EN 14988:2017+A2:2024

(Main)Children's high chairs - Requirements and test methods

Children's high chairs - Requirements and test methods

This European Standard specifies safety requirements for free standing children's high chairs that elevate children to dining table height usually for the purposes of feeding or eating. Children's high chairs are for children up to 3 years of age who are capable of sitting unaided.

With the exception of special high chairs for medical purposes, this standard applies to children's high chairs for domestic and non-domestic use.

NOTE If a children's high chair has to or can be converted into other functions, additional European Standards may apply.

Kinderhochstühle - Anforderungen und Prüfverfahren

Dieses Dokument legt sicherheitstechnische Anforderungen an freistehende Kinderhochstühle fest, die ein Kind auf die Höhe eines Esstisches heben, üblicherweise zum Füttern oder Essen. Kinderhochstühle sind für Kinder bis zu einem Alter von 3 Jahren, die eigenständig sitzen können.

Dieses Dokument ist für Kinderhochstühle für den Wohn- und Nicht-Wohnbereich anwendbar, mit Ausnahme von Spezialhochstühlen für medizinische Zwecke.

ANMERKUNG Falls ein Kinderhochstuhl für andere Funktionen umgebaut werden muss oder kann, können zusätzliche Europäische Normen gelten.

Chaises hautes pour enfants - Exigences et méthodes d'essai

Otroški visoki stoli - Zahteve in preskusne metode (vključno z dopolnilom A2)

Ta evropski standard določa varnostne zahteve za prosto stoječe otroške visoke stole na višini jedilne mize, običajno namenjene za hranjenje ali prehranjevanje otrok. Otroški visoki stoli so namenjeni otrokom do tretjega leta starosti, ki lahko samostojno sedijo.

Ta standard se uporablja za otroške visoke stole za domačo in javno rabo, razen za posebne visoke stole za medicinsko uporabo.

OPOMBA: Če otroški visoki stol mogoče pretvoriti tako, da pridobi še druge funkcije, se lahko uporabljajo dodatni evropski standardi.

General Information

- Status

- Published

- Publication Date

- 23-Apr-2024

- Technical Committee

- CEN/TC 364 - Project Committee - High Chairs

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 24-Apr-2024

- Due Date

- 21-Mar-2024

- Completion Date

- 24-Apr-2024

- Directive

- Not Harmonized2001/95/EC - General product safety

Relations

- Effective Date

- 07-Feb-2024

- Effective Date

- 07-Feb-2024

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14988:2017+A2:2024 - published by CEN - is the European Standard for children's high chairs. It specifies safety requirements and test methods for free‑standing high chairs that raise children (up to 3 years old, able to sit unaided) to dining table height for feeding or eating. The standard covers domestic and non‑domestic use and excludes special high chairs for medical purposes. This edition incorporates Amendment A2 (2024) and consolidates previous parts into a hazard‑based format.

Key topics and technical requirements

- Scope and definitions: Applies to free‑standing high chairs for children up to 3 years; defines restraint types (crotch, waist, shoulder), locking/parking devices and the junction line between seat and backrest.

- Hazard‑based requirements: Addresses mechanical hazards, entrapment, suffocation, choking/ingestion, entanglement, thermal and chemical hazards.

- Restraint systems: Improved requirements for restraint systems, including the requirement for a passive crotch restraint when a horizontal component is in front of the child. Differentiates active vs passive restraints.

- Strength, stability and durability: Static and dynamic strength tests and stability checks (including particular rules for high chairs with more than two castors/wheels).

- Folding and adjustment hazards: Tests for hazards caused by folding, height adjustments and moving parts; assembly and most onerous configuration guidance.

- Test methods & equipment: Specifies test masses, impact hammer, probes for finger entrapment, loading pads and tolerances; tests must be performed in defined sequences and conditions.

- Chemical & flammability references: Normative references include EN 71‑2 (flammability), EN 71‑3 (migration of certain elements) and EN 13210‑1; materials testing references like ISO 48‑4 are included.

- Marking and instructions: Requirements for product marking, user instructions and purchase information to ensure safe use.

Practical applications - who uses this standard

- Manufacturers and product designers: To design compliant, safe high chairs and select appropriate restraint and locking systems.

- Test laboratories and conformity assessors: For type testing, durability and dynamic strength evaluation against EN 14988 test methods.

- Retailers & procurement teams: To verify that supplied products meet European safety requirements.

- Regulators and safety authorities: For market surveillance and enforcement of child‑product safety.

- Childcare facilities: To specify safe equipment for infants and toddlers.

Related standards

- EN 71‑2:2020 (Safety of toys - Flammability)

- EN 71‑3:2019+A1:2021 (Migration of certain elements)

- EN 13210‑1:2020 (Child care harnesses/reins)

- ISO 48‑4:2018 (Shore hardness testing)

Keywords: EN 14988, children's high chairs, safety requirements, test methods, CEN, high chair standard, restraint system, stability, mechanical hazards.

