EN 50059:2018

(Main)Electrostatic hand-held spraying equipment - Safety requirements - Hand-held spraying equipment for non-ignitable coating materials

Electrostatic hand-held spraying equipment - Safety requirements - Hand-held spraying equipment for non-ignitable coating materials

1.1 This European Standard specifies the requirements for hand-held or hand-operated electrostatic spraying equipment for non-ignitable liquid coating materials which — do not generate an explosive atmosphere inside the spraying area; — are used to process materials with a conductivity of less than 2 000 µS/cm; — operate with direct current having a sinusoidal ripple of not more than 10 % of the rms value. This European Standard deals with all electrical hazards significant for the electrostatic spraying of non-ignitable liquid coating materials, which could also contain small quantities of added metal particles, if the work is carried out under conditions recommended by the manufacturer. This European Standard specifies the design-related and test requirements for electrostatic spraying equipment of type A-NL according to Table 1 of EN 50348:2010. 1.2 With regard to all other significant hazards relevant for applicators (e.g. ejection of fluids, mechanical strength, electrical - apart from electrostatic - hazards, noise, contact with or inhalation of dangerous substances, ergonomics) the requirements of EN 1953 apply. 1.3 This European Standard also gives details regarding quality assurance systems for electrostatic spraying equipment, see Annex D. 1.4 For electrostatic spraying equipment used in food and pharmaceutical industry, additional requirements may apply. 1.5 This document is not applicable to — electrostatic hand-held spraying equipment for non-ignitable coating materials which are manufactured before the date of its publication as EN, — cleaning of spraying areas, see instruction manual of the spraying booth, — fire prevention and protection [for instance fire hazards due to other sources; see EN 12215, EN 12981], — requirements for machinery for the supply and recirculation of coating material under pressure [see EN 12621]. The requirements of EN 12621 apply for specific requirements for machinery for the supply and recirculation of coating materials under pressure.

Elektrostatische Handsprüheinrichtungen - Sicherheitsanforderungen - Handsprüheinrichtungen für nichtentzündbare Beschichtungsstoffe

Diese Europäische Norm legt Anforderungen für in der Hand gehaltene oder von Hand geführte elektrostatische Sprüheinrichtungen für nichtentzündbare flüssige Beschichtungsstoffe, die: – keine explosionsfähige Atmosphäre innerhalb des Sprühbereiches erzeugen; – zur Verarbeitung von Stoffen mit einer Leitfähigkeit von weniger als 2 000 S/cm verwendet werden; – mit Gleichstrom mit einer sinusförmigen Welligkeit von höchstens 10 % des Effektivwertes betrieben werden. Diese Europäische Norm behandelt alle elektrischen Gefährdungen, die für den elektrostatischen Sprühauf-trag von nichtentzündbaren Beschichtungsstoffen, die auch geringe Mengen an zugesetzten Metallpartikel enthalten können, von Bedeutung sind, wenn unter Bedingungen, die der Hersteller empfiehlt, gearbeitet wird. Diese Europäische Norm legt die Anforderungen für Konstruktion und Prüfung von elektrostatischen Sprüh-einrichtungen des Typ A-NL nach EN 50348:2010, Tabelle 1 fest. 1.2 Bezüglich aller anderen für Auftragseinrichtungen signifikanten Gefährdungen (z. B. Herausspritzen von Flüssigkeiten, mechanische Festigkeit, elektrische – ausgenommen elektrostatische – Gefährdungen, Lärm, Kontakt mit oder Einatmen von schädlichen Stoffen, Ergonomie) gelten die Anforderungen von EN 1953. 1.3 Diese Europäische Norm enthält auch Einzelheiten zu Qualitätssicherungssystemen für elektro-statische Sprüheinrichtungen, siehe Anhang D. 1.4 Für elektrostatische Sprüheinrichtungen, die in der Lebensmittel- und Pharmaindustrie eingesetzt werden, können zusätzliche Anforderungen gelten. 1.5 Dieses Dokument ist nicht anwendbar auf: – elektrostatische Handsprüheinrichtungen für nichtentzündbare Beschichtungsstoffe, die vor dem Erscheinen dieses Dokuments als Europäische Norm, hergestellt wurden; – die Reinigung von Sprühbereichen, siehe Betriebsanleitung der Lackierkabine; – den Brandschutz [z. B. Brandgefahren durch andere Quellen, siehe EN 12215, EN 12981]; – Anforderungen an Förder und Umlaufanlagen für Beschichtungsstoffe unter Druck [siehe EN 12621]. Für Förder- und Umlaufanlagen für Beschichtungsstoffe unter Druck gelten die spezifischen Anforderungen von EN 12621.

