set up for measurement insulation resistance

of internal coupled induction lamp

Electrical connection between Cu-foil

and mounting bracket

Copper foil

IEC 237/11

Figure C.2 – Test set up for measurement of insulation resistance external

coupled induction lamp

62532 IEC:2011 – 17 –

Annex D

(informative)

Information for ballast design

To ensure safe lamp operation, it is essential to observe the following recommendations.

– Time limitation for high voltages

Under no condition the working voltage should exceed the values given in Table D.1 for a

period longer than 2 s.

– Working voltage

The working voltage of the ballast should not exceed the maximum allowable voltages

between any lamp terminals and any lamp terminal and ground as given in Table D.1.

Table D.1 – Maximum operating voltage of induction lamps

between lamp terminals and between lamp terminals and ground

Lamp type Frequency Maximum operating voltage

between any lamp terminals and

kHz

between any lamp terminal and

ground

V

rms

Internally coupled induction lamp - 55 W 2 500 to 3 000 300

Internally coupled induction lamp - 85 W 2 500 to 3 000 300

Internally coupled induction lamp - 165 W 2 500 to 3 000 350

Internally coupled induction lamp - 30 W 120 to 145 300

Internally coupled induction lamp - 50 W 120 to 145 350

Internally coupled induction lamp - 150 W 120 to 145 450

Internally coupled induction lamp - 240 W 120 to 145 350

Externally coupled induction lamp - 70 W 225 to 275 300

Externally coupled induction lamp - 100 W 225 to 275 300

Externally coupled induction lamp - 150 W 225 to 275 300

If the voltage is not given in Table D.1, a reference should be made in the manufacturer’s

documentation.

– Maximum voltage between the lamp terminals

The peak voltage between the lamp terminals should under no circumstances exceed the

values in the Table D.2.

NOTE It should be noted that the cables and wires between lamp connector and discharge vessel are part of

the lamp.

– 18 – 62532 IEC:2011

Table D.2 – Maximum voltage between lamp terminals

Lamp type Frequency Maximum peak voltage between lamp

terminals*

kHz

V

peak

Internally coupled induction lamp - 55 W 2 500 to 3 000 1 500

Internally coupled induction lamp - 85 W 2 500 to 3 000 1 500

Internally coupled induction lamp - 165 W 2 500 to 3 000 1 500

Internally coupled induction lamp - 30 W 120 to 145 2 500

Internally coupled induction lamp - 50 W 120 to 145 2 500

Internally coupled induction lamp - 150 W 120 to 145 2 500

Internally coupled induction lamp - 240 W 120 to 145 2 500

Externally coupled induction lamp - 70 W 225 to 275 2 000

Externally coupled induction lamp - 100 W 225 to 275 2 000

Externally coupled induction lamp - 150 W 225 to 275 2 000

* Not to be measured against ground.

62532 IEC:2011 – 19 –

Annex E

(normative)

Information for thermal test

E.1 Check for the system

Samples shall be tested for a period of 168 h in a heating cabinet with a temperature of

Table E.1.

Table E.1 – Heating test temperature levels

Lamp type Frequency Temperature of the heating cabinet

kHz °C

Internally coupled induction lamp - 55 W 2 500 to 3 000 105 °C

Internally coupled induction lamp - 85 W 2 500 to 3 000 105 °C

Internally coupled induction lamp - 165 W 2 500 to 3 000 105 °C

Internally coupled induction lamp - 30 W 120 to 145 95 °C

Internally coupled induction lamp - 50 W 120 to 145 95 °C

Internally coupled induction lamp - 150 W 120 to 145 95 °C

Internally coupled induction lamp - 240 W 120 to 145 95 °C

Externally coupled induction lamp - 70 W 225 to 275 150 °C*

Externally coupled induction lamp - 100 W 225 to 275 150 °C*

Externally coupled induction lamp - 150 W 225 to 275 150 °C*

* During the test, the connector should stay outside the heating cabinet.

Compliance is checked at the end of the test. The samples shall not have undergone any

change impairing their future safety, especially in the following respects:

– reduction in the protection against electric shock as required for:

• insulation resistance (4.4);

• electric strength. (4.5);

– loosening of mechanical and electrical interface, cracks, swelling and shrinking as

determined by visual inspection.

At the end of the test, the dimensions shall comply with the requirements for mechanical and

electrical connections. (4.3).

