EN 17344:2020

(Main)Agricultural machinery - Self-propelled agricultural and forestry vehicles - Requirements for braking

Agricultural machinery - Self-propelled agricultural and forestry vehicles - Requirements for braking

This document applies to wheeled and/or track-laying self-propelled agricultural and forestry vehicles when used on public roads. It specifies the definitions, construction and performance requirements and the means for verification of braking systems on vehicles with a maximum design speed not exceeding 60 km/h.

Following items are excluded from the scope of this document:

- coupling force control;

- endurance braking systems;

- Anti-Lock Braking Systems and EBS;

- vacuum braking systems;

- safety related parts of complex electronic control systems;

- trailer braking control systems.

NOTE For assisted trailer braking the EU Regulation 2015/68 can be used but before including these requirements into this document, an additional review of 2015/68 is needed.

Landmaschinen - Selbstfahrende Arbeitsmaschinen - Anforderungen an Bremsanlagen

Dieses Dokument gilt für selbstfahrende land- und forstwirtschaftliche Fahrzeuge auf Rädern und/oder Raupenlaufwerken bei der Nutzung auf öffentlichen Straßen. Es legt Definitionen, konstruktions- und leistungsbezogene Anforderungen und Mittel zur Überprüfung von Bremsanlagen von Fahrzeugen mit einer bauartbedingten Höchstgeschwindigkeit von nicht mehr als 60 km/h fest.

Die folgenden Sachverhalte sind vom Anwendungsbereich dieses Dokuments ausgenommen:

- Koppelkraftregelung;

- Dauerbremsanlage;

- Antiblockiersysteme und EBS;

- Unterdruckbremsanlagen;

- sicherheitsbezogene Teile komplexer elektronischer Steuerungssysteme;

- Anhänger-Bremssteuerungssysteme.

ANMERKUNG In Bezug auf Hilfskraft-betätigte Bremsanlagen für Anhänger kann die EU-Verordnung 2015/68 angewendet werden. Bevor diese Anforderungen in dieses Dokument übernommen werden können, ist jedoch eine zusätzliche Überprüfung der Verordnung 2015/68 erforderlich.

Matériel agricole - Véhicules agricoles et forestiers automoteurs - Exigences en matière de freinage

Le présent document s’applique aux véhicules agricoles et forestiers automoteurs à roues et/ou à chenilles lorsqu’ils sont utilisés sur la voie publique. Il spécifie les définitions, les exigences de construction et d’efficacité ainsi que les moyens de vérification des systèmes de freinage sur les véhicules dont la vitesse maximale par construction ne dépasse pas 60 km/h.

Les éléments suivants sont exclus du domaine d’application du présent document :

- commande en fonction de la force sur l’attelage ;

- systèmes de freinage d’endurance ;

- systèmes de freinage antiblocage et EBS ;

- systèmes de freinage à dépression ;

- parties des systèmes complexes de commande électronique relatives à la sécurité ;

- systèmes de commande de freinage de remorque.

NOTE Pour le freinage assisté des remorques, le règlement européen 2015/68 peut être utilisé mais avant d'inclure ces exigences dans ce document, une révision supplémentaire de 2015/68 est nécessaire.

Kmetijski stroji - Kmetijska in gozdarska vozila z lastnim pogonom - Zahteve za zaviranje

General Information

- Status

- Published

- Publication Date

- 03-Mar-2020

- Withdrawal Date

- 29-Sep-2020

- Technical Committee

- CEN/TC 144 - Tractors and machinery for agriculture and forestry

- Drafting Committee

- CEN/TC 144/WG 2 - Tractors and self propelled machines

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 04-Dec-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 17344:2020 (braking requirements for agricultural machinery)

EN 17344:2020 specifies braking requirements for wheeled and track‑laying self‑propelled agricultural and forestry vehicles used on public roads. The standard covers definitions, construction and performance requirements, and verification methods for braking systems on vehicles with a maximum design speed ≤ 60 km/h. It is intended to support safe on‑road operation and can be used during EU or national type approval and conformity assessment processes.

Key topics and technical requirements

- Scope and vehicle classes: Applies to vehicles not primarily designed to tow heavy trailers. Defines speed classes:

- Class I: ≤ 12 km/h

- Class II: > 12 km/h ≤ 30 km/h

- Class III: > 30 km/h ≤ 40 km/h

- Class IV: > 40 km/h ≤ 60 km/h

- Braking system definitions: Clear terminology for service, parking, secondary, friction, fluid, electrical, engine and stepless‑drive braking systems, plus combination systems and spring/brake energy storage concepts.

