prEN IEC 60127-7:2024

(Main)Miniature fuses - Part 7: Miniature fuse-links for special applications

Miniature fuses - Part 7: Miniature fuse-links for special applications

Geräteschutzsicherungen - Teil 7: G-Sicherungseinsätze für besondere Anwendungen

Coupe-circuit miniatures - Partie 7: Eléments de remplacement miniatures pour applications spéciales

Miniaturne varovalke - 7. del: Miniaturni taljivi vložki za posebne namene

General Information

- Status

- Not Published

- Publication Date

- 12-May-2026

- Technical Committee

- CLC/SR 32C - Miniature fuses

- Current Stage

- 4060 - Enquiry results established and sent to TC, SR, BTTF - Enquiry

- Start Date

- 10-Jan-2025

- Completion Date

- 10-Jan-2025

Relations

- Effective Date

- 05-Dec-2023

Overview

The prEN IEC 60127-7:2024 standard specifies requirements for miniature fuse-links designed for special applications. This part of IEC 60127 targets miniature fuses with rated voltages up to 1,000 V, rated currents up to 125 A, and breaking capacities up to 50 kA. It excludes fuses covered by other parts of IEC 60269-1 and those intended for use in corrosive or explosive atmospheres. The standard sets out uniform test methods for verifying manufacturer-supplied characteristics such as melting time and breaking capacity, ensuring enhanced safety and reliability in specialized uses. Miniature fuse-links under this standard are not designed for user replacement and apply alongside general requirements from IEC 60127-1.

Key Topics

Scope and Ratings

Defines fuse-links with maximum voltage of 1,000 V, current ratings up to 125 A, and breaking capacity up to 50 kA. Ratings are agreed upon between manufacturer and testing bodies, including rated voltage, current, breaking capacity, and time/current characteristics.Terminology

Clarifies specific terms such as miniature fuse-links for special applications, time/current characteristics, and test currents at various conditions critical for testing endurance and dissipation.Marking Requirements

Specifies mandatory marking details such as type designation and rated breaking capacity on the fuse and packaging. The standard prohibits traditional color band markings but allows distinct color codes with manufacturer-provided information.Testing Procedures

Provides detailed test schedules covering type tests, endurance, breaking capacity, and electrical performance at various temperatures and currents. Specifies the number of fuse samples required for tests, including spares.Test Boards and Mounting

Describes the design of standardized test boards for wire termination and surface mount fuse-links, based on PCB parameters such as copper layer thickness, track widths, and land patterns. These ensure consistent and reliable electrical testing environments.Safety and IEC References

Aligns with complementary IEC standards like IEC 60127-1, IEC 60664-1 (insulation coordination), IEC 60695 series (fire hazard testing), and IPC 7351B (land pattern standards for surface mount devices). This ensures miniature fuses comply with electrical safety, environmental robustness, and flame resistance.

Applications

Miniature fuse-links covered by prEN IEC 60127-7:2024 are used in:

Specialized Electronic Devices

Protection of low power electrical devices requiring precise starting and fault interruption characteristics within strict size constraints (max dimensions 12 mm x 50 mm).Industrial and Commercial Equipment

Where unique fuse specifications and ratings are necessary to meet application-specific safety and performance needs not addressed by general fuse standards.Embedded and Surface Mount Technology (SMT)

Miniature fuse-links designed for mounting on printed circuit boards following IPC standards facilitate compact, reliable circuit protection in modern electronic assemblies.Electrical Components with Non-User Replacement

Fuses intended for internal appliance protection, preventing end-user replacement to maintain compliance and reduce incorrect fuse substitution risks.

Related Standards

- IEC 60127-1:2023 - General definitions and requirements for miniature fuse-links.

- IEC 60127-4 - Universal modular fuse-links, including through-hole and surface mount types.

- IEC 60127-6:2023 - Fuse-holders designed for miniature fuse-links.

- IEC 60664-1:2020 - Standards for insulation coordination in low-voltage systems.

- IEC 60695 series (2-12, 2-13, 4:2021) - Fire hazard testing methods related to glow-wire ignition and flammability for electronic components.

