IEC 63093-4:2019

(Main)Ferrite cores - Guidelines on dimensions and the limits of surface irregularities - Part 4: RM-cores

Ferrite cores - Guidelines on dimensions and the limits of surface irregularities - Part 4: RM-cores

IEC 63093-4:2019 specifies the dimensions that are of importance for mechanical interchangeability for a preferred range of RM-cores and low-profile RM-cores made of ferrite, and the locations of their terminal pins on a 2,54 mm printed wiring grid in relation to the base outlines of the cores. It also gives guidance on allowable limits of surface irregularities applicable to RM-cores in accordance with the relevant generic specification.

The selection of core sizes for this document is based on the philosophy of including those sizes which are industrial standards, either by inclusion in a national standard, or by broad-based use in industry.

This document is a specification useful in the negotiations between ferrite core manufacturers and customers about surface irregularities.

This first edition cancels and replaces the first edition of IEC 62317-4 published in 2005 and the second edition of IEC 60424-2 published in 2015. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to IEC 62317-4:2005 and IEC 60424-2:2015:

a) IEC 63093-4 integrates the contents of IEC 62317-4:2005 and IEC 60424-2:2015;

b) IEC 60424-2:2015, Table 2, has been included in Annex C as Table C.1.

Noyaux ferrites – Lignes directrices relatives aux dimensions et aux limites des irrégularités de surface - Partie 4: Noyaux RM

L'IEC 63093-4:2019 spécifie les dimensions qui jouent un rôle majeur dans l'interchangeabilité mécanique d'une gamme préférentielle de noyaux RM et de noyaux RM extra plats constitués de ferrite, et les emplacements de leurs broches de sortie sur une grille au pas de 2,54 mm d'un circuit imprimé par rapport aux encombrements de base des noyaux. Elle fournit également des recommandations sur les limites d'irrégularités de surface admissibles des noyaux RM, conformément à la spécification générique applicable.

Le choix de la taille des noyaux pour le présent document est fondé sur la philosophie consistant à introduire des tailles qui correspondent à des normes industrielles, soit par une prise en compte dans une norme nationale, soit par le biais d'une utilisation à grande échelle dans l'industrie.

Le présent document est une spécification utile pour les négociations entre les fabricants de noyaux ferrites et les clients à propos des irrégularités de surface.

Cette première édition annule et remplace la première édition de l'IEC 62317-4 parue en 2005 et la deuxième édition de l'IEC 60424-2 parue en 2015. Cette édition constitue une révision technique.

La présente édition inclut les modifications techniques majeures suivantes par rapport à l'IEC 623174:2005 et à l'IEC 60424-2:2015:

a) l'IEC 63093-4 intègre le contenu de l'IEC 62317-4:2005 et de l'IEC 60424-2:2015;

b) le Tableau 2 de l'IEC 60424-2:2015 a été inclus dans l'Annexe C en tant que Tableau C.1.

General Information

- Status

- Published

- Publication Date

- 07-Mar-2019

- Technical Committee

- TC 51 - Magnetic components, ferrite and magnetic powder materials

- Drafting Committee

- WG 1 - TC 51/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 08-Mar-2019

- Completion Date

- 29-Mar-2019

Relations

- Effective Date

- 13-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 63093-4:2019 is an international standard published by the International Electrotechnical Commission (IEC) that provides comprehensive guidelines on the dimensions and permissible limits of surface irregularities for RM-type ferrite cores. These ferrite cores are widely used in electrical and electronic components, particularly in inductors and transformers. This standard specifically addresses mechanical interchangeability by specifying critical dimensions for a preferred range of standard and low-profile RM-cores, as well as terminal pin locations on a 2.54 mm printed wiring board grid in relation to the core base outlines.

This standard consolidates and updates previous IEC standards IEC 62317-4:2005 and IEC 60424-2:2015, reflecting industry best practices and ensuring global harmonization for manufacturing and quality control of RM ferrite cores.

Key Topics

Core Dimensions and Mechanical Interchangeability

IEC 63093-4 defines principal dimensions essential for mechanical compatibility among RM-cores, covering both standard and low-profile variations. This includes exact measurements of core height, width, and pin placements.Terminal Pin Locations

The standard specifies terminal pin placements with precise relation to the ferrite core base and the 2.54 mm printed wiring board grid. This facilitates standardized mounting and ease of integration into PCBs.Surface Irregularity Limits

The document provides detailed guidance on acceptable limits for various surface irregularities such as chips, cracks, pull-outs, crystallites, flashes, and pores, differentiating between those found on mating surfaces versus other areas.Mounting and Coil Formers

Instructions for coil former dimensions and standardized mounting configurations for both standard and power application RM-cores ensure compatibility and repeatability in assembly processes.Testing and Measurement Guidance

Annex sections include methods to measure clamping forces for core testing and examples of allowed areas for surface defects, supporting manufacturers and customers in quality negotiations.

Applications

Magnetic Component Manufacturing

Manufacturers of ferrite RM-cores benefit from standardized dimension and quality criteria that improve product interchangeability and reliability.Transformer and Inductor Assembly

The defined pin positions and mounting specifications streamline the design and assembly of magnetic components on printed circuit boards.Quality Assurance and Inspection

Inspectors and quality control teams use this standard to assess allowable surface defects, ensuring components meet industry-accepted mechanical and visual quality levels.Contractual and Supplier Negotiations

The unified guidelines facilitate clear communication between ferrite core suppliers and customers on dimensional and surface quality expectations, reducing disputes and improving consistency.

