IEC 62270:2004

(Main)Hydroelectric power plant automation - Guide for computer-based control

Hydroelectric power plant automation - Guide for computer-based control

IEC 62270:2004 provides guidelines for the application, design concepts, and implementation of computer-based control systems for hydroelectric plant automation. This standard addresses functional capabilities, performance requirements, interface requirements, hardware considerations, and operator training. Recommendations for system testing and acceptance are also included.Keywords: Hydroelectric, Automation

Automatisation des centrales hydroélectriques - Lignes directrices pour la commande informatique

La CEI 62270:2004 établit les lignes directrices pour l'application, la conception et la mise en oeuvre de systèmes de commande informatiques destinés à l'automatisation des centrales hydroélectriques. Elle traite des capacités fonctionnelles, des exigences de performance, des exigences applicables aux interfaces, de considérations matérielles et de la formation des opérateurs. Elle inclut des recommandations pour l'essai et l'acceptation des systèmes. Mots clé : Hydroélectrique, automatisation

General Information

- Status

- Published

- Publication Date

- 27-Apr-2004

- Technical Committee

- TC 4 - Hydraulic turbines

- Drafting Committee

- WG 14 - TC 4/WG 14

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 16-Sep-2013

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62270:2004 - Hydroelectric power plant automation: Guide for computer-based control provides authoritative guidance for applying, designing, and implementing computer-based control systems in hydroelectric plants. The standard covers functional capabilities, performance and interface requirements, hardware considerations, operator training, and recommendations for system testing and acceptance. It also includes real-world case studies and is based on IEEE Standard 1249 (1996).

Keywords: hydroelectric, automation, computer-based control, control systems, operator training, system testing

Key topics

The standard addresses practical technical topics essential to reliable hydroelectric automation:

- Functional capabilities: control algorithms, data logging, alarm processing, diagnostics, reporting and maintenance interfaces.

- Control and data acquisition: control capabilities for unit and plant-level automation, sensor and actuator integration, and acquisition requirements.

- Alarm processing & diagnostics: event sequencing, alarm handling and fault diagnostics to support safe operation.

- Data management: archival, retrieval, forecasting, scheduling and report generation for operations and maintenance.

- System architecture & communications: recommended architectures, network topologies, database configuration and communication attributes for plant networks.

- User and plant interfaces: human-machine interfaces (HMIs), local vs centralized control and plant I/O integration.

- Performance & backup: performance requirements, hardware sizing, communications performance, backup control design and protective function considerations.

- Site integration & testing: environmental, power and grounding considerations, retrofits, acceptance testing and quality assurance.

- System management: maintenance, documentation, operator simulation training and staff training requirements.

- Case studies: practical examples of implementations and retrofit projects.

Applications and who uses it

IEC 62270 is of practical value to:

- Control and systems engineers designing hydroelectric automation and SCADA integrations

- Plant operators and operations managers implementing automated control strategies

- Project managers and system integrators specifying procurement and acceptance tests

- Maintenance teams defining diagnostics, archival and lifecycle support

- Regulators and asset owners assessing compliance, safety and performance

Practical benefits include improved unit control reliability, reduced operating costs through automation, enhanced operator situational awareness (GUIs, trending), and support for advanced features such as sequence-of-events logging and expert systems.

Related standards

- IEEE Standard 1249 (1996) - the guide upon which IEC 62270’s text is based

- Relevant IEC publications on communications, electrical safety, and instrumentation (see IEC catalogue for normative references)

IEC 62270 is a practical reference for implementing robust, standards-aligned computer-based control systems in hydroelectric power plants.

IEC 62270:2004 - Hydroelectric power plant automation - Guide for computer-based control Released:4/28/2004 Isbn:2831874904

IEC 62270:2004 - Hydroelectric power plant automation - Guide for computer-based control Released:4/28/2004 Isbn:9782832202357

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 62270:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Hydroelectric power plant automation - Guide for computer-based control". This standard covers: IEC 62270:2004 provides guidelines for the application, design concepts, and implementation of computer-based control systems for hydroelectric plant automation. This standard addresses functional capabilities, performance requirements, interface requirements, hardware considerations, and operator training. Recommendations for system testing and acceptance are also included.Keywords: Hydroelectric, Automation

IEC 62270:2004 provides guidelines for the application, design concepts, and implementation of computer-based control systems for hydroelectric plant automation. This standard addresses functional capabilities, performance requirements, interface requirements, hardware considerations, and operator training. Recommendations for system testing and acceptance are also included.Keywords: Hydroelectric, Automation

IEC 62270:2004 is classified under the following ICS (International Classification for Standards) categories: 27.140 - Hydraulic energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62270:2004 has the following relationships with other standards: It is inter standard links to IEC 62270:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62270:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 62270

First edition

2004-04

Hydroelectric power plant automation –

Guide for computer-based control

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (http://www.iec.ch/searchpub/cur_fut.htm)

enables you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (http://www.iec.ch/online_news/

justpub/jp_entry.htm) is also available by email. Please contact the Customer

Service Centre (see below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 62270

First edition

2004-04

Hydroelectric power plant automation –

Guide for computer-based control

IEC 2004 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale XB

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 62270 IEC:2004(E)