- IEC 61249-2-7:2002 - Material requirements for printed circuit boards used in fuse testing.

- IPC 7351B:2010 - Generic requirements for surface mount design and land pattern standards referenced for fuse testing boards.

- ISO 3:1973 - Series of preferred numbers, used for defining nominal ratings and test values.

Keywords: miniature fuse-links, special applications, miniature fuses, IEC 60127-7, fuse ratings, breaking capacity, electrical testing standards, miniature fuse marking, fuse safety, fuse testing procedures, surface mount fuse, fuse-holder, electrical protection devices, CLC standards.

Frequently Asked Questions

prEN IEC 60127-7:2024 is a draft published by CLC. Its full title is "Miniature fuses - Part 7: Miniature fuse-links for special applications". This standard covers: Miniature fuses - Part 7: Miniature fuse-links for special applications

Miniature fuses - Part 7: Miniature fuse-links for special applications

prEN IEC 60127-7:2024 is classified under the following ICS (International Classification for Standards) categories: 29.120.50 - Fuses and other overcurrent protection devices. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN IEC 60127-7:2024 has the following relationships with other standards: It is inter standard links to EN 60127-7:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN IEC 60127-7:2024 is associated with the following European legislation: EU Directives/Regulations: 2014/35/EU; Standardization Mandates: M/511. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN IEC 60127-7:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN IEC 60127-7:2024

01-december-2024

Miniaturne varovalke - 7. del: Miniaturni taljivi vložki za posebne namene

Miniature fuses - Part 7: Miniature fuse-links for special applications

Geräteschutzsicherungen - Teil 7: G-Sicherungseinsätze für besondere Anwendungen

Coupe-circuit miniatures - Partie 7: Eléments de remplacement miniatures pour

applications spéciales

Ta slovenski standard je istoveten z: prEN IEC 60127-7:2024

ICS:

29.120.50 Varovalke in druga Fuses and other overcurrent

nadtokovna zaščita protection devices

oSIST prEN IEC 60127-7:2024 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN IEC 60127-7:2024

oSIST prEN IEC 60127-7:2024

32C/647/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 60127-7 ED3

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2024-10-18 2025-01-10

SUPERSEDES DOCUMENTS:

32C/630/CD, 32C/641A/CC

IEC SC 32C : MINIATURE FUSES

SECRETARIAT: SECRETARY:

China Mr Jun Cai

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

SC 32B

ASPECTS CONCERNED:

Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of CENELEC,

is drawn to the fact that this Committee Draft for Vote (CDV) is

submitted for parallel voting.

The CENELEC members are invited to vote through the CENELEC

online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of which they are aware

and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some Countries” clauses to be

included should this proposal proceed. Recipients are reminded that the CDV stage is the final stage for submitting ISC clauses. (SEE

AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Miniature fuses - Part 7: Miniature fuse-links for special applications

PROPOSED STABILITY DATE: 2027

NOTE FROM TC/SC OFFICERS:

file, to make a copy and to print out the content for the sole purpose of preparing National Committee positions. You may not copy or

"mirror" the file or printed version of the document, or any part of it, for any other purpose without permission in writing from IEC.

