prEN IEC 61514:2024

(Main)Industrial-process control systems - Methods of evaluating the performance of valve positioners with pneumatic outputs

Industrial-process control systems - Methods of evaluating the performance of valve positioners with pneumatic outputs

Systeme der industriellen Prozesstechnik - Methoden der Beurteilung des Betriebsverhaltens von Ventilstellungsreglern mit pneumatischen Ausgängen

Systèmes de commande des processus industriels - Méthodes d'évaluation des performances des positionneurs de vannes à sorties pneumatiques

Sistemi za upravljanje industrijskih procesov - Postopki za ocenjevanje lastnosti pozicionirnikovz ventili s pnevmatskimi izhodi

General Information

- Status

- Not Published

- Publication Date

- 25-Jan-2026

- Technical Committee

- CLC/TC 65X - Industrial-process measurement, control and automation

- Drafting Committee

- IEC/SC 65B - IEC_SC_65B

- Current Stage

- 4060 - Enquiry results established and sent to TC, SR, BTTF - Enquiry

- Start Date

- 27-Sep-2024

- Completion Date

- 27-Sep-2024

Relations

- Effective Date

- 03-Aug-2021

Overview

The prEN IEC 61514:2024 standard, titled "Industrial-process control systems - Methods of evaluating the performance of valve positioners with pneumatic outputs," is developed by the CLC and published by the International Electrotechnical Commission (IEC). It provides internationally recognized test methods and evaluation criteria to assess the static and dynamic performance of valve positioners used in industrial process control systems.

Designed for positioners with pneumatic outputs that receive analogue input signals, this standard addresses the measurement and control of valve positioning accuracy, reliability, and responsiveness. Its application spans both single-acting and double-acting analogue positioners, tested either independently or in connection with actuators.

The document facilitates a uniform approach for manufacturers, users, and independent testing bodies to validate product performance against consistent criteria, supporting improved quality assurance, safety, and operational efficiency in industrial valve control systems.

Key Topics

Scope and Objective

prEN IEC 61514:2024 specifies detailed testing procedures for analogue valve positioners with pneumatic outputs, excluding digital or pulsed input/output devices. The standard supports full and partial evaluation programs tailored to product design and intended operational conditions.Performance Test Procedures

It outlines methods to evaluate fundamental performance aspects, including:- Gain and travel characteristics

- Accuracy metrics such as inaccuracy, conformity error, hysteresis, and repeatability error

- Dead band measurements for input and output paths

- Airflow characteristics and steady-state air consumption

- Effects of influence quantities like supply pressure, temperature, humidity, vibration, shock, and electromagnetic interference

- Drift assessment (start-up and long-term)

- Dynamic response via frequency and step response tests

- Accelerated life testing

Test Conditions and Setup

The standard defines environmental test conditions such as ambient temperature and humidity limits, supply pressure tolerances, and proper test equipment arrangements. It distinguishes between testing a positioner alone versus as part of an actuator assembly.Documentation and Reporting

It emphasizes comprehensive test reporting, including manufacturer specifications, testing conditions, deviations, and results interpretation. Manufacturer input is encouraged to ensure accuracy and completeness of evaluation.Safety and Quality Assurance

Addresses safety considerations and conformity with protective enclosure degrees, routine maintenance, repair guidelines, and installation practices to support reliable operation and compliance with industrial standards.

Applications

prEN IEC 61514:2024 is essential for:

- Valve positioner manufacturers aiming to certify product performance and comply with international standards.

- Industrial process control engineers requiring validated performance data for pneumatic valve control systems in sectors such as chemical processing, oil and gas, power generation, and automation.

- Testing and certification bodies conducting performance assessments to verify manufacturer claims and ensure system reliability and safety.

- End-users and plant operators implementing maintenance and quality assurance programs using standardized performance benchmarks.

This standard enhances industrial automation, process safety, and maintenance efficiency by enabling rigorous and repeatable evaluation of valve positioners critical to precision flow control.

Related Standards

- IEC 60381 & IEC 60382 – Define analogue signal input standards for control devices, referenced for input signal conformity.

- IEC 61511 – Functional safety of safety instrumented systems within the process industry may use valve positioner performance data in safety validation.

- IEC 61508 – General functional safety standards related to programmable electronic safety-related systems.

- ISO/IEC Directives – Guide the formatting and publication of IEC standards, ensuring consistency across international documents.

These related standards collectively support the holistic evaluation and certification of industrial process control devices, driving interoperability, safety, and quality in automation systems.