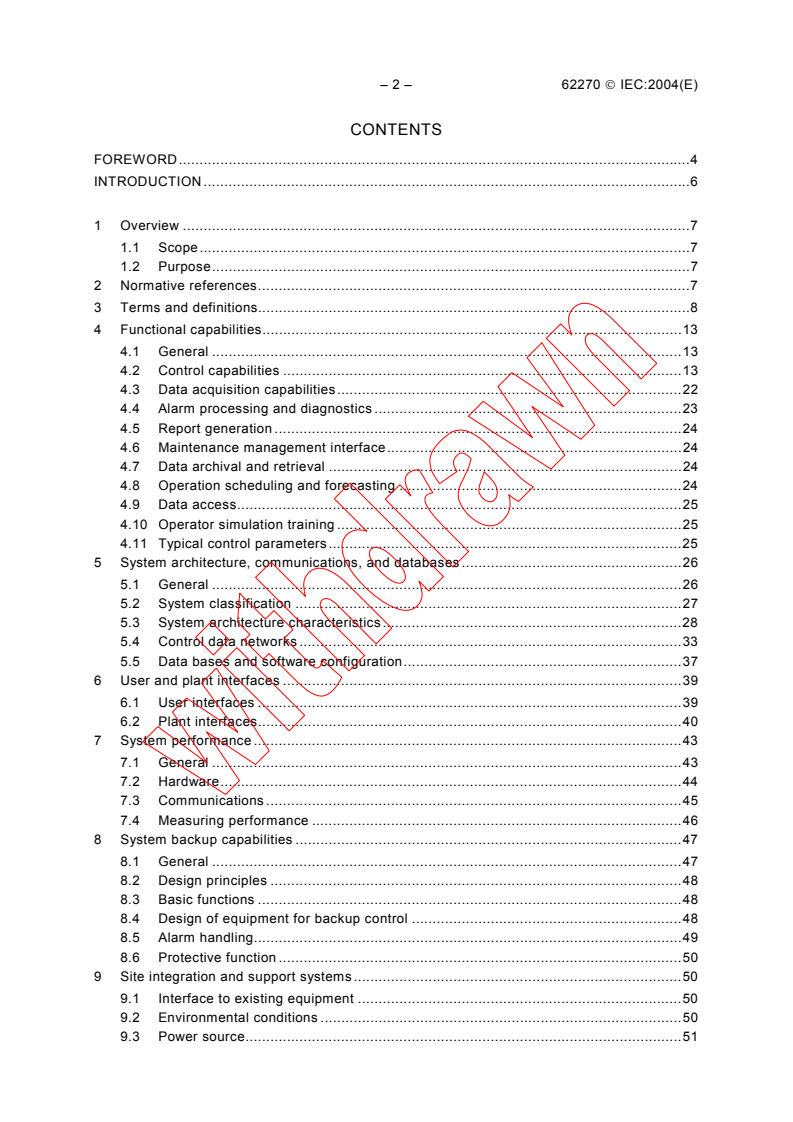

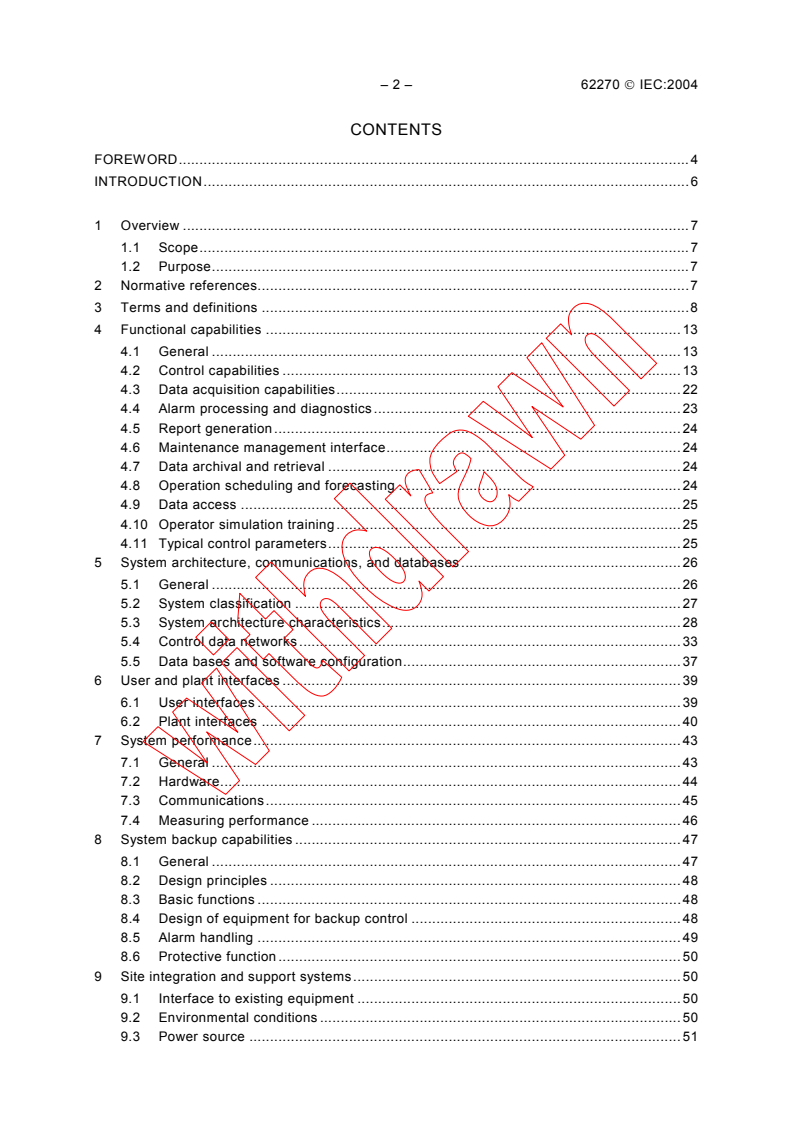

CONTENTS

FOREWORD.4

INTRODUCTION .6

1 Overview.7

1.1 Scope.7

1.2 Purpose.7

2 Normative references.7

3 Terms and definitions.8

4 Functional capabilities.13

4.1 General.13

4.2 Control capabilities.13

4.3 Data acquisition capabilities.22

4.4 Alarm processing and diagnostics .23

4.5 Report generation.24

4.6 Maintenance management interface.24

4.7 Data archival and retrieval .24

4.8 Operation scheduling and forecasting .24

4.9 Data access.25

4.10 Operator simulation training .25

4.11 Typical control parameters.25

5 System architecture, communications, and databases .26

5.1 General.26

5.2 System classification.27

5.3 System architecture characteristics.28

5.4 Control data networks .33

5.5 Data bases and software configuration.37

6 User and plant interfaces .39

6.1 User interfaces.39

6.2 Plant interfaces.40

7 System performance.43

7.1 General.43

7.2 Hardware.44

7.3 Communications.45

7.4 Measuring performance.46

8 System backup capabilities .47

8.1 General.47

8.2 Design principles.48

8.3 Basic functions.48

8.4 Design of equipment for backup control .48

8.5 Alarm handling.49

8.6 Protective function.50

9 Site integration and support systems.50

9.1 Interface to existing equipment .50

9.2 Environmental conditions.50

9.3 Power source.51

62270 IEC:2004(E) – 3 –

9.4 Supervision of existing contact status points .51

9.5 Supervision of existing transducers .52

9.6 Supervision of existing control output points.52

9.7 Grounding.52

9.8 Static control.52

10 Recommended test and acceptance criteria .53

10.1 Specific test requirements.53

10.2 Quality assurance.54

10.3 Acceptance.54

11 System management.54

11.1 Maintenance.54

11.2 Training.54

11.3 Documentation.55

12 Case studies.57

12.1 Automation of the Conowingo Hydroelectric Station.57

12.2 Computer-based control system at Waddell Pump-Generating Plant.59

12.3 Retrofit of TrŠngslet Hydro Power Station .63

12.4 Computer-based control system at Wynoochee Hydroelectric Project .68

Bibliography .72

Figure 1 – Relationship of local, centralized, and offsite control .15

Figure 2 – Local control configuration .15

Figure 3 – Computer communication network .28

Figure 4 – Multi-point data link versus LANs .33

Figure 5 – Star topology .35

Figure 6 – Ring topology.35

Figure 7 – Bus topology.36

Figure 8 – Conowingo control system overview.58

Figure 9 – System configuration .61

Figure 10 – Control system configuration.64

Figure 11 – Station control configuration after upgrading .67

Figure 12 – System configuration .69

Figure 13 – Local and remote interface.70

Table 1 – Summary of control hierarchy for hydroelectric power plants.14

Table 2 – Typical parameters necessary to implement automated control.25

Table 3 – Classifications of hydroelectric power plant computer control systems .27

Table 4 – Hydroplant computer control systems data communications attributes .36

Table 5 – Cable media characteristics .37

Table 6 – System performance .66

– 4 – 62270 IEC:2004(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HYDROELECTRIC POWER PLANT AUTOMATION –

GUIDE FOR COMPUTER-BASED CONTROL

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62270 has been prepared by IEC technical committee 4: Hydraulic

turbines.