- Construction requirements:

- Braking equipment must be robust, readily serviceable and comparable in safety to other essential systems (e.g., steering).

- Brake linings shall not contain asbestos.

- Adjustable valves that could let users degrade braking performance are prohibited unless secured against tampering.

- For Class IV vehicles, service‑brake wear must be compensated automatically; wear compensation (manual or automatic) and easy external inspection are required for other classes.

- Performance and testing: The standard sets out brake testing and verification procedures, and includes normative annexes addressing energy source categories, energy storage capacity (pneumatic/hydraulic) and a standard test report format.

Practical applications - who uses EN 17344:2020

- Manufacturers of self‑propelled agricultural and forestry machines - to design and document compliant braking systems.

- Design engineers - for selecting energy sources, transmissions and brake components that meet construction and safety requirements.

- Test laboratories and type‑approval authorities - to evaluate braking performance and produce compliant test reports.

- Fleet operators and safety managers - to understand regulatory expectations for on‑road braking performance and maintenance checks.

Related standards and references

- EU Regulation 2015/68 (assisted trailer braking; review needed before integration)

- UNECE Regulation No. 13 (braking regulations)

- ISO standards cited as normative references (e.g., ISO 9128, ISO 3767‑1)

- EN 17344:2020 produced by CEN/TC 144 - useful alongside national regulations and vehicle type approval guidance.

Keywords: EN 17344:2020, braking requirements, agricultural machinery, self‑propelled vehicles, brake testing, type approval, construction requirements.

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

ECOCERT

Organic and sustainability certification.

Rainforest Alliance Certification

Sustainable agriculture and forestry certification.

Sponsored listings

Frequently Asked Questions

EN 17344:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Agricultural machinery - Self-propelled agricultural and forestry vehicles - Requirements for braking". This standard covers: This document applies to wheeled and/or track-laying self-propelled agricultural and forestry vehicles when used on public roads. It specifies the definitions, construction and performance requirements and the means for verification of braking systems on vehicles with a maximum design speed not exceeding 60 km/h. Following items are excluded from the scope of this document: - coupling force control; - endurance braking systems; - Anti-Lock Braking Systems and EBS; - vacuum braking systems; - safety related parts of complex electronic control systems; - trailer braking control systems. NOTE For assisted trailer braking the EU Regulation 2015/68 can be used but before including these requirements into this document, an additional review of 2015/68 is needed.

This document applies to wheeled and/or track-laying self-propelled agricultural and forestry vehicles when used on public roads. It specifies the definitions, construction and performance requirements and the means for verification of braking systems on vehicles with a maximum design speed not exceeding 60 km/h. Following items are excluded from the scope of this document: - coupling force control; - endurance braking systems; - Anti-Lock Braking Systems and EBS; - vacuum braking systems; - safety related parts of complex electronic control systems; - trailer braking control systems. NOTE For assisted trailer braking the EU Regulation 2015/68 can be used but before including these requirements into this document, an additional review of 2015/68 is needed.

EN 17344:2020 is classified under the following ICS (International Classification for Standards) categories: 65.060.01 - Agricultural machines and equipment in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17344:2020 has the following relationships with other standards: It is inter standard links to EN ISO 6887-2:2017, EN 1965-1:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17344:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2020

Kmetijski stroji - Kmetijska in gozdarska vozila z lastnim pogonom - Zahteve za

zaviranje

Agricultural machinery - Self-propelled agricultural and forestry vehicles - Requirements

for braking

Landmaschinen - Selbstfahrende Arbeitsmaschinen - Anforderungen an Bremsanlagen

Matériel agricole - Véhicules agricoles et forestiers automoteurs - Exigences en matière

de freinage

Ta slovenski standard je istoveten z: EN 17344:2020

ICS:

65.060.01 Kmetijski stroji in oprema na Agricultural machines and

splošno equipment in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17344

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2020

EUROPÄISCHE NORM

ICS 65.060.01

English Version

Agricultural machinery - Self-propelled agricultural and

forestry vehicles - Requirements for braking

Matériel agricole - Véhicules agricoles et forestiers Landmaschinen - Selbstfahrende Arbeitsmaschinen -

automoteurs - Exigences en matière de freinage Anforderungen an Bremsanlagen

This European Standard was approved by CEN on 27 October 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17344:2020 E

worldwide for CEN national Members.