E.2 Check for the plastic parts of the lamp

Insulating material of lamps shall be resistant to abnormal heat and to fire.

Compliance is checked by the following test.

Parts are subjected to a test using a nickel-chromium glow-wire heated to 650 °C. The test

apparatus shall be that described in IEC 60695-2-10.

The method of test shall be according IEC 60695-2-11.

– 20 – 62532 IEC:2011

The sample to be tested shall be mounted vertically on the carriage and pressed against the

glow wire tip with a force of 1 N, preferably 15 mm or more from the upper edge of the

sample. The penetration of the glow-wire into the sample shall be mechanically limited to

7 mm. After 30 s, the sample shall be withdrawn from contact with the glow-wire tip.

Any flame or glowing of the sample shall extinguish within 30 s of withdrawing the glow-wire

and any burning or molten drops shall not ignite a piece of tissue paper consisting of five

layers, spread out horizontally 200 mm ± 5 mm below the sample.

The glow-wire temperature and heating current shall be constant for 1 min prior to

commencing the test. Care shall be taken to ensure that heat radiation does not influence the

sample during this period. The glow-wire tip temperature shall be measured by means of a

sheathed fine-wire thermocouple constructed and calibrated as described in IEC 60695-2-10.

NOTE Precautions should be taken to safeguard the health of personnel conducting tests against risks of

– explosion or fire;

– inhalation of smoke and/or toxic products;

– toxic residues.

62532 IEC:2011 – 21 –

Annex F

(normative)

Values and method of measurement of the maximum temperature rise

of the measurement points

F.1 Test method

This test method describes how to establish the equilibrium temperature of the temperature

measurement points.

The test shall be carried out in draft free air at a temperature of 25 °± 2 °C which shall not

vary by more than 1 °C during the test.

The measuring accuracy should be ±1 °C.

The thermocouples to be used are described in IEC 60360 Clause 7.

The minimum operating time for each lamp before measurement shall be 120 min. The

equilibrium temperature has been reached when the temperature at the measuring point

doesn’t change by more than 1 °C/h over a period of at least 15 min.

The test is conducted operating the lamp with a reference ballast.

F.2 Values of maximum allowed temperature rise of the measurement points

F.2.1 Maximum temperature rise of the lamp temperature test points

Table F.1 gives the maximum temperature rise of the lamp temperature test points.

Table F.1 – Maximum temperature rise of the lamp temperature test points

Lamp type Frequency Lamp power to test Maximum allowed Maximum allowed

temperature rise of temperature rise temperature rise

KHz

the mechanical

Point 1 Point 2

interface

°C °C

W

Internally coupled

2 500 to 3 000 50 ± 4 % 80 NA

induction lamp - 55 W

Internally coupled

2 500 to 3 000 80 ± 4 % 80 NA

induction lamp - 85 W

Internally coupled

2 500 to 3 000 150 ± 4 % 80 NA

induction lamp - 165 W

Internally coupled

120 to 145 30 ± 4 % 85 NA

induction lamp - 30 W

Internally coupled

120 to 145 50 ± 4 % 85 NA

induction lamp - 50 W

Internally coupled

120 to 145 85 NA

150 ± 4 %

induction lamp - 150 W

Internally coupled

120 to 145 85 NA

240 ± 4 %

induction lamp - 240 W

Externally coupled

225 to 275 75 ± 4 % 95 85

induction lamp - 70 W

Externally coupled

225 to 275 100 ± 4 % 95 85

induction lamp - 100 W

– 22 – 62532 IEC:2011

Lamp type Frequency Lamp power to test Maximum allowed Maximum allowed

temperature rise of temperature rise temperature rise

KHz

the mechanical

Point 1 Point 2

interface

°C °C

W

Externally coupled

225 to 275 150 ± 4 % 95 85

induction lamp - 150 W

NA: Not applicable.

F.2.2 Test condition to measure temperature on the temperature test point of an

internal coupled lamp

Figure F.1 shows the temperature test point of an internal coupled induction lamp

(operating frequency 2 500 kHz to 3 000 kHz); Figure F.2 shows the temperature test point of

an internal coupled induction lamp (operating frequency 120 kHz to 145 kHz).

Test point

IEC 238/11

Figure F.1 – Temperature test point of internal coupled induction lamp

(operating frequency 2 500 kHz to 3 000 kHz)

62532 IEC:2011 – 23 –

X

Test point

IEC 239/11

Figure F.2 – Temperature test point of internal coupled induction lamp

(operating frequency 120 kHz to 145 kHz)

The internal coupled lamp is tested base down with anodized aluminium heat sinks.