Frequently Asked Questions

EN 14988:2017+A2:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Children's high chairs - Requirements and test methods". This standard covers: This European Standard specifies safety requirements for free standing children's high chairs that elevate children to dining table height usually for the purposes of feeding or eating. Children's high chairs are for children up to 3 years of age who are capable of sitting unaided. With the exception of special high chairs for medical purposes, this standard applies to children's high chairs for domestic and non-domestic use. NOTE If a children's high chair has to or can be converted into other functions, additional European Standards may apply.

This European Standard specifies safety requirements for free standing children's high chairs that elevate children to dining table height usually for the purposes of feeding or eating. Children's high chairs are for children up to 3 years of age who are capable of sitting unaided. With the exception of special high chairs for medical purposes, this standard applies to children's high chairs for domestic and non-domestic use. NOTE If a children's high chair has to or can be converted into other functions, additional European Standards may apply.

EN 14988:2017+A2:2024 is classified under the following ICS (International Classification for Standards) categories: 97.140 - Furniture; 97.190 - Equipment for children. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14988:2017+A2:2024 has the following relationships with other standards: It is inter standard links to EN 14988:2017+A1:2020/FprA2, EN 14988:2017+A1:2020, ISO 48-4:2018, EN 13210-1:2020, EN 71-2:2020, EN 71-3:2019+A1:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14988:2017+A2:2024 is associated with the following European legislation: EU Directives/Regulations: 2001/95/EC; Standardization Mandates: M/527. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14988:2017+A2:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2024

Nadomešča:

SIST EN 14988:2017+A1:2020

Otroški visoki stoli - Zahteve in preskusne metode (vključno z dopolnilom A2)

Children's high chairs - Requirements and test methods

Kinderhochstühle - Anforderungen und Prüfverfahren

Chaises hautes pour enfants - Exigences et méthodes d'essai

Ta slovenski standard je istoveten z: EN 14988:2017+A2:2024

ICS:

97.140 Pohištvo Furniture

97.190 Otroška oprema Equipment for children

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14988:2017+A2

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2024

EUROPÄISCHE NORM

ICS 97.140; 97.190 Supersedes EN 14988:2017+A1:2020

English Version

Children's high chairs - Requirements and test methods

Chaises hautes pour enfants - Exigences et méthodes Kinderhochstühle - Anforderungen und Prüfverfahren

d'essai

This European Standard was approved by CEN on 18 November 2019 and includes Amendment approved by CEN on 20

November 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14988:2017+A2:2024 E

worldwide for CEN national Members.

