EN 14972-8:2020

(Main)Fixed firefighting systems - Water mist systems - Part 8: Test protocol for machinery in enclosures exceeding 260 m³ for open nozzle systems

Fixed firefighting systems - Water mist systems - Part 8: Test protocol for machinery in enclosures exceeding 260 m³ for open nozzle systems

This document specifies fire testing requirements for water mist systems used for fire protection of machinery in enclosures with volumes exceeding 260 m³.

Ortsfeste Brandbekämpfungsanlagen - Feinsprüh-Löschanlagen - Teil 8: Prüfprotokoll für Maschinen in Gehäusen über 260 m³ für offene Düsensysteme

Dieses Dokument legt Anforderungen an Brandprüfungen von Feinsprüh-Löschanlagen fest, die für den Brandschutz von Maschinen in geschlossenen Räumen mit einem Volumen über 260 m3 eingesetzt werden.

Installations fixes de lutte contre l'incendie - Systèmes à brouillard d'eau - Partie 8 : Protocole d'essai des systèmes à buses ouvertes pour machines situées dans des enceintes de plus de 260 m³

Le présent document spécifie les exigences relatives aux essais au feu pour les systèmes à brouillard d'eau utilisés pour la protection contre l'incendie des machines situées dans des enceintes d'un volume supérieur à 260 m3.

Vgrajeni gasilni sistemi - Sistemi s pršečo vodo - 8. del: Protokol preskušanja sistemov z odprtimi šobami za požarno zaščito strojev v ohišjih nad 260 m³

Ta dokument določa zahteve glede požarnega preskušanja za sisteme s pršečo vodo, ki se uporabljajo za požarno zaščito strojev v ohišjih s prostornino nad 260 m³.

General Information

- Status

- Published

- Publication Date

- 21-Jan-2020

- Withdrawal Date

- 30-Jul-2020

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 10 - Water mist systems

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 03-Sep-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14972-8:2020 is a CEN European standard that defines the test protocol for water mist systems (open nozzle systems) protecting machinery in enclosures exceeding 260 m³. It specifies fire testing requirements, test enclosure setup, machinery mock-up geometry, instrumentation and pass/fail criteria to demonstrate automatic water mist performance for large machinery spaces.

Key topics and technical requirements

- Scope: Fire testing for water mist systems used for machinery enclosures with volume > 260 m³.

- General requirements:

- Systems must operate without manual intervention and complete all performance fire tests.

- Tests follow the manufacturer’s DIOM manual for nozzle placement, spray flux and duration.

- Intermittent spray cycles: off time ≤ 50% of a cycle and system off period ≤ 1 minute.

- Twin-fluid systems (except compressed-air driven) require straight discharge tests to measure discharge and oxygen concentration for personnel safety.

- Test enclosure:

- Test the maximum enclosure volume and height claimed by the manufacturer.

- Enclosure construction, sealing, and openings: central 2.00 m × 2.00 m opening 0.50 m above floor; two hinged ceiling hatches (~1.00 m × 2.00 m) in diagonal corners.

- Preferred near-square floor plan; minimum side length 8.00 m; side ratio ≤ 2.5:1.

- Machinery mock-up:

- Steel mock-up 3.00 m × 1.00 m × 3.00 m with 100 mm deep top tray, two 300 mm diameter × 3.00 m pipes, and a 0.70 m wide shelf to allow concealed/exposed fire scenarios.

- Floor plate system around mock-up: 6.00 m × 4.00 m × 0.75 m; tray beneath.

- Test equipment & conditions:

- Ambient temperature (20 ± 10) °C; eliminate drafts; repeatable nozzle pressure within ±5%.

- Maximum nozzle ceiling height and spacing per manufacturer to be used.

- Instrumentation:

- Comprehensive temperature, fuel pressure/flow, fuel temperature and oxygen monitoring with data logged ≤1 s intervals and ±5% tolerance.

- Fire tests covered (see standard for full details): multiple spray and pool fires, flowing fires, wood crib tests, low/high pressure scenarios and concealed vs exposed spray fires.