Keywords: valve positioner performance, pneumatic valve control, industrial process control, valve positioning accuracy, IEC 61514, test procedures, static performance, dynamic response, analogue positioners, industrial automation standards, quality assurance, process safety

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

prEN IEC 61514:2024 is a draft published by CLC. Its full title is "Industrial-process control systems - Methods of evaluating the performance of valve positioners with pneumatic outputs". This standard covers: Industrial-process control systems - Methods of evaluating the performance of valve positioners with pneumatic outputs

Industrial-process control systems - Methods of evaluating the performance of valve positioners with pneumatic outputs

prEN IEC 61514:2024 is classified under the following ICS (International Classification for Standards) categories: 23.060.99 - Other valves; 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN IEC 61514:2024 has the following relationships with other standards: It is inter standard links to EN 61514:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN IEC 61514:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2024

Sistemi za upravljanje industrijskih procesov - Postopki za ocenjevanje lastnosti

pozicionirnikovz ventili s pnevmatskimi izhodi

Industrial-process control systems - Methods of evaluating the performance of valve

positioners with pneumatic outputs

Systeme der industriellen Prozesstechnik - Methoden der Beurteilung des

Betriebsverhaltens von Ventilstellungsreglern mit pneumatischen Ausgängen

Systèmes de commande des processus industriels - Méthodes d'évaluation des

performances des positionneurs de vannes à sorties pneumatiques

Ta slovenski standard je istoveten z: prEN IEC 61514:2024

ICS:

23.060.99 Drugi ventili Other valves

25.040.40 Merjenje in krmiljenje Industrial process

industrijskih postopkov measurement and control

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

65B/1256/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 61514 ED2

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2024-07-05 2024-09-27

SUPERSEDES DOCUMENTS:

65B/1202/RR, 65B/1249/CC

IEC SC 65B : MEASUREMENT AND CONTROL DEVICES

SECRETARIAT: SECRETARY:

United States of America Mr Wallie Zoller

OF INTEREST TO THE FOLLOWING COMMITTEES: PROPOSED HORIZONTAL STANDARD:

Other TC/SCs are requested to indicate their interest, if any, in

this CDV to the secretary.

FUNCTIONS CONCERNED:

EMC ENVIRONMENT QUALITY ASSURANCE SAFETY

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft

for Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of which

they are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some Countries”

clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is the final stage for

submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Industrial-process control systems - Methods of evaluating the performance of valve positioners with

pneumatic outputs

PROPOSED STABILITY DATE: 2027

NOTE FROM TC/SC OFFICERS:

file, to make a copy and to print out the content for the sole purpose of preparing National Committee positions. You may not copy

or "mirror" the file or printed version of the document, or any part of it, for any other purpose without permission in writing from IEC.