Équipement manuel de projection électrostatique - Exigences de sécurité - Équipement manuel de projection de revêtement ininflammable

1.1 La présente Norme européenne spécifie les exigences relatives aux équipements portatifs ou manuels de projection électrostatique de produits liquides de revêtement ininflammables qui - ne génèrent pas d'atmosphère explosive au sein de l'emplacement de projection; - sont utilisés pour traiter les matériaux ayant une conductivité inférieure à 2 000 µS/cm; - fonctionnent en courant continu avec une ondulation sinusoïdale inférieure ou égale à 10 % de la valeur efficace. La présente Norme européenne traite de tous les dangers électriques importants concernant la projection électrostatique de produits liquides de revêtement ininflammables pouvant également comporter de petites quantités de particules de métal supplémentaires, si la tâche est réalisée dans les conditions recommandées par le constructeur. La présente Norme européenne spécifie les exigences relatives à la conception et les exigences d'essai des équipements de projection électrostatique de type A-NL, conformément au Tableau 1 de l'EN 50348:2010. 1.2 Les exigences de l'EN 1953 s'appliquent pour tous les autres dangers significatifs concernant les applicateurs (par exemple, éjection de fluides, résistance mécanique, dangers électriques (à l’exception des dangers électrostatiques), bruit, contact avec ou inhalation des substances dangereuses, ergonomie). 1.3 La présente Norme européenne fournit également des informations détaillées concernant les systèmes d'assurance qualité des équipements de projection électrostatique, voir l'Annexe D. 1.4 Pour les équipements de projection électrostatique utilisés dans l'industrie alimentaire et dans l'industrie pharmaceutique, des exigences supplémentaires peuvent s'appliquer. 1.5 Le présent document ne s'applique pas - aux équipements portatifs de projection électrostatique de revêtement ininflammable fabriqués avant sa date de publication comme EN, - au nettoyage des emplacements de projection, voir le manuel d'instructions de la cabine de projection, - à la prévention et la protection contre le feu [par exemple dangers d'incendie dus à d’autres sources; voir l'EN 12215 et l'EN 12981], - aux exigences relatives aux machines d'alimentation et de circulation de produits de revêtement sous pression [voir l'EN 12621]. Les exigences de l'EN 12621 s'appliquent aux exigences spécifiques applicables aux machines d'alimentation et de circulation de produits de revêtement sous pression.

Oprema za ročno elektrostatično brizganje - Varnostne zahteve - Ročna oprema za brizganje nevnetljivih premazov

1.1 Ta evropski standard določa zahteve za ročno opremo za elektrostatično brizganje nevnetljivih premazov, ki

– ne ustvarjajo eksplozivne atmosfere na območju brizganja;

– se uporabljajo za obdelavo materialov s prevodnostjo manj kot 2000 μS/cm;

– delujejo z enosmernim tokom s sinusoidnim valovanjem, ki ne presega 10 % efektivne vrednosti.

Ta evropski standard zajema vse električne nevarnosti, ki se pojavijo pri elektrostatičnem brizganju nevnetljivih tekočih materialov, ki lahko vsebujejo tudi manjše količine dodanih kovinskih delcev, če se delo izvaja pod pogoji, ki jih priporoča proizvajalec.

Ta evropski standard določa zahteve, povezane z zasnovo in preskušanjem, za elektrostatično opremo za brizganje vrste A–NL v skladu s tabelo 1 standarda EN 50348:2010.