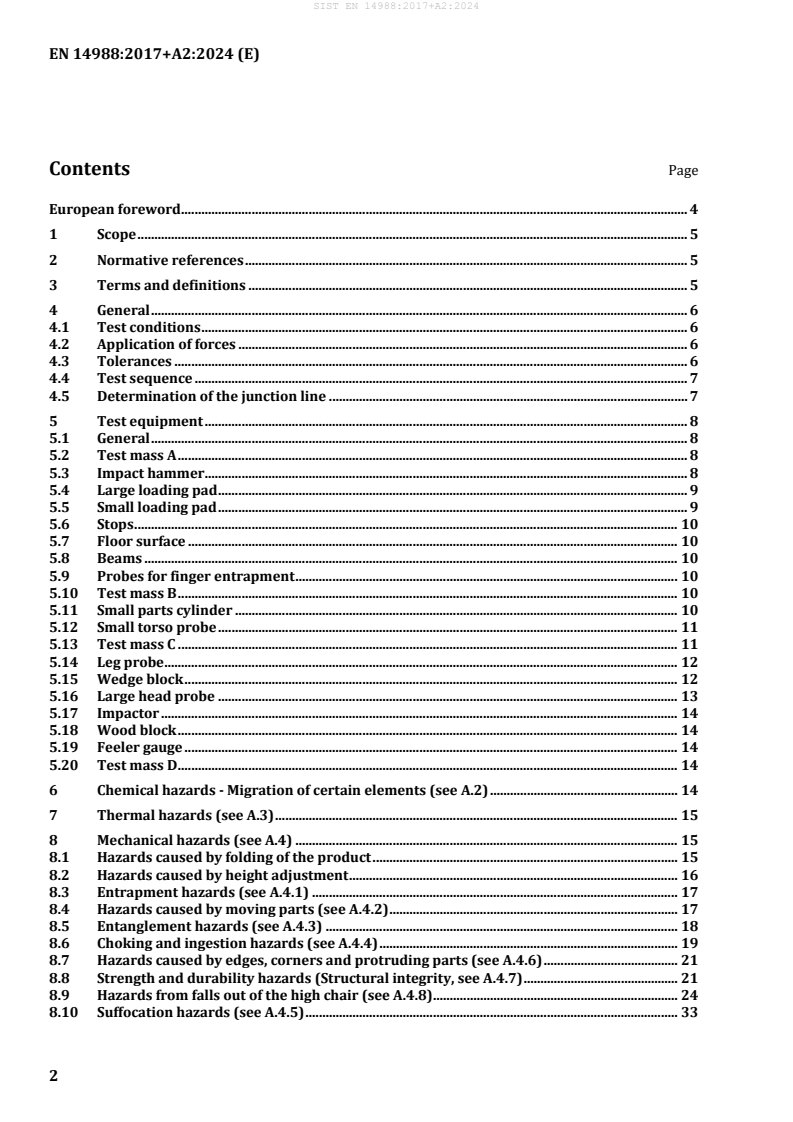

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 General . 6

4.1 Test conditions . 6

4.2 Application of forces . 6

4.3 Tolerances . 6

4.4 Test sequence . 7

4.5 Determination of the junction line . 7

5 Test equipment . 8

5.1 General . 8

5.2 Test mass A . 8

5.3 Impact hammer . 8

5.4 Large loading pad . 9

5.5 Small loading pad . 9

5.6 Stops . 10

5.7 Floor surface . 10

5.8 Beams . 10

5.9 Probes for finger entrapment . 10

5.10 Test mass B . 10

5.11 Small parts cylinder . 10

5.12 Small torso probe . 11

5.13 Test mass C . 11

5.14 Leg probe . 12

5.15 Wedge block . 12

5.16 Large head probe . 13

5.17 Impactor . 14

5.18 Wood block . 14

5.19 Feeler gauge . 14

5.20 Test mass D . 14

6 Chemical hazards - Migration of certain elements (see A.2) . 14

7 Thermal hazards (see A.3) . 15

8 Mechanical hazards (see A.4) . 15

8.1 Hazards caused by folding of the product . 15

8.2 Hazards caused by height adjustment . 16

8.3 Entrapment hazards (see A.4.1) . 17

8.4 Hazards caused by moving parts (see A.4.2) . 17

8.5 Entanglement hazards (see A.4.3) . 18

8.6 Choking and ingestion hazards (see A.4.4) . 19

8.7 Hazards caused by edges, corners and protruding parts (see A.4.6) . 21

8.8 Strength and durability hazards (Structural integrity, see A.4.7) . 21

8.9 Hazards from falls out of the high chair (see A.4.8) . 24

8.10 Suffocation hazards (see A.4.5) . 33

8.11 Castors and wheels (see A.4.9) . 33

8.12 Stability (see A.A.4.10) . 35

9 Marking and product information . 39

9.1 General . 39

9.2 Marking . 39

9.3 Instructions for use . 40

9.4 Purchase information . 41

Annex A (informative) Rationales . 42

A.1 Introduction. 42

A.2 Chemical hazards (see Clause 6) . 42

A.3 Thermal hazards (see Clause 7) . 42

A.4 Mechanical hazards (see Clause 8) . 42

Annex B (informative) A- deviations . 45

Annex C #Deleted text$ . 47

Bibliography . 50

European foreword

This document (EN 14988:2017+A2:2024) has been prepared by Technical Committee CEN/TC 364

"High Chairs", the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2024, and conflicting national standards shall

be withdrawn at the latest by April 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 2019-03-29, and Amendment 2 approved

by CEN on 2023-11-30.

This document supersedes #EN 14988-1:2017+A1:2020$.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !"

and #$.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association.

This document contains the following main modifications in comparison to the previous versions:

— EN 14988-1:2006+A1:2012 and EN 14988-2:2006+A1:2012 have been merged into one single

document;

— complete review of the standard in a hazard base format;

— modifications necessary to comply with European Decision 2013/121/EU;

— addition of a dynamic strength test;

— inclusion of specific requirements for high chair with more than two castors/wheels;

— improvement of restraint system requirements to require a passive crotch restraint for products

with a horizontal component in front of the baby.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

1 Scope

This document specifies safety requirements for free standing children's high chairs that elevate

children to dining table height usually for the purposes of feeding or eating. Children's high chairs are

for children up to 3 years of age who are capable of sitting unaided.

With the exception of special high chairs for medical purposes, this document applies to children's high

chairs for domestic and non-domestic use.

NOTE If a children's high chair has to or can be converted into other functions, additional European

Standards may apply.