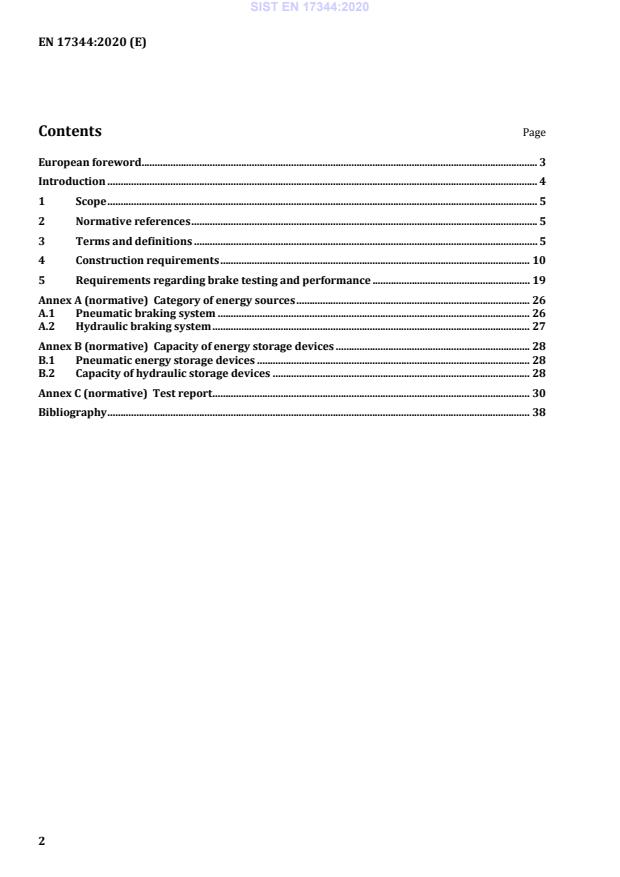

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Construction requirements . 10

5 Requirements regarding brake testing and performance . 19

Annex A (normative) Category of energy sources . 26

A.1 Pneumatic braking system . 26

A.2 Hydraulic braking system . 27

Annex B (normative) Capacity of energy storage devices . 28

B.1 Pneumatic energy storage devices . 28

B.2 Capacity of hydraulic storage devices . 28

Annex C (normative) Test report . 30

Bibliography . 38

European foreword

This document (EN 17344:2020) has been prepared by Technical Committee CEN/TC 144 “Tractors and

machinery for agriculture and forestry”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2020, and conflicting national standards shall

be withdrawn at the latest by month year of September 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document applies to braking systems for on-road use, installed on self-propelled agricultural and

forestry machinery. These vehicles are not primarily designed to pull heavy trailers or implements. For

this reason, this standard does not contain provisions for assisted trailer braking control. Information

about such systems can be found in EU Regulation 2015/68, last amended by 2018/828, or in UNECE

Regulation No. 13, or in any national legislation dealing with braking systems on vehicles.

This document can be used during an EU or national type approval process for self-propelled agricultural

or forestry machines.

The sources of this document are, among others:

— EU Regulation 2015/68, as last amended by 2018/828;

— ISO 10998:2008 Agricultural tractors – Requirements for steering.

1 Scope

This document applies to wheeled and/or track-laying self-propelled agricultural and forestry vehicles

when used on public roads. It specifies the definitions, construction and performance requirements and

the means for verification of braking systems on vehicles with a maximum design speed not

exceeding 60 km/h.

Following items are excluded from the scope of this document:

— coupling force control;

— endurance braking systems;

— Anti-Lock Braking Systems and EBS;

— vacuum braking systems;

— safety related parts of complex electronic control systems;

— trailer braking control systems.

NOTE For assisted trailer braking the EU Regulation 2015/68 can be used but before including these

requirements into this document, an additional review of 2015/68 is needed.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 9128:2006, Road vehicles — Graphical symbols to designate brake fluid types

ISO 3767-1:2016, Tractors, machinery for agriculture and forestry, powered lawn and garden

equipment — Symbols for operator controls and other displays — Part 1: Common symbols

ISO 3583:1984, Road vehicles — Pressure test connection for compressed-air pneumatic braking equipment

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/ui

3.1

braking system

combination of parts whose function is to reduce progressively the speed of a moving vehicle or to bring

it to a halt, or to keep it stationary if it has already halted

Note 1 to entry: the system consists of the control device, the transmission and the brake