Dimensions of the heat sink are given in Table F.2.

Table F.2 – Dimensions of the heat sink of internally coupled induction lamps

Lamp type Frequency Heat sink dimensions

KHz mm*mm*mm

Internally coupled induction lamp - 55 W 2 500 to 3 000 85*85*2

Internally coupled induction lamp - 85 W 2 500 to 3 000 150*150*2

Internally coupled induction lamp - 165 W 2 500 to 3 000 140*140*2

Internally coupled induction lamp - 30 W 120 to 145 117*117*2

Internally coupled induction lamp - 50 W 120 to 145 140*140*2

Internally coupled induction lamp - 150 W 120 to 145 300*150*3

Internally coupled induction lamp - 240 W 120 to 145 420*210*3

– 24 – 62532 IEC:2011

F.2.3 Test condition to measure temperature on the temperature test point of an

external coupled lamp (operating frequency 225 kHz to 275 kHz)

Tape

Measurement point 1

Cable

x

Centre plane of the lamp

Measurement point 2

Centre of

x

the core

Centre plane of

the core ring

IEC 240/11

Figure F.3 – Temperature test points of external coupled induction lamp

(operating frequency 225 kHz to 275 kHz)

Figure F.3 shows the temperature test points of an external coupled induction lamp

(operating frequency 225 kHz to 275 kHz).

During the test, there is a no heat sink to the lamp allowed.

62532 IEC:2011 – 25 –

Bibliography

IEC 60112:2003, Method for the determination of the proof and the comparative tracking

indices of solid insulating materials

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

IEC 60664-1:2007, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

IEC 61199:1999, Single-capped fluorescent lamps – Safety specifications

IEC 62471:2006, Photobiological safety of lamps and lamp systems

___________

– 26 – 62532 CEI:2011

SOMMAIRE

AVANT-PROPOS . 28

1 Domaine d’application . 30

2 Références normatives . 30

3 Termes et définitions .

...

IEC 62532 ®

Edition 1.1 2016-01

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Fluorescent induction lamps – Safety specifications

Lampes à fluorescence à induction – Spécifications de sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC

65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte,

et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les

publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées.

antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Restez informé sur les nouvelles publications IEC. Just Service Clients - webstore.iec.ch/csc

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62532 ®

Edition 1.1 2016-01

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Fluorescent induction lamps – Safety specifications

Lampes à fluorescence à induction – Spécifications de sécurité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.140.30 ISBN 978-2-8322-3135-7

IEC 62532 ®

Edition 1.1 2016-01

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Fluorescent induction lamps – Safety specifications