1.2. Vse ostale večje nevarnosti, povezane z opremo za nanašanje (npr. nanašanje tekočin, mehanska trdnost, nevarnosti zaradi elektrike (razen elektrostatičnih nevarnosti), hrup, stik z nevarnimi snovmi ali njihovo vdihavanje, ergonomika), so zajete v standardu EN 1953.

1.3 Ta evropski standard navaja tudi podrobnosti glede sistemov zagotavljanja kakovosti za opremo za elektrostatično brizganje.

1.4 Za opremo za elektrostatično brizganje, ki se uporablja v živilski in farmacevtski industriji, lahko veljajo dodatne zahteve.

General Information

- Status

- Published

- Publication Date

- 26-Jul-2018

- Withdrawal Date

- 26-Jul-2021

- Technical Committee

- CLC/TC 204 - Safety of electrostatic painting and finishing equipment

- Drafting Committee

- CLC/TC 204 - Safety of electrostatic painting and finishing equipment

- Current Stage

- 6060 - Document made available - Publishing

- Start Date

- 27-Jul-2018

- Due Date

- 20-Mar-2018

- Completion Date

- 27-Jul-2018

Relations

- Effective Date

- 07-Jun-2022

- Effective Date

- 22-Oct-2019

- Refers

EN ISO 20344:2021 - Personal protective equipment - Test methods for footwear (ISO 20344:2021) - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 60079-7:2007 - Explosive atmospheres - Part 7: Equipment protection by increased safety "e" - Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

Overview

EN 50059:2018 (CLC) - Electrostatic hand-held spraying equipment - Safety requirements - specifies safety, design and test requirements for hand-held or hand-operated electrostatic spraying equipment used with non-ignitable liquid coating materials. The standard covers equipment that:

- does not generate an explosive atmosphere in the spraying area,

- processes coating liquids with conductivity < 2 000 µS/cm,

- operates on direct current with a sinusoidal ripple ≤ 10% of the rms value.

EN 50059:2018 focuses on electrical and electrostatic hazards specific to electrostatic hand-held spraying equipment (type A‑NL per EN 50348) and includes requirements for design, testing, user information and quality assurance.

Key Topics and Requirements

- Electrical safety and electrostatic hazards: measures to limit hazardous discharges, earthing, insulation and prevention of dangerous contact currents (ventricular fibrillation risk is specifically addressed).

- Performance and type tests: tests for earth connections, resistance, OFF-position integrity, and measurement of high-voltage and short‑circuit current parameters.

- Mechanical conditioning tests: cable/hose pull, impact and drop tests to verify durability of applicators and accessories.

- Discharge testing: normative Annex A defines tests for discharge peak current IC(p) and pulse duration ti; Annex B provides an informative example.

- Degree of protection and IP: tests for applicator enclosures and accessories (IP ratings per EN 60529).

- Information for use and marking: instruction manual content, cleaning/maintenance guidance, test intervals and mandatory marking of applicators and control devices.

- Quality assurance: Annex D describes quality assurance systems applicable to electrostatic spraying equipment.

Applications

EN 50059:2018 is intended for:

- Manufacturers of electrostatic hand-held spraying applicators and control devices.

- Test laboratories performing type and routine tests for electrostatic applicators.

- Safety engineers and compliance officers in coating and finishing operations.

- OEMs integrating electrostatic applicators into booths or finishing lines.

Typical use-cases include industrial paint shops, automotive refinishing, and general powder/liquid coating processes using non-ignitable coatings. Note: additional or stricter requirements may apply for food and pharmaceutical industries.

Who Should Use This Standard

- Product designers and R&D teams developing electrostatic applicators.

- Certification bodies and notified test houses.

- Plant managers and safety officers responsible for safe operation and maintenance.

- Procurement teams specifying compliance for hand-held electrostatic equipment.

Related Standards

EN 50059:2018 references and complements standards such as:

- EN 50348 (stationary electrostatic equipment, type A‑NL classification)

- EN 1953 (general atomising and spraying safety)

- EN 12621, EN 12215 (supply/recirculation and spray booth safety)

- EN 1149-5, EN 60204-1, EN 60529, EN ISO 12100, EN ISO 13849-1, EN 62061

Using EN 50059:2018 helps manufacturers and users reduce electrostatic and electrical risks and ensures conformity with relevant EU safety requirements.