Related Standards

- IEC 62317-4:2005 – Former standard that focused on dimensions of magnetic components, now integrated into IEC 63093-4.

- IEC 60424-2:2015 – Previous specification for ferrite cores, particularly on surface quality limits, now incorporated into this standard.

- IEC 63093 Series – A comprehensive family of standards covering various types of ferrite cores and their dimensional and surface quality guidelines.

- ISO/IEC Directives, Part 2 – Governs the drafting and structure of IEC International standards to ensure consistency and clarity.

Keywords: IEC 63093-4, RM ferrite cores, ferrite core dimensions, surface irregularities, mechanical interchangeability, printed circuit board mounting, ferrite core standards, electromagnetic components, ferrite core quality control, IEC ferrite core guidelines.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 63093-4:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Ferrite cores - Guidelines on dimensions and the limits of surface irregularities - Part 4: RM-cores". This standard covers: IEC 63093-4:2019 specifies the dimensions that are of importance for mechanical interchangeability for a preferred range of RM-cores and low-profile RM-cores made of ferrite, and the locations of their terminal pins on a 2,54 mm printed wiring grid in relation to the base outlines of the cores. It also gives guidance on allowable limits of surface irregularities applicable to RM-cores in accordance with the relevant generic specification. The selection of core sizes for this document is based on the philosophy of including those sizes which are industrial standards, either by inclusion in a national standard, or by broad-based use in industry. This document is a specification useful in the negotiations between ferrite core manufacturers and customers about surface irregularities. This first edition cancels and replaces the first edition of IEC 62317-4 published in 2005 and the second edition of IEC 60424-2 published in 2015. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to IEC 62317-4:2005 and IEC 60424-2:2015: a) IEC 63093-4 integrates the contents of IEC 62317-4:2005 and IEC 60424-2:2015; b) IEC 60424-2:2015, Table 2, has been included in Annex C as Table C.1.

IEC 63093-4:2019 specifies the dimensions that are of importance for mechanical interchangeability for a preferred range of RM-cores and low-profile RM-cores made of ferrite, and the locations of their terminal pins on a 2,54 mm printed wiring grid in relation to the base outlines of the cores. It also gives guidance on allowable limits of surface irregularities applicable to RM-cores in accordance with the relevant generic specification. The selection of core sizes for this document is based on the philosophy of including those sizes which are industrial standards, either by inclusion in a national standard, or by broad-based use in industry. This document is a specification useful in the negotiations between ferrite core manufacturers and customers about surface irregularities. This first edition cancels and replaces the first edition of IEC 62317-4 published in 2005 and the second edition of IEC 60424-2 published in 2015. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to IEC 62317-4:2005 and IEC 60424-2:2015: a) IEC 63093-4 integrates the contents of IEC 62317-4:2005 and IEC 60424-2:2015; b) IEC 60424-2:2015, Table 2, has been included in Annex C as Table C.1.

IEC 63093-4:2019 is classified under the following ICS (International Classification for Standards) categories: 29.100.10 - Magnetic components. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 63093-4:2019 has the following relationships with other standards: It is inter standard links to IEC 62317-4:2005/COR1:2016, IEC 60424-2:2015, IEC 62317-4:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 63093-4:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 63093-4 ®

Edition 1.0 2019-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Ferrite cores – Guidelines on dimensions and the limits of surface irregularities –

Part 4: RM-cores

Noyaux ferrites – Lignes directrices relatives aux dimensions et aux limites des

irrégularités de surface –

Partie 4: Noyaux RM

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 63093-4 ®

Edition 1.0 2019-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Ferrite cores – Guidelines on dimensions and the limits of surface irregularities –

Part 4: RM-cores

Noyaux ferrites – Lignes directrices relatives aux dimensions et aux limites des

irrégularités de surface –

Partie 4: Noyaux RM

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.100.10 ISBN 978-2-8322-6615-1