2 Normative references

#The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 71-2:2020, Safety of toys - Part 2: Flammability

EN 71-3:2019+A1:2021, Safety of toys - Part 3: Migration of certain elements

EN 13210-1:2020, Child care articles - Part 1: Children's harnesses, reins - Safety requirements and test

methods

ISO 48-4:2018, Rubber, vulcanized or thermoplastic — Determination of hardness — Part 4: Indentation

hardness by durometer method (Shore hardness)$

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

active restraint system

system where the carer performs an action to ensure that the child is secured in the restraint system

3.2

passive restraint system

system where the carer does not perform an action to ensure that the child is secured in the restraint

system

3.3

crotch restraint

device passing between the legs of the child and preventing the child from slipping forwards out of the

high chair

3.4

waist restraint

rigid or flexible device(s), which when fastened, goes from one side of the high chair to the other

passing in front of the child’s waist or surrounding the child’s waist

3.5

shoulder restraint

device passing over the shoulders and connecting either to the crotch restraint or to the waist restraint

3.6

locking device

component that maintains part(s) of the product in the position of use

EXAMPLE Latch, a hook, an over centre lock.

3.7

operating device

part of the locking mechanism(s) or parking device(s) designed to be activated by the carer by one or

several action(s)

3.8

parking device

device intended to prevent rolling of castors/wheels

3.9

locking mechanism

assembly consisting of one or more locking device(s) and one or more operating device(s)

3.10

junction line

intersection of the seat and the back rest

4 General

4.1 Test conditions

The high chair shall be tested as delivered. If the high chair is a knock-down type, it shall be assembled

according to the instructions supplied with it. If the instructions allow for different adjustments or

configurations of components (e.g. inclination of the backrest, height of the seat, position of the tray,

position of castors/wheels, etc.), the most onerous combination shall be used for each test, unless

otherwise specified in the test method.

Knock-down fittings shall be tightened before testing. Further re-tightening shall not take place.

4.2 Application of forces

The forces in the static load tests shall be applied sufficiently slowly to ensure that negligible dynamic

force is applied.

The tests are described in terms of the application of forces, however masses can be used. The

relationship 10 N = 1 kg shall be used for this purpose.

4.3 Tolerances

Unless otherwise stated, the following tolerances apply:

— Forces: ± 5 % of the nominal force;

— Masses: ± 0,5 % of the nominal mass;

— Dimensions: ± 1,0 mm of the nominal dimension;

— Angles: ± 2° of the nominal angle;

— Positioning of loading pads: ± 5 mm.

NOTE For the purposes of uncertainty in measurements, test results are not considered to be adversely

affected when the above tolerances are met.

4.4 Test sequence

The tests in Clause 8 shall be carried out on the same high chair and in the order of the clauses of this

standard.

4.5 Determination of the junction line

The junction line is shown in Figure 1 below.

Where the backrest and the seat do not meet, the junction line is the projection of the backrest onto the

seat (see Figure 1).

Key

LL junction line

1 backrest

2 seat

Figure 1 — Junction line

When the seat unit is in the form of a hammock, a theoretical junction line, “LL”, shall be determined as

shown in Figure 2. The junction line may vary when the backrest is adjusted in different positions.

Key

AA top edge of the backrest

BB front edge of the seat

LL junction line

CL vertical projection of C on the hammock

C mid-point between A and B

Figure 2 — Junction line for seat units in the form of a hammock

5 Test equipment

5.1 General

Unless otherwise specified, test forces may be applied by any suitable device as results are dependent

only upon correctly applied forces and not upon the apparatus.

5.2 Test mass A

A rigid cylinder 200 mm in diameter and 300 mm in height, having a mass of 15 kg with its centre of

gravity 150 mm above its base. The edges shall have a radius of 5 mm. Two anchorage points shall be

provided. These shall be positioned 150 mm from the base and at an angle of 180° to each other around

the circumference (see Figure 3).

Dimensions in millimetres

Key

1 edge radius: (5 ± 1) mm

2 anchorage points

Figure 3 — Test mass A

5.3 Impact hammer

A striker in the form of a cylindrical object having a total mass of 6,5 kg supported from a pivot by a

steel tube of 38 mm in diameter and with a wall thickness of 2 mm (see Figure 4). The distance between

the pivot and the centre of gravity of the striker shall be 1 000 mm. The pendulum arm shall be pivoted

by a low friction bearing.

Dimensions in millimetres

Key

1 pendulum head, steel mass 6,4 kg

2 hardwood

3 rubber 50 ± 10 Shore A (#ISO 48-4 :2018$)

4 pendulum arm, length 950 mm; high tensile steel tube ∅ 38 mm x 2 mm; mass (2 ± 0,2) kg

5 pivot point

Mass of assembly (Key numbers 1, 2 and 3): (6,5 ± 0,07) kg

Figure 4 — Impact hammer

5.4 Large loading pad

A rigid cylindrical object 100 mm in diameter having a smooth hard surface and edges rounded with

radius of 12 mm.

5.5 Small loading pad

A rigid cylindrical object 30 mm in diameter having a smooth hard surface and edges rounded with

radius of (0,8 ± 0,3) mm.

