IEC 60079-19:2006

(Main)Explosive atmospheres - Part 19: Equipment repair, overhaul and reclamation

Explosive atmospheres - Part 19: Equipment repair, overhaul and reclamation

This part of IEC 60079 gives instructions, principally of a technical nature, on the repair, overhaul, reclamation and modification of a certified equipment designed for use in explosive atmospheres; it is not applicable to maintenance, other than when repair and overhaul cannot be disassociated from maintenance, neither does it give advice on cable entry systems which may require renewal when the equipment is re-installed.

Atmosphères explosives - Partie 19: Réparation, révision et remise en état du matériel

La présente partie de la CEI 60079 donne des instructions, principalement de nature technique, pour la réparation, la révision, la remise en état et la modification du matériel certifié conçu pour être utilisé en atmosphères explosives; il n'est pas applicable à l'entretien sauf lorsque la réparation et la révision ne peuvent être dissociées de l'entretien, pas plus qu'elle ne donne un conseil sur les systèmes d'entrées de câbles qui peuvent exiger un renouvellement quand le matériel est ré-installé.

General Information

- Status

- Published

- Publication Date

- 26-Oct-2006

- Technical Committee

- SC 31J - Classification of hazardous areas and installation requirements

- Drafting Committee

- MT 60079-19 - TC 31/SC 31J/MT 60079-19

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 29-Nov-2010

- Completion Date

- 13-Feb-2026

Relations

- Revised

IEC 60079-19:2010 - Explosive atmospheres - Part 19: Equipment repair, overhaul and reclamation - Effective Date

- 05-Sep-2023

Overview

IEC 60079-19:2006 is an international standard published by the International Electrotechnical Commission (IEC) that provides comprehensive technical guidance on the repair, overhaul, reclamation, and modification of certified electrical equipment designed for use in explosive atmospheres. This standard addresses safety-critical practices for maintaining equipment that operates in hazardous environments containing flammable gases, vapors, mists, or combustible dusts. It ensures that repaired or overhauled equipment continues to comply with original certification and safety requirements essential for preventing explosions.

Key to the IEC 60079 series, this part focuses specifically on maintaining electrical equipment’s explosion protection integrity after repair or overhaul. It does not cover routine maintenance unrelated to repair or overhaul processes, nor does it give instructions on cable entry systems renewal. The standard is vital for organizations involved in servicing explosion-protected equipment to uphold high safety standards and regulatory compliance.

Key Topics

Scope and General Principles

The standard outlines general requirements for repair and overhaul processes ensuring that the explosion protection characteristics of electrical equipment are preserved after service. It emphasizes technical measures and statutory requirements, along with clear instructions for both users and repair facilities.Types of Protection Covered

IEC 60079-19 details additional specific repair and overhaul provisions according to various explosion protection types, including:- Flameproof (“d”)

- Intrinsic Safety (“i”)

- Pressurization (“p”)

- Increased Safety (“e”)

- Non-sparking (“n”)

- Type “tD” for combustible dust protection

- Pressurization for dust “pD”

The standard ensures each protection method retains its safety integrity post-repair.

Competency and Responsibilities

The document defines necessary knowledge, skills, and competencies for “Responsible Persons” and “Operatives” involved in repair operations, reflecting the importance of qualified personnel in maintaining equipment safety.Measurement and Testing Procedures

It includes detailed requirements and guidelines for conducting measurements on flameproof equipment during overhaul and reclamation phases, ensuring tolerances and clearances meet explosion protection criteria.Equipment Identification

Normative annexes provide instructions on marking repaired equipment, facilitating traceability and compliance verification following repair or modification.