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 2 32C/647CDV

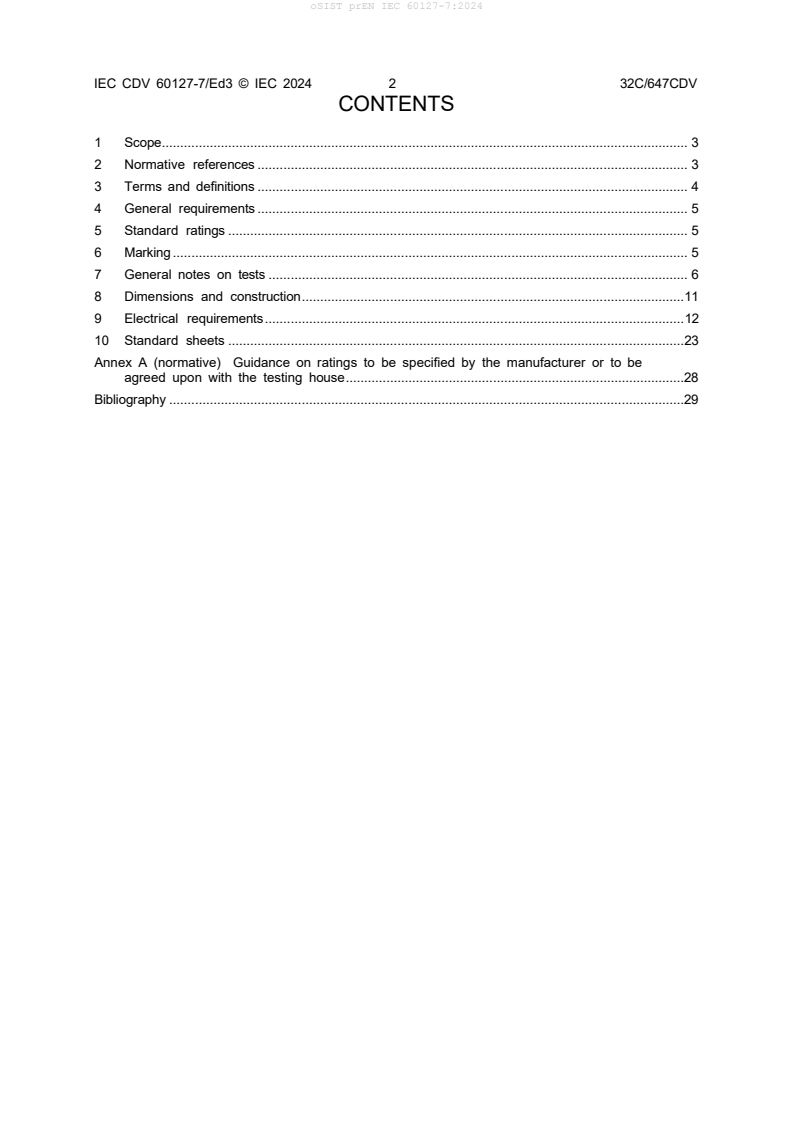

CONTENTS

1 Scope . 3

2 Normative references . 3

3 Terms and definitions . 4

4 General requirements . 5

5 Standard ratings . 5

6 Marking . 5

7 General notes on tests . 6

8 Dimensions and construction . 11

9 Electrical requirements . 12

10 Standard sheets . 23

Annex A (normative) Guidance on ratings to be specified by the manufacturer or to be

agreed upon with the testing house .28

Bibliography .29

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 3 32C/647CDV

1 Miniature fuses - Part 7: Miniature fuse-links for special application

3 1 Scope

4 This part of IEC 60127 covers requirements for miniature fuse-links for special applications.

5 This part of IEC 60127 is applicable to fuse-links with a rated voltage not exceeding 1 000 V, a

6 rated current not exceeding 125 A and a rated breaking capacity not exceeding 50 kA.

8 Note:Nominal currents above 20A are intended for protection of low power electric devices at low

voltage and not for energy distribution.

9 It does not apply to fuses completely covered by the subsequent parts of IEC 60269-1.

10 It does not apply to miniature fuse-links for appliances intended to be used under special

11 conditions, such as in corrosive or explosive atmospheres.

12 This part of IEC 60127 applies in addition to the requirements of IEC 60127-1.

13 Miniature fuse-links for special applications are not intended to be replaced by the end-user of

14 an electrical / electronic appliance.

15 The object of this part of IEC 60127 is to establish uniform test methods for miniature fuse-links

16 for special applications, so as to allow verification of the values (for example melting time and

17 breaking capacity values) specified by the manufacturer.

19 2 Normative references

20 The following documents, in whole or in part, are normatively referenced in this document and

21 are indispensable for its application. For dated references, only the edition cited applies. For

22 undated references, the latest edition of the referenced document (including any amendments)

23 applies.