Applications and users

This standard is used by:

- Water mist system manufacturers (product validation and DIOM documentation),

- Fire testing laboratories and certification bodies (type testing and compliance),

- System designers and specifiers (design verification for machinery spaces),

- Facility owners/operators with large machinery enclosures seeking validated suppression solutions.

Related standards

EN 14972 is a multipart series. Relevant parts include:

- EN 14972-1 (design, installation, inspection and maintenance) and other EN 14972 parts addressing different occupancies and open/automatic nozzles (Parts 9–17).

Keywords: EN 14972-8:2020, water mist systems, open nozzle systems, test protocol, machinery enclosures, fixed firefighting systems, fire testing requirements.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 14972-8:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fixed firefighting systems - Water mist systems - Part 8: Test protocol for machinery in enclosures exceeding 260 m³ for open nozzle systems". This standard covers: This document specifies fire testing requirements for water mist systems used for fire protection of machinery in enclosures with volumes exceeding 260 m³.

This document specifies fire testing requirements for water mist systems used for fire protection of machinery in enclosures with volumes exceeding 260 m³.

EN 14972-8:2020 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14972-8:2020 has the following relationships with other standards: It is inter standard links to EN 14972-1:2020+A1:2025, EN 17450-2:2024, EN 14972-1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14972-8:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2020

Vgrajeni gasilni sistemi - Sistemi s pršečo vodo - 8. del: Protokol preskušanja

sistemov z odprtimi šobami za požarno zaščito strojev v ohišjih nad 260 m³

Fixed firefighting systems - Water mist systems - Part 8- Test protocol for machinery in

enclosures exceeding 260 m³ for open nozzle systems

Ortsfeste Brandbekämpfungsanlagen - Feinsprüh-Löschanlagen - Teil 8: Prüfprotokoll

für Maschinen in Gehäusen über 260 m³ für offene Düsensysteme

Installations fixes de lutte contre l'incendie - Systèmes à brouillard d'eau - Partie 8 :

Protocole d'essai des systèmes à buses ouvertes pour machines situées dans des

enceintes de plus de 260 m³

Ta slovenski standard je istoveten z: EN 14972-8:2020

ICS:

13.220.10 Gašenje požara Fire-fighting

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14972-8

EUROPEAN STANDARD

NORME EUROPÉENNE

January 2020

EUROPÄISCHE NORM

ICS 13.220.20

English Version

Fixed firefighting systems - Water mist systems - Part 8-

Test protocol for machinery in enclosures exceeding 260

m³ for open nozzle systems

Installations fixes de lutte contre l'incendie - Systèmes Ortsfeste Brandbekämpfungsanlagen - Feinsprüh-

à brouillard d'eau - Partie 8 : Protocole d'essai des Löschanlagen - Teil 8: Prüfprotokoll für Maschinen in

systèmes à buses ouvertes pour machines situées dans Gehäusen über 260 m³ für offene Düsensysteme

des enceintes de plus de 260 m³

This European Standard was approved by CEN on 11 November 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14972-8:2020 E

worldwide for CEN national Members.