The text of this standard is based on the IEEE Standard 1249 (1996) IEEE guide for computer-

based control for hydroelectric power plant automation. It was submitted to the national

committees for voting under the Fast Track procedure as the following documents:

FDIS Report on voting

4/188/FDIS 4/190/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

62270 IEC:2004(E) – 5 –

The committee has decided that the contents of this publication will remain unchanged until

2005. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 62270 IEC:2004(E)

INTRODUCTION

Automation of hydroelectric generating plants has been a known technology for many years.

Due to the relative simplicity of the control logic for hydroelectric power plants, the application

of computer-based control has lagged, compared to other types of generating stations, such as

fossil. Now that computer-based control can be implemented for comparable costs as relay-

based logic and can incorporate additional features, it is being applied in hydroelectric power

stations worldwide, both in new installations and in the rehabilitation of older plants.

62270 IEC:2004(E) – 7 –

HYDROELECTRIC POWER PLANT AUTOMATION –

GUIDE FOR COMPUTER-BASED CONTROL

1 Overview

1.1 Scope

This standard sets down guidelines for the application, design concepts, and implementation of

computer-based control systems for hydroelectric plant automation. It addresses functional

capabilities, performance requirements, interface requirements, hardware considerations, and

operator training. It includes recommendations for system testing and acceptance. Finally, case

studies of actual computer-based automatic control applications are presented.

The automation of control and data logging functions has relieved the plant operator of these

tasks, allowing the operator more time to concentrate on other duties. In many cases, the

plant’s operating costs can be significantly reduced by automation (primarily via staff reduction)

while still maintaining a high level of unit control reliability.

Automatic control systems for hydroelectric units based on electromechanical relay logic have

been in general use for a number of years and, in fact, were considered standard practice for

the industry. Within the last decade, microprocessor-based controllers have become available

that are suitable for operation in a power plant environment. These computer-based systems

have been applied for data logging, alarm monitoring, and unit and plant control. Advantages of

computer-based control include use of graphical user interfaces, the incorporation of sequence

of events and trending into the control system, the incorporation of artificial intelligence and

expert system capabilities, and reduced plant life cycle cost.

1.2 Purpose

This standard is directed to the practicing engineer who has some familiarity with computer-

based control systems and who is designing or implementing hydroelectric unit or plant control

systems, either in a new project or as a retrofit to an existing one. This standard assumes that

the control system logic has already been defined; therefore, its development is not covered.

For information on control sequence logic, the reader is directed to the IEEE guides for control

of hydroelectric power plants listed in Clause 2 of this standard.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 61158, Digital data communications for measurement and control - Fieldbus for use in

industrial control systems

ANSI C63.4-2001, Methods of Measurement of Radio-Noise Emissions from Low-Voltage

Electrical and Electronic Equipment in the Range of 9 kHz–40 GHz

IEEE Std 100-1996, The IEEE Standard Dictionary of Electrical and Electronics Terms

___________

ANSI publications are available from the Sales Department, American National Standards Institute, 11 West

42nd Street, 13th Floor, New York, NY 10036, USA.

IEEE publications are available from the Institute of Electrical and Electronics Engineers, 445 Hoes Lane, P.O.

Box 1331, Piscataway, NJ 08855-1331, USA.

– 8 – 62270 IEC:2004(E)

IEEE Std 485-1997, IEEE Recommended Practice for Sizing Lead-Acid Batteries for Stationary

Applications (ANSI)

IEEE Std 610-1990, IEEE Standard Glossary of Software Engineering Terminology (ANSI).

IEEE Std 1010-1987 (Reaffirmed 1992), IEEE Guide for Control of Hydroelectric Power Plants

(ANSI)

IEEE Std 1014-1987 IEEE Standard for A Versatile Backplane Bus: VMEbus

IEEE Std 1020-1988 (Reaffirmed 1994), IEEE Guide for Control of Small Hydroelectric Power

Plants. (ANSI)

IEEE Std 1046-1991 (Reaffirmed 1996), IEEE Guide for Distributed Digital Control and

Monitoring for Power Plants (ANSI)

IEEE Std 1147-1991 (Reaffirmed 1996), IEEE Guide for the Rehabilitation of Hydroelectric

Power Plants (ANSI)

IEEE Std C37.1-1994, IEEE Standard Definition, Specification, and Analysis of Systems Used

for Supervisory Control, Data Acquisition, and Automation Control (ANSI)

IEEE Std C37.90.1-2002, IEEE Standard for Surge Withstand Capability (SWC) Tests for

Protective Relays and Relay Systems (ANSI)

IEEE Std C37.90.2-1995, IEEE Trial Use Standard Withstand Capability of Relay Systems to

Radiated Electromagnetic Interference from Transceivers (ANSI)

IEEE 1379: 2000, IEEE Recommended Practice for Data Communications Between Remote

Terminal Units and Intelligent Electronic Devices in a Substation (ANSI)

ISO/IEC 8802-3:2001, Information technology – Telecommunications and information exchange

between systems – Local and metropolitan area networks – Specific requirements – Part 3:

Carrier sense multiple access with collision detection (CSMA/CD) access method and physical

layer specifications (ANSI/IEEE Std 802.3, 1996 Edition)

ISO/IEC 8802-4:1990 (Reaffirmed 1995), Information processing systems – Local area

networks – Part 4: Token-passing bus access method and physical layer specifications

(ANSI/IEEE 802.4-1990 Edition)

ISO/IEC 8802-5:1998, Information technology –Telecommunications and information exchange

between systems – Local and metropolitan area networks – Specific requirements – Part 5:

Token ring access method and physical layer specifications (ANSI/IEEE Std 802.5, 1995

Edition)

3 Terms and definitions

For the purposes of this document the definitions provided here reflect common industry usage

as related to automation of hydroelectric power plants, and may not in all instances be in

accordance with IEEE Std 100-1996, or IEEE Std 610-1990, or other applicable standards. For

more rigorous definitions, or for definitions not covered herein, the reader is referred to the

appropriate IEEE standards.