IEC CDV 61514 © IEC:2024 – 2 –

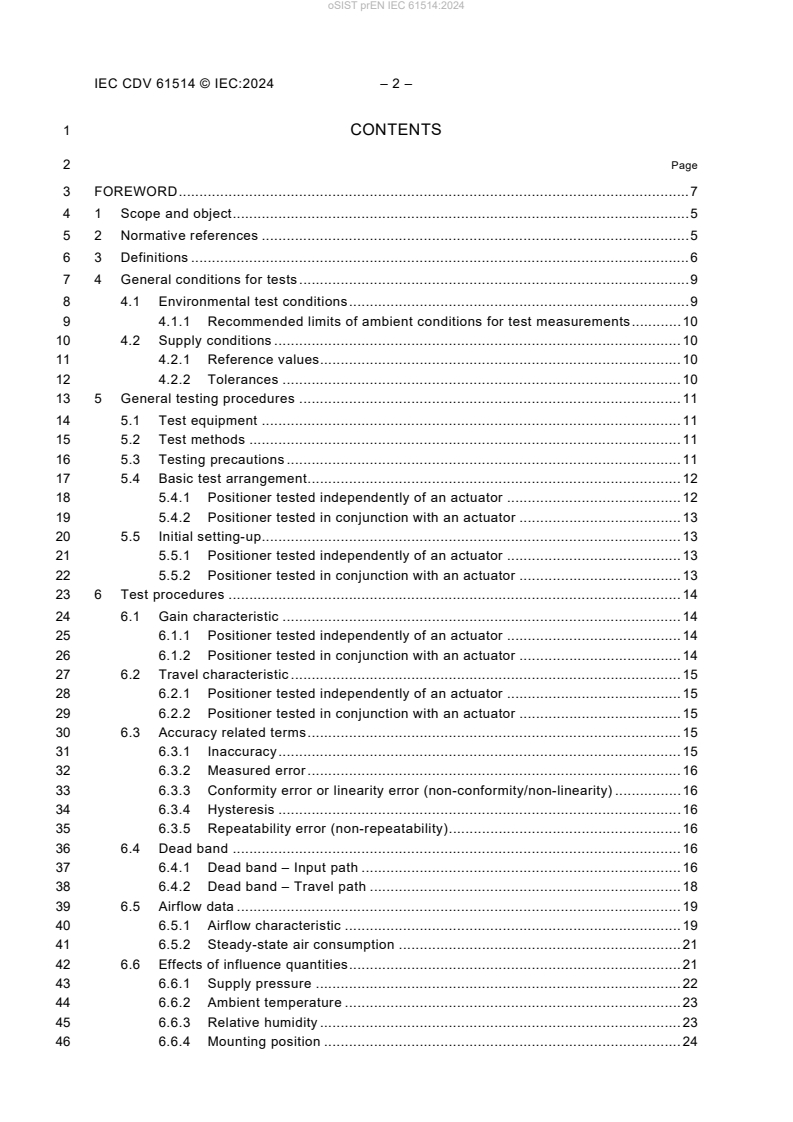

1 CONTENTS

2 Page

3 FOREWORD . 7

4 1 Scope and object . 5

5 2 Normative references . 5

3 Definitions . 6

7 4 General conditions for tests . 9

8 Environmental test conditions . 9

4.1

9 4.1.1 Recommended limits of ambient conditions for test measurements . 10

10 4.2 Supply conditions . 10

11 4.2.1 Reference values. 10

12 4.2.2 Tolerances . 10

13 5 General testing procedures . 11

14 5.1 Test equipment . 11

15 5.2 Test methods . 11

16 5.3 Testing precautions . 11

17 5.4 Basic test arrangement . 12

18 Positioner tested independently of an actuator . 12

5.4.1

19 5.4.2 Positioner tested in conjunction with an actuator . 13

20 5.5 Initial setting-up . 13

21 5.5.1 Positioner tested independently of an actuator . 13

22 5.5.2 Positioner tested in conjunction with an actuator . 13

23 6 Test procedures . 14

24 6.1 Gain characteristic . 14

25 6.1.1 Positioner tested independently of an actuator . 14

26 6.1.2 Positioner tested in conjunction with an actuator . 14

27 6.2 Travel characteristic . 15

28 Positioner tested independently of an actuator . 15

6.2.1

29 6.2.2 Positioner tested in conjunction with an actuator . 15

30 6.3 Accuracy related terms . 15

31 6.3.1 Inaccuracy . 15

32 6.3.2 Measured error . 16

33 6.3.3 Conformity error or linearity error (non-conformity/non-linearity) . 16

34 Hysteresis . 16

6.3.4

35 6.3.5 Repeatability error (non-repeatability) . 16

36 6.4 Dead band . 16

37 6.4.1 Dead band – Input path . 16

38 6.4.2 Dead band – Travel path . 18

39 6.5 Airflow data . 19

40 Airflow characteristic . 19

6.5.1

41 6.5.2 Steady-state air consumption . 21

42 6.6 Effects of influence quantities . 21

43 6.6.1 Supply pressure . 22

44 6.6.2 Ambient temperature . 23

45 6.6.3 Relative humidity . 23

46 Mounting position . 24

6.6.4

IEC CDV 61514 © IEC:2024 – 3 –

47 6.6.5 Mechanical shock . 25

48 6.6.6 Vibration . 25

49 6.6.7 Power-frequency magnetic field . 26

50 6.6.8 Radiated electromagnetic field interference . 27

51 6.6.9 Electrical fast transients (burst) . 28

52 Surge voltage immunity . 28

6.6.10

53 6.6.11 Series mode interference . 29

54 6.7 Input over-range . 30

55 6.7.1 Positioner tested independently of an actuator . 30

56 6.7.2 Positioner tested in conjunction with an actuator . 30

57 6.7.3 Common text for positioners tested independently of an actuator/with

an actuator . 30

59 6.8 Drift . 31

60 6.8.1 Start-up drift . 31

61 6.8.2 Long-term drift . 31

62 6.9 Accelerated life test . 32

63 6.9.1 Positioner tested independently of an actuator . 32

64 Positioner tested in conjunction with an actuator . 32

6.9.2

65 6.9.3 Common test for positioners tested in conjunction with/independently of

66 an actuator . 32

67 6.10 Dynamic response . 32

68 6.10.1 General considerations . 32

69 6.10.2 Basic test arrangement . 33

70 Frequency response . 33

6.10.3

71 6.10.4 Step response . 35

72 7 Other considerations . 36

73 7.1 General . 36

74 Safety . 37

7.2

75 7.3 Degree of protection provided by enclosures . 37

76 7.4 Documentary information . 37

77 7.5 Installation . 38

78 7.6 Routine maintenance and adjustment . 38

79 7.7 Repair . 38

80 Protective finishes . 38

7.8

81 7.9 Design features . 38

82 7.10 Variants . 38

83 7.11 Tools and equipment . 38

84 8 Test report and documentation . 38

85 9 Bibliography . 40

IEC CDV 61514 © IEC:2024 – 4 –

88 INTERNATIONAL ELECTROTECHNICAL COMMISSION

89 ____________

91 INDUSTRIAL-PROCESS CONTROL SYSTEMS –

92 Methods of evaluating the performance of valve positioners

93 with pneumatic outputs

95 FOREWORD

96 1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

97 all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

98 international co-operation on all questions concerning standardization in the electrical and electronic fields. To

99 this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

100 entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

101 participate in this preparatory work. International, governmental and non-governmental organizations liaising with

102 the IEC also participate in this preparation. The IEC collaborates closely with the International Organization for

103 Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

104 2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

105 international consensus of opinion on the relevant subjects since each technical committee has representation

106 from all interested National Committees.