Lampes à fluorescence à induction – Spécifications de sécurité

– 2 – IEC 62532:2011+AMD1:2016 CSV

IEC 2016

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Safety requirements . 9

4.1 General . 9

4.2 Marking . 9

4.2.1 Marking of the lamps . 9

4.2.2 Requirements . 10

4.3 Requirements for mechanical and electrical connections . 10

4.3.1 Construction and assembly of the lamp . 10

4.3.2 Requirements for electrical connections . 10

4.3.3 Caps and holders . 10

4.4 Insulation resistance . 10

4.4.1 Test method to determine insulation resistance after humidity

treatment . 10

4.4.2 Requirement for the insulation resistance . 11

4.5 Electric strength . 11

4.5.1 Test method to determine the electric strength . 11

4.5.2 Requirement for the electric strength . 11

4.5.3 Compliance . 11

4.6 Parts which can become accidentally live . 11

4.6.1 Metal parts intended to be insulated . 11

4.6.2 Live parts that project from the lamp . 12

4.6.3 Methods to show compliance . 12

4.7 Resistance to heat and fire . 12

4.8 Creepage distances and clearances for lamps . 12

4.9 Temperature rise of the measuring points . 12

4.10 Endurance . 12

4.11 UV radiation . 12

4.12 Information for luminaire design . 12

4.13 Information for ballast design . 12

5 Assessment . 12

Annex A (informative) Schematic drawings of induction lamps . 13

Annex B (informative) Information for luminaire design . 16

Annex C (normative) Schematic drawings for insulation resistance test . 17

Annex D (informative) Information for ballast design . 18

Annex E (normative) Information for thermal test . 20

Annex F (normative) Values and method of measurement of the maximum

temperature rise of the measurement points . 22

Annex G (informative) Information for luminaire design . 26

Bibliography . 27

IEC 2016

Figure A.1 – Schematic drawing of an internal coupled induction lamp (operating

frequency 2 500 kHz to 3 000 kHz) . 13

Figure A.2 – Schematic drawing of an internal coupled induction lamp (operating

frequency 120 kHz to 145 kHz) . 14

Figure A.3 – Schematic drawing of an external coupled induction lamp (operating

frequency 225 kHz to 275 kHz) . 15

Figure C.1 – Test set up for measurement insulation resistance of internal coupled

induction lamp . 17

Figure C.2 – Test set up for measurement of insulation resistance external coupled

induction lamp . 17

Figure F.1 – Temperature test point of internal coupled induction lamp (operating

frequency 2 500 kHz to 3 000 kHz) . 23

Figure F.2 – Temperature test point of internal coupled induction lamp (operating

frequency 120 kHz to 145 kHz) . 24

Figure F.3 – Temperature test points of external coupled induction lamp (operating

frequency 225 kHz to 275 kHz) . 25

Table 1 – Requirements for the electric strength . 11

Table B.1 – Maximum temperature at measurement point(s) under operating condition . 16

Table D.1 – Maximum operating voltage of induction lamps between lamp terminals

and between lamp terminals and ground . 18

Table D.2 – Maximum voltage between lamp terminals . 19

Table E.1 – Heating test temperature levels . 20

Table F.1 – Maximum temperature rise of the lamp temperature test points . 23

Table F.2 – Dimensions of the heat sink of internally coupled induction lamps . 24

– 4 – IEC 62532:2011+AMD1:2016 CSV

IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FLUORESCENT INDUCTION LAMPS –

SAFETY SPECIFICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 62532 edition 1.1 contains the first edition (2011-01) [documents 34A/1422/FDIS and

34A/1446/RVD] and its amendment 1 (2016-01) [documents 34A/1871/FDIS and 34A/1883/RVD].

In this Redline version, a vertical line in the margin shows where the technical content

is modified by amendment 1. Additions are in green text, deletions are in strikethrough

red text. A separate Final version with all changes accepted is available in this

publication.

IEC 2016

International Standard IEC 62532 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62532:2011+AMD1:2016 CSV

IEC 2016

INTRODUCTION

Amendment 1 to this standard contains requirements for photobiology and information on

water contact.

IEC 2016

FLUORESCENT INDUCTION LAMPS –

SAFETY SPECIFICATIONS

1 Scope

This International Standard specifies the safety requirements for fluorescent induction lamps

for general lighting purposes.

It also specifies the method a manufacturer should use to show compliance with the

requirements of this standard on the basis of whole production appraisal in association with

his test records on finished products. This method can also be applied for certification

purposes.

Details of a batch test procedure, which can be used to make limited assessment of batches,

are also given in this standard.

The schematic drawings of the systems are shown in Annex A.

NOTE Self-ballasted induction lamps (where the discharge vessel, the power coupler and the control gear are

integrated in the same product) are excluded from the scope of this standard.

This standard covers photobiological safety according to IEC 62471 and IEC TR 62471-2.

Blue light and infrared hazards are below the level which requires marking.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60061, Lamp caps and holders together with gauges for the control of interchangeability

and safety

IEC 60360:1998, Standard method of measurement of lamp cap temperature rise

IEC 60598-1:2008, Luminaires – Part 1: General requirements and tests

IEC 60901, Single-capped fluorescent lamps. Performance specifications

IEC 60695-2-10, Fire Hazard testing – Part 2-10: Glowing/hot-wire based test methods –

Glow-wire apparatus and common test procedure

IEC 60695-2-11, Fire hazard testing – Part 2-11: Glowing/hot-wire based test methods –

Glow-wire flammability test method for end-products

IEC 61347-1, Lamp control gear – Part 1: General and safety requirements

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

– 8 – IEC 62532:2011+AMD1:2016 CSV

IEC 2016

3.1

induction lamp

assembly of a low pressure mercury discharge vessel and an inductive power coupler

3.2

discharge vessel (closed containment description)

vessel containing at least a low pressure mercury vapour, which will be energized by means

of the inductive coupler

NOTE 1 The ultra violet radiation from the resulting discharge is converted by a layer of fluorescent material into

visible light.