5.6 Stops

Stops to prevent the high chair from sliding but not tilting, no higher than 12 mm except in cases where

the design of the item necessitates the use of higher stops, in which case the lowest stops that will

prevent the item from sliding shall be used.

5.7 Floor surface

#A horizontal, flat and rigid plane with a smooth surface.

For the tests according to 8.8.6.4, a 2 mm thick rubber mat, with hardness (75 ± 10) Shore A according

to ISO 48-4:2018, shall be used on a concrete floor.$

5.8 Beams

5.8.1 Beam for stability testing and for measuring the length of the lateral protection

A beam, not less than 900 mm long, with a square section of 25 mm x 25 mm and with a mass of

(0,5 ± 0,01) kg.

5.8.2 Beam for measuring the height for lateral protection test

A beam, 86 mm wide and with a mass of (0,5 ± 0,01) kg.

5.9 Probes for finger entrapment

0 +01,

Probes made of plastic or other hard, smooth material with diameters() mm and () mm

7 12

−01, 0

with a hemispherical end (see Figure 5) and which can be mounted on a force-measuring device.

Dimensions in millimetres

Key

1 line around the probe showing the depth of penetration

Probe type 7 mm probe 12 mm probe

0 +0,1

7 12

Diameter A

-0,1 0

Figure 5 — Test probes with hemispherical ends

5.10 Test mass B

A cylinder with a mass of 5 kg and a diameter of 100 mm.

5.11 Small parts cylinder

A cylinder for assessment of small components, having dimensions in accordance with Figure 6.

Dimension in millimetres

Figure 6— Small parts cylinder

5.12 Small torso probe

A probe made from plastic or other hard, smooth material with dimensions as shown in Figure 7.

Dimensions in millimetres

Key

1 handle

a 86 mm

b 40 mm

c 120 mm

Figure 7 — Small torso probe

5.13 Test mass C

An object made of steel with a total mass of (9 ± 0,1) kg and with dimensions as specified in Figure 8.

All edges shall be rounded or chamfered.

Dimensions in millimetres

Key

1 seat part [mass: (4,495 ± 0,05) kg]

2 backrest part [mass: (4,501 ± 0,05) kg]

3 hinge pin made of steel [mass of hinge pin: (17 ± 0,5) g, length: 79,5 mm]

D Diameter: 6 mm

Dimension tolerances: ± 2 mm

Figure 8 — Test mass C

5.14 Leg probe

A cylindrical probe with a diameter of 38 mm and a length of at least 76 mm.

5.15 Wedge block

A block made of plastic or other hard, smooth material and with dimensions according to Figure 9.

Dimensions in millimetres

Top view

Front view Side view

Figure 9 — Wedge block

5.16 Large head probe

A probe made of plastic or other hard smooth material, with dimensions according to Figure 10.

Dimensions in millimetres

Key

1 handle

Figure 10 — Large head probe

5.17 Impactor

A cylindrical bag with a diameter of 150 mm filled with steel shot with a diameter of (4 ± 2) mm. The

total mass shall be 23 kg.

5.18 Wood block

A wood block, with dimensions of 150 mm by 150 mm with a thickness of 25 mm and with the edges

rounded with a radius of 8 mm.

5.19 Feeler gauge

A gauge with a thickness of (0,4 ± 0,02) mm and an insertion end radius of (3 ± 0,5) mm (see Figure 11).

Dimensions in millimetres

Figure 11 — Feeler gauge

5.20 Test mass D

A mass of 9 kg on a base area of 200 mm x 100 mm.

6 Chemical hazards - Migration of certain elements (see A.2)

#Separate samples may be used for these tests.

The migration of elements from surface materials located on or above the plane defined by the seat

surface with the exception of the back of the backrest shall not exceed the limits listed in Table 1 when

tested in accordance with EN 71-3:2019+A1:2021.

Table 1 — Limits for heavy metals migration

Element mg/kg

Aluminium 28 130

Antimony 560

Arsenic 47

Barium 18 750

Boron 15 000

Cadmium 17

Chromium (III) 460

Chromium (VI) 0,053

Element mg/kg

Cobalt 130

Copper 7 700

Lead 23

Manganese 15 000

Mercury 94

Nickel 930

Selenium 460

Strontium 56 000

Tin 180 000

Organic tin 12

Zinc 46 000

$

7 Thermal hazards (see A.3)

#Separate samples may be used for these tests.

This clause applies only to textiles, coated textiles and plastic coverings. Hook and loop fasteners, cords

and alike are excluded.

When tested in accordance with EN 71-2:2020, 5.5, there shall be no surface flash.$

8 Mechanical hazards (see A.4)

8.1 Hazards caused by folding of the product

8.1.1 Requirements

8.1.1.1 General

There shall be at least one locking mechanism which prevents a high chair from folding whilst in use

and also when a child is being placed into and removed from the high chair.