107 3) The documents produced have the form of recommendations for international use and are published in the form

108 of standards, technical specifications, technical reports or guides and they are accepted by the National

109 Committees in that sense.

110 4) In order to promote international unification, IEC National Committees undertake to apply IEC International

111 Standards transparently to the maximum extent possible in their national and regional standards. Any divergence

112 between the IEC Standard and the corresponding national or regional standard shall be clearly indicated in the

113 latter.

114 5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

115 equipment declared to be in conformity with one of its standards.

116 6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

117 of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

118 International Standard IEC 61514 has been prepared by subcommittee 65B: Devices, of IEC

119 technical committee 65: Industrial-process measurement and control.

120 The text of this standard is based on the following documents:

FDIS Report on voting

65B/394/FDIS 65B/403/RVD

122 Full information on the voting for the approval of this standard can be found in the report on

123 voting indicated in the above table.

124 This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

125 The committee has decided that the contents of this publication will remain unchanged

126 until 2006. At this date, the publication will be

127 • reconfirmed;

128 • withdrawn;

129 • replaced by a revised edition, or

130 • amended.

IEC CDV 61514 © IEC:2024 – 5 –

132 INDUSTRIAL-PROCESS CONTROL SYSTEMS –

133 Methods of evaluating the performance of valve positioners

134 with pneumatic outputs

135 1 Scope and object

136 This International Standard specifies tests designed to determine the static and dynamic

137 performance of single-acting or double-acting analogue positioners. The tests may be applied

138 to positioners which receive standard analogue input signals (as specified in IEC 60381 and

139 IEC 60382) and have a pneumatic output.

140 Positioners with pulsed or digital input signals, positioners with digital controllers and

141 positioners with pulsed outputs are outside the scope of this standard.

143 Testing may be conducted either on a positioner alone, independently of an actuator, or on a

144 positioner mounted and connected to a specific actuator, as a combined unit. The text makes

145 clear where different approaches are required.

146 The methods of evaluation given in this standard are intended for use by manufacturers to

147 determine the performance of their products, and by users, or independent testing establish-

148 ments, to verify manufacturers' performance specifications.

149 The closest liaison should be maintained between the evaluating body and the manufacturer.

150 Note should be taken of the manufacturer's specifications for the instrument when the test

151 programme is being decided, and the manufacturer should be invited to comment on both the

152 test programme and the results. His comments on the results should be included in any report

153 produced by the testing organization.

154 This standard is intended to provide definitions of positioner elements, actions, and

155 characteristics, to specify uniform methods of measuring performance errors and effects of

156 influence quantities on those characteristics, and to describe methods of reporting and

157 evaluating the results of the measurement data obtained.

158 The test conditions described in this publication (for example range of ambient temperatures

159 and power supply) relate to conditions which commonly arise in use. Consequently, the values

160 specified shall be used where no other values are specified by the manufacturer or user. If other

161 values are used, they should be stated. It is recognized that the manufacturer's specifications

162 and instructions for installation and operation should apply during all steps.

163 The tests specified in this standard are not necessarily sufficient for instruments specifically

164 designed for unusually arduous conditions. Conversely, a reduced series of tests may serve

165 adequately for instruments designed to perform within a more limited range of conditions.

166 When a full evaluation, in accordance with this standard, is not required or possible, those tests

167 which are required should be performed and the results reported in accordance with the relevant

168 parts of this standard. In such cases, the test report should state that it does not cover the full

169 number of tests specified herein.

170 2 Normative references

171 The following documents, in whole or in part, are normatively referenced in this document and

172 are indispensable for its application. For dated references, only the edition cited applies. For

173 undated references, the latest edition of the referenced document (including any amendments)

174 applies.

IEC CDV 61514 © IEC:2024 – 6 –

175 IEC 60050, International Electrotechnical Vocabulary (IEV):

176 - Part 311: Electrical and electronic measurements - General terms relating to electrical

177 measurements

178 - Part 351: Control technology

179 IEC 60068-2-1, Environmental testing – Part 2-1: Tests. Test A: Cold

180 IEC 60068-2-2, Environmental testing – Part 2-2: Tests. Test B: Dry heat

181 IEC 60068-2-6, Environmental testing – Part 2-6: Tests. Test Fc: Vibration (sinusoidal)

182 IEC 60068-2-31, Environmental testing - Part 2-31: Tests - Test Ec: Rough handling shocks,

183 primarily for equipment-type specimens

184 IEC 60068-2-78, Environmental testing – Part 2-78: Tests. Test Cab: Damp heat, steady state

185 IEC 60079 (all parts), Electrical apparatus for explosive gas atmospheres

186 IEC 60381-1, Analogue signals for process control systems – Part 1: Direct current signals

187 IEC 60381-2, Analogue signals for process control systems – Part 2: Direct voltage signals

188 IEC 60382, Analogue pneumatic signal for process control systems

189 IEC 60529, Degree of protection provided by enclosures (IP Code)

190 IEC 60534-1, Industrial-process control valves – Part 1: Control valve terminology and general

191 considerations

192 IEC 60654 (all parts), Operating conditions for industrial-process measurement and control

193 equipment

194 IEC 60721-3, Classification of environmental conditions – Part 3 Classification of groups of

195 environmental parameters and their severities

196 IEC 61010-1, Safety requirements for electrical equipment for measurement, control, and

197 laboratory use – Part 1: General requirements

198 IEC 61032, Protection of persons and equipment by enclosures – Probes for verification

199 IEC 61326-1:2020, Electrical equipment for measurement, control and laboratory use – EMC

200 requirements

202 IEC 62828-1: 2017, Reference conditions and procedures for testing industrial and process

203 measurement transmitters – Part 1: General procedures for all types of transmitters