24 IEC 60068-2-21:2021, Environmental testing – Part 2-21: Tests – Test U: Robustness of

25 terminations and integral mounting devices

26 IEC 60127-1:2023, Miniature fuses – Part 1: Definitions for miniature fuses and general

27 requirements for miniature fuse-links

28 IEC 60127-4:20XX, Miniature fuses – Part 4: Universal modular fuse-links (UMF) – Through-

29 hole and surface mount types

31 IEC 60127-6:2023, Miniature fuses – Part 6: Fuse-holders for miniature fuse-links

32 IEC 60664-1:2020, Insulation coordination for equipment within low-voltage systems – Part 1:

33 Principles, requirements and tests

34 IEC 60695-2-12:2021, Fire hazard testing – Part 2-12: Glowing/hot-wire based test methods –

35 Glow-wire flammability index (GWFI) test method for materials

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 4 32C/647CDV

37 IEC 60695-2-13:2021, Fire hazard testing – Part 2-13: Glowing/hot-wire based test methods –

38 Glow-wire ignition temperature (GWIT) test method for materials

40 IEC 60695-4:2021, Fire hazard testing – Part 4: Terminology concerning fire tests for

41 electrotechnical products

42 IEC 61249-2-7:2002, Materials for printed boards and other interconnecting structures – Part

43 2-7: Reinforced base materials clad and unclad – Epoxide woven E-glass laminated sheet of

44 defined flammability (vertical burning test), copper-clad

46 IPC 7351B: 2010 Generic requirements for surface mount design and land pattern standard

48 ISO 3:1973, Preferred numbers – Series of preferred numbers

49 3 Terms and definitions

50 For the purposes of this document, the terms and definitions given in Clause 3 of IEC 60127-

51 1:2023, except 3.5, as well as the following apply.

52 3.1

53 miniature fuse-link for special applications

54 enclosed fuse-link which is not covered in IEC 60127-2, IEC 60127-3 or IEC 60127-4 and of

55 rated breaking capacity not exceeding 50 kA, with a width and height not exceeding 12 mm and

56 a length not exceeding 50 mm

57 Note 1 to entry: Special precautions may be necessary to ensure that the fuse-links will be replaced by a fuse-link

58 with the same technical parameters.

59 Note 2 to entry: For fuse-links having a metallic cap at each end, any member of terminals or terminations other

60 than the metallic cap such as wire terminations, pins and bolt-in contacts may not be included in the total length of

61 50 mm and the width and height of 12 mm.

62 3.2

63 t to t

1 8

64 limit values for time/current characteristic

65 3.3

66 I

67 test current for testing at elevated temperature of 70 °C

68 Note 1 to entry: Preferred values are 0,8 I or 1,0 I or 1,1 I .

N N N

69 3.4

70 I (A)

test

71 test current for endurance testing according to method A

72 Note 1 to entry: Preferred values are 1,0 I or 1,05 I or 1,2 I .

N N N

73 3.5

74 I (B)

test

75 test current for endurance testing according to method B

76 Note 1 to entry: Preferred values are 0,8 I or 1,0 I .

N N

77 3.6

78 I (A)

OVL

79 test current for measuring the maximum sustained dissipation according to method A

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 5 32C/647CDV

80 Note 1 to entry: Preferred values are 1,0 I or 1,25 I or 1,35 I or 1,5 I . 1,0 I is allowable only for n omi n al currents above

N N N N N

81 20 A.

82 3.7

83 I (B)

OVL

84 test current for measuring the maximum sustained dissipation according to method B

85 Note 1 to entry: Preferred values are 1,0 I or 1,25 I .

N N

86 4 General requirements

87 Clause 4 of IEC 60127-1:2006 applies.

88 5 Standard ratings

89 Clause 5 of IEC 60127-1:2006 does not apply.

90 Replacement:

91 The following ratings shall be agreed upon between the testing house and the manufacturer:

92 – rated voltage;

93 – rated current (see standard sheet 1 for preferred ratings);

94 – rated breaking capacity (a.c. and/or d.c.);

95 – time/current characteristic (at least at 2,0 I or 2,1 I and 10 I ).

N N N

96 The following may be agreed upon on an optional basis:

97 – test at elevated temperature;

98 – time/current characteristic (additionally at 2,75 I and 4 I ).