– 2 – IEC 63093-4:2019 © IEC 2019

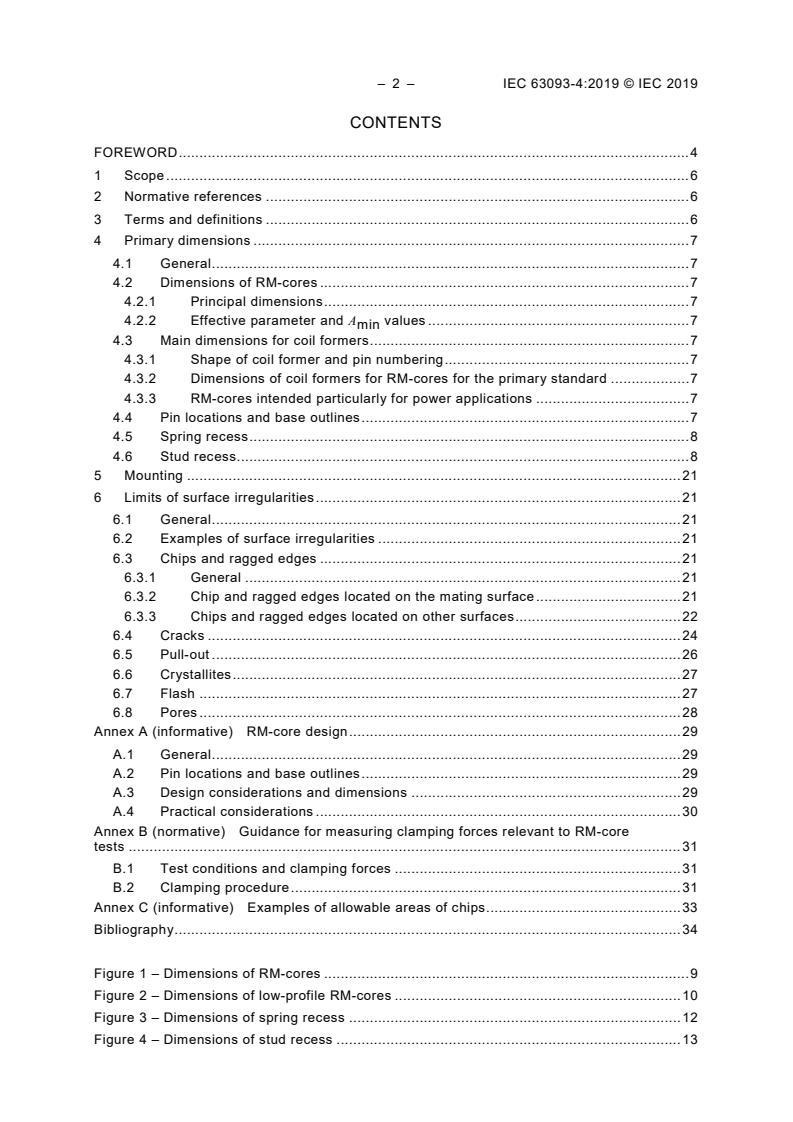

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Primary dimensions . 7

4.1 General . 7

4.2 Dimensions of RM-cores . 7

4.2.1 Principal dimensions . 7

4.2.2 Effective parameter and A values . 7

min

4.3 Main dimensions for coil formers . 7

4.3.1 Shape of coil former and pin numbering . 7

4.3.2 Dimensions of coil formers for RM-cores for the primary standard . 7

4.3.3 RM-cores intended particularly for power applications . 7

4.4 Pin locations and base outlines . 7

4.5 Spring recess . 8

4.6 Stud recess . 8

5 Mounting . 21

6 Limits of surface irregularities . 21

6.1 General . 21

6.2 Examples of surface irregularities . 21

6.3 Chips and ragged edges . 21

6.3.1 General . 21

6.3.2 Chip and ragged edges located on the mating surface . 21

6.3.3 Chips and ragged edges located on other surfaces . 22

6.4 Cracks . 24

6.5 Pull-out . 26

6.6 Crystallites . 27

6.7 Flash . 27

6.8 Pores . 28

Annex A (informative) RM-core design . 29

A.1 General . 29

A.2 Pin locations and base outlines . 29

A.3 Design considerations and dimensions . 29

A.4 Practical considerations . 30

Annex B (normative) Guidance for measuring clamping forces relevant to RM-core

tests . 31

B.1 Test conditions and clamping forces . 31

B.2 Clamping procedure . 31

Annex C (informative) Examples of allowable areas of chips . 33

Bibliography . 34

Figure 1 – Dimensions of RM-cores . 9

Figure 2 – Dimensions of low-profile RM-cores . 10

Figure 3 – Dimensions of spring recess . 12

Figure 4 – Dimensions of stud recess . 13

Figure 5 – Main dimensions of coil formers for RM-cores . 14

Figure 6 – Pin locations and base outlines viewed from the underside of the board . 16

Figure 7 – Dimensions of specific features . 18

Figure 8 – Pin locations and base outlines viewed from the underside of the board . 20

Figure 9 – Examples of surface irregularities . 21

Figure 10 – Chips on mating surfaces . 22

Figure 11 – Location of cracks – Top view . 24

Figure 12 – Location of cracks – Bottom view . 24

Figure 13 – Dimension W . 26

Figure 14 – Location of pull-out . 26

Figure 15 – Pull-out in the clamping recess area . 27

Figure 16 – Location of a crystallite . 27

Figure 17 – Location of a flash . 28

Figure 18 – Location of pore . 28

Figure B.1 – Mounting device. 31

Table 1 – Dimensions of RM-cores . 9

Table 2 – Dimensions of low-profile RM-cores . 10

Table 3 – Effective parameter and A values for RM-cores . 11

min

Table 4 – Effective parameter and A values for low-profile RM-cores. 12

min

Table 5 – Dimensions of spring recess . 13

Table 6 – Dimensions of stud recess . 13

Table 7 – Dimensional limits for coil formers for RM-cores . 14

Table 8 – Dimensional limits for coil formers for low-profile RM-cores . 15

Table 9 – Dimensions of specific features . 19

Table 10 – Area and length reference of irregularities for visual inspection . 23

Table 11 – Limits for cracks . 25

Table 12 – W dimensions . 25

Table B.1 – Inner diameters and recommended clamping forces . 32

Table C.1 – Examples of allowable area of chips . 33

– 4 – IEC 63093-4:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FERRITE CORES –

GUIDELINES ON DIMENSIONS AND

THE LIMITS OF SURFACE IRREGULARITIES

Part 4: RM-cores

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 63093-4 has been prepared by IEC technical committee 51:

Magnetic components, ferrite and magnetic powder materials.

This first edition cancels and replaces the first edition of IEC 62317-4 published in 2005 and

the second edition of IEC 60424-2 published in 2015. This edition constitutes a technical

revision.