Frequently Asked Questions

EN 50059:2018 is a standard published by CLC. Its full title is "Electrostatic hand-held spraying equipment - Safety requirements - Hand-held spraying equipment for non-ignitable coating materials". This standard covers: 1.1 This European Standard specifies the requirements for hand-held or hand-operated electrostatic spraying equipment for non-ignitable liquid coating materials which — do not generate an explosive atmosphere inside the spraying area; — are used to process materials with a conductivity of less than 2 000 µS/cm; — operate with direct current having a sinusoidal ripple of not more than 10 % of the rms value. This European Standard deals with all electrical hazards significant for the electrostatic spraying of non-ignitable liquid coating materials, which could also contain small quantities of added metal particles, if the work is carried out under conditions recommended by the manufacturer. This European Standard specifies the design-related and test requirements for electrostatic spraying equipment of type A-NL according to Table 1 of EN 50348:2010. 1.2 With regard to all other significant hazards relevant for applicators (e.g. ejection of fluids, mechanical strength, electrical - apart from electrostatic - hazards, noise, contact with or inhalation of dangerous substances, ergonomics) the requirements of EN 1953 apply. 1.3 This European Standard also gives details regarding quality assurance systems for electrostatic spraying equipment, see Annex D. 1.4 For electrostatic spraying equipment used in food and pharmaceutical industry, additional requirements may apply. 1.5 This document is not applicable to — electrostatic hand-held spraying equipment for non-ignitable coating materials which are manufactured before the date of its publication as EN, — cleaning of spraying areas, see instruction manual of the spraying booth, — fire prevention and protection [for instance fire hazards due to other sources; see EN 12215, EN 12981], — requirements for machinery for the supply and recirculation of coating material under pressure [see EN 12621]. The requirements of EN 12621 apply for specific requirements for machinery for the supply and recirculation of coating materials under pressure.

1.1 This European Standard specifies the requirements for hand-held or hand-operated electrostatic spraying equipment for non-ignitable liquid coating materials which — do not generate an explosive atmosphere inside the spraying area; — are used to process materials with a conductivity of less than 2 000 µS/cm; — operate with direct current having a sinusoidal ripple of not more than 10 % of the rms value. This European Standard deals with all electrical hazards significant for the electrostatic spraying of non-ignitable liquid coating materials, which could also contain small quantities of added metal particles, if the work is carried out under conditions recommended by the manufacturer. This European Standard specifies the design-related and test requirements for electrostatic spraying equipment of type A-NL according to Table 1 of EN 50348:2010. 1.2 With regard to all other significant hazards relevant for applicators (e.g. ejection of fluids, mechanical strength, electrical - apart from electrostatic - hazards, noise, contact with or inhalation of dangerous substances, ergonomics) the requirements of EN 1953 apply. 1.3 This European Standard also gives details regarding quality assurance systems for electrostatic spraying equipment, see Annex D. 1.4 For electrostatic spraying equipment used in food and pharmaceutical industry, additional requirements may apply. 1.5 This document is not applicable to — electrostatic hand-held spraying equipment for non-ignitable coating materials which are manufactured before the date of its publication as EN, — cleaning of spraying areas, see instruction manual of the spraying booth, — fire prevention and protection [for instance fire hazards due to other sources; see EN 12215, EN 12981], — requirements for machinery for the supply and recirculation of coating material under pressure [see EN 12621]. The requirements of EN 12621 apply for specific requirements for machinery for the supply and recirculation of coating materials under pressure.