8.1.1.2 Incomplete deployment

In order to prevent the hazards due to incomplete deployment, the high chair shall fulfil one of the

following:

a) the weight of the child in the high chair shall act to prevent the folding; or

b) at least one locking device shall engage automatically, when the product is ready for use.

8.1.1.3 Unintentional folding of the high chair

Unintentional folding of the high chair shall be prevented. This requirement is fulfilled if one of the

following conditions is met before and after testing in accordance with 8.1.2.1:

a) at least one operating device requires a minimum force of 50 N to activate, with and without test

mass A on the seat, or

b) folding is only possible if at least one locking mechanism requires the use of a tool, or

c) folding is only possible, when two independent operating devices are operated simultaneously, or

d) there are two or more automatically engaging locking devices that both cannot be released by one

single action, or

e) folding of the high chair requires two consecutive actions, the first of which shall be maintained

while the second is carried out.

8.1.1.4 Locking mechanism strength

When tested in accordance with 8.1.2.2, the high chair shall not fold and the locking mechanism shall

remain engaged.

8.1.2 Test methods

8.1.2.1 Durability of the locking mechanism

Operate all locking mechanisms 300 times.

8.1.2.2 Strength of the locking mechanism

Place the high chair on the floor with the test mass A (5.2) at the centre of the seat.

Apply a force of 200 N at the point and in the direction considered most likely for the high chair to fold.

If the high chair tends to tilt, secure it in a manner which prevents tilting but not folding.

8.2 Hazards caused by height adjustment

8.2.1 General

High chairs in which the seat height cannot be adjusted either due to the construction of the high chair

or when the child is inside the high chair are excluded from this requirement.

There shall be locking mechanism(s) to prevent the seat unit of a high chair from moving from a higher

to a lower position

8.2.2 Incomplete seat height adjustment

In order to prevent hazards due to incomplete seat height adjustment, at least one locking device shall

engage automatically when the seat is adjusted in height.

8.2.3 Unintentional release of the seat height adjustment mechanism

In order to prevent unintentional release of the seat adjustment mechanism, one of the following

requirements shall be fulfilled before and after testing in accordance with 8.1.2.1:

a) at least one operating device requires a minimum force of 50 N to activate, with and without test

mass A on the seat, or

b) height adjustment requires the use of a tool, or

c) release is only possible when two independent operating devices are operated simultaneously, or

d) there are two or more automatically engaging locking devices that both cannot be released by one

single action, or

e) height adjustment requires two consecutive actions, the first of which shall be maintained while the

second is carried out.

8.3 Entrapment hazards (see A.4.1)

8.3.1 Entrapment of fingers

8.3.1.1 Requirement

With the exception of the back of the backrest, parts of the high chair from the floor up to and including

the under-surface of the seat and buckles and adjusters of the restraint system, there shall be no

completely bounded circular openings in rigid materials between 7 mm and 12 mm, which are deeper

than 10 mm, when tested in accordance with 8.3.1.2.

8.3.1.2 Test method

Check whether the 7 mm probe (see 5.9) with an applied force of up to 30 N, enters 10 mm or more into

any completely bounded opening in rigid materials in any possible direction. If the 7 mm probe enters

10 mm or more, check if the 12 mm probe (see 5.9) enters 10 mm or more with an applied force of up to

5 N.

8.3.2 Entrapment of head

8.3.2.1 Requirements

With the exception of the entrance to the seat unit, the two openings for the child’s legs and openings in

the frame above the level of the top surface of the lateral protection, there shall be no holes, gaps or

openings above the seat surface which allow the small torso probe to pass through when tested

according to 8.3.2.2.

8.3.2.2 Test method

Check whether the small torso probe (5.12) with an applied force of up to 30 N, enters into any

accessible opening located above the seat.

The probe shall be inserted from inside the seat unit in a straight direction along the longitudinal axis of

the probe.

8.4 Hazards caused by moving parts (see A.4.2)

8.4.1 Requirements on compression points

The back of the backrest, parts from the floor up to and including the under-surface of the seat and

buckles of the restraint system are excluded from the following requirement.

After the high chair has been set up for normal use in accordance with the manufacturer's instructions,

there shall be no accessible hazardous compression points, which can close to less than 12 mm, unless

they are always less than 5 mm, as the result of:

a) movement of the high chair; or

b) movements of the child using the high chair; or

c) the application of an external force (either by another child or, unintentionally, by the carer, or by a

powered mechanism).

!Hazardous compression points between the tray and the structure shall be assessed by applying a

vertical downward force of 50 N in the most onerous point on the tray."

8.4.2 Requirements for shearing points

The back of the backrest, parts from the floor up to and including the under-surface of the seat and

buckles of the restraint system are excluded from the following requirement.