Applications

IEC 60079-19:2006 is essential for industries where electrical equipment operates in explosive atmospheres, such as:

- Oil and gas extraction and refining

- Chemical and petrochemical plants

- Mining operations

- Pharmaceutical manufacturing

- Grain handling and processing facilities

- Any hazardous area installations requiring explosion-proof electrical systems

The standard helps repair organizations and maintenance teams:

- Rebuild and restore certified explosion-protected equipment to original safety standards

- Safeguard personnel and assets by preventing ignition sources in hazardous areas

- Comply with international and national safety regulations for explosive atmospheres

- Extend the lifecycle of expensive explosion-protected equipment through proper overhaul and reclamation

Related Standards

IEC 60079-19 is part of the broader IEC 60079 series addressing explosive atmospheres. Other closely related standards include:

- IEC 60079-0: General requirements for explosion-protected electrical equipment

- IEC 60079-1: Requirements for flameproof enclosures (“d”)

- IEC 60079-11: Requirements for intrinsic safety (“i”)

- IEC 60079-7: Increased safety (“e”)

- IEC 60079-26: Equipment with optical radiation protection

- IEC 60364: Electrical installations in buildings, including those in hazardous locations

These standards collectively guide design, installation, repair, and maintenance of explosion-protected systems, ensuring safety and reliability throughout the equipment lifecycle.

IEC 60079-19:2006 remains a critical reference for engineers, maintenance experts, certification bodies, and safety managers involved in the upkeep of electrical equipment in hazardous environments. Adhering to this standard helps maintain safety, ensures regulatory compliance, and supports operational continuity in explosive atmospheres.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60079-19:2006 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Explosive atmospheres - Part 19: Equipment repair, overhaul and reclamation". This standard covers: This part of IEC 60079 gives instructions, principally of a technical nature, on the repair, overhaul, reclamation and modification of a certified equipment designed for use in explosive atmospheres; it is not applicable to maintenance, other than when repair and overhaul cannot be disassociated from maintenance, neither does it give advice on cable entry systems which may require renewal when the equipment is re-installed.

This part of IEC 60079 gives instructions, principally of a technical nature, on the repair, overhaul, reclamation and modification of a certified equipment designed for use in explosive atmospheres; it is not applicable to maintenance, other than when repair and overhaul cannot be disassociated from maintenance, neither does it give advice on cable entry systems which may require renewal when the equipment is re-installed.

IEC 60079-19:2006 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60079-19:2006 has the following relationships with other standards: It is inter standard links to IEC 60079-19:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60079-19:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60079-19

Edition 2.0 2006-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 19: Equipment repair, overhaul and reclamation

Atmosphères explosives –

Partie 19: Réparation, révision et remise en état du matériel

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60079-19

Edition 2.0 2006-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 19: Equipment repair, overhaul and reclamation