204 3 Definitions

205 For the purpose of this standard, the terms and definitions given in IEC 60050 Part 311 and

206 351 as well as the following definitions shall be applied.

207 3.1

208 positioner

209 position controller connected to the moving part of a final control element or its actuator;

210 automatically adjusts its output signal Y to the actuator in order to maintain a desired travel

211 signal X that bears a predetermined relationship to the input signal W

212 NOTE In this standard, only positioners with pneumatic output signals Y are considered. The input signal W may

213 be an air pressure (pneumatic positioner), or an electric current or voltage (electro-pneumatic positioner).

IEC CDV 61514 © IEC:2024 – 7 –

214 3.1.1

215 single-acting positioner

216 positioner (see figure 1a) having one output signal Y which acts on one side of the actuator.

217 The returning force for the actuator is usually provided by springs

218 3.1.2

219 double-acting positioner

220 positioner (see figure 1b) providing two output signals Y and Y connected to opposite sides

D R

221 of the actuator diaphragm or piston

Actuator

Output

signal

Y

Input signal W

Travel

Positioner

signal

X

Friction Supply

P

s

IEC 340/2000

225 Figure 1a – Single-acting positioner/actuator

Actuator

Output

signal

Output

Y

D

signal Y

R

Input signal W

Travel

Positioner

signal

X

Friction

Supply

P

s

227 IEC 341/ 2000

228 Figure 1b – Double-acting positioner/actuator

229 Figure 1 – Single- and double-acting positioner/actuator

230 3.2

231 input signal W

232 reference input signal which represents the desired position of the associated control element

233 3.3

234 travel signal X

235 signal which results from the linear or angular travel caused by movement of the final control

236 element or its actuator

237 3.4

238 output signal Y

239 air pressure delivered to the actuator of the final control element

IEC CDV 61514 © IEC:2024 – 8 –

240 3.5

241 supply pressure P

s

242 air pressure at the supply connector of the positioner

243 3.6

244 action

245 action is direct when the output signal Y increases as the value of the input signal W increases.

246 The action is reverse when the output signal Y decreases as the value of the input signal W

247 increases

248 3.7

249 split ranging

250 special adjustment in which the full travel of the actuator is achieved from only part of the whole

251 input range (for example 0 % to 50 % or 50 % to 100 %)

252 3.8

253 gain characteristic

254 relationship between input signal W and output signal Y with travel signal X kept constant (i.e.

255 locked stem); see figure 2

256 Incremental gain ∆Y/∆W varies with pressure and the related pressure shall be stated.

257 3.9

258 proportional (average) gain factor K

p

259 gain over the full range of the actuator. The proportional gain factor for a single-acting positioner

260 may be derived from the gain characteristic (figure 2a):

ΔY

max

261 K =

p

ΔW

max

262 where ∆W is the change of input signal W as a percentage of span required to change the

max

263 output signal over the whole range (∆Y for 100 %). In this case ∆W (%) corresponds to

max max

264 the proportional band X (%). The output signal range ∆Y is taken to be the nominal range

p max

265 stated by the manufacturer.

266 For a double-acting positioner, a gain factor for each output may be derived separately (see

267 figure 2b):

∆Y ∆Y

max max

268 K = K =

pD pR

∆W ∆W

D max R max

269 The proportional gain factor K for a double-acting positioner may then be calculated as the

p

270 summation of the two individual gain factors, i.e.:

271 K = K + K

p pD pR

272 or derived from the differential pressure characteristic (Y – Y ); see figure 2b.

D R

273 The balance pressure Y is the cross-over point of the direct Y and reverse Y characteristics.

B D R

274 Generally, this value depends on the supply pressure applied to the positioner.

IEC CDV 61514 © IEC:2024 – 9 –

∆W

Rmax

100 %

100 %

Y

D

Y

∆Y R

max

Y

Y

B

Y

(Y - Y )

D R

∆W

0 %

max

0 %

∆W

Dmax

IEC 343/2000

W

IEC 342/2000

W

277 Figure 2a – Single-acting positioner Figure 2b – Double-acting positioner

278 Figure 2 – Gain characteristic

279 3.10

280 proportional band X

p

281 the proportional band X is defined as

p

100 %

X (%)=

p

K

p

283 3.11

284 local gain factor K

l

285 slope of the gain characteristic at a specific input value

286 3.12

287 travel characteristic

288 closed-loop relationship of a positioner/actuator between the input signal W and the travel

289 signal X

290 The intended relationship between input signal W and travel signal X (for example linear or

291 equal percentage) determines the ideal characteristic.