NOTE 2 The discharge vessel may have means of mechanical fixation to position it to the inductive power

coupler.

3.3

inductive power coupler

component to transform high frequency electrical energy, by means of induction, in order to

energize the low pressure mercury in the discharge vessel

NOTE 1 The component includes electrical connection.

NOTE 2 The inductive power coupler can contain a means to fixate and position the discharge vessel.

3.4

mechanical interface

means to fixate and position the induction lamp

3.5

internally coupled induction lamp

induction lamp where the coupler is partly surrounded by the discharge vessel

3.6

externally coupled induction lamp

induction lamp where the discharge vessel is partly surrounded by the coupler

3.7

group

lamps having the same electrical characteristics and physical dimensions

3.8

type

lamps of the same group having the same photometric and colour characteristics

3.9

family

lamp groups which have common features of materials, components, and/or method of

processing

3.10

nominal wattage

wattage used to designate the lamp

3.11

working voltage

highest RMS voltage which may occur across any insulation at rated supply voltage,

transients being neglected, in open-circuit conditions or during normal operation

IEC 2016

3.12

equilibrium temperature

steady-state temperature of a lamp reached after a sufficient operating time

3.13

design test

test made on a sample for the purpose of checking compliance of the design of a family,

group or a number of groups with the requirements of the relevant clause

3.14

periodic test

test, or series of tests, repeated at intervals in order to check that a product does not deviate

in certain respects from the given design

3.15

running test

test repeated at frequent intervals to provide data for assessment

3.16

batch

all lamps of one family and/or group and identified as such and put forward at one time for

test or checking compliance

3.17

whole production

production during a period of twelve months of all types of lamps within the scope of this

standard and nominated in a list of the manufacturer for inclusion in the certificate

4 Safety requirements

4.1 General

In this document, the term “lamp” stands for “induction lamp”.

Lamps shall be so designed and constructed that in normal use they present no danger to the

user or the surroundings if operated with a ballast complying with IEC 61347-1.

In general, compliance is checked by carrying out all the tests specified.

All plastic materials shall meet all safety requirements of this standard after exposure to UV

and temperature over the claimed lifetime of the lamp. Any accelerated test shall correspond

to the real lifetime effect. The allowed temperature range for the use of the lamp as given by

the lamp manufacturer or responsible vendor shall be noticed.

Plastic material which is directly exposed to UV by the lamp shall be tested at a wavelength of

254 nm. UV irradiance, temperature and testing time are under consideration.

Schematic drawings of the construction of internally and externally coupled induction lamps

are given in Annex A.

4.2 Marking

4.2.1 Marking of the lamps

The following information shall be legibly and durably marked on the lamps:

a) mark of origin (this may take the form of a trade mark, the manufacturer's name or the

name of the responsible vendor);

– 10 – IEC 62532:2011+AMD1:2016 CSV

IEC 2016

b) the nominal wattage (marked "W" or "watts") or any other indication which identifies the

lamp.

4.2.2 Requirements

Compliance is checked by the following:

a) presence and legibility of the marking by visual inspection;

b) durability of marking by applying the following test on unused lamps.

The area of the marking on the lamp shall be rubbed by hand with a smooth cloth damped

with water for a period of 15 s.

After this test, the marking shall still be legible.

4.3 Requirements for mechanical and electrical connections

4.3.1 Construction and assembly of the lamp

The construction shall be such that the whole assembly remains safe during and after

operation.

Wiring and cables shall be so situated or protected that they cannot be damaged by sharp

edges, rivets, screws and similar components. Wiring and cables shall not be twisted through

an angle exceeding 360°.

Compliance is checked by visual inspection.

Minimum bending radius, as specified in the manufacturer’s documentation, of the applied

cables and wiring should be observed.

Compliance is checked by measurement of the radii.

4.3.2 Requirements for electrical connections

Electrical connections shall have adequate electrical performance and mechanical strength.

Compliance is checked by carrying out the same kind of tests as given in section 15 of

IEC 60598-1.

4.3.3 Caps and holders

If applicable, the requirements of IEC 60061 apply.

4.4 Insulation resistance

4.4.1 Test method to determine insulation resistance after humidity treatment

Wrap a copper foil around the lamp and connect it to metal parts if any. For schematic

drawing, see Annex c. The lamp shall be conditioned for 48 h in a cabinet containing air with

a relative humidity between 91 % and 95 %. The temperature of the air, t, is maintained within

1 °C of any convenient value between 20 °C and 30 °C.