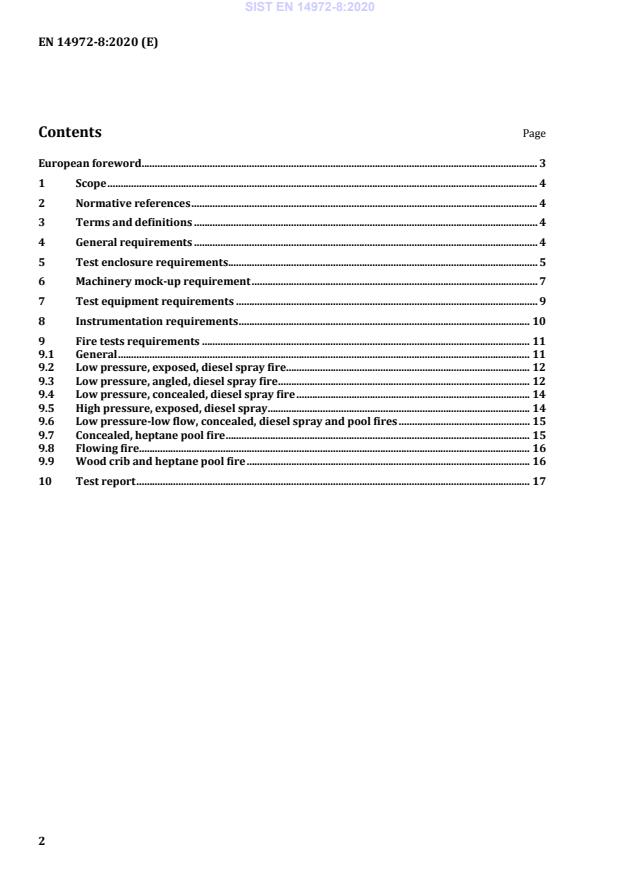

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 General requirements . 4

5 Test enclosure requirements . 5

6 Machinery mock-up requirement . 7

7 Test equipment requirements . 9

8 Instrumentation requirements . 10

9 Fire tests requirements . 11

9.1 General . 11

9.2 Low pressure, exposed, diesel spray fire. 12

9.3 Low pressure, angled, diesel spray fire . 12

9.4 Low pressure, concealed, diesel spray fire . 14

9.5 High pressure, exposed, diesel spray . 14

9.6 Low pressure-low flow, concealed, diesel spray and pool fires . 15

9.7 Concealed, heptane pool fire . 15

9.8 Flowing fire. 16

9.9 Wood crib and heptane pool fire . 16

10 Test report . 17

European foreword

This document (EN 14972-8:2020) has been prepared by Technical Committee CEN/TC 191 “Fixed

firefighting systems”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by July 2020 and conflicting national standards shall be

withdrawn at the latest by July 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

EN 14972, Fixed firefighting systems — Water mist systems consists of the following parts:

— Part 1: Design, installation, inspection and maintenance;

— Part 2: Test protocol for shopping areas for automatic nozzle systems;

— Part 3: Test protocol for office, school and hotel for automatic nozzle systems;

— Part 4: Test protocol for non-storage occupancies for automatic nozzle systems;

— Part 5: Test protocol for car garages for automatic nozzle systems;

— Part 6: Test protocol for false floors and false ceilings for automatic nozzle systems;

— Part 7: Test protocol for commercial low hazard occupancies for automatic nozzle systems;

— Part 8: Test protocol for machinery in enclosures exceeding 260 m for open nozzle systems;

— Part 9: Test protocol for machinery in enclosures not exceeding 260 m for open nozzle systems;

— Part 10: Test protocol for atrium protection with sidewall nozzles for open nozzle systems;

— Part 11: Test protocol for cable tunnels for open nozzle systems;

— Part 12: Test protocol for commercial deep fat cooking fryers for open nozzle systems;

— Part 13: Test protocol for wet benches and other similar processing equipment for open nozzle systems;

— Part 14: Test protocol for combustion turbines in enclosures exceeding 260 m for open nozzle systems;

— Part 15: Test protocol for combustion turbines in enclosures not exceeding 260 m for open nozzle

systems;

— Part 16: Test protocol for industrial oil cookers for open nozzle systems;

— Part 17: Test protocol for residential occupancies for automatic nozzle systems.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document specifies fire testing requirements for water mist systems used for fire protection of

machinery in enclosures with volumes exceeding 260 m .

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

1)

EN 14972-1:— , Fixed firefighting systems — Water mist systems — Part 1: Design, installation,

inspection and maintenance

3 Terms and definitions

1)

For the purposes of this document, the terms and definitions given in EN 14972-1 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

machinery enclosure

any enclosure containing equipment that uses fuel and/or lubrication fluids with

volatilities less than or equal to heptane

4 General requirements

4.1 The water mist system, operating without manual intervention, shall successfully complete all

described performance fire tests for their specific applications.

4.2 The fire tests shall be conducted until the fire is extinguished, as required by the applicable fire

test.

4.3 System components, component locations, operating conditions and test enclosure details shall

remain unaltered throughout all of the fire tests for a given application.