N N

99 Any additional specified values are given in standard sheet 1.

100 6 Marking

101 Clause 6 of IEC 60127-1:2006 applies except as follows.

102 6.1

103 Replacement:

104 d) Not applicable.

105 NOTE A symbol denoting the time/current characteristic cannot be stated, because this part of IEC 60127 does not

106 specify any values for this parameter.

107 Addition:

108 e) Type designation.

109 f) Rated breaking capacity in amperes (A) or in kilo amperes (kA).

110 6.2

111 Deletion of NOTE 2.

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 6 32C/647CDV

112 6.3

113 Addition after first paragraph:

114 Furthermore the rated breaking capacity in amperes (A) or in kilo amperes (kA) shall be marked

115 on the package label.

116 6.4

117 Addition of heading title and replacement of text:

118 6.4 Colour coding for miniature fuse-links for special applications

119 Marking of fuse-links by means of colour bands according to IEC 60127-1:2006, Annex A, is

120 not permitted. It is, however, possible to use colour markings that clearly differ from this colour

121 band system. In this case, the manufacturer shall provide the relevant information, for example

122 colour key.

123 Additional subclause:

124 6.101 Where marking is impracticable due to space limitations, the relevant information should

125 appear on the smallest package and in the manufacturer’s technical literature.

126 7 General notes on tests

127 Clause 7 of IEC 60127-1:2006 applies except as follows.

128 7.2 Type tests

129 7.2.1

130 Replacement:

131 For testing the individual current ratings of fuses with a.c. or d.c. breaking capacity, the number

132 of fuse-links required is 51, of which 12 are kept as spares. For fuse-links with wire terminations

133 six extra samples (E1 to E6) have to be taken by random and not sorted according to voltage

134 drop. If necessary, these samples can be used as additional spares after performing the tests

135 according to 8.3.

136 The testing schedule is shown in Table 2.

137 For testing the individual current ratings of fuses with a.c. and d.c. breaking capacity, the

138 number of fuse-links required is 63, of which 9 are kept as spares. For fuse-links with wire

139 terminations six extra samples (E1 to E6) have to be taken by random and not sorted according

140 to voltage drop. If necessary, these samples can be used as additional spares after performing

141 the tests according to 8.3.The testing schedule is shown in Table 3.

142 For testing the maximum ampere rating of a homogenous series with a.c. or d.c. breaking

143 capacity the number of fuse-links required is 51, of which 22 are kept as spares. For fuse-links

144 with wire terminations six extra samples (E1 to E6) have to be taken by random and not sorted

145 according to voltage drop. If necessary, these samples can be used as additional spares after

146 performing the tests according to 8.3.

147 The testing schedule is shown in Table 4.

148 For testing the maximum ampere rating of a homogenous series with a.c. and d.c. breaking

149 capacity the number of fuse-links required is 66, of which 32 are kept as spares. For fuse-links

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 7 32C/647CDV

150 with wire terminations six extra samples (E1 to E6) have to be taken by random and not sorted

151 according to voltage drop. If necessary, these samples can be used as additional spares after

152 performing the tests according to 8.3.

153 The testing schedule is shown in Table 5.

154 For testing the minimum ampere rating of a homogenous series with a.c. and / or d.c. breaking

155 capacity the number of fuse-links required is 38, of which 16 are kept as spares.

156 The testing schedule is shown in Table 6.

157 For testing all of the intermediate ampere rating of a homogenous series with a.c. and / or d.c.

158 breaking capacity the number of fuse-links required is 38, of which 16 are kept as spares.

159 The testing schedule is shown in Table 7.

160 7.3 Fuse-bases for tests

161 Addition after first paragraph:

162 For fuse-links designed for use in a special type of fuse-holder, testing shall be performed in

163 that fuse-holder. Fuse-holder information shall be supplied to users in manufacturer’s literature.

164 For tests that require a printed circuit board for mounting and connection of the fuse-links, a

165 test board according to Figure 1 or Figure 2 shall be used.

166 The test board according to Figure 1 shall be used for fuse links with wire terminations intended

167 for insertion in suitably designed holes or sockets.