___________

ISO publications are available from the ISO Central Secretariat, Case Postale 56, 1 rue de Varembé, CH-1211,

Genève 20, Switzerland/Suisse. ISO publications are also available in the United States from the Sales

Department, American National Standards Institute, 11 West 42nd Street, 13th Floor, New York, NY 10036,

USA.

62270 IEC:2004(E) – 9 –

3.1

analog-to-digital (a/d) conversion

production of a digital output corresponding to the value of an analog input quantity

3.2

automatic control

arrangement of electrical controls that provides for switching or controlling, or both, of

equipment in a specific sequence and under predetermined conditions without operator

intervention

3.3

automatic generation control (AGC)

capability to regulate the power output of selectable units in response to total power plant

output, tie-line power flow, and power system frequency

3.4

automatic voltage control (AVC)

capability to regulate a specific power system voltage, via adjustment of unit excitation within

the limits of unit terminal voltage and VAR capability

3.5

automation hierarchy

design and implementation of automation functions in a multilevel structure, such as local level,

group level, unit level, etc.

3.6

availability

ratio of uptime (system functional) to uptime plus downtime (system not functional)

3.7

backplane

circuit board with connectors or sockets that provides a standardized method of transferring

signals between plug-in circuit cards

3.8

bridge

device that allows two networks of the same or similar technology to communicate

3.9

centralized control

control location one step removed from local control; remote from the equipment or generating

unit, but still within the confines of the plant (e.g. controls located in a plant control room)

3.10

closed loop control

type of automatic control in which control actions are based on signals fed back from the

controlled equipment or system. For example, a plant control system can control the power

output of a multi-unit hydroelectric power plant by monitoring the total plant megawatt value

and, in response, by controlling the turbine governors of each unit, change the plant power

output to meet system needs

3.11

computer-based automation

use of computer components, such as logic controllers, sequence controllers, modulating

controllers, and processors in order to bring plant equipment into operation, optimize operation

in a steady-state condition, and shut down the equipment in the proper sequence under safe

operating conditions

– 10 – 62270 IEC:2004(E)

3.12

control hierarchy

system organization incorporating multiple levels of control responsibility

3.13

control philosophy

total concept on which a power plant control system is based

3.14

data acquisition system

centralized system that receives data from one or more remote points. Data may be

transported in either analog or digital form

3.15

database

collection of stored data regarding the process variables and processing procedures

3.16

data bus

control network technology in which data stations share one single communication system

medium. Messages propagate over the entire medium and are received by all data stations

simultaneously

3.17

device (electrical equipment)

operating element such as a relay, contactor, circuit breaker, switch or valve, used to perform a

given function in the operation of electrical equipment

3.18

digital-to-analog (d/a) conversion

production of an analog signal whose magnitude is proportional to the value of a digital input

3.19

distributed processing

design in which data is processed in multiple processors. Processing functions could be shared

by the processors throughout the control system

3.20

event

discrete change of state (status) of a system or device

3.21

expert system

computer programs that embody judgmental and experimental knowledge about an application.

Expert systems are able to reach decisions from new, uncertain and incomplete information

with a specified degree of certainty. Expert system abilities include: making logical inferences

under unforeseen conditions; using subjective and formal knowledge; explaining the

procedures used to reach a conclusion; growing in effectiveness as embedded expertise is

expanded and modified

3.22

firmware

hardware used for the non-volatile storage of instructions or data that can be read only by the

computer. Stored information is not alterable by any computer program

62270 IEC:2004(E) – 11 –

3.23

gateway

device that allows two networks of differing technology to communicate

3.24

local control

for auxiliary equipment, controls that are located at the equipment itself or within sight of the

equipment. For a generating station, the controls that are located on the unit

switchboard/governor control station

3.25

logic:(control or relay logic)

predetermined sequence of operation of relays and other control devices

3.26

manual control

control in which the system or main device, whether direct or power-aided in operation, is

directly controlled by an operator

3.27

mean-time-between-failure (MTBF)

time interval (hours) that may be expected between failures of an operating equipment

3.28

mean-time-to-repair (MTTR)

time interval (hours) that may be expected to return a failed equipment to proper operation

3.29

modem

modulator/demodulator device that converts serial binary digital data to and from the signal

form appropriate for an analog communication channel

3.30

monitoring

means of providing automatic performance supervision and alarming of the status of the

process to personnel and control programs

3.31

offsite control

controls that are not resident at the plant (e.g. at a switchyard, another plant, etc.)

3.32

open loop control

form of control without feedback

3.33

proportional integral derivative (PID) [control system]

control action in which the output is proportional to a linear combination of the input, the time

integral of input, and the time rate of change of input. Commonly used in hydroelectric

applications for the control of a generator’s real power, reactive power, or flow

3.34

pixel

in image processing, the smallest element of a digital image that can be assigned a gray level

– 12 – 62270 IEC:2004(E)

3.35

programmable logic controller (PLC)

solid state control system with programming capability that performs functions similar to a relay

logic system

3.36

protocol

structured data format required to initiate and maintain communication

3.37

relay, interposing

device that enables the energy in a high-power circuit to be switched by a low-power control

signal

3.38

remote control

control of a device from a distant point

3.39

reliability

characteristic of an item or system expressed by the probability that it will perform a required

mission under stated conditions for a stated mission time

3.40

response time

elapsed time between the moment when a signal is originated in an input device until the

moment the corresponding processed signal is made available to the output device(s), under

defined system loading conditions

3.41

resistance temperature detector (RTD)

resistor for which the electrical resistivity is a known function of the temperature

3.42

scan (interrogation)

process by which a data acquisition system sequentially interrogates remote stations for data at

a specific frequency

3.43

scan cycle

time in seconds required to obtain a collection of data (for example, all data from one

controller, all data from all controllers, and all data of a particular type from all controllers)

3.44

serial communication

method of transmitting information between devices by sending digital data serially over a

single communication channel

3.45

sequential control

mode of control in which the control actions are executed consecutively

3.46

supervisory control and data acquisition (SCADA)

system operating with coded signals over communication channels so as to provide control of

remote equipment and to acquire information about the status of the remote equipment for

display or for recording functions

62270 IEC:2004(E) – 13 –

3.47

user interface

functional system used specifically to interface the computer-based control system to the

operator, maintenance personnel, engineer, etc.

4 Functional capabilities

4.1 General

Computer-based automation has enhanced hydroelectric power plant operation and

maintenance activities. Many activities previously accomplished by plant personnel can now be

performed more accurately, safely, and consistently by computer-based automation systems.