3.2

brake

part in which the forces opposing the movement of the vehicle develop

Note 1 to entry: This may be a friction brake, or an electrical brake, or a fluid brake, or an engine/transmission

brake

3.2.1

friction brake

brake where the braking forces are generated only by the friction brakes without taking into account of

the braking effect of the stepless drive braking system

3.2.2

fluid brake

brake where the braking forces are generated by the action of a fluid situated between two parts of the

vehicle moving relatively to one another

3.2.3

electrical brake

brake where the braking forces are generated by electromagnetic action between two parts of the vehicle

moving relatively to another but not in contact with one another

3.2.4

engine brake

brake where the forces are generated by a controlled increase of the braking action from the engine which

remains connected with the wheels or tracks by the transmission

3.3

service braking system

braking system that enables the driver to control the movement of the vehicle and to halt it safely,

speedily and effectively, for all the range of speed and load that the vehicle is approved to operate, on any

up or down gradient

3.4

graduated braking

braking which, within the normal range of operation of the equipment, during either the application or

the releasing of the brakes, fulfils all the following conditions:

— the driver can, at any time, increase or reduce the braking force through action of the control

device; and

— it is easily possible to make a sufficiently fine adjustment to the braking force

3.5

control device

device actuated directly by the driver to supply to the transmission the energy required for braking or

controlling it. This energy may be the muscular energy of the driver, or energy from another source

controlled by the driver or in appropriate cases the kinetic energy of a towed vehicle, or a combination

of these various kinds of energy

3.6

transmission

combination of components comprised between the control device and the brake, and linking them

functionally through mechanical, hydraulic, pneumatic or electric means or through the use of a

combination of those means; where the braking power is derived from or assisted by a source of energy

3.7

parking braking system

system that enables the vehicle to be held stationary on an up or down gradient even in the absence of

the driver

3.8

secondary braking system

means the braking system that allows the driver to halt the vehicle within a reasonable distance in the

event of a failure of the service braking system

3.9

inertia braking

braking by utilizing the forces generated by the towed vehicle's moving up on the towing vehicle

3.10

laden vehicle

vehicle laden at its technically permissible maximum laden mass as declared by the manufacturer for on

road operation

3.11

unladen vehicle

vehicle with its mass in running order for road operation

Note 1 to entry: This includes the coupling device(s), coolants, oils, liquids necessary for road circulation, fuel

and DEF (Diesel Emission Fluid) tanks, if provided and filled minimum 90 % and a driver of 75 kg

[SOURCE: UNECE R.E.3]

3.12

axle load

sum of the vertical static forces of the road surface in the contact area on the wheels of the axle

3.13

maximum stationary axle load

stationary axle load achieved under the condition of the technically permissible maximum laden mass of

the vehicle

3.14

towed vehicle

agricultural trailer or an interchangeable towed equipment

3.15

attachment trailer

any towed vehicle which is designed to be towed by a self-propelled vehicle, and only intended to carry

the attachment of its towing vehicle during road operation (for example harvesting attachment)

3.16

spring compression chamber

chamber where the pressure variation that induces the compression of the spring is actually produced

3.17

energy source

device that provides the energy required to actuate the brakes, either directly or indirectly through an

energy storage device

3.18

energy storage device

device that stores the energy provided by the energy source to apply or release the brakes

3.19

energy reserve

pneumatic, hydraulic or electric energy that is stored in an energy storage device

3.20

technically permissible maximum laden mass

maximum laden mass declared by the manufacturer on the basis of its construction features and design

performances, irrespective from the load capacity of the tyres or tracks

3.21

technically permissible maximum mass per axle

mass corresponding to the maximum permissible static vertical load transmitted to the ground by the

wheels of the axle or the tracks, on the basis of the construction features and of the vehicle and their

design performances, irrespective from the load capacity of the tyres

3.22

brake assisted steering function

system allowing to brake a single wheel on one axle, by means of two separate controls, with the aim to

shorten the turning radius during off-road use

3.23

measured maximum design speed

measured speed exceeding the nominal value for the maximum design speed by maximum 3 km/h plus

an additional 5 % tolerance taking into account variations due to tyre size

Note 1 to entry: This is justified to take account of various unavoidable errors due, in particular to the measuring

technique and to the increase in running speed of the engine with a partial load

3.24

unbraked towed vehicle mass

sum of the maximum stationary axle loads of the towed vehicle

3.25

spring braking system

braking system for which the energy required for braking is supplied by one or more springs acting as an

energy storage device

3.26

stepless drive braking system

stepless drive with a substantial braking capability other than by friction and having at least one speed

range going from forward to reverse and vice versa

Note 1 to entry: The variable component of the stepless drive can be mechanic, hydraulic, or electric. The

connection between engine and output shaft to the wheels or tracks shall remain connected at standstill