This edition includes the following significant technical changes with respect to

IEC 62317-4:2005 and IEC 60424-2:2015:

a) IEC 63093-4 integrates the contents of IEC 62317-4:2005 and IEC 60424-2:2015;

b) IEC 60424-2:2015, Table 2, has been included in Annex C as Table C.1.

The text of this International Standard is based on the following documents:

FDIS Report on voting

51/1265/FDIS 51/1275/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 63093 series, published under the general title Ferrite cores –

Guidelines on dimensions and the limits of surface irregularities, can be found on the IEC

website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 63093-4:2019 © IEC 2019

FERRITE CORES –

GUIDELINES ON DIMENSIONS AND

THE LIMITS OF SURFACE IRREGULARITIES

Part 4: RM-cores

1 Scope

This part of IEC 63093 specifies the dimensions that are of importance for mechanical

interchangeability for a preferred range of RM-cores and low-profile RM-cores made of ferrite,

and the locations of their terminal pins on a 2,54 mm printed wiring grid in relation to the base

outlines of the cores. It also gives guidance on allowable limits of surface irregularities

applicable to RM-cores in accordance with the relevant generic specification.

The selection of core sizes for this document is based on the philosophy of including those

sizes which are industrial standards, either by inclusion in a national standard, or by broad-

based use in industry.

This document is a specification useful in the negotiations between ferrite core manufacturers

and customers about surface irregularities.

The general considerations that the design of this range of cores is based upon are given in

Annex A.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60205, Calculation of the effective parameters of magnetic piece parts

IEC 60401-1, Terms and nomenclature for cores made of magnetically soft ferrites – Part 1:

Terms used for physical irregularities

IEC 60424-1, Ferrite cores – Guidelines on the limits of surface irregularities – Part 1:

General specification

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60401-1 and

IEC 60424-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Primary dimensions

4.1 General

Compliance with the following requirements ensures mechanical interchangeability of

complete assemblies and wound coil formers.

4.2 Dimensions of RM-cores

4.2.1 Principal dimensions

The principal dimensions of RM-cores shall be as given in Table 1 and those of the low-profile

RM-cores shall be as given in Table 2. See also Figure 1 and Figure 2.

4.2.2 Effective parameter and A values

min

The effective parameter values for cores having the dimensions given in 4.2.1 are as shown in

Table 3 and Table 4. The definitions of effective parameters and their calculations shall be as

given in IEC 60205.

4.3 Main dimensions for coil formers

4.3.1 Shape of coil former and pin numbering

When the coil former is viewed from the pin side, the pins shall be numbered in a clockwise

direction. Pin 1 shall be a corner pin, or the pin immediately to the right of a corner, and

closest to the base outline.

For asymmetrical arrangements, pin 1 shall be at the side with the largest number of pins.

The coil former shall show an asymmetry, which shall preferably be visible (or detectable)

when the assembled inductor is held with the pins downwards. This asymmetry shall clearly

indicate pin 1. For pin numbering of recommended core patterns and for recommended

asymmetrical pin arrangements, see 4.4.

NOTE It is not required that the pin numbers be marked on the coil former.

4.3.2 Dimensions of coil formers for RM-cores for the primary standard

The dimensions specified in Table 7 and Table 8 are illustrated in Figure 5.

4.3.3 RM-cores intended particularly for power applications

These coil formers are intended for use with cores RM 6-S, RM 8, RM 10, RM 12 and RM 14A,

all without centre holes. Each is provided with twelve terminal pins except for the RM 6-S coil

former, which has only eight.

Figure 7 shows the features specific to this format and the corresponding dimensions are

given in Table 9.

4.4 Pin locations and base outlines

These shall be as shown in Figure 6 and Figure 8 (for power applications), in which the base

is viewed from the pin side, i.e. from the underside of the printed wiring boards.

The pins should fit into holes, the nominal hole diameter being:

• 1 mm when the shortest distance between pins is 2,54 mm;

• 1,3 mm when the shortest distance between pins is 2,54 mm or more.

– 8 – IEC 63093-4:2019 © IEC 2019

4.5 Spring recess

RM-cores usually have recesses that allow the core halves to be held together by two spring

clamps snapping into these recesses. The recesses consist of a flat spring rest and a locking

ridge. The dimensions are given in Table 5 and Figure 3; the profile of this spring recess is

not defined but the limit dimensions shall be complied with.

4.6 Stud recess

Those RM-cores with centre-pole holes may have recesses for the fixed part of the adjusting

device with dimensions in accordance with Table 6 and Figure 4. These dimensions are not

mandatory for manufacturers who supply cores with the fixed part of the adjusting device

attached

Figure 1 – Dimensions of RM-cores

Table 1 – Dimensions of RM-cores

a

A B C D E F G H J R

mm mm mm

Size mm mm mm mm mm mm mm Type

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Min. Max. Min. Max. Max.