Also, new tasks are within the capabilities of computer-based systems.

Power plant operators have long been responsible for manually performing control and data

acquisition tasks. Relay logic type automatic control systems were, for many years, the only

automated control assistance for operations staff. These systems were limited to unit control

sequencing (start/stop) and were not easily changed, once installed. The quality of data

acquisition has been subject to the limitations of available staff and human error.

Computer-based control and data acquisition systems have made major changes in the way

these tasks are carried out. Power plant operator expertise has been supplemented in many

plants by the computer, which can assist with unit start/stop sequencing and data logging; in

other plants, the computer has replaced the operator altogether by performing these tasks. The

online diagnostic, corrective, and protective capabilities of these computer systems continue to

be developed.

Computer-based automation systems now allow plant owners to operate and maintain their

plants in ways not possible before. Control algorithms based on criteria such as efficiency,

automatic generation control, and voltage control allow more cost effective and safe operation

of plants and interconnected power systems. It is now possible to acquire and process more

data than in the past, so generated reports can keep operators and maintenance staff apprised

of the total plant condition. Maintenance activities are enhanced by the computer’s ability to

isolate problems, describe trends, and keep maintenance records.

Computer-based automation systems also permit operation of the power plant, switchyard, and

outlet works (spillway gates, bypass gates and valves, fishways, fish ladders, etc.) from a

single control point that can be local, centralized, or offsite. This one-point control has many

advantages, including reduced operations staff, consistent operating procedures, and the

capability to have all control and data available for reference during normal and abnormal

conditions.

Subclauses 4.2 - 4.11 outline the functional capabilities of hydroelectric plant computer-based

automation systems.

4.2 Control capabilities

4.2.1 Control hierarchy

A general hierarchy of control for hydroelectric power plants is defined in IEEE Std 1010-1987.

The combination of computer-based and noncomputer-based equipment utilized for unit, plant,

and system control should be arranged in accordance with Table 1.

– 14 – 62270 IEC:2004(E)

Table 1 – Summary of control hierarchy for hydroelectric power plants

Control category Subcategory Remarks

Location Local Control is local at the controlled equipment or within sight of the

equipment.

Centralized Control is remote from the controlled equipment, but within the

plant.

OffSite Control location is remote from the project.

Mode Manual Each operation needs a separate and discrete initiation; could

be applicable to any of the three locations.

Automatic Several operations are precipitated by a single initiation; could

be applicable to any of the three locations.

Operation Attended Operator is available at all times to initiate control action.

(supervision)

Unattended Operation staff is not normally available at the project site.

A decision is required on the extent of functions to be included in the computer-based

equipment. At one extreme, the computer-based equipment may incorporate all aspects of

local, centralized, offsite, manual, and automatic control. At the other extreme, the computer-

based equipment may handle only automatic unit sequences and data acquisition, with all other

functions, such as local manual control, handled by noncomputer-based equipment.

Manual controls are used during testing, and maintenance, and as a backup to the automatic

control equipment. Generally, manual controls are installed adjacent to the devices being

controlled, such as pumps, compressors, valves, and motor control centers. Transfer of control

to higher levels is accomplished by means of local-remote transfer switches installed at the

equipment. Often, capability to operate individual items of equipment is also provided at the

unit switchboard while in the local-manual mode. If this capability is designed to backup the

computer-based equipment, then additional interposing relays and other devices will be

required. Alternately, with the high reliability of modern computer equipment, local-manual

operation from the unit switchboard may be incorporated into the computer controls, thereby

reducing control complexity. In this case, direct manual operation will still be possible at the

equipment location. Further backup control considerations are described in 8.2.

For severe faults that require high-speed tripping of a unit, separate protective equipment is

included in the unit control system. This protective equipment comprises relay-based, solid-

state, or microprocessor-based protection for electrical and mechanical equipment and trip

logic. These high-speed protective functions are generally not incorporated into the computer-

based systems used for control.

Figure 1 illustrates the arrangement of control locations, typical functions at each location, and

typical interchange of control and operating information. Local control, centralized control, and

offsite control functions are described in 4.2.2–4.2.4.

62270 IEC:2004(E) – 15 –

IEC 496/04

Figure 1 – Relationship of local, centralized, and offsite control

4.2.2 Local control

Local control can be provided by equipment located near the generating unit itself. The local

unit computer is part of this equipment and backup manual control may be desired depending

on the operator’s design philosophy. Where there are multiple units in a plant, one computer is

typically allocated to each unit. The local unit computer interfaces to higher level plant or offsite

computers exchanging control signals and data without the need for additional wiring. Figure 2

illustrates the local control configuration.

IEC 497/04

Figure 2 – Local control configuration

– 16 – 62270 IEC:2004(E)

4.2.2.1 Start/stop sequencing

One of the most obvious uses for computer-based automation in power plants is for automating

unit start/stop control sequencing. Older designs that use electromechanical relay-based

start/stop sequential logic are being replaced with modern computer automation systems. The

computer is programmed to completely start or stop the unit when directed by higher level

control or by the operator. The computer system controls the generator’s electrical and

electrical/mechanical auxiliary systems to start or stop the unit. Inputs to the computer are unit

and plant status points that are constantly monitored for change during the sequence. The

computer can continuously monitor and display more status information than an operator can

assimilate so that control actions, such as abort sequences, can be initiated immediately,

without operator reaction time. Because the computer is programmable, modifications to the

sequence control can be made relatively simply, even after the plant is operational. Computer-

based start/stop sequencing is cost-effective, reliable, and easy to maintain, compared to older

electromechanical relay systems. Some owners of hydroelectric plants may not be comfortable

with full computer automation of the start/stop sequencing. In these cases, the start/stop

sequencing can be made more conservative by containing breakpoints in the sequencing to

allow for operator intervention or permissive action.

The computer system can also monitor the control sequence and provide troubleshooting

information identifying where in the sequence a failure occurred. The computer can then pause

in the sequencing to suggest operator intervention or to implement the corrective action. This

diagnostic capability can speed up the process of correcting the problem and returning the unit

to service. Systems with very high-resolution time stamping can provide sequence-of-events

recording that can be used to augment and analyze the protective and control relay actions.

One of the most important features is the automation system’s capability to provide diagnostic

information in the event something fails to operate during the start sequence. This information

can be used to isolate the problem and get the unit online as fast as possible.

Examples of some of the equipment controlled and monitored during the start/stop sequence

are as follows:

a) intake gate or inlet valve;

b) governor hydraulic oil system;

c) gate limit position;

d) gate position;

e) high pressure oil system for the thrust bearing;

f) mechanical brakes;

g) cooling water system;

h) excitation equipment;

i) unit speed;

j) protective relaying status;

k) unit alarms;

l) unit breaker status.