EN 50059:2018 is classified under the following ICS (International Classification for Standards) categories: 87.100 - Paint coating equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 50059:2018 has the following relationships with other standards: It is inter standard links to EN 50059:1990, EN 50059:2025, EN ISO 20344:2021, EN 1149-5:2018, EN ISO 12100:2010, EN ISO 13849-1:2023, EN 16985:2018, EN 1953:2025, EN 12621:2025, EN 60079-7:2007, EN 60204-1:2018, EN 50348:2010, EN 60529:1991, EN IEC 62061:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 50059:2018 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 50059:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Elektrostatische Handsprüheinrichtungen - Sicherheitsanforderungen - Handsprüheinrichtungen für nichtentzündbare BeschichtungsstoffeEquipement manuel de projection électrostatique - Exigences de sécurité - Equipement manuel de projection de revêtement ininflammableElectrostatic hand-held spraying equipment - Safety requirements - Hand-held spraying equipment for non-ignitable coating materials87.100Oprema za nanašanje premazovPaint coating equipmentICS:Ta slovenski standard je istoveten z:EN 50059:2018SIST EN 50059:2018en01-oktober-2018SIST EN 50059:2018SLOVENSKI

STANDARDSIST EN 50059:20011DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 50059

July 2018 ICS 87.100

Supersedes

EN 50059:1990

English Version

Electrostatic hand-held spraying equipment - Safety requirements - Hand-held spraying equipment for non-ignitable coating materials

Équipement manuel de projection électrostatique - Exigences de sécurité - Équipement manuel de projection de revêtement ininflammable

Elektrostatische Handsprüheinrichtungen - Sicherheitsanforderungen - Handsprüheinrichtungen für nichtentzündbare Beschichtungsstoffe This European Standard was approved by CENELEC on 2018-01-02. CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions. CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique Europäisches Komitee für Elektrotechnische Normung CEN-CENELEC Management Centre: Rue de la Science 23,

B-1040 Brussels © 2018 CENELEC All rights of exploitation in any form and by any means reserved worldwide for CENELEC Members.

Ref. No. EN 50059:2018 E SIST EN 50059:2018

Test of a discharge with the peak current value IC (p) and the pulse duration ti (type test) . 21 Annex B (informative)

Example for discharge test . 24 Annex C (informative)

Ignitability of water-based paints . 26 Annex D (informative)

Quality assurance systems for electrostatic spraying equipment . 28 Annex ZZ (informative)

Relationship between this European standard and the essential requirements of Directive 2006/42/EC aimed to be covered . 30 Bibliography . 31

Tables Table 1 — Test intervals . 18 Table ZZ.1 — Correspondence between this European Standard and Annex I of Directive 2006/42/EC . 30

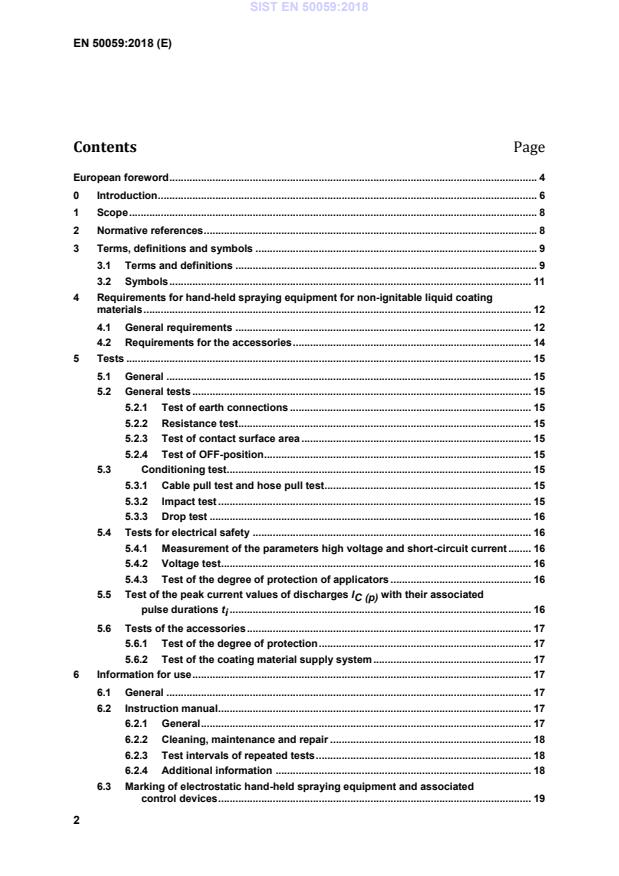

Figures Figure 1 — Pulse duration - body current, ventricular fibrillation risk . 12 Figure A.1 — Equivalent circuit diagram . 22 Figure A.2 — Schematic discharge curve . 23 Figure B.1 — Discharge plot . 24