3.27

combination stepless drive braking system

braking system utilising both, the stepless drive and friction braking effect, where, however, the braking

forces are generated by a predominant proportion generated by the stepless drive

3.28

combination friction braking system

braking system utilising both, the friction and stepless drive braking effect, where, however, the braking

forces are generated by a predominant proportion generated by the friction brakes

3.29

graduated stepless drive braking

stepless drive braking through which the driver is able to increase or decrease the vehicle speed at any

time by a progressive action on its stepless drive control device

3.30

stepless drive control device

device, such as a lever or pedal, used to vary the vehicle speed

3.31

service brake control device

control device by whose operation the prescribed service braking performance is attained

3.32

inch device

device that affects the speed of the vehicle independently of the stepless drive control. The inch device

may be used in confined spaces or where inching of the vehicle is required, e.g. to pick-up or set off

attachments

3.33

class I vehicles

self-propelled vehicles with a maximum design speed ≤ 12 km/h

3.34

class II vehicles

self-propelled vehicles with a maximum design speed > 12 km/h and ≤ 30 km/h

3.35

class III vehicles

self-propelled vehicles with a maximum design speed > 30 km/h and ≤ 40 km/h

3.36

class IV vehicles

self-propelled vehicles with a maximum design speed > 40 km/h and ≤ 60 km/h

4 Construction requirements

4.1 Braking components and braking surfaces

4.1.1 For the purpose of this document, the brake, all mechanical parts of the transmission and the

control device, hereafter called ‘braking equipment’ shall not be regarded as liable to breakage if they are

amply dimensioned, readily accessible for maintenance and exhibit safety features at least equal to those

prescribed for other essential components (such as the steering system).

4.1.2 The braking equipment shall be designed, constructed and fitted, so that it is capable of

withstanding the stresses arising during normal operation for which the vehicle is designated it.

4.1.3 Brake linings shall not contain asbestos.

4.1.4 Unless otherwise specified, it is not permitted to fit any adjustable valves that would allow the

performance of the braking system to be changed by the user of the vehicle such that, in service, it falls

outside the requirements of this document. An adjustable valve that can only be operated by the

manufacturer through the use of special tool or the provision of a tamper proof seal or both shall be

permitted provided that the user of the vehicle is not able to adjust this valve, or that any user

modification is readily identifiable.

4.1.5 For Class IV vehicles, the wear of the service brakes shall be compensated by means of a system

of automatic adjustment. In addition, the control device and the components of the transmission and of

the brakes shall possess a reserve of travel and, if necessary, suitable means of compensation such that,

when the brakes become heated or when the brake linings have reached a certain degree of wear,

effective braking shall be ensured without immediate adjustment being necessary.

4.1.6 It shall be possible for the wear of the service brakes to be compensated by means of a system of

manual or automatic adjustment. It shall be possible to easily check this wear on service brake linings

from the outside or underside of the vehicle, utilizing only the tools or equipment normally supplied with

the vehicle, for instance, by the provision of appropriate inspection holes. Alternatively, acoustical or

optical devices warning the driver at his driving position when lining replacement is necessary are

acceptable.

4.1.7 The requirements of point 4.1.6 are not applicable to oil immersed brakes which are designed for

a long life in the vehicle without servicing.

4.2 Functions of the braking system and the basic requirements

4.2.1 Service braking system: It shall be possible to graduate the service braking system action. The

driver shall be able to achieve this braking action from his driving position without removing his hands

from the steering control device or with one hand on the steering control device and the other on the

stepless drive control device. The service braking system can be one of the following braking systems, as

declared by the manufacturer:

— a mere friction braking system;

— a combination friction braking system;

— a combination stepless drive braking system;

— a mere stepless drive braking system.

4.2.1.1 In the case that the manufacturer declares the stepless drive to act as a braking system, it

shall not be possible to disconnect the transmission between the engine and the drive wheels during on-

road use, in order to ensure that the stepless drive maintains its braking capabilities. This shall not apply

to the presence of an inch device.