RM 4 10,6 11,8 5,15 5,25 4,40 4,60 3,50 3,70 7,95 8,35 3,70 3,90 5,80 2,0 2,1 9,40 9,80 0,3 3

RM 5 14,0 14,9 5,15 5,25 6,40 6,80 3,15 3,35 10,20 10,60 4,70 4,90 6,00 2,0 2,1 11,80 12,30 0,3 3

RM 6-S 17,2 18,3 6,15 6,25 7,80 8,20 4,00 4,20 12,40 12,90 6,10 6,40 8,40 3,0 3,1 14,10 14,70 0,3 1

RM 6-R 17,2 18,3 6,15 6,25 7,00 7,40 4,00 4,20 12,40 12,90 6,10 6,40 6,30 3,0 3,1 14,10 14,70 0,3 4

RM 7 19,5 20,3 6,65 6,75 6,95 7,25 4,20 4,45 14,75 15,40 6,95 7,25 9,30 3,0 3,1 16,50 17,20 0,3 2

RM 8 22,3 23,2 8,15 8,25 10,60 11,00 5,40 5,65 17,00 17,70 8,25 8,55 9,50 4,4 4,6 18,90 19,70 0,3 3

RM 10 27,2 28,5 9,25 9,35 13,00 13,50 6,20 6,50 21,20 22,10 10,50 10,90 10,90 5,4 5,6 23,60 24,70 0,3 3

RM 12 36,1 37,4 12,20 12,30 15,60 16,10 8,40 8,70 25,00 26,00 12,30 12,80 12,90 - - 28,70 29,80 0,3 3

RM 14 40,8 42,2 14,40 14,50 18,40 19,00 10,40 10,70 29,00 30,20 14,40 15,00 17,00 5,4 5,6 33,50 34,70 0,3 3

RM 14A 40,8 42,2 15,00 15,10 18,40 19,00 10,40 10,70 29,00 30,20 14,40 15,00 17,00 - - 33,50 34,70 0,3 3

a

Solid centre-pole cores are available for each size.

– 10 – IEC 63093-4:2019 © IEC 2019

Figure 2 – Dimensions of low-profile RM-cores

Table 2 – Dimensions of low-profile RM-cores

a

A B C D E F G H J R

Size mm mm mm mm mm mm mm mm mm mm Type

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Min. Max. Min. Max. Max.

RM 4/8 10,6 11,8 3,80 3,90 4,40 4,60 2,15 2,35 7,95 8,35 3,70 3,90 5,80 2,0 2,1 9,40 9,80 0,3 3

RM 5/8 14,0 14,9 3,80 3,90 6,40 6,80 1,80 2,00 10,20 10,60 4,70 4,90 6,00 2,0 2,1 11,80 12,30 0,3 3

RM 6/9 17,2 18,3 4,40 4,50 7,80 8,20 2,25 2,45 12,40 12,90 6,10 6,40 8,40 3,0 3,1 14,10 14,70 0,3 1

RM 7/10 19,5 20,3 4,80 4,90 6,95 7,25 2,35 2,60 14,75 15,40 6,95 7,25 9,30 3,0 3,1 16,50 17,20 0,3 2

RM 8/11 22,3 23,2 5,70 5,80 10,60 11,00 2,95 3,15 17,00 17,70 8,25 8,55 9,50 4,4 4,6 18,90 19,70 0,3 3

RM 10/13 27,2 28,5 6,40 6,50 13,00 13,50 3,35 3,55 21,20 22,10 10,50 10,90 10,90 5,4 5,6 23,60 24,70 0,3 3

RM 12/17 36,1 37,4 8,30 8,40 15,60 16,10 4,50 4,75 25,00 26,00 12,30 12,80 12,90 5,4 5,6 28,70 29,80 0,3 3

RM 14/20 40,8 42,2 10,15 10,25 18,40 19,00 5,55 5,85 29,00 30,20 14,40 15,00 17,00 5,4 5,6 33,50 34,70 0,3 3

a

Solid centre-pole cores are available for each size.

Table 3 – Effective parameter and A values for RM-cores

min

a

with hole ○ C C A l V A

1 2 e e e min

Size

-1 -3 -3 2 3 2

no hole Φ mm × 10 mm mm mm mm mm

○ 1,874 3 171,63 10,9 20,5 224 8,04

RM 4

Φ 1,617 3 115,43 14,0 22,7 318 11,3

○ 1,021 5 50,075 20,4 20,8 425 14,8

RM 5

Φ 0,943 62 39,983 23,6 22,3 526 18,1

○ 0,897 83 29,592 30,3 27,2 830 23,4

RM 6-S

Φ 0,816 68 23,099 35,4 28,9 1 020 30,7

○ 0,821 49 25,728 31,3 25,7 810 23,4

RM 6-R

Φ 0,740 34 19,737 37,5 27,8 1 040 30,7

○ 0,720 27 17,389 41,4 29,8 1 240 32,3

RM 7

Φ 0,672 53 14,509 46,4 31,2 1 450 39,6

○ 0,680 17 13,134 51,8 35,2 1 820 39.5

RM 8

Φ 0,602 06 9,546 4 63,1 38,0 2 390 55,4

○ 0,503 89 6,034 9 83,5 42,1 3 510 66,2

RM 10

Φ 0,454 85 4,647 8 97,9 44,5 4 360 89,9

RM 12 Φ 0,383 33 2,626 6 146 55,9 8 160 124

○ 0,381 70 2,187 8 174 66,6 11 600 146

RM 14

Φ 0,362 17 1,918 9 189 68,4 12 900 170

RM 14A Φ 0,350 29 1,771 1 198 69,3 13 700 170

The manufacturers may indicate in their catalogues more precise values than those given in the above table.

a

See IEC 60205 for the definition of A .