292 3.13

293 travel factor U

294 ratio between the travel span and the corresponding input span. This may be adjustable.

295 3.14

296 maximum measured error

297 largest positive or negative value of error of the average up-scale or down-scale value at each

298 point of measurement

299 4 General conditions for tests

300 4.1 Environmental test conditions

301 The tests shall be performed under the ambient test conditions recommended below:

IEC CDV 61514 © IEC:2024 – 10 –

304 Table 1 – Environmental conditions

Atmospheric test conditions Temperature Relative humidity Atmospheric pressure

°C % kPa

Standard reference

20 65 101,3

atmosphere

Recommended limits 15 to 25 45 to 75 86 to 106

Referee measurements a: 20 ± 2 65 ± 5 86 to 106

b: 23 ± 2 50 ± 5 86 to 106

306 The test values shall be corrected back to the standard reference atmosphere conditions listed

307 above. The standard reference atmosphere is equivalent to the normal reference operating

308 conditions commonly identified by the manufacturer.

309 It is recognized that there may not be a factor to correct for humidity. When measurements

310 within the recommended range of ambient conditions are unsatisfactory, and the correction

311 factors to adjust parameters to the standard atmosphere are unknown, repeat measurements

312 (referee measurements) may be conducted under the conditions listed in table 1, a or b, or

313 other reference operating conditions identified by the manufacturer.

314 NOTE Special equipment may be required to maintain the basic test conditions within the limits specified.

315 4.1.1 Recommended limits of ambient conditions for test measurements

316 Electromagnetic field: value to be stated, if relevant.

317 Maximum rate of change of ambient temperature permissible during any test: 1 °C in 10 min,

318 but not more than 3 °C/h.

319 4.2 Supply conditions

320 4.2.1 Reference values

321 Electrical supply: the values specified by the manufacturer.

322 Pneumatic supply: the values specified by the manufacturer, or a supply pressure of 4,0 bar

323 (400 kPa).

324 4.2.2 Tolerances

325 The tolerances given below apply, unless closer tolerances are agreed between user and

326 manufacturer.

327 a) Electrical supply

328 – Rated voltage: ±1 %.

329 – Rated frequency: ±1 %.

330 – Harmonic distortion (AC supply): less than 5 %.

331 – Ripple (DC supply): less than 0,1 %.

332 b) Pneumatic supply

333 – Rated pressure: ±3 %;

334 – Supply air temperature: ambient temperature ±2 °C.

335 – Supply air humidity: dew-point at least 10 °C below device body

336 temperature.

IEC CDV 61514 © IEC:2024 – 11 –

337 – Oil and dust content

–6

338 • oil: less than 10 by weight;

339 • dust: absence of particles greater than 3 µm in

340 diameter.

341 5 General testing procedures

342 5.1 Test equipment

343 When the accuracy rating of the reference measuring means is one-tenth or less than that of

344 the device under test, the accuracy rating of the reference measuring means may be ignored in

345 calculations, but shall be reported. When the accuracy rating of the reference measuring means

346 is one-third or less, but greater than one-tenth of that of the device under test, the accuracy

347 rating of the reference measuring means shall be stated in the report.

348 5.2 Test methods

349 Specific test methods and test configurations are described separately in clause 6.

350 5.3 Testing precautions

351 Unless affecting the influence condition being tested, the following conditions shall apply.

352 An adequate time, as specified by the manufacturer, shall be allowed after switching on the

353 power supply in order to allow stabilization of the positioner and/or associated test equipment.

354 In the absence of a manufacturer specification, a period of at least 15 min shall be allowed (at

355 least 30 min for electrical supplies).

356 Prior to recording observations, the device under test shall be exercised by three or more full

357 range traverses in each direction.

358 The measurement points used to determine the relevant performance characteristic should be

359 distributed over the range. They should include points at or near (within 10 %) the lower- and

360 upper-range values. There should be at least six measurement points, and preferably more.

361 The number and location of these measurement points should be consistent with the degree of

362 precision required and the characteristic being evaluated. Each measurement point should be

363 reached avoiding any overshoot of the input signal.

364 At each point being observed, the recording shall be made after the device becomes stabilized

365 at its apparent steady-state value.

366 Tapping or vibrating the device under test is not allowed unless the performance characteristic

367 under study requires such action.

368 All testing should be conducted with positioner covers in place.

369 Any mechanical stops should be adjusted so that they do not interfere with the measurements.

370 All tests shall be conducted with the device in an agreed mounting position(s), which shall be

371 stated in the report.

372 Characteristics and data which are dependent on the supply pressure value (for example air

373 consumption, flow capacity, etc.) should be measured at minimum and maximum values of the

374 specified supply pressure range.

375 Positioners fitted with a cam shall be tested with input/travel characteristics which are normally

376 linear.