Atmosphères explosives –

Partie 19: Réparation, révision et remise en état du matériel

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XA

CODE PRIX

ICS 29.260.20 ISBN 2-8318-8858-1

60079-19 © IEC:2006 –– 2 – 3 – 60079-19 © IEC:2006

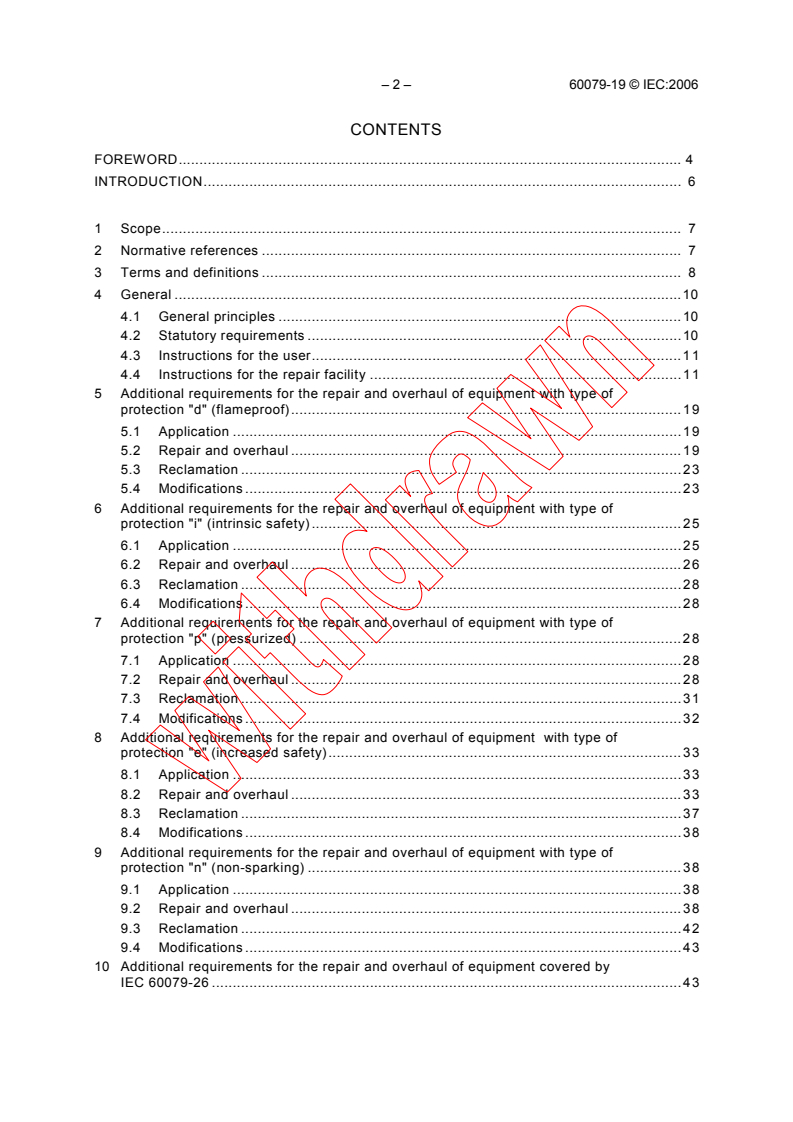

CONTENTS

FOREWORD. 4

INTRODUCTION. 6

1 Scope. 7

2 Normative references . 7

3 Terms and definitions . 8

4 General .10

4.1 General principles .10

4.2 Statutory requirements .10

4.3 Instructions for the user.11

4.4 Instructions for the repair facility .11

5 Additional requirements for the repair and overhaul of equipment with type of

protection "d" (flameproof).19

5.1 Application .19

5.2 Repair and overhaul .19

5.3 Reclamation .23

5.4 Modifications .23

6 Additional requirements for the repair and overhaul of equipment with type of

protection "i" (intrinsic safety) .25

6.1 Application .25

6.2 Repair and overhaul .26

6.3 Reclamation .28

6.4 Modifications .28

7 Additional requirements for the repair and overhaul of equipment with type of

protection "p" (pressurized) .28

7.1 Application .28

7.2 Repair and overhaul .28

7.3 Reclamation .31

7.4 Modifications .32

8 Additional requirements for the repair and overhaul of equipment with type of

protection "e" (increased safety).33

8.1 Application .33

8.2 Repair and overhaul .33

8.3 Reclamation .37

8.4 Modifications .38

9 Additional requirements for the repair and overhaul of equipment with type of

protection "n" (non-sparking) .38

9.1 Application .38

9.2 Repair and overhaul .38

9.3 Reclamation .42

9.4 Modifications .43

10 Additional requirements for the repair and overhaul of equipment covered by

IEC 60079-26 .43

60079-19 © IEC:200660079-19 © IEC:2006 –– 3 – 5 –

11 Additional requirements for the repair and overhaul of equipment with type of

protection ‘tD’ .43

11.1 Application .43

11.2 Repair and overhaul .44

11.3 Reclamation .46

11.4 Modifications .47

12 Additional requirements for the repair and overhaul of equipment with type of

protection pressurization “pD”.48

12.1 Application .48

12.2 Repair and overhaul .48

12.3 Reclamation .48

12.4 Modifications .48

Annex A (normative) Identification of repaired equipment by marking .49

Annex B (normative) Knowledge, skills and competencies of “Responsible Persons”

and “Operatives” . 51

Annex C (normative) Requirements for measurements in flameproof equipment during

overhaul, repair and reclamation (including guidance on tolerances). 53

Figure C.1 – Determination of maximum gap of reclaimed parts. 55

Table C.1 – Determination of maximum gap of reclaimed parts . 54

– 4 – 60079-19 © IEC:2006

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHERES –

Part 19: Equipment repair, overhaul and reclamation

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60079-19 has been prepared by subcommittee 31J: Classification

of hazardous areas and installation requirements, of IEC technical committee 31: Equipment

for explosive atmospheres.

This second edition cancels and replaces the first edition published in 1993 and constitutes a

technical revision.