Before being placed in the humidity cabinet, the lamp wrapped with copper foil is brought to a

temperature between t and (t + 4) °C.

Before the insulation test, visible drops of water, if any, are removed by means of blotting

paper.

IEC 2016

Immediately after the moisture treatment, the insulation resistance shall be measured with a

d.c. voltage of 500 V, 1 min after application of the voltage.

4.4.2 Requirement for the insulation resistance

The insulation resistance between the foil and all lamp connections connected together shall

not be less than 2 MΩ.

4.5 Electric strength

4.5.1 Test method to determine the electric strength

Immediately after the insulation resistance test, the same parts as those referred to in 4.4

shall withstand the test voltage of 4.5.2.

The high-voltage transformer used for the test shall be so designed that when the output

terminals are short-circuited after the output voltage has been adjusted to the appropriate test

voltage, the output current is at least 200 mA.

The overcurrent relay shall not trip when the output current is less than 100 mA.

The r.m.s. value of the test voltage applied shall be measured to within ±3 %.

The metal foil referred to in 4.4 shall be placed so that no flashover occurs at the edges of the

insulation.

4.5.2 Requirement for the electric strength

Compliance is checked with a test voltage of substantially sine-wave form, see Table 1, with a

frequency of 50 Hz or 60 Hz and applied for 1 min. Initially, not more than half the prescribed

voltage shall be applied; it shall then be raised rapidly to the full value. The working voltage

shall be given in the manufacturer’s documentation.

Table 1 – Requirements for the electric strength

Test voltage

Working voltage U

V

Up to and including 42 V 500

Above 42 V up to and including 1 000 V 2U + 1 000

4.5.3 Compliance

No flashover or breakdown shall occur during the test.

Glow discharges without a drop in voltage are neglected.

4.6 Parts which can become accidentally live

4.6.1 Metal parts intended to be insulated

Metal parts, if any, intended to be insulated from live parts shall not be or become live.

– 12 – IEC 62532:2011+AMD1:2016 CSV

IEC 2016

4.6.2 Live parts that project from the lamp

With the exception of the electrical connection, no live part shall project from any part of the

lamp.

4.6.3 Methods to show compliance

Compliance is checked by a suitable measuring system, which may include visual inspection

where appropriate. It shall be safeguarded that during assembly damage to insulation cannot

occur.

4.7 Resistance to heat and fire

The lamp shall be sufficiently resistant to heat.

Compliance is checked by the test in Annex E.

4.8 Creepage distances and clearances for lamps

The same requirements apply as in section 11 of IEC 60598-1.

4.9 Temperature rise of the measuring points

The values and measurement methods of the maximum temperature rises of the measuring

points are given in Annex F.

4.10 Endurance

Under consideration.

4.11 UV radiation

The specific effective radiant UV power emitted by the lamp shall not exceed the value of

2 mW/klm. For reflector lamps, it shall not exceed the value of 2 mW/(m klx).

NOTE 1 In IEC 62471, exposure limits are given as effective irradiance values (unit:W/m ) and for risk group

classification, the values for general lighting lamps are reported at an illuminance level of 500 lx. The borderline for

risk group exempt is 0,001 W/m at an illuminance level of 500 lx. This means the specific value, related to the

2 2 2

illuminance, is 0,001 divided by 500 in W/(m lx), which is 2 mW/(m klx). Since lx = lm/m this equals 2 mW/klm

specific UV power.

NOTE 2 Compliance is checked by spectroradiometric measurement, under the same conditions as for the lamp’s

electrical and photometric characteristics as given in IEC 60901 or in Annex B of the forthcoming performance

standard for induction lamps.

4.12 Information for luminaire design

The luminaire manufacturer should observe the maximum temperature(s) specified in

Annex B.

4.13 Information for ballast design

The ballast manufacturer should observe the requirements in Annex D.

5 Assessment

Under consideration.

IEC 2016

Annex A

(informative)

Schematic drawings of induction lamps

To clarify the construction of an internally and an externally coupled induction lamp,

schematic drawings are given in Figures A.1 to A.3.

Figure A.1 – Schematic drawing of an internal coupled induction lamp

(operating frequency 2 500 kHz to 3 000 kHz)

– 14 – IEC 62532:2011+AMD1:2016 CSV