min

– 12 – IEC 63093-4:2019 © IEC 2019

Table 4 – Effective parameter and A values for low-profile RM-cores

min

a

with hole ○ C C A l V A

1 2 e e e min

Size

-1 -3 -3 2 3 2

no hole Φ mm × 10 mm mm mm mm mm

○ 1,377 4 120,26 11,5 15,8 181 8,04

RM 4/8

Φ 1,218 7 84,830 14,4 17,5 252 11,3

○ 0,748 11 34,680 21,6 16,1 348 14,8

RM 5/8

Φ 0,703 52 28,678 24,5 17,3 423 18,1

○ 0,656 34 20,781 31,6 20,7 655 23,4

RM 6/9

Φ 0,610 85 16,976 36,0 22,0 791 31,2

○ 0,528 24 12,220 43,2 22,8 987 32,3

RM 7/10

Φ 0,501 64 10,529 47,6 23,9 1 140 39,6

○ 0,477 42 8,744 5 54,6 26,1 1 420 39,5

RM 8/11

Φ 0,435 25 6,717 3 64,8 28,2 1 830 55,4

○ 0,358 02 4,117 3 87,0 31,1 2 710 66,2

RM 10/13

Φ 0,332 13 3,339 0 99,5 33,0 3 290 89,9

○ 0,294 33 2,226 4 132 38,9 5 140 99,9

RM 12/17

Φ 0,277 60 1,882 8 147 40,9 6 030 124

○ 0,262 62 1,411 5 186 48,9 9 090 146

RM 14/20

Φ 0,252 35 1,262 9 200 50,4 10 100 170

The manufacturers may indicate in their catalogues more precise values than those given in the above table.

a

See IEC 60205 for the definition of A .

min

Figure 3 – Dimensions of spring recess

Table 5 – Dimensions of spring recess

a, b a, c a, d

H H G G m

3 4 1 2

mm mm mm mm mm

Size

Min. Max. Min. Max. Max. Min. Max.

RM 4 8,75 9,25 0,05 0,15 1,0 1,65 2,5

RM 5 8,75 9,25 0,05 0,15 1,0 1,65 2,5

RM 6 10,09 10,59 0,10 0,20 1,3 2,20 2,5

RM 7 11,09 11,59 0,10 0,20 1,3 2,20 3,3

RM 8 14,05 14,55 0,10 0,20 1,3 2,20 5,0

RM 10 15,95 16,45 0,15 0,25 1,3 2,25 5,0

RM 12 21,4 21,90 0,15 0,25 1,3 3,50 5,0

RM 14 25,55 26,05 0,15 0,25 1,3 3,60 5,6

RM 14A 26,80 27,30 0,15 0,25 1,3 3,60 5,6

a

Dimensions G and G define the boundaries of the flat spring rest.

1 2

b

In particular cases, the design of the spring can require the tolerance on H to be smaller.

c

The form of the locking ridge is not specified but it shall be essentially uniform over the width m in order not to

hinder the correct application of the spring. The outer side may be of any form facilitating the introduction of

the spring into the recess; the inner side may be of any form but shall not protrude through a flat plane making

an angle of 120° with the flat spring rest and containing its boundary defined by dimensions G .

d

The inner side of the spring recess may be of any form but it shall not protrude through a flat plane making an

angle of 120° with the flat spring rest and containing its boundary defined by dimension G .

Figure 4 – Dimensions of stud recess

Table 6 – Dimensions of stud recess

d t

Size mm mm

Min. Min. Max.

RM 4 3,0 0,4 0,7

RM 5 3,0 0,4 0,7

RM 6 4,3 0,7 1,0

RM 7 4,3 0,7 1,0

RM 8 6,0 0,7 1,0

RM 10 7,6 0,8 1,1

RM 14 7,6 0,8 1,1

– 14 – IEC 63093-4:2019 © IEC 2019

Figure 5 – Main dimensions of coil formers for RM-cores

Table 7 – Dimensional limits for coil formers for RM-cores

d d d h h h l P

1 2 3 2 4 5

Size mm mm mm mm mm mm mm mm

Min. Max. Min. Max. Min. Max. Min. Max. Max. Max. Min. Min. Max.

RM 4 7,65 7,85 4,75 4,95 4,00 4,15 6,65 6,85 0,80 0,50 3,90 0,50 0,60

RM 5 9,90 10,10 5,75 5,95 5,00 5,15 5,95 6,15 0,80 0,55 4,50 0,50 0,60

RM 6-R 12,10 12,30 7,20 7,30 6,50 6,60 7,70 7,85 0,80 0,55 4,80 0,58 0,62

RM 6-S 12,10 12,30 7,25 7,45 6,50 6,60 7,70 7,85 0,90 0,55 4,30 0,50 0,60

RM 7 14,40 14,66 8,00 8,30 7,30 7,60 8,10 8,25 0,80 0,55 6,60 0,78 0,82

RM 8 16,70 16,90 9,75 9,95 8,70 8,90 10,40 10,65 1,05 0,65 5,00 0,60 0,70

RM 10 20,80 21,00 12,30 12,50 11,10 11,30 12,00 12,25 1,05 0,70 5,35 0,60 0,70

RM 12 24,50 24,70 14,20 14,50 13,00 13,30 16,25 16,50 1,05 0,75 6,00 0,75 0,85

RM 14 28,60 28,80 16,60 16,80 15,20 15,40 20,20 20,50 1,05 0,85 6,10 0,75 0,85

h

Table 8 – Dimensional limits for coil formers for low-profile RM-cores

d d d h h h l P

1 2 3 2 4 5

mm mm mm mm mm mm mm mm

Size

Min. Max. Min. Max. Min. Max. Min. Max. Max. Max. Min. Min. Max.