4 European foreword This document (EN 50059:2018) has been prepared by Technical Committee CEN-CENELEC/TC 204 “pafety of electrostatic painting and finishing equipment”. The following dates are fixed: • latest date by which this document has to be implemented at national level by publication of an identical national standard or by endorsement bdop) 2M19-M1-2q • latest date by which the national standards conflicting with this document have to be withdrawn bdow) 2M21-Mq-2q qhis document supersedes bN oMMo9:199M. bN oMMo9:2M18 includes the following significant technical changes with respect to bN oMMo9:199M: — modification of the title of the standard; — extension of introduction; — extension of normative references; — extension of terms and definitions; — new arrangement, amendment and complement of the requirements for hand-held spraying equipment for non-ignitable liquid coating materials; — definition of requirements for safety functions; — new arrangement, amendment and complement of tests for hand-held spraying equipment for non-ignitable liquid coating materials; — new arrangement and extension of the information for use; — definition of requirements for repeated tests; — introduction of the normative Annex A "Test of a discharge with the peak current value IC (p) and the pulse duration ti (type test)"; — introduction of the informative Annex B “bxample for discharge test”; — introduction of the informative Annex C “fgnitability of water-based paints”; — introduction of the informative Annex D “nuality assurance systems for electrostatic spraying equipment”; — introduction of the informative Annex ZZ “oelationship between this European standard and the essential requirements of Directive 2006/42/EC aimed to be covered". Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CENELEC shall not be held responsible for identifying any or all such patent rights. SIST EN 50059:2018

6 0 Introduction 0.1 Process During the electrostatic coating process the non-ignitable liquid coating material is transported from a reservoir to an applicator where it is atomised by mechanical forces and by the influence of an electric field. The coating material is charged by high voltage of some 10 kV and a spray cloud is generated. The charged droplets of the coating materials are attracted by and applied to the earthed workpiece. Droplets of the coating material, which are not applied to the workpiece (overspray) are removed by a suction device or by other means. After the coating process the coated workpieces are introduced into a dryer or oven where a dry film of coating material is generated. 0.2 Fire hazards 0.2.1 Fire hazards can be caused by deposits of coating materials inside the spray booth, exhaust air ducts, the recovery system for coating materials, and filters. During operation, malfunctions or electrical faults may cause ignition of these residues. The propagation of the fire leads to hazards also in adjacent areas. 0.2.2 Particular attention should be paid to the prevention of electrostatic charges on different surfaces, which are in the vicinity of the spray cloud. This could apply both to workpieces during the coating process or the reciprocating devices and the mounting parts of the spraying system, etc. 0.2.3 When spraying non-ignitable coating material, the formation of an explosive atmosphere is not likely to occur. Electrostatic application equipment for ignitable coating materials are covered by EN 50050-1, EN 50050-2 and EN 50050-3. 0.3 Electric hazards 0.3.1 Electric shock (by direct or indirect contact) can be generated, for instance, by contact with — live parts, which are not insulated for operational reasons, — conductive parts, which are not connected to dangerous voltage during normal operation, but only in case of failure, — insulated live parts with insufficient or damaged insulation due to external impact, — charged passive parts with inadequate earthing. 0.3.2 Inadequate earthing may occur, for instance, due to — faulty connections to the protective earthing system, — a too high resistance to earth (e.g. contamination by coating materials). 0.3.3 Hazards could occur, for instance, if hazardous malfunctions (e.g. shortcut of electronic safety circuits) occur due to interferences of the electrostatic high voltage equipment and the components of the control and safety systems. 0.3.4 Hazardous electrostatic discharges could be generated, for instance, by non-earthed conductive components or by large insulating surfaces, especially if they are backed with conductive material. SIST EN 50059:2018

or the specific fibrillation energy in accordance with IEC/TS 60479-1 and IEC TS 60479-2. A power limit as given in the standards EN 50176, EN 50177, EN 50223 and EN 50348 is not applicable in this standard due to the characteristics of the equipment and the resulting hazard of electric current. SIST EN 50059:2018