After the high chair has been set up for normal use in accordance with the manufacturer's instructions

there shall be no accessible hazardous shearing points which can close to less than 12 mm, as the result

of:

a) movement of the high chair; or

b) the movement of the child using the high chair; or

c) the application of an external force (either by another child or, unintentionally, by the carer,

or by a powered mechanism).

8.5 Entanglement hazards (see A.4.3)

8.5.1 Requirements

The restraint system is excluded from this clause.

Cords, ribbons and similar parts shall have a maximum free length of 220 mm when tested in

accordance with 8.5.2.

Where cords, ribbons and similar parts are attached to the high chair together or within 80 mm of each

other, all single cords shall have a maximum free length of 220 mm and the combined length from one

loose end to the end of another loose end shall be a maximum of 360 mm (see Figure 12).

Loops shall have a maximum peripheral dimension of 360 mm, when tested in accordance with 8.5.2.

Monofilament threads shall not be used.

Dimensions in millimetres

Key

Lx length of the single cord

D distance between the attachments

Figure 12 — Examples of measuring cords, ribbons or similar parts

8.5.2 Test method

The length of a cord, ribbon or similar part shall be measured from the fixing point on the high chair to

the free end of the cord, ribbon or similar part under a 25 N tensile force.

The peripheral dimension of a loop shall be measured from the fixing point on the high chair of one end

to the fixing point of the other end under a 25 N tensile force.

8.6 Choking and ingestion hazards (see A.4.4)

8.6.1 Requirements

Any component that is considered capable of being gripped by a child in accordance with 8.6.2.1 shall

be tested in accordance with 8.6.2.2 and 8.6.2.3. Any component or part of a component that is removed

shall not fit entirely within the small parts cylinder specified in 5.11.

!With the exception of the back of the backrest, parts from the floor up to and including the under-

surface of the seat, and buckles and adjusters of the restraint system, parts of a high chair containing

filling material shall have at least one covering. When tested in accordance with 8.6.2.4, it shall not be

possible to insert the front part of a 12 mm diameter probe (5.9) by more than 6 mm into any generated

opening in the covering materials or their joints that gives access to the filling material."

8.6.2 Test methods

8.6.2.1 Assessment of child’s ability to grip components

A component is considered able to be gripped if the child can grip the component between its thumb

and forefinger or between its teeth.

Where it is difficult to assess whether a child can grip a component, establish whether it is possible to

insert the feeler gauge specified in 5.19 between the component and the underlying layer or body of the

high chair at an angle between 0° and 10° from the surface of the underlying layer or high chair, using a

force of (10 ± 1) N. If the gauge can be inserted more than 2 mm, the component is considered able to be

gripped by the child.

8.6.2.2 Torque test

Apply a torque gradually to the component within a period of 5 s in the clockwise direction until either:

a) a rotation of 180° from the original position has been attained; or

b) a torque of 0,34 Nm is reached.

The maximum rotation or required torque shall be applied for 10 s.

The component shall then be allowed to return to a relaxed condition and the procedure repeated in the

anticlockwise direction.

Where projections, components or assemblies are rigidly mounted on an accessible rod or shaft

designed to rotate together with the projections, components or assemblies, the rod or shaft shall be

clamped to prevent rotation during the test.

If a component, which is attached by a screw or similar fixing device, becomes loose during the

application of the required torque, the torque shall continue to be applied until the required torque is

met or the component disassembles or it becomes apparent that the component will not disassemble.

Clamps and test equipment shall not cause damage the attachment mechanism or body of the

component.

Check whether any component or part of a component that is removed during the test fits wholly in any

orientation without compressing or manipulating it, within the small parts cylinder specified in 5.11.

8.6.2.3 Tensile test

Attach a suitable clamp to the component, taking care not to damage the attachment mechanism or the

body of the component.

Apply a tensile force of up to 90 N to the component. The force shall be applied gradually within a

period of 5 s and maintain it for 10 s.

Check whether any component or part of a component that is removed during the test fits wholly within

the small parts cylinder specified in 5.11 in any orientation without compressing or manipulating it.

8.6.2.4 Accessibility of filling materials

Use clamps with jaws to which discs with a diameter of 19 mm are affixed.

Attach the clamps to the covering where the disc jaws can be fully applied not less than 30 mm apart

and equidistant to the junction of parts (e.g. seam, welding, glued, etc.).

Gradually apply a force of (70 ± 2) N between the two clamps over a period of approximately 5 s.

Maintain the force for 10 s, and then release the force.

Apply the test once for each different joint of covering materials.

!Check whether it is possible to insert the 12 mm probe (see 5.9) by more than 6 mm using a

maximum force of 10 N."

Key

1 disc

2 seam

3 free space between discs

Figure 13 — Examples of clamping

8.7 Hazards caused by edges, corners and protruding parts (see A.4.6)

All accessible edges, corners and protruding parts on the high chair shall be rounded or chamfered and

free from burrs.