IEC CDV 61514 © IEC:2024 – 12 –

377 5.4 Basic test arrangement

378 The basic test arrangements are shown in figures 3a and 3b.

379 5.4.1 Positioner tested independently of an actuator

380 Tests carried out on a positioner, tested independently of an actuator, are conducted with the

381 output Y of the positioner connected only to a dummy load (sometimes referred to as "open-

382 loop" operation).

383 Unless otherwise agreed, a 1 000 cm volume shall be connected to the output. In this way, the

384 performance of the positioner is not affected by the performance of the actuator.

385 This is the only test method which provides positioner data independent of an actuator, and

386 may be useful in comparing the performance of one positioner with another, or in checking a

387 manufacturer's specification for a positioner.

388 The travel adjustment can be made manually or by using an actuator (manually controlled).

389 The input signal W can be manually adjusted to obtain the required re-balance of output signal

390 Y, or a loop between output signal Y and input signal W can be arranged if desired, i.e.

391 automatic re-balance.

Dummy

load

Output

signal

Y

Travel

signal Positioner

Input signal W

X

Supply

P

s

392 IEC 344/2000

394 Figure 3a

Travel

Positioner

signal

Input

X

signal W

Output

signal

Y

P/E

Supply

P + I

P

s

W

IEC 345/2000

397 Figure 3b

398 Figure 3 – Basic test arrangement

399 NOTE 1 With positioners possessing an additional integral mode (i.e. PI control action) it is necessary to use an

400 automatic re-balance loop to achieve stable measurements. In this case, the output Y of the positioner is connected

401 to the input (+) of the pneumatic rebalance device (for example summing relay or PI controller), whose output is fed

402 back to the input W of the positioner. In cases where the input W is an electrical signal, a pressure/electrical convertor

IEC CDV 61514 © IEC:2024 – 13 –

403 must be included in the circuit, after the re-balance device. The arrangement for this additional test is shown in figure

404 3b.

405 NOTE 2 The input signal W can be a pressure or an electrical signal. The output signal Y is a pressure. The normal

406 test procedure will be to set the travel input signal X to some desired position and then to adjust the input signal W

407 sufficiently to balance a change in output signal Y.

408 5.4.2 Positioner tested in conjunction with an actuator

409 Tests carried out in conjunction with an actuator are conducted on a positioner when it is

410 mounted on and connected to an actuator, as a complete positioner/actuator assembly.

411 The positioner may be fitted to any commercially available actuator with which it is compatible.

412 The selected actuator is the choice of the user or the manufacturer. Generally, the results of

413 tests may be affected by performance of the actuator used for the test. Therefore, supporting

414 information about the actuator used (such as friction, inertia, type of packing material, etc.)

415 should be included in the presentation of the test report (see clause 8).

416 NOTE 1 The input signal W can be a pressure or an electrical signal. Some means of accurately measuring the

417 travel X is necessary. The normal test procedure will be to set the input signal W to some desired value and then to

418 read the corresponding value of the travel signal X.

419 NOTE 2 Since the output pressure signals Y (or Y and Y for a double-acting positioner) are connected to the

D R

420 actuator (sometimes referred to as "closed-loop" operation) and since their actual values are only an internal signal,

421 they need be measured only if specifically required.

422 5.5 Initial setting-up

423 The positioner shall be adjusted in accordance with the manufacturer's instructions.

424 5.5.1 Positioner tested independently of an actuator

425 Where the gain of the positioner can be altered, it should be set at a value K = 50 or at a

p

426 proportional band X = 2 %. If this is not convenient, another value recommended by the

p

427 manufacturer may be used.

428 If required, some characteristics and data may be measured at minimum or maximum K (X )

p p

429 values.

430 Adjust the travel span and input range as required. When a positioner can be set for a travel

431 span of 25 mm or 90° for a rotary-actuating positioner, this is preferred.

432 The output pressure range for a single-acting positioner will be 0,2 bar to 1 bar. For a double-

433 acting positioner it will be ±0,4 bar from the balance pressure Y . Other values may be specified

B

434 by the manufacturer.

435 With the normal characteristics (i.e. without splitting) the lower range point is determined by 0 %

436 input and 0 % travel, the upper range point is determined by 100 % input and 100 % travel.

437 5.5.2 Positioner tested in conjunction with an actuator

438 With a single range (i.e. not split) the lower range point is determined by 0 % input and 0 %

439 travel, and the upper range point is determined by 100 % input and 100 % travel.

440 Normally, the gain of the positioner should be set as high as possible in order to minimize the

441 deviations, but otherwise the gain shall be kept low enough to avoid "hunting" in the closed

442 loop. If a positioner with a fixed gain is under test, some other means of damping may be used

443 to avoid "hunting". If the positioner provides additional adjustment means (for example integral

444 control action), this should be adjusted as specified by the manufacturer. The set values of the

445 gain and/or other adjustment means should be reported.