168 The test board according to Figure 2 shall be used for surface mount fuse-links. The test board

169 shall be made of epoxide woven glass fabric copper-clad laminated sheet, as defined in

170 IEC 61249-2-7. The manufacturer must dec l a r e the PCB parameters and provide assembled

PCBs for the tests.

171 When two or more fuse-links are tested in series, the fuse-bases shall be located so that there

172 will be a spacing of not less than 50 mm between any two fuse-links under testing. The

173 conductor connecting the fuse-bases together, and connecting the fuse-bases to the ammeter

174 and the source of supply shall be insulated copper wire. The length of each conductor shall be

175 500 mm. The cross-sectional area of the wire shall be according to Table 8.

176 Table 8 – Cross-sections of conductors

Rated current Copper conductor cross section

A mm

Up to and including 5 1

More than 5, and up to and including 10 1.5

More than 10, and up to and including 16 2.5

More than 16, and up to and including 25 4

More than 25, and up to and including 35 6

More than 35, and up to and including 60 35

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 8 32C/647CDV

More than 60, and up to and including 125 50

177 Dimensions in millimetres

∅4,2

O U

U

n × e

Figure 1A

∅ D

n1 × e

Radius =

IEC

179 Key

180 O copper layer; thickness 0,035 mm or 0,070 mm

181 U connection for voltage drop measurement

182 D diameter of 1 mm for rated currents up to and including 6,3 A;

183 diameter of 1,5 mm for rated currents exceeding 6,3 A.

184 e 2,5 mm

185 n 1, 2, 3, 4

186 n 1, 2, 3 … (to be adapted depending on the length of the fuse-link)

187 Figure 1 – Standard test board for fuse-links with wire terminations

188 This test board shall be mounted on the fuse-base according to Figure 3a.

n × e

16,5 3

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 9 32C/647CDV

Dimensions in millimetres

oSIST prEN IEC 60127-7:2024

191 Key

IEC CDV 60127-7/Ed3 © IEC 2024 10 32C/647CDV

192 O copper layer, thickness, refer to table 8

193 U connection for voltage drop measurement. The connection tracks covered by the solder resist should be placed

194 as closely to the solder pads as possible. A minimum separation of 1 mm must be ensured.

195 W Track width, refer to table 8. For small devices, it may be necessary to use reduced track widths, representing

196 normal use of these devices. This should be recorded in the test report and in the manufacturer's literature.

200 NOTE 1 Solder resist to be applied in hatched areas. The whole surface is covered, only soldering pads and

201 connectors are exposed.

202 NOTE 2 Land sizes of the test boards are calculated following IPC-7351B-2010 Clause 3.1.5.

2 2 2

203 Z =L +2J +sqrt(C +F +P )

max min T L

2 2 2

204 G =S -2J -sqrt(C +F +P )

min max H S

2 2 2

205 X =W +2J +sqrt(C +F +P )

max min S W

Z is the overall length of land pattern,

G is the distance between lands of the pattern,

X is the width of land pattern,

L is the overall length of component,

S is the distance between component terminations,

W is the width of the lead or termination,

J is the desired dimension of solder fillet or land protrusion:

JT is the solder fillet or land protrusion at toe (typically 0 mm for fuses),

JH is the solder fillet or land protrusion at heel (typically 0 mm for fuses),

J is the solder fillet or land protrusion at side (typically 0.1 mm for fuses),

S

C is the component tolerances:

C is the tolerance on component length

L

C is the tolerance on distance between component terminations

S

C is the tolerance on the lead width

W

F is the printed board fabrication (land pattern geometric) tolerances,

P is the part placement tolerance (placement equipment accuracy)

206 Figure 2 – Test board for surface mount fuse-links

207 This test board shall be mounted on the fuse-base according to Figure 3b.

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 11 32C/647CDV

208 The land areas should be suitably prepared for soldering.

209 A mechanical device may be used as long as it is demonstrated that the results are the same

210 (not applicable to 9.7).