4.2.2.2 Synchronizing

Synchronizing has traditionally been performed either manually or by a dedicated automatic

synchronizer unit. Today, automatic synchronizers use computer technology to optimize their

performance.

62270 IEC:2004(E) – 17 –

In some cases, the synchronizing function is performed by the plant computer-based

automation system. Synchronizing is a critical function that requires accurate and reliable

monitoring of voltage magnitude, frequency, and phase angle. Not all systems can provide the

synchronizing function as part of the computer-based automation system. The advantages of

the synchronizing function being internal to the automation system include less plant wiring,

less maintenance, reduced installation costs, and much better diagnostic capabilities. For

security, a synchrocheck relay is typically used as a permissive for the circuit breaker close.

4.2.2.3 Synchronous condenser mode

Hydroelectric generating units are often used in synchronous condenser mode where real

power output is negative (the unit is running as a motor) while the unit is online and excited.

One reason for this is to provide reactive power control, as described below. Synchronous

condenser mode is generally dispatched according to prevailing power flow conditions, but can

be regulated automatically by the computer-based control system to achieve optimal real and

reactive power capability and maximum transmission utilization.

In cases where a turbine is located below the tailwater level and runs as a synchronous

condenser, the water is expelled from the runner area by compressed air to reduce power

losses and turbine wear and tear. The computer-based automation system can control the

auxiliary devices and monitor the generator during this mode of operation. For example, the

automation system can override the reverse power relay during this mode of operation.

Another purpose of synchronous condenser operation is to provide readily available, real-power

spinning reserve dictated by power system operating requirements. Computer-based control

schemes can be useful in efficiently and automatically performing this mode of operation.

4.2.2.4 Pumped storage control

The computer-based automation system can provide the complete control necessary for a unit

to operate in pumping or generating mode. The system can control the switchgear and related

equipment necessary to run the unit in either mode. Some basic features easy to implement in

a computer-based control system include providing a run time summary of units in the pump

mode, providing an automatic restart timer feature in the event the unit fails to start properly,

and determining which unit should be started to balance the run time between multiple units. All

t

...

IEC 62270 ®

Edition 1.0 2004-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Hydroelectric power plant automation – Guide for computer-based control

Automatisation des centrales hydroélectriques – Lignes directrices pour la

commande informatique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62270 ®

Edition 1.0 2004-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Hydroelectric power plant automation – Guide for computer-based control

Automatisation des centrales hydroélectriques – Lignes directrices pour la

commande informatique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX XB

ICS 27.140 ISBN 978-2-83220-235-7

– 2 – 62270 IEC:2004

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Overview . 7

1.1 Scope . 7

1.2 Purpose . 7

2 Normative references. 7

3 Terms and definitions . 8

4 Functional capabilities . 13

4.1 General . 13

4.2 Control capabilities . 13

4.3 Data acquisition capabilities . 22

4.4 Alarm processing and diagnostics . 23

4.5 Report generation . 24

4.6 Maintenance management interface . 24

4.7 Data archival and retrieval . 24

4.8 Operation scheduling and forecasting . 24

4.9 Data access . 25

4.10 Operator simulation training . 25

4.11 Typical control parameters . 25

5 System architecture, communications, and databases . 26

5.1 General . 26

5.2 System classification . 27

5.3 System architecture characteristics . 28

5.4 Control data networks . 33

5.5 Data bases and software configuration . 37

6 User and plant interfaces . 39

6.1 User interfaces . 39

6.2 Plant interfaces . 40

7 System performance . 43

7.1 General . 43

7.2 Hardware . 44

7.3 Communications . 45

7.4 Measuring performance . 46

8 System backup capabilities . 47

8.1 General . 47

8.2 Design principles . 48

8.3 Basic functions . 48

8.4 Design of equipment for backup control . 48

8.5 Alarm handling . 49

8.6 Protective function . 50

9 Site integration and support systems . 50

9.1 Interface to existing equipment . 50

9.2 Environmental conditions . 50

9.3 Power source . 51

62270 IEC:2004 – 3 –

9.4 Supervision of existing contact status points . 51

9.5 Supervision of existing transducers . 52

9.6 Supervision of existing control output points . 52

9.7 Grounding . 52

9.8 Static control . 52

10 Recommended test and acceptance criteria . 53

10.1 Specific test requirements. 53

10.2 Quality assurance . 54

10.3 Acceptance . 54

11 System management . 54

11.1 Maintenance . 54

11.2 Training . 54

11.3 Documentation . 55

12 Case studies . 57

12.1 Automation of the Conowingo Hydroelectric Station . 57

12.2 Computer-based control system at Waddell Pump-Generating Plant . 59

12.3 Retrofit of TrŠngslet Hydro Power Station . 63

12.4 Computer-based control system at Wynoochee Hydroelectric Project . 68

Bibliography . 72

Figure 1 – Relationship of local, centralized, and offsite control . 15

Figure 2 – Local control configuration . 15

Figure 3 – Computer communication network . 28

Figure 4 – Multi-point data link versus LANs . 33

Figure 5 – Star topology . 35

Figure 6 – Ring topology . 35

Figure 7 – Bus topology . 36

Figure 8 – Conowingo control system overview . 58

Figure 9 – System configuration . 61

Figure 10 – Control system configuration . 64

Figure 11 – Station control configuration after upgrading . 67

Figure 12 – System configuration . 69

Figure 13 – Local and remote interface . 70

Table 1 – Summary of control hierarchy for hydroelectric power plants. 14

Table 2 – Typical parameters necessary to implement automated control . 25

Table 3 – Classifications of hydroelectric power plant computer control systems . 27

Table 4 – Hydroplant computer control systems data communications attributes . 36

Table 5 – Cable media characteristics . 37

Table 6 – System performance . 66

– 4 – 62270 IEC:2004

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HYDROELECTRIC POWER PLANT AUTOMATION –

GUIDE FOR COMPUTER-BASED CONTROL

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62270 has been prepared by IEC technical committee 4: Hydraulic

turbines.

This bilingual version (2012-07) corresponds to the monolingual English version, published in

2004-04.

The text of this standard is based on the IEEE Standard 1249 (1996) IEEE guide for computer-

based control for hydroelectric power plant automation. It was submitted to the national

committees for voting under the Fast Track procedure as the following documents:

FDIS Report on voting

4/188/FDIS 4/190/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

62270 IEC:2004 – 5 –

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

2005. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 62270 IEC:2004

INTRODUCTION

Automation of hydroelectric generating plants has been a known technology for many years.

Due to the relative simplicity of the control logic for hydroelectric power plants, the application

of computer-based control has lagged, compared to other types of generating stations, such as

fossil. Now that computer-based control can be implemented for comparable costs as relay-

based logic and can incorporate additional features, it is being applied in hydroelectric power

stations worldwide, both in new installations and in the rehabilitation of older plants.