IEC CDV 61514 © IEC:2024 – 14 –

446 6 Test procedures

447 6.1 Gain characteristic

448 Adjust the positioner input signal W to bring the output signal Y to 0 % of its range. Then slowly

449 vary the input signal W so that the output signal Y will successively assume values of 20 %,

450 40 %, 60 %, 80 %, and 100 % (or other sufficiently small increments) and back to 0 %.

451 At each setting, measure the input signal W and the output signal Y. Plot the values of the

452 output signal Y against the input signal W. A typical plot is shown in figure 2a.

453 From the gain characteristic (see figure 2) can be measured the proportional band X or gain

p

454 K , and if required the local gain factor K may be derived as the differential quotient.

p l

dY

455 K =

l

dW

456 Where the gain of the positioner can be adjusted, minimum and maximum K (or X ) values as

p p

457 specified by the manufacturer should be measured.

458 In order to check if the gain of the positioner is dependent on the supply pressure, the influence

459 of the supply pressure change on the gain value shall be measured.

460 The influence should be reported as the maximum change in gain per 0,1 bar change in supply

461 pressure.

462 When a single-acting positioner has options for direct and reverse action, the gain of each shall

463 be measured.

464 The same procedure as specified above may be used for a double-acting positioner, plotting a

465 separate gain characteristic for each output. A typical plot is shown in figure 2b.

466 6.1.1 Positioner tested independently of an actuator

467 Adjust the travel X to its mid-range (50 %) and secure it in this position. If required, the gain

468 characteristic may, in addition, be measured at travel X settings of approximately 10 % and

469 90 % of its range.

470 NOTE For positioners that include an additional integral mode (i.e. PI control action), the integral action should be

471 switched off or set to minimum effect.

472 6.1.2 Positioner tested in conjunction with an actuator

473 Set up the positioner/actuator assembly as described in 5.5.

474 Check the nominal pressure range of the actuator, i.e. read the output signal range Y which

max

475 is necessary to drive the actuator from 0 % to 100 % of its travel signal X (only with a single-

476 acting positioner).

477 Adjust the input signal W so that the travel signal X corresponds to its mid-range value

478 (i.e. 50 %) and lock the actuator stem in this position.

479 NOTE If required, the gain characteristic may, in addition, be measured at travel X settings of approximately 10 %

480 and 90 % of its range.

481 Disconnect the output Y (or outputs Y and Y in the case of a double-acting positioner) from

D R

482 the actuator, and seal off the outputs; the gain characteristic will be measured in so-called

483 "open loop".

484 NOTE 1 With positioners possessing an additional integral mode (i.e. PI control action), the integral action should

485 be switched off or set to its minimum effect.

IEC CDV 61514 © IEC:2024 – 15 –

486 NOTE 2 With single-acting positioners in conjunction with a spring-returned actuator, the nominal pressure range

487 of the actuator should be used as ∆Y for the calculation of the proportional gain factor (refer to 3.9).

max

488 NOTE 3 With double-acting positioners, the output pressure change ±40 kPa from the balance pressure Y should

489 be used as ∆Y for calculation of the proportional gain factor of each output (refer to 3.9).

max

490 When a single-acting positioner has options for direct and reverse action, the gain of each shall

491 be measured.

492 6.2 Travel characteristic

493 For assessment of non-conformity/non-linearity and non-repeatability, the measurement cycle

494 shall be made at least three times.

495 Present the measured values of input signal W and travel signal X in tabulated form (see

496 table 2).

497 If the positioner has been designed to give a non-linear travel characteristic, this can be shown

498 in graphical form, showing travel signal X against input signal W.

499 The results may also be presented as an error plot, as follows: at each measured value of input

500 signal W, calculate the error in travel signal X as the difference between the measured value of

501 signal X and its corresponding ideal value. This error may be expressed in terms of percentage

502 of ideal travel span. Plot the averaged error against the input signal W for both upscale and

503 downscale traverse. A typical plot is shown in figure 4.

504 6.2.1 Positioner tested independently of an actuator

505 Adjust the travel span and input range as required. When a positioner can be set for a travel

506 span of 25 mm, or 90° for a rotary actuator, this is preferred.

507 Slowly increase the input signal W from 0 % to 100 % and back to 0 % in steps of 20 % or less,

508 stopping after each step to allow the positioner to attain steady state. At each stage, re-balance

509 the output signal Y to 50 % by carefully adjusting the travel signal X, always approaching the

510 final balance point from the same direction. Note the corresponding values of the input signal

511 W and the travel signal X at each stage.

512 For a double-acting positioner, at each stage re-balance the output until both output signals Y

D

513 and Y are approximately equal or the difference in pressure (Y – Y ) is approximately zero.

R D R

514 6.2.2 Positioner tested in conjunction with an actuator

515 Adjust the travel span and the input range as required.

516 Slowly increase the input signal W from 0 % to 100 % and back to 0 % in steps of 20 % or less,

517 stopping after each step to allow the positioner to attain steady state. Note the corresponding

518 values of input signal W and travel signal X at each stage.

519 6.3 Accuracy related terms

520 6.3.1 Inaccuracy

521 Inaccuracy may be determ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...