The significant technical changes with respect to the previous edition are as follows:

• additional requirements for repair and overhaul of equipment covered by IEC 60079-26

are included;

• additional requirements for repair and overhaul of equipment with type of protection 'tD'

and 'pD' for combustible dusts are included;

60079-19 © IEC:200660079-19 © IEC:2006 –– 5 – 9 –

• knowlege, skills and competencies of "Responsible Persons" and "Operatives" are

explained;

• requirements for measurements in flameproof equipment during overhaul, repair and

reclamation (including guidance on tolerances) are added.

The text of this standard is based on the following documents:

FDIS Report on voting

31J/124/FDIS 31J/135/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 60079 series, under the general title Explosive atmospheres, can

be found on the the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

60079-19 © IEC:2006 –– 6 – 11 – 60079-19 © IEC:2006

INTRODUCTION

When electrical equipment is installed in areas where dangerous concentrations and

quantities of flammable gases, vapours, mists or dusts may be present in the atmosphere,

protective measures are to be applied to reduce the likelihood of explosion due to ignition by

arcs, sparks or hot surfaces produced either in normal operation or under specified fault

conditions.

This part of IEC 60079 is supplementary to other relevant IEC standards, for example

IEC 60364, as regards installation requirements, and also refers to IEC 60079 and its

appropriate parts for the design requirements of suitable electrical equipment.

Clause 4 of this part of IEC 60079 contains general requirements for the repair and overhaul

of equipment and should be read in conjunction with the other relevant clauses of this

standard dealing with the detailed requirements for individual types of protection.

In cases where protected equipment incorporates more than one type of protection, reference

should be made to all clauses involved.

This part not only gives guidance on the practical means of maintaining the electrical safety

and performance requirements of repaired equipment, but also defines procedures for

maintaining, after repair, overhaul or reclamation, compliance of the equipment with the

provisions of the certificate of conformity or with the provisions of the appropriate explosion

protection standard where a certificate is not available.

The nature of the explosion protection offered by each type of protection varies according to

its unique features. Reference should be made to the appropriate standard(s) for details.

Users will utilize the most appropriate repair facilities for any particular item of equipment,

whether they be the facilities of the manufacturer or a suitably competent and equipped

repairer (see note).

This part recognizes the necessity of a required level of competence for the repair, overhaul

and reclamation of the equipment. Some manufacturers may recommend that the equipment

be repaired only by them.

In the case of the repair, overhaul or reclamation of equipment which has been the subject of

design certification, it may be necessary to clarify the position of the continued conformity of

the equipment with the certificate.

NOTE Whilst some manufacturers recommend that certain equipment be returned to them for repair or

reclamation, there are also competent independent repair organizations who have the facilities to carry out repair

work on equipment employing some or all of the types of protection covered by IEC 60079. For repaired equipment

to retain the integrity of the type(s) of protection employed in its design and construction, detailed knowledge of the

original manufacturer’s design (which may only be obtainable from design and manufacturing drawings) and any

certification documentation may be necessary. Where equipment is not being returned to the original manufacturer

for repair or reclamation, the use of repair organizations that are recommended by the original manufacturer should

be considered.

60079-19 © IEC:200660079-19 © IEC:2006 –– 7 – 13 –

EXPLOSIVE ATMOSPHERES –

Part 19: Equipment repair, overhaul and reclamation

1 Scope

This part of IEC 60079

– gives instructions, principally of a technical nature, on the repair, overhaul, reclamation

and modification of a certified equipment designed for use in explosive atmospheres;

– is not applicable to maintenance, other than when repair and overhaul cannot be

disassociated from maintenance, neither does it give advice on cable entry systems which

may require renewal when the equipment is re-installed;

– is not applicable to type of protection 'm';

– assumes that good engineering practices are adopted throughout.