220 Dimensions in millimetres

C

F

D

D

G

E

E B

A

IEC

222 Figure 3a – Fuse-links with wire terminations (printed circuit track underneath)

C

K

K

J

J

F

E

E

B

A

IEC

224 Figure 3b – Surface mount fuse-link (printed circuit track on top)

225 Dimensions in millimetres

H

IEC

A base of low heat conducting material, thickness F printed circuit board (see Figure 1 and Figure 2)

10 mm

B G space between fuse body and board equals

brass electrodes 10 mm × 10 mm

(0,5 ± 0,25) mm

C Fuse-link soldered in place H top view of base with brass electrodes

D fixing screws J silver-plated brass washer (two places)

E contact screws holding solder terminal K silver-plated brass screw to make contact with

the conducting surface on top of the printed

circuit board(two places)

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 12 32C/647CDV

227 Figure 3 – Test fuse base

228 The test board shall be made of epoxide woven glass fabric copper-clad laminated sheet, as

229 defined in IEC 61249-2-7.

230 The nominal sheet thickness shall be 1,6 mm.

231 Preferred values for the nominal thickness and width of copper layer are given in table 8.

232 Manufacturer may specify different values. Multilayer designs using VIAs are allowed.

233 The nominal thickness and nominal width of applied copper layer shall be stated in the test

234 report.

235 Metal parts of the fuse-base shall be made of brass with a copper content between 58 % and

236 70 %. Contact parts shall be silver-plated.

237 Table 8: Copper track specifications for test board for surface mount fuse-links

Rated current [A] O copper thickness TW track width [mm] Copper cross section

[µm] [mm ]

+/- 15%

≤ 5 A 35 5 0.18

6.3 A to 8 A 70 7.5 0.53

10 A to 12.5 A 140 7.5 1.05

16 A to 20 A 140 10 1.40

25 A to 30 A 140 15 2.10

40 A to 50 A 210 20 4.20

60 A to 125 A 280 22 6.20

238 Note: The cable connector shall be in accordance with the cable cross section.

239 The copper layer thickness and track width information shall be supplied to users in manufacturer’s literature.

240 7.4 Nature of supply

241 Addition, after second paragraph:

242 Schedule for testing fuse-links with a.c. or d.c. breaking capacity according to Standard Sheet 1,

243 see Table 2.

244 Schedule for testing fuse-links with a.c. and d.c. breaking capacity according to Standard

245 Sheet 1, see Table 3.

246 8 Dimensions and construction

247 Clause 8 of IEC 60127-1:2006 applies except as follows.

248 8.2 Construction

249 Replacement:

oSIST prEN IEC 60127-7:2024

IEC CDV 60127-7/Ed3 © IEC 2024 13 32C/647CDV

250 The fuse-element shall be completely enclosed.

251 The fuse-links shall be resistant to heat according to 9.7, and to fire according to IEC 60695-2-

252 12 and IEC 60695-2-13.

253 This is not applicable for fuse-links which represent small parts according to IEC 60695-4:2012,

254 3.78.

255 For fuse bodies made of plastic material or of material containing organic substances the

256 following minimum requirements apply:

257 – Glow-wire ignition temperature (GWIT) = 775 °C

258 – Glow-wire flammability index (GWFI) = 850 °C

259 NOTE 1 Dimensions for the material plates for the glow wire tests are given in IEC 60695-2-12:2010, 4.2 or in

260 IEC 60695-2-13:2010, 4.2.

261 NOTE 2 For materials such as glass and ceramic whose GWIT and GWFI are thought to be higher than 775 °C and

262 respectively 850 °C the glow-wire tests do not apply.

263 8.3 Fuse-link terminations

264 Replacement:

265 Subclause 8.3 applies only to fuse-links with wire terminations.

266 Fuse-link contacts shall be made of non-corroding material or of material suitably protected

267 against corrosion, and shall be effectively free from flux or other non-conducting substance on

268 their outer surfaces.

269 Nickel or silver plating is deemed to be adequate protection for brass end caps.

270 The fuse-link terminations shall be reliably attached.

271 The samples shall be immersed in water for 24 h at a temperature of between 15 °C and 35 °C.

272 Terminations shall withstand the mechanical forces likely to be encountered during normal use.

273 With the fuse-link held in a fixed position,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...