4.4 All fire tests shall be conducted using the specifications from the manufacturer’s DIOM manual in

regard to nozzle placement, spray flux, and spray duration. Sprays can be continuous or intermittent in

time. In the case of intermittent, or cycled, sprays, the time period during which the system is not

discharging shall not be greater than 50 % of one complete on/off cycle. The system off period shall not

exceed one minute.

4.5 In conjunction with the performance fire tests, all twin fluid water mist systems (except for those

applying compressed air) shall be subjected to a straight discharge test with no fire to evaluate the

resulting discharge and oxygen concentration. This evaluation shall be conducted using the maximum

extinguishing agent flow and pressure. The discharge duration for the test shall be the maximum

required for the system and occupancy to be protected. Oxygen measurements shall be recorded at a

1) Under preparation. Stage at the time of publication: prEN 14972-1:2019.

location(s) within the test enclosure. This information shall be used to evaluate personnel safety, and

shall be accounted for in the manufacturer’s DIOM manual.

4.6 Up to a maximum of 5 nozzles used in the fire tests shall be kept for later verification.

5 Test enclosure requirements

The maximum enclosure volume (as specified by the manufacturer) shall be tested. The enclosure area

should be preferable squared. If this is not possible length sides shall not exceed 2.5:1 ratio. In any case,

the length of any of the sides shall be at least 8,00 m.

The maximum enclosure height (as specified by the manufacturer) shall be tested. The enclosure shall

be constructed of wood or metal frame with an inner lining of minimum 13,00 mm gypsum or 0,70 mm

galvanized steel.

To minimize leakages, all joints and gaps shall be sealed. An opening measuring 2,00 m by 2,00 m and

0,50 m above the floor level shall be installed in the centre of one wall, as shown in Figure 1.

A minimum of two hinged ceiling hatches measuring approximately 1,00 m by 2,00 m shall be installed

in opposite diagonal corners for heat and smoke release at the conclusion of the fire test. The floor shall

be non-combustible and any floor drainage or vent openings shall be sealed during testing.

A small vent can be provided to allow the intake of air, to prevent excessive suctioning of the walls and

ceiling and maintain structural integrity of the fire test enclosure.

The machinery mock-up unit shall be centred in the test enclosure.

Dimensions in metres

Key

1 tray for “Class A Fire Test”

2 bilge enclosure

3 test enclosure

4 opening

5 steel pipe

Figure 1 — Test enclosure

6 Machinery mock-up requirement

The machinery mock-up unit measures 3,00 m long by 1,00 m wide by 3,00 m high. It is fabricated from

sheet steel with a nominal thickness of 5,00 mm. A tray with a depth of 100,00 mm is formed at the top

of the mock-up unit. Two 300,00 mm diameter pipes, 3,00 m in length, are attached to the unit to

simulate obstructions. A 0,70 m wide solid shelf is also connected to the unit, which provides a barrier

to allow shielded fire tests to be conducted.

A 200,00 mm by 50,00 mm notch is cut into the side of the top tray opposite the solid shelf for the

purposes of the flowing fire test (see Figure 2 and 3).

The mock-up unit shall be surrounded by a steel floor plate system, 6,00 m long by 4,00 m wide by

0,75 m high.

A 4,00 m by 0,254 m high square tray shall be located underneath the floor plate system.

Dimensions in metres

Key

a) front view b) top view

1 exposed and concealed spray nozzle 7 top tray (3,00 m )

2 bilge steel plate 8 solid steel plate (5,00 mm)

3 bilge enclosure 9 steel pipes

tray (0,10 m )

4 10 gap between engine and inside perimeter of bilge plate

5 tray (4,00 m ) thermocouple

6 location for notch for flowing fuel

Figure 2 — Machinery mock-up unit

Dimensions in metres

Key

1 obstruction rod 6 bilge enclosure

2 flowing oil feed pipe DN 12 7 concealed oil spray

3 steel pipes 8 tray (4,00 m )

a

4 engine mock-up notch for flowing fuel

5 bilge steel plate thermocouple

Figure 3 — Machinery mock-up unit (continued)

7 Test equipment requirements

7.1 The test laboratory s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...