NOTE Much of the content of this standard is concerned with the repair and overhaul of electrical rotating

machines. This is not because they are the most important items of explosion-protected equipment but rather

because they are often major items of repairable capital equipment in which, whatever type of protection is

involved, sufficient commonality of construction exists as to make possible more detailed instructions for their

repair, overhaul, reclamation or modification.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60079 (all parts), Explosive atmospheres

IEC 60085, Electrical insulation – Thermal classification

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 61241-0, Electrical apparatus for use in the presence of combustible dust – Part 0:

General requirements

IEC 61241-2, Electrical apparatus for use in the presence of combustible dust – Part 2: Test

methods

ISO 4526, Metallic coatings – Electroplated coatings of nickel for engineering purposes

ISO 6158, Metallic coatings – Electrodeposited coatings of chromium for engineering

purposes

ISO 9000, Quality management and systems – Fundamentals and vocabulary

60079-19 © IEC:2006 –– 8 – 15 – 60079-19 © IEC:2006

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

serviceable condition

condition which permits a replacement or reclaimed component part to be used without

prejudice to the performance or explosion protection aspects of the equipment, with due

regard to the certification requirements as applicable, in which such a component part is used

3.2

repair

action to restore faulty equipment to its fully serviceable condition and in compliance with the

relevant standard

NOTE The relevant standard means the standard to which the equipment was originally designed.

3.3

overhaul

action to restore to a fully serviceable condition equipment which has been in use or in

storage for a period of time but which is not faulty

3.4

maintenance

routine actions taken to preserve the fully serviceable condition of the installed equipment

(see Clause 1)

3.5

component part

an indivisible item

NOTE The assembly of such items may form equipment.

3.6

reclamation

means of repair involving, for example, the removal or addition of material to reclaim

component parts which have sustained damage, in order to restore such parts to a

serviceable condition in accordance with the relevant standard

NOTE The relevant standard means the standard to which the individual parts were originally manufactured.

3.7

modification

change to the design of the equipment which affects material, fit, form or function

3.8

manufacturer

maker of the equipment (who may also be the supplier, the importer or the agent) in whose

name usually the certification, where appropriate, of the equipment was originally registered

3.9

user

user of the equipment

60079-19 © IEC:200660079-19 © IEC:2006 –– 9 – 17 –

3.10

repair facility

facility providing a service that consists of repairs, overhauls, or reclamations of explosion-

protected equipment who may be the manufacturer, the user or a third party (repair agency)

3.11

certification

certification leading to the issue of a certificate of conformity which refers primarily to

assessments of equipment carried out by a recognized testing authority.

This standard may also apply to equipment certified by other certification authorities, or to

equipment which has been self-certified by manufacturers or users as complying with

recognized standards.

3.12

certificate references

a certificate reference number may refer to a single design or a range of equipment of similar

design

3.13

symbol "X"

the symbol "X" is used to denote special conditions of safe use. The certification documents

need to be studied before such equipment is installed, repaired, overhauled, reclaimed or

modified.

3.14

copy winding

process by which a winding is totally or partially replaced by another, the characteristics and

properties of which are at least as good as those of the original

3.15

type of protection "d"

type of protection in which parts which can ignite an explosive atmosphere are placed in an

enclosure which can withstand the pressure developed during an explosion of an explosive

mixture and which prevents the transmission of the explosion to the explosive atmosphere

surrounding the enclosure

3.16

type of protection "i"

circuit in which no spark or any thermal effect produced in the test conditions prescribed in

the relevant standard(s) (which include normal operation and specific fault condition) is

capable of causing ignition of a given explosive atmosphere.

3.17

type of protection "p"

type of protection by which the entry of a surrounding atmosphere into the enclosure of the

electrical equipment is prevented by maintaining, inside the said enclosure, a protective gas

at a higher pressure than that of the surrounding atmosphere. The overpressure is maintained

either with or without a continuous flow of the protective gas.

3.18

type of protection "e"

type of protection by which measures are applied so as to prevent, with a higher degree of

security, the possibility of excessive temperatures and the occurrence of arcs or sparks in the

interior and on the external parts of the electrical equipment which would not produce them in

normal service

60079-19 © IEC:2006 –– 10 – 19 – 60079-19 © IEC:2006

3.19

type of protection "n"

type of protection applied to the electrical equipment such that, in normal operation, it is not

capable of igniting the surrounding explosive atmosphere and that a fault capable of causing

ignition is not likely to occur

3.20

type of protection “tD”

type of protection for explosive dust atmospheres where electrical equipment is provided with

an enclosure providing dust ingress protection and a means to limit surface temperatures

3.21

type of protection “pD”

type of protection reliant upon the enclosure being subjected to a continuous pressure,

according to IEC 61241-2, from a supply of uncontaminated air or other non-flammable gas

while electricity is connected to the enclosure

4 General

4.1 General principles

This clause covers those aspects of repair, overhaul, reclamation and modification which are

common to all explosion-protected equipment. Subsequent clauses provide instructions for

the additional requirements relevant to specific types of protection. When equipment

incorporates more than one type of protection, reference shall be made to the appropriate

clauses.