8 1 Scope 1.1 This European Standard specifies the requirements for hand-held or hand-operated electrostatic spraying equipment for non-ignitable liquid coating materials which — do not generate an explosive atmosphere inside the spraying area; — are used to process materials with a conductivity of less than 2 000 µS/cm; — operate with direct current having a sinusoidal ripple of not more than 10 % of the rms value. This European Standard deals with all electrical hazards significant for the electrostatic spraying of non-ignitable liquid coating materials, which could also contain small quantities of added metal particles, if the work is carried out under conditions recommended by the manufacturer. This European Standard specifies the design-related and test requirements for electrostatic spraying equipment of type A-NL according to Table 1 of EN 50348:2010. 1.2 With regard to all other significant hazards relevant for applicators (e.g. ejection of fluids, mechanical strength, electrical - apart from electrostatic - hazards, noise, contact with or inhalation of dangerous substances, ergonomics) the requirements of EN 1953 apply. 1.3 This European Standard also gives details regarding quality assurance systems for electrostatic spraying equipment, see Annex D. 1.4 For electrostatic spraying equipment used in food and pharmaceutical industry, additional requirements may apply. 1.5 This document is not applicable to — electrostatic hand-held spraying equipment for non-ignitable coating materials which are manufactured before the date of its publication as EN, — cleaning of spraying areas, see instruction manual of the spraying booth, — fire prevention and protection [for instance fire hazards due to other sources; see EN 12215, EN 12981], — requirements for machinery for the supply and recirculation of coating material under pressure [see EN 12621]. The requirements of EN 12621 apply for specific requirements for machinery for the supply and recirculation of coating materials under pressure. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 1149-5, Protective clothing - Electrostatic properties - Part 5: Material performance and design requirements EN 1953, Atomising and spraying equipment for coating materials - Safety requirements EN 12215, Coating plants - Spray booths for application of organic liquid coating materials - Safety requirements SIST EN 50059:2018

10 3.1.5 high voltage electrode conductive part, which is at high voltage and serves to directly or indirectly charging of the coating material 3.1.6 control device device generally having the following functions: — control of, for instance, the coating material supply system and the control air Note 1 to entry: A combination of the control device and the high voltage supply according to 3.1.8 is possible. 3.1.7 applicator equipment for application of coating material that comprises the following parts in general: — if applicable, high voltage electrode; — high voltage supply (as far as integrated into the applicator); — housing; — spraying device; — exchangeable attachment parts (e.g. nozzles, extensions, angular pieces, etc.); — if applicable, battery unit (integrated fixedly, or attached) 3.1.8 high voltage supply for applicators high voltage supply comprising the following parts in general: — low voltage section with devices for switching on and off the hand-held spraying equipment and for adjustment, control, regulation, limitation and monitoring of current and voltage, as well as the required connecting cables; — high voltage generator 3.1.9 spraying area area, closed or not, in which the coating material is applied to the workpiece by the hand-held spraying equipment 3.1.10 dangerous discharge discharge which generates a hazard of electric shock 3.1.11 coating material supply system coating material supply system that comprises the following in general: — reservoir for coating materials; — dosing and mixing devices for coating materials; — supply lines for coating materials; — devices for drive, control and monitoring supply of coating materials; — charging device for liquid coating material SIST EN 50059:2018

12 4 Requirements for hand-held spraying equipment for non-ignitable liquid coating materials 4.1 General requirements 4.1.1 Hand-held spraying equipment shall be designed and constructed that both — in case of long-time contact (> 1 s) of live parts and charged passive parts, the short-circuit current flowing through the user does not exceed the maximum of 30 mA DC (see 5.4.1.2), and — in case of discharge times of less than 10 ms from live parts and charged passive parts the body current with the value IB rms of a discharge does not exceed the boundary line C1 of Figure 1 (see 5.5, 5.6.2 and Annex A and Annex B). NOTE 1 A discharge in the timeframe between 10 ms and 1 s does not occur in this type of equipment.