62270 IEC:2004 – 7 –

HYDROELECTRIC POWER PLANT AUTOMATION –

GUIDE FOR COMPUTER-BASED CONTROL

1 Overview

1.1 Scope

This standard sets down guidelines for the application, design concepts, and implementation of

computer-based control systems for hydroelectric plant automation. It addresses functional

capabilities, performance requirements, interface requirements, hardware considerations, and

operator training. It includes recommendations for system testing and acceptance. Finally, case

studies of actual computer-based automatic control applications are presented.

The automation of control and data logging functions has relieved the plant operator of these

tasks, allowing the operator more time to concentrate on other duties. In many cases, the

plant’s operating costs can be significantly reduced by automation (primarily via staff reduction)

while still maintaining a high level of unit control reliability.

Automatic control systems for hydroelectric units based on electromechanical relay logic have

been in general use for a number of years and, in fact, were considered standard practice for

the industry. Within the last decade, microprocessor-based controllers have become available

that are suitable for operation in a power plant environment. These computer-based systems

have been applied for data logging, alarm monitoring, and unit and plant control. Advantages of

computer-based control include use of graphical user interfaces, the incorporation of sequence

of events and trending into the control system, the incorporation of artificial intelligence and

expert system capabilities, and reduced plant life cycle cost.

1.2 Purpose

This standard is directed to the practicing engineer who has some familiarity with computer-

based control systems and who is designing or implementing hydroelectric unit or plant control

systems, either in a new project or as a retrofit to an existing one. This standard assumes that

the control system logic has already been defined; therefore, its development is not covered.

For information on control sequence logic, the reader is directed to the IEEE guides for control

of hydroelectric power plants listed in Clause 2 of this standard.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 61158, Digital data communications for measurement and control - Fieldbus for use in

industrial control systems

ANSI C63.4-2001, Methods of Measurement of Radio-Noise Emissions from Low-Voltage

Electrical and Electronic Equipment in the Range of 9 kHz–40 GHz

IEEE Std 100-1996, The IEEE Standard Dictionary of Electrical and Electronics Terms

___________

ANSI publications are available from the Sales Department, American National Standards Institute, 11 West

42nd Street, 13th Floor, New York, NY 10036, USA.

IEEE publications are available from the Institute of Electrical and Electronics Engineers, 445 Hoes Lane, P.O.

Box 1331, Piscataway, NJ 08855-1331, USA.

– 8 – 62270 IEC:2004

IEEE Std 485-1997, IEEE Recommended Practice for Sizing Lead-Acid Batteries for Stationary

Applications (ANSI)

IEEE Std 610-1990, IEEE Standard Glossary of Software Engineering Terminology (ANSI)

IEEE Std 1010-1987 (Reaffirmed 1992), IEEE Guide for Control of Hydroelectric Power Plants

(ANSI)

IEEE Std 1014-1987 IEEE Standard for A Versatile Backplane Bus: VMEbus

IEEE Std 1020-1988 (Reaffirmed 1994), IEEE Guide for Control of Small Hydroelectric Power

Plants. (ANSI)

IEEE Std 1046-1991 (Reaffirmed 1996), IEEE Guide for Distributed Digital Control and

Monitoring for Power Plants (ANSI)

IEEE Std 1147-1991 (Reaffirmed 1996), IEEE Guide for the Rehabilitation of Hydroelectric

Power Plants (ANSI)

IEEE Std C37.1-1994, IEEE Standard Definition, Specification, and Analysis of Systems Used

for Supervisory Control, Data Acquisition, and Automation Control (ANSI)

IEEE Std C37.90.1-2002, IEEE Standard for Surge Withstand Capability (SWC) Tests for

Protective Relays and Relay Systems (ANSI)

IEEE Std C37.90.2-1995, IEEE Trial Use Standard Withstand Capability of Relay Systems to

Radiated Electromagnetic Interference from Transceivers (ANSI)

IEEE 1379: 2000, IEEE Recommended Practice for Data Communications Between Remote

Terminal Units and Intelligent Electronic Devices in a Substation (ANSI)

ISO/IEC 8802-3:2001, Information technology – Telecommunications and information exchange

between systems – Local and metropolitan area networks – Specific requirements – Part 3:

Carrier sense multiple access with collision detection (CSMA/CD) access method and physical

layer specifications (ANSI/IEEE Std 802.3, 1996 Edition)

ISO/IEC 8802-4:1990 (Reaffirmed 1995), Information processing systems – Local area

networks – Part 4: Token-passing bus access method and physical layer specifications

(ANSI/IEEE 802.4-1990 Edition)

ISO/IEC 8802-5:1998, Information technology –Telecommunications and information exchange

between systems – Local and metropolitan area networks – Specific requirements – Part 5:

Token ring access method and physical layer specifications (ANSI/IEEE Std 802.5, 1995

Edition)

3 Terms and definitions

For the purposes of this document the definitions provided here reflect common industry usage

as related to automation of hydroelectric power plants, and may not in all instances be in

accordance with IEEE Std 100-1996, or IEEE Std 610-1990, or other applicable standards. For

more rigorous definitions, or for definitions not covered herein, the reader is referred to the

appropriate IEEE standards.

___________

ISO publications are available from the ISO Central Secretariat, Case Postale 56, 1 rue de Varembé, CH-1211,

Genève 20, Switzerland/Suisse. ISO publications are also available in the United States from the Sales

Department, American National Standards Institute, 11 West 42nd Street, 13th Floor, New York, NY 10036,

USA.

62270 IEC:2004 – 9 –

3.1

analog-to-digital (a/d) conversion

production of a digital output corresponding to the value of an analog input quantity

3.2

automatic control

arrangement of electrical controls that provides for switching or controlling, or both, of

equipment in a specific sequence and under predetermined conditions without operator

intervention

3.3

automatic generation control (AGC)

capability to regulate the power output of selectable units in response to total power plant

output, tie-line power flow, and power system frequency

3.4

automatic voltage control (AVC)

capability to regulate a specific power system voltage, via adjustment of unit excitation within

the limits of unit terminal voltage and VAR capability

3.5

automation hierarchy

design and implementation of automation functions in a multilevel structure, such as local level,

group level, unit level, etc.