RM 4/8 7,65 7,85 4,75 4,95 4,00 4,15 4,05 4,20 0,80 0,50 3,90 0,50 0,60

RM 5/8 9,90 10,10 5,75 5,95 5,00 5,15 3,35 3,50 0,80 0,55 4,50 0,50 0,60

RM 6/9 12,10 12,30 7,20 7,30 6,50 6,60 4,25 4,40 0,90 0,55 4,80 0,58 0,62

RM 7/10 14,40 14,66 8,00 8,30 7,30 7,60 4,45 4,60 0,80 0,55 6,60 0,78 0,82

RM 8/11 16,70 16,90 9,75 9,95 8,70 8,90 5,55 5,70 1,05 0,65 5,00 0,60 0,70

RM 10/13 20,80 21,00 12,30 12,50 11,10 11,30 6,35 6,50 1,05 0,70 5,35 0,60 0,70

RM 12/17 24,50 24,70 14,20 14,50 13,00 13,30 8,65 8,80 1,05 0,75 6,00 0,75 0,85

RM 14/20 28,60 28,80 16,60 16,80 15,20 15,40 10,75 10,90 1,05 0,85 6,10 0,75 0,85

– 16 – IEC 63093-4:2019 © IEC 2019

Figure 6 – Pin locations and base outlines viewed

from the underside of the board (1 of 2)

RM14

To obtain an asymmetrical arrangement, one pin may be omitted on one side from a symmetrical arrangement.

For RM 7, the five-pin version has an asymmetrical arrangement.

For the other cores, omit:

– for RM 4, RM 5 and RM 6 with five pins: No. 4 pin;

– for RM 8 with eleven pins: No. 6 pin;

– for RM 10 with eleven pins: No. 9 pin;

– for RM 12 with eleven pins: No. 10 pin;

– for RM 14 with ten pins: No. 5 and No. 8 pins.

Figure 6 (2 of 2)

– 18 – IEC 63093-4:2019 © IEC 2019

Figure 7 – Dimensions of specific features

Table 9 – Dimensions of specific features

d d d h h h

1 2 3 2 4 5

Size mm mm mm mm mm mm

Min. Max. Min. Max. Min. Max. Min. Max. Max. Max.

RM 6-S 12,1 12,3 7,25 7,45 6,50 6,60 7,70 7,95 1,05 0,60

RM 8 16,7 16,9 9,75 9,95 8,70 8,90 10,40 10,65 1,20 0,75

RM 10 20,8 21,0 12,30 12,50 11,10 11,30 12,00 12,25 1,30 0,80

RM 12 24,5 24,7 14,20 14,50 13,00 13,30 16,25 16,50 1,30 0,80

RM 14A 28,6 28,8 16,60 16,80 15,20 15,40 20,20 20,50 1,40 0,90

a b c f e p q

max max

Size

mm mm mm mm mm mm mm

RM 6-S 16,0 24,9 2,2 2,60 0,3 0,63 3,8

RM 8 23,5 29,9 2,5 3,10 0,3 0,63 3,8

RM 10 23,3 39,4 3,1 3,45 0,3 1,00 3,8

RM 12 28,4 45,2 3,2 3,70 0,3 1,00 4,2

RM 14A 31,4 48,4 4,0 4,40 0,3 1,00 4,2

– 20 – IEC 63093-4:2019 © IEC 2019

Figure 8 – Pin locations and base outlines viewed from the underside of the board

5 Mounting

In order to ensure a good contact between mating surfaces, a specific clamping force shall be

applied. The clamping force and the procedure are specified in Annex B.

6 Limits of surface irregularities

6.1 General

Surface irregularities are defined in IEC 60424-1.

6.2 Examples of surface irregularities

Figure 9 shows different examples of surface irregularities on an RM-core.

Figure 9 – Examples of surface irregularities

6.3 Chips and ragged edges

6.3.1 General

The minimum chipping area is taken as 0,5 mm , to be distinguishable to the naked eye.

The maximum chipping area is taken as 30 mm , to be referenced to the design for the cores.

6.3.2 Chip and ragged edges located on the mating surface

The areas of the chips located on the mating surface (see C1, C1’ and C1” irregularities in

Figure 10) shall not exceed the following limits:

– the cumulative area of the chips located on the mating surface shall be less than 4 % of

the total mating surface;

– the total length of the ragged edges shall be less than 25 % of the perimeter of the relevant

mating surface.

– 22 – IEC 63093-4:2019 © IEC 2019

C1, C1′, C1″: chip

R1, R1′: ragged edge

L , L : length of ragged edge

1 2

Figure 10 – Chips on mating surfaces

The examples of allowable chipping areas for a given core are summarized in Annex C.

6.3.3 Chips and ragged edges located on other surfaces

For chips and ragged edges located on other surfaces:

– the allowable chipping areas are doubled as compared to the limits for the whole mating

surfaces;

– the rule for the ragged edges is the same as for the mating surfaces;

– chips and ragged edges are not acceptable on the ridge of the clamping recess area;

– chips and ragged edges are not acceptable on the inner edges of the wire slot area.

Area and length reference of irregularities for visual inspection are given in Table 10.

Table 10 – Area and length reference of irregularities for visual inspection

– 24 – IEC 63093-4:2019 © IEC 2019

6.4 Cracks

A single continuous crack that intersects the perimeter of the relevant surface at two points is

not acceptable (see S1, S1' and S1'' irregularities in Figure 11).

The limits of cracks at various locations shown in Figure 11 and Figure 12 are given in

Table 11.