NOTE 1 Additional requirements for types of protection "o" and "q" have not been defined.

Assuming that repairs and overhauls are carried out using good engineering practices, then

a) if manufacturers' specified parts or parts as specified in the certification documentation

are used in a repair or overhaul, the equipment is presumed to be in conformity with the

certificate;

b) if repairs or modifications are carried out on the equipment specifically as detailed in the

certification documents, the equipment should still conform with the certificate.

In circumstances where the certification documents are not available, then the repair or

overhaul shall be carried out on the equipment in accordance with this standard and other

relevant standard(s). The steps taken to obtain the certification documents shall be recorded

in the repair facility records (see 4.4.1.5.3).

If other repair or modification techniques are used which are not in accordance with this

standard, then it will be necessary to ascertain, from the manufacturers, and/or the

certification authority, the suitability of the equipment for continued use in an explosive

atmosphere.

NOTE 2 Repair of equipment which has no marking plate should be avoided.

4.2 Statutory requirements

4.2.1 Repair facility

The repair facility shall be aware of any specific requirements in relevant national legislation

which may govern the repair or overhaul operation.

60079-19 © IEC:200660079-19 © IEC:2006 –– 11 – 21 –

4.2.2 User

The equipment user should be aware of any relevant legislation should he wish to undertake

the repair or overhaul of equipment himself. In addition, he should be aware of any changes in

responsibility for health and safety, should refurbishment and/or re-installation be carried out

by a third party.

4.3 Instructions for the user

4.3.1 Certificates and documents

The equipment design certificate and other related documents (see 4.4.1.5.1) should be

obtained as part of the original purchase contract.

4.3.2 Records and work instructions

All relevant documentation that is available shall be obtained as part of the original purchase

contract. Records of any previous repairs, overhauls or modifications shall be kept by the user

and made available to the repairer.

NOTE It will be in the interests of the user that the repairer is notified, whenever possible, of the fault and/or

nature of the work to be done.

Special requirements stipulated in the user's specifications, and which are supplementary to

the various standards, e.g. enhanced ingress protection, shall be brought to the attention of

the repairer.

The user shall inform the repairer of any statutory requirement for compliance with

certification (see note in the introduction).

4.3.3 Re-installation of repaired equipment

Before the repaired equipment is re-commissioned, cable/conduit entry systems shall be

checked to ensure that they are undamaged and are appropriate to the equipment type of

protection. Recommendations may be found in the wiring systems clause of IEC 60079-14.

4.3.4 Repair facilities

The user shall ascertain that the repair facility concerned can demonstrate compliance with

the relevant stipulations of this standard.

4.4 Instructions for the repair facility

4.4.1 Repair and overhaul

4.4.1.1 General

Repair facilities shall operate a Quality Management System that meets with the requirements

of the ISO 9000 series of standards.

The repair facility shall appoint a person ('Responsible Person') with the required competency

(see Annex B), within the management organization, to accept responsibility and authority for

ensuring that the overhauled/repaired equipment complies with the certification status agreed

with the user. The person so appointed shall have a working knowledge of the appropriate

explosion protection standards and an understanding of this standard.

60079-19 © IEC:2006 –– 12 – 23 – 60079-19 © IEC:2006

The repair facility must have adequate repair and overhaul facilities as well as the appropriate

equipment necessary and trained Operatives with the required competency (see Annex B)

and authority to carry out the activities, taking into account the specific type of protection.

The repair facility shall conduct an assessment of the status of the equipment to be repaired,

agree with the user the expected certification status of the equipment after repair and the

scope of work to be done. This should include the omission of any tests mentioned within this

document that the user could reasonably assume to be included. The assessment shall be

documented and shall address the relevant clauses of the appropriate equipment standard

and this standard and be included in the job report to the user. Such assessments shall be

conducted by the Responsible Person (supported by appropriate Operatives). The

Responsible Person shall only conduct assessments with the explosion protection techniques

for which he has demonstrated his competence.