8.8 Strength and durability hazards (Structural integrity, see A.4.7)

8.8.1 Requirements

Connecting screws for direct fastening, e.g. self-tapping screws, shall not be used for the assembly of

any component that is designed to be removed or loosened when dismantling the high chair for the

purpose of transportation or storage.

After completing all the tests in accordance with 8.8.2, 8.8.3, 8.8.4, 8.8.5, 8.8.6.1, 8.8.6.2 and 8.8.6.3, the

requirements in 8.1, 8.3 and 8.7 shall be fulfilled and the safety and functions of the high chair shall be

unimpaired.

8.8.2 Impact test

The high chair shall be placed on the floor surface (5.7) in the normal position of use with the legs

against stops (5.6) in the opposite direction of the force.

Adjust the impact hammer (5.3) to fall from a height (H) of 116 mm. The hammer shall strike the

structure at the impact point, when the arm of the impact hammer is vertical (see Figure 14).

The impact hammer shall strike from the outside to:

— the centre of the uppermost point of the back (see Figure 14 b)), and

— the centre of the tray if available, and

— the centre of the horizontal member (see Figure 14 c)), and

— both lateral protections (see Figure 14 a)).

If the high chair can be fitted with a detachable tray, the tests shall be done with and without the tray.

If the high chair overturns during the test, it shall be prevented from touching the ground.

Repeat the test on the backrest from the inside of the high chair in the same manner as above.

The tests shall be carried out for a total of 5 times at each point.

Key

H falling height

Figure 14 — Impact test

8.8.3 Seat vertical static load test

Place 40 kg distributed over an area of 150 mm x 150 mm on the centre of the seat. Maintain the load

for 1 min. Lift the high chair clear of the floor by the lateral protection at the point of balance. Maintain

the high chair off the floor for 1 min. Remove the load.

8.8.4 Footrest vertical static load test

Place 20 kg distributed over an area of 75 mm x 150 mm on the centre of the footrest with the longer

side parallel to the front line of the footrest. Maintain the load for 1 min. Remove the load.

8.8.5 Dynamic strength test

The high chair shall be placed on the floor surface (see 5.7) in the normal position of use. Prevent

movement of the high chair on the floor surface without impairing the test.

Place the wood block (5.18) in the centre of the seat.

Position the impactor (5.17) above the wood block and let it drop freely from a height of 75 mm.

Repeat for a total of 500 cycles at a frequency of (15 ± 1) cycles per minute.

For high chairs that can be adjusted in height, the number of drops shall be equally divided in the

highest and the lowest positions.

Damages caused by the wooden block (e.g. splinters, damages in the fabric cover, etc.) shall be

disregarded.

8.8.6 Tray tests

8.8.6.1 Requirements

When tested according to 8.8.6.2, the tray shall not break or become detached and its function shall be

unimpaired.

When tested according to 8.8.6.3, the high chair shall not overturn.

When tested according to 8.8.6.4, the tray shall fulfil the requirements of 8.3.1, 8.4, 8.6 and 8.7 and its

function shall be unimpaired.

8.8.6.2 Tray strength test

With the tray fitted to the high chair, fix the seat so that it cannot move in the direction of the force

being applied. Apply in turn a horizontal force of 200 N 10 times to the tray at each of the following

positions:

a) forwards at the centre of the front edge at its uppermost surface;

b) rearwards at the centre of the rear edge at its uppermost surface;

c) sideways outwards at the centre of one side at its uppermost surface;

d) sideways outwards at the centre of the opposite side at its uppermost surface.

Each test force shall be maintained for 30 s.

8.8.6.3 Tray stability

With the high chair unloaded, apply a downwards vertical force of 200 N at the mid-point of centre line

of the tray (see Figure 15). Maintain the load for 1 min.

Key

1 application point

2 tray

Figure 15 — Tray stability

8.8.6.4 Tray drop test

This test is only applicable to removable trays.

Remove the tray from the high chair and drop it once through a height of 1 000 mm onto the floor

surface (5.7), on each of the following positions:

— on one long edge, and

— on one short edge, and

— on the bottom, and

— adjacent to the fastening points, and

— one other point likely to be damaged by the test.

8.9 Hazards from falls out of the high chair (see A.4.8)

8.9.1 Restraint system

8.9.1.1 Requirements on restraint systems

8.9.1.1.1 General requirements

The high chair shall have either an active restraint system complying with 8.9.1.1.2 or a passive

restraint system complying with 8.9.1.1.3.

If the backrest can be reclined to less than 60° to the horizontal measured in accordance with 8.9.1.2.1,

the product shall have an active restraint system (see 8.9.1.1.2).

Straps of the restraint system, if any, shall have a minimum width of 19 mm.

All parts of the restraint system shall function as intended before and after testing in accordance with

8.9.1.2.3.

The maximum slippage of the straps through any type of ad

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...