Figure 1 — Pulse duration - body current, ventricular fibrillation risk SIST EN 50059:2018

4.1.6 Operating triggers of the applicators shall be biased to the OFF-position. In this position, the coating material supply system shall be cut-off immediately, and the high voltage supply shall be cut-off. For high voltage supplies having several outlets, the cut-off function shall be ensured for each outlet/applicator individually. 4.1.7 Applicators shall have an earth connection. The resistance to earth shall not exceed 1 The connection shall be designed in accordance with 4.2.1 of EN 60079-7:2007. 4.1.8 All components shall be designed, arranged and built in to not impair the safety of the electrostatic hand-held spraying equipment. Examples are spray nozzles, material supply hoses, cables of the earthing system, resistances, mechanical and other electrical or electronic components. Insulating materials of parts under high voltage shall be constructed according to the operation, transport and storage conditions. 4.1.9 The electric equipment not connected to the high voltage system shall comply with EN 60204-1. 4.1.10 If electric limiting components (e.g. resistances) and mechanical limiting components (e.g. material supply hoses) are used, they shall be designed in such a way that they are protected from damage. This can be fulfilled for electric limiting components by switching off the applicator automatically. As an alternative all electric limiting components shall withstand a short-circuit between the high voltage electrode and earth for 5 min. Furthermore, the degree of protection shall remain unchanged. For mechanical limiting components this can be fulfilled e.g. by appropriate construction of hose connections, which prevents the use of non-original spare parts. SIST EN 50059:2018

14 4.1.11 All electrical components of the applicator, other than the spraying device shall be constructed at least equivalent with IP54 of EN 60529.

4.1.12 Electrical cables connected to the applicator shall have an earthed shielding. 4.1.13 High voltage cable shall pass the tests of 5.3.1 and 5.4.2.1. 4.1.14 Material supply hose under high voltage connected to the applicator shall have an earthed shielding. See also EN 12621. 4.1.15 Material supply hose under high voltage shall pass the tests of 5.3.1 and 5.4.2.2. 4.1.16 It shall be ensured that parameters specified in 4.1.1 are observed under any operating conditions. Faults of the high voltage supply for applicators shall be considered. Safety functions (monitoring functions) shall meet the requirements of SIL 2 (e.g. according to EN 62061) or PL d (e.g. according to EN ISO 13849-1). Alternatively, this safety level will be reached if — the parameters specified in 4.1.1 will be limited by the diameter and the length of the material supply hose under high voltage and be limited by the maximum design short-circuit current; — the values for the outlet high voltage according to 5.4.1.1 will be limited by two Zener diodes or equivalent parts (e.g. power semiconductors) loaded up to two-thirds of the maximum rated current in the case of failure. In general, the fail-safe principle shall be applied. In case of failure of the safety functions the hand-held spraying equipment shall be led in a safe state. 4.1.17 Hand-held spraying equipment shall be equipped with an interface for the exchange of safety related signals (e.g. for interlocking with the forced ventilation of the spray booth). 4.2 Requirements for the accessories 4.2.1 Accessories shall fulfil the applicable requirements of 4.1.1. If parts of the coating material supply system do not meet this requirement, protective measures shall be taken to avoid any contact with parts under high voltage potential during normal operation. 4.2.2 Accessories to be used in spraying areas shall at least comply with the requirements of degree of protection IP54 according to EN 60529. 4.2.3 Control devices shall have a separate earth connection. 4.2.4 It shall not be possible to modify the safety-relevant operating parameters outlet high voltage and short-circuit current from the limit values tested according to 5.4.1.1 and 5.4.1.2. 4.2.5 Detachable earth connections shall be marked clearly. 4.2.6 In case conductive parts are used for coating material supply system, these parts shall be earthed according to 4.1.7, or shall be connected to the high voltage supply in such a way that their potential is per

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...