Figure 11 – Location of cracks – Top view

NOTE A boundary between the outer wall and the back wall is shown by a dashed line.

Figure 12 – Location of cracks – Bottom view

Table 11 – Limits for cracks

Limits for Limits for

Type Location

single crack multiple cracks

S1, S1’/S1” Any place Not acceptable Not acceptable

50 % of centre-pole

S2, S2’ Mating surface of centre-pole Centre-pole thickness

thickness

S3, S3’ Mating surface of outer wall Wall thickness, W 2 W

S4, S4’ Centre-pole Centre-pole thickness Centre-pole thickness

S5 Outer wall Wall thickness, W 4 W

S6, S6’ Back surface Back wall thickness 4 ´ Back wall thickness

Corner of centre-pole/back 25 % of centre-pole 25 % of centre-pole

wall circumference circumference

S7, S7’

and outer wall/back wall 25 % of relevant arc 25 % of relevant arc

NOTE For cores without a hole in the centre-pole, the centre-pole thickness is replaced by a half of the centre-

pole diameter, i.e. in Table 11 the limit of "50 % of the centre-pole thickness" becomes "25 % of the centre-pole

diameter", and "centre-pole thickness" becomes "half of the centre-pole diameter".

The acceptance criteria for the size of a crack are based on the minimum thickness W of the

outer wall of the relevant core size (see Figure 13). Table 12 gives all W values approximated

as (a – d )/2.

Table 12 – W dimensions

W

Core size

mm

RM 4 0,72

RM 5 0,82

RM 6 0,88

RM 7 0,88

RM 8 1,00

RM 10 1,25

RM 12 1,88

RM 14 2,55

– 26 – IEC 63093-4:2019 © IEC 2019

Figure 13 – Dimension W

6.5 Pull-out

Figure 14 and Figure 15 show an example of the location of a pull-out on the RM-core.

The cumulative area of the pull-outs on the bottom surface or the clamping recess area of the

core shall be less than 25 % of the total respective surface area (including wire-way areas for

the bottom surface).

Figure 14 – Location of pull-out

Figure 15 – Pull-out in the clamping recess area

6.6 Crystallites

Figure 16 shows an example of the location of a crystallite on the RM-core:

– the single area of the crystallites located on any surface shall be less than 2 % of the

respective surface area;

– the cumulative area of the crystallites located on any surface shall be less than 4 % of the

respective surface area.

Figure 16 – Location of a crystallite

6.7 Flash

Figure 17 shows an example of the location of a flash on the RM-core:

– there shall be no flash extending from the core into the wire slot.

– 28 – IEC 63093-4:2019 © IEC 2019

Figure 17 – Location of a flash

6.8 Pores

Figure 18 shows an example of the location of pores on the RM-core:

– the number of pores located on the same surface shall not exceed two; the total number of

pores located on all surfaces shall not exceed five;

– a hole with an area larger than 1 mm on any surface is not acceptable.

Figure 18 – Location of pore

Annex A

(informative)

RM-core design

A.1 General

The design of RM-cores standardized by the IEC is based on the following considerations:

a) RM-cores are especially suited for use on printed wiring boards, because it is possible to

solder the wire leads of the coils directly to the pin terminations moulded in the coil former.

Normally, these pins should remain within the outline of the core base.

b) RM-cores are primarily used for inductors and tuned transformers, but they can also be

used for broad-band transformers and in switched mode power supply applications.

For RM-cores which are used for fixed inductors and untuned transformers, where the

adjuster hole is unnecessary, a solid centre pole (no hole) construction may be used. This

gives a higher effective permeability and, in particular, more efficient operation than the

corresponding cores with a hole, an important consideration for power applications.

Cores up to and including RM 10 are specified for both forms of construction, whilst RM 12

and RM 14A are specifically intended for applications requiring a solid centre pole.

The counterpart to RM 14, with an adjuster hole, is a taller core RM 14A with solid centre

pole, whose essential advantage is a thicker base, to permit greater values of A and A

e min

to be achieved, while enabling the ratio A /A to be maintained almost unchanged.

e min

c) The base areas are square with cut-outs for the terminal pins in two opposite corners. The

winding space is annular.

A.2 Pin locations and base outlines

In order to provide for the largest possible number of pins, the shortest distance between pin

centres of 2,54 mm should be chosen. This can be safely handled by modern soldering

techniques for miniature printed wiring. The result is a maximum of six pins on the smallest

cores (e.g. base dimensions of 10 mm × 10 mm) and up to twelve pins for a large core (base

dimensions of 20 mm × 20 mm). If the maximum number of pins is not required, the shortest

mm by omitting certain pins.

distance between pin centres can be increased to 2,54 2

When the pins are placed on the primary grid, the sides of the core base are located at half

the grid spacing (except for RM 10). This allows the neighbouring pins of adjacent cores when

placed side by side to be located on parallel grid lines which are 2,54 mm apart.

A.3 Design considerations and dimensions

The range of base sizes is compatible with 4, 5, 6, 7, 8, 10 and 14 printed wiring modules of

2,54 mm.

Further aspects of the design are:

– a maximum wall height to thickness ratio of 5:1;

– a thickness of the core base sufficient to accommodate the wires terminated on the pins of

the coil former;

– an adjuster hole diameter in accordance with IEC 62317-2.

Within these limitations, and assuming acceptable core heights and reasonable cut-out

dimensions, the optimum inner and outer diameters of the winding space can be calculate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...