The repair facility shall include procedures and systems to carry out overhaul/repair work at

sites external to the repair facility, where appropriate.

4.4.1.2 Certification and standards

The repairer’s attention is directed to the need to be informed of, and to comply with, the

relevant explosion-protection standards and certification requirements applicable to the

equipment to be repaired or overhauled.

4.4.1.3 Competency

The repairer of the equipment shall ensure that those operatives directly concerned with the

repair and/or overhaul of the certified equipment are trained, experienced, skilled,

knowledgeable and/or supervised on this type of work.

Training and competency assessments are specified in Annex B.

Appropriate training and assessment shall be undertaken from time to time at intervals

depending on the frequency of utilization of the technique or skill and change of standards or

regulations. The interval should normally not exceed three years.

4.4.1.4 Testing

Should it prove impracticable to carry out certain tests, e.g., a component of a complete

equipment taken off site for repair such as a rotor of a rotating machine, the repairer shall,

before putting the repaired equipment back into service, ascertain from the user or

manufacturer the consequences of omitting such tests.

NOTE In some countries, legal consequences may depend upon the extent to which the carrying out or not of

certain actions or tests is practicable.

4.4.1.5 Documentation

4.4.1.5.1 General

The repair facility should seek to obtain all necessary information/data from the manufacturer

or user for the repair and/or overhaul of the equipment. This may include information relating

to previous repairs, overhauls or modifications. He should also have available and refer to the

relevant explosion-protection standard.

60079-19 © IEC:200660079-19 © IEC:2006 –– 13 – 25 –

The data available for the repair and/or overhaul should include but need not be limited to,

details of the

– technical specification;

– drawings;

– explosion protection performance and conditions of use;

– dismantling and assembly instructions;

– certificate limitations (special conditions for safe use), where specified;

– marking (including certification marking);

– recommended methods of repair/overhaul for the equipment;

– list of spare parts.

The information may be subject to amendments including those relative to certification.

NOTE 1 It is not reasonably practicable to assume that adequate information is, or can be, so widely circulated

that it is always available where and when it is needed. Sources of adequate information are users, manufacturers

or certifying authorities.

NOTE 2 As from IEC 60079-0 (Edition 4), manufacturers are required to give instructions including repair.

The repair facility shall maintain controlled copies of any relevant explosion protection

standards with which repaired/overhauled equipment is claimed to comply.

4.4.1.5.2 Job report to the user

At the completion of the work, job reports shall be submitted to the user (see 4.3.2)

containing, at least, the following:

– details of fault detected;

– full details of repair and overhaul;

– list of replaced or reclaimed parts;

– results of all checks and tests (in sufficient detail to be useful if required by the next

repairer, see 4.3.2);

– summary of previous history of the repaired product including information as gathered

under 4.3.2;

– copy of the user contract or order.

The job reports of repairs/overhauls shall be retained for a period of time as agreed with the

user. Retained information shall be adequately controlled to ensure correct retrieval.

4.4.1.5.3 Repair facility records

The following records shall be retained by the repair facility:

– current and past copies of relevant Technical Standards;

– certification of Facility Quality Standard including:

1) details of Repair provider's Quality Assessment Scheme;

2) test instrument calibration;

3) competency and training records of personnel;

4) purchasing control system;

5) customer complaints system;

60079-19 © IEC:2006 –– 14 – 27 – 60079-19 © IEC:2006

6) internal and, where appropriate, external audit documentation;

7) management review;

8) process control procedures;

9) register of manufacturer’s drawings;

– job records including:

1) the steps taken to obtain the certification documents;

2) mechanical inspection record for compliance with relevant standards;

3) defect identification;

4) electrical test records before and after repair including traceability of instruments used

and pass/fail criteria;

5) certificates of conformity for replacement components;

6) recovery procedure for repaired components;

7) record of mechanical inspection during assembly and upon completion;

8) record of work undertaken by the repair facility.