3.6

availability

ratio of uptime (system functional) to uptime plus downtime (system not functional)

3.7

backplane

circuit board with connectors or sockets that provides a standardized method of transferring

signals between plug-in circuit cards

3.8

bridge

device that allows two networks of the same or similar technology to communicate

3.9

centralized control

control location one step removed from local control; remote from the equipment or generating

unit, but still within the confines of the plant (e.g. controls located in a plant control room)

3.10

closed loop control

type of automatic control in which control actions are based on signals fed back from the

controlled equipment or system. For example, a plant control system can control the power

output of a multi-unit hydroelectric power plant by monitoring the total plant megawatt value

and, in response, by controlling the turbine governors of each unit, change the plant power

output to meet system needs

3.11

computer-based automation

use of computer components, such as logic controllers, sequence controllers, modulating

controllers, and processors in order to bring plant equipment into operation, optimize operation

in a steady-state condition, and shut down the equipment in the proper sequence under safe

operating conditions

– 10 – 62270 IEC:2004

3.12

control hierarchy

system organization incorporating multiple levels of control responsibility

3.13

control philosophy

total concept on which a power plant control system is based

3.14

data acquisition system

centralized system that receives data from one or more remote points. Data may be

transported in either analog or digital form

3.15

database

collection of stored data regarding the process variables and processing procedures

3.16

data bus

control network technology in which data stations share one single communication system

medium. Messages propagate over the entire medium and are received by all data stations

simultaneously

3.17

device (electrical equipment)

operating element such as a relay, contactor, circuit breaker, switch or valve, used to perform a

given function in the operation of electrical equipment

3.18

digital-to-analog (d/a) conversion

production of an analog signal whose magnitude is proportional to the value of a digital input

3.19

distributed processing

design in which data is processed in multiple processors. Processing functions could be shared

by the processors throughout the control system

3.20

event

discrete change of state (status) of a system or device

3.21

expert system

computer programs that embody judgmental and experimental knowledge about an application.

Expert systems are able to reach decisions from new, uncertain and incomplete information

with a specified degree of certainty. Expert system abilities include: making logical inferences

under unforeseen conditions; using subjective and formal knowledge; explaining the

procedures used to reach a conclusion; growing in effectiveness as embedded expertise is

expanded and modified

3.22

firmware

hardware used for the non-volatile storage of instructions or data that can be read only by the

computer. Stored information is not alterable by any computer program

62270 IEC:2004 – 11 –

3.23

gateway

device that allows two networks of differing technology to communicate

3.24

local control

for auxiliary equipment, controls that are located at the equipment itself or within sight of the

equipment. For a generating station, the controls that are located on the unit

switchboard/governor control station

3.25

logic:(control or relay logic)

predetermined sequence of operation of relays and other control devices

3.26

manual control

control in which the system or main device, whether direct or power-aided in operation, is

directly controlled by an operator

3.27

mean-time-between-failure (MTBF)

time interval (hours) that may be expected between failures of an operating equipment

3.28

mean-time-to-repair (MTTR)

time interval (hours) that may be expected to return a failed equipment to proper operation

3.29

modem

modulator/demodulator device that converts serial binary digital data to and from the signal

form appropriate for an analog communication channel

3.30

monitoring

means of providing automatic performance supervision and alarming of the status of the

process to personnel and control programs

3.31

offsite control

controls that are not resident at the plant (e.g. at a switchyard, another plant, etc.)

3.32

open loop control

form of control without feedback

3.33

proportional integral derivative (PID) [control system]

control action in which the output is proportional to a linear combination of the input, the time

integral of input, and the time rate of change of input. Commonly used in hydroelectric

applications for the control of a generator’s real power, reactive power, or flow

3.34

pixel

in image processing, the smallest element of a digital image that can be assigned a gray level

– 12 – 62270 IEC:2004

3.35

programmable logic controller (PLC)

solid state control system with programming capability that performs functions similar to a relay

logic system

3.36

protocol

structured data format required to initiate and maintain communication

3.37

relay, interposing

device that enables the energy in a high-power circuit to be switched by a low-power control

signal

3.38

remote control

control of a device from a distant point

3.39

reliability

characteristic of an item or system expressed by the probability that it will perform a required

mission under stated conditions for a stated mission time

3.40

response time

elapsed time between the moment when a signal is originated in an input device until the

moment the corresponding processed signal is made available to the output device(s), under

defined system loading conditions

3.41

resistance temperature detector (RTD)

resistor for which the electrical resistivity is a known function of the temperature

3.42

scan (interrogation)

process by which a data acquisition system sequentially interrogates remote stations for data

at a specific frequency

3.43

scan cycle

time in seconds required to obtain a collection of data (for example, all data from one

controller, all data from all controllers, and all data of a particular type from all controllers)

3.44

serial communication

method of transmitting information between devices by sending digital data serially over a

single communication channel

3.45

sequential control

mode of control in which the control actions are executed consecutively

3.46

supervisory control and data acquisition (SCADA)

system operating with coded signals over communication channels so as to provide control of

remote equipment and to acquire information about the status of the remote equipment for

display or for recording functions

62270 IEC:2004 – 13 –

3.47

user interface

functional system used specifically to interface the computer-based control system to the

operator, maintenance personnel, engineer, etc.

4 Functional capabilities

4.1 General

Computer-based automation has enhanced hydroelectric power plant operation and

maintenance activities. Many activities previously accomplished by plant personnel can now be

performed more accurately, safely, and consistently by computer-based automation systems.

Also, new tasks are within the capabilities of computer-based systems.

Power plant operators have long been responsible for manually performing control and data

acquisition tasks. Relay logic type automatic control systems were, for many years, the only

automated control assistance for operations staff. These systems were limited to unit control

sequencing (start/stop) and were not easily changed, once installed. The quality of data

acquisition has been subject to the limitations of available staff and human error.

Computer-based control and data acquisition systems have made major changes in the way

these tasks are carried out. Power plant operator expertise has been supplemented in many

plants by the computer, which can assist with unit start/stop sequencing and data logging; in

other plants, the computer has replaced the operator altogether by performing these tasks. The

online diagnostic, corrective, and protective capabilities of these computer systems continue to

be developed.

Computer-based automation systems now allow plant owners to operate and maintain their

plants in ways not possible before. Control algorithms based on criteria such as efficiency,

automatic generation control, and voltage control allow more cost effective and safe operation

of plants and interconnected power systems. It is now possible to acquire and process more

data than in the past, so generated reports can keep operators and maintenance staff apprised

of the total plant condition. Maintenance activities are enhanced by the computer’s ability to

isolate problems, describe trends, and keep maintenance records.

Computer-based automation systems also permit operation of the power plant, switchyard, and

outlet works (spillway gates, bypass gates and valves, fishways, fish ladders, etc.) from a

single control point that can be local, centralized, or offsite. This one-point control has many

advantages, including reduced operations staff, consistent operating procedures, and the

capability to have all control and data available for reference during normal and abnormal

conditions.

Subclauses 4.2 - 4.11 outline the functional capabilities of hydroelectric plant computer-based

automation systems.

4.2 Control capabilities

4.2.1 Control hierarchy

A general hierarchy of control for hydroelectric power plants is defined in IEEE Std 1010-1987.