The record of the recovery procedure for repaired components should, at least, identify the

following:

a) a detailed justification for the work carried out;

b) various options considered (e.g., welding, metal spraying);

c) technical parameters, e.g., bond strength;

d) the reasons for selecting the chosen technique;

e) consumables used and method of storage;

f) base material;

g) manufacturers’ instructions considered;

h) procedure utilized;

i) identity and competency of the operator;

j) inspection procedure used, e.g., ultra-sonic, dye-penetration, X-ray;

k) maintenance and calibration details of automatic systems.

These records shall be retained for a period of at least ten years or as agreed with the user.

4.4.1.6 Spare parts

4.4.1.6.1 General

It is preferable to obtain new parts from the manufacturer, and the repairer shall ensure that

only appropriate spare parts are used in the repair or overhaul of certified equipment.

Depending on the nature of the equipment, these spare parts may be identified by the

manufacturer, the equipment standard or the relevant certification documentation.

4.4.1.6.2 Sealed parts

Parts, which are required by the equipment specification and certificate documents to be

sealed, shall be replaced only by the particular spare part(s) detailed in the parts list.

60079-19 © IEC:200660079-19 © IEC:2006 –– 15 – 29 –

NOTE Devices incorporated in equipment to indicate interference by third parties (e.g., security seals) as distinct

from those required in the certification documents, are not intended to fall within the scope of this subclause.

4.4.1.7 Identification of repaired equipment

The equipment shall be marked to identify the repair or overhaul and the repairer's identity.

The marking for the repaired equipment is given in Annex A.

Marking may be provided on a separate label. It may be necessary to amend or remove or

supplement the label in certain circumstances as follows.

a) If after repair, overhaul or modification, an equipment is changed such that it no longer

conforms with the standard and certificate (see 3.11), the certification label shall be

removed unless a supplementary certificate has been obtained.

b) If the equipment is changed during repair or overhaul so that it still complies with the

restrictions imposed by this standard and the explosion protection standards to which it

was manufactured, but does not necessarily comply with the certificate, the certification

label should not normally be removed and the repair symbol "R" shall be written within an

inverted triangle (see Annex A).

c) Where the standards to which the previously certified equipment was manufactured are not

known, the requirements of this standard and the current edition of the relevant explosion

protection standards shall apply. An assessment, by a person competent in assessing

explosion protected equipment, shall be conducted to verify compliance with the relevant

level of safety prior to release of the equipment by the repairer.

4.4.2 Reclamations

4.4.2.1 General

Reclamations not affecting the explosion protection are not the subject of this subclause.

Such parts should be reclaimed using good engineering practices.

Where the repair process involves reclamation work, then, in addition to the requirements of

4.4.1 for repairs and overhauls, the requirements of 4.4.2 also apply.

4.4.2.2 Exclusions

Some component parts are considered not to be reclaimable and are therefore excluded from

the scope of this standard, such as:

– component parts made from the following materials: glass, plastics, or any material that is

not dimensionally stable;

– fasteners;

– component parts, e.g., some encapsulated assemblies, which have been stated by the

manufacturer to be not subject to repair.

4.4.2.3 Requirements

4.4.2.3.1 General

Any reclamation shall be carried out by competent personnel, skilled in the process to be

employed and using good engineering practices (see Annex B). Operators of reclamation

techniques, e.g. welding, metal spraying, shall be required to undertake a practical skill test in

the technique before being permitted to utilize the technique for the first time and every three

years thereafter. If the operator has not used the technique in the previous six months, he

shall undertake a re-test.

60079-19 © IEC:2006 –– 16 – 31 – 60079-19 © IEC:2006

If any proprietary process is used, the instructions of the originator of such a process should

be followed.

All reclamation shall be properly documented and records retained. Such records include:

– identification of the component part;

– method of reclamation;

– detail of any dimensions which differ from those in relevant certification documents or the

original dimensions of the component part;

– drawing showing reclamation details including material removed and replaced;

– date;

– name of the organization carrying out the reclamation.

If the reclamation is carried out other than by the user, the user shall be provided with a copy

of the record.

A reclamation procedure which would result in dimensions affecting explosion-protection

integrity being different from those given in relevant certification documents may be

permissible if such changed dimensions still meet the requirem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...