4.2.1.2 However, to facilitate vehicle recovery, the operator's manual shall outline how to tow the

vehicle without the risk for damage to the stepless drive. If a dedicated tool is needed for this purpose, it

shall be carried on the vehicle.

4.2.1.3 The control device of the stepless drive shall be made in a way that inadvertent change of

direction is prevented.

4.2.1.4 It is allowed to automatically engage the parking brake system at the end of the brake cycle,

in order to bring the vehicle to a stop on a gradient or in the event of residual creep.

4.2.1.5 In case of a combination braking system it is allowed to use simultaneously two controls in order

to achieve the required braking performance.

4.2.2 Secondary braking system: The secondary braking system shall make it possible to halt the

vehicle within a reasonable distance in the event of a failure of (part of) the service braking system. It

shall be possible to graduate this braking action. The driver shall be able to obtain this braking action

from his driving seat while keeping at least one hand on the steering control device. For the purpose of

this requirement, it is assumed that not more than one failure of the service braking system can occur at

one time.

4.2.3 Parking braking system: The parking braking system shall enable the vehicle to be held stationary

on an up or down gradient even in the absence of the driver, the working parts of the braking system

being then held in the locked position by a purely mechanical device. The driver shall be able to achieve

this braking action from his driving seat.

4.2.4 The service, secondary and the parking braking systems shall act on braking surfaces

permanently connected to the wheels through components of adequate strength. It shall not be possible

to disconnect a braking surface from the wheels; however, such disconnection shall be required in the

case of the parking braking system actuated by a spring, in order to allow retrieval of the machine in a

recovery situation.

4.3 Axles subject to braking

4.3.1 On Class I, II and III vehicles the service braking system shall act on all the wheels of at least one

axle.

4.3.2 On Class IV vehicles the service braking system shall act:

— on all the wheels of at least two axles; or

— in case of vehicles with a braked axle and an automatic engagement of the drive to another axle

during braking, these wheels are deemed to be braked.

When more than one axle is subject to braking, one axle may be decoupled provided that activation of the

service braking system automatically re-couples this axle and that, in the case of a failure in the energy

supply or a failure in the control transmission of the re-coupling control device, then automatic re-

coupling shall be ensured.

4.4 Brake assisted steering function

4.4.1 In case the vehicle is equipped with a brake assisted steering function, the service braking system

of the vehicle may consist of two brake circuits, each connected to one right and one left brake control.

Such system, due to its technical concept, is not to be considered as a braking system consisting of two

independent circuits.

4.4.2 For Class IV vehicles: If the brake assisted steering function is enabled, for instance when both

pedals are not latched, it shall not be possible to travel at speeds exceeding 40 km/h or at speeds in excess

of 40 km/h the brake assisted steering function shall be disabled. These two operations shall be ensured

by automatic means.

4.4.3 In vehicles where the separate pedals can be connected manually, the driver shall be able to easily

verify from his driving place whether these pedals are connected or not.

4.5 Requirements for controls

4.5.1 The equipment providing service, secondary and parking braking may have common

components, provided they fulfil the following conditions:

4.5.1.1 There shall be at least two controls, each corresponding to a different braking system,

independent of each other and readily accessible to the driver from his normal driving position. Every

brake control device shall be designed in a way that it returns to the full-off position when released. This

requirement may not apply to a parking braking system control device when it is mechanically locked in

an applied position or to a hand operated stepless drive control device.

4.5.1.2 The control device of the service braking system shall be independent of the control device of

the parking braking system.

4.5.1.3 Where the service and secondary braking systems have the same control device, the

effectiveness of the linkage between that control device and the various components of the transmission

systems shall comply with points 4.1.1 and 4.1.2.

4.5.1.4 Where the service and secondary braking systems have the same control device, the parking

braking system shall be so designed that it can be actuated when the vehicle is in motion. This

requirement shall not apply if the vehicle’s service braking system can be actuated even partially, by

means of an auxiliary control.

4.5.2 In the event of a breakage

— of any component other than the brakes themselves; or

— of any other failure or malfunction of the service braking system, including;

— failure of the energy source and partial or total exhaustion of an energy reserve;

the secondary braking system or that part of the service braking system which is not affected by the

failure shall be able to bring the vehicle to a halt in the conditions prescribed for secondary braking.

4.5.3 In particular, where the secondary braking system and the service braking system have a

common control device and common transmission:

4.5.3.1 Where the service braking system is actuated by the muscular energy of the driver assisted

by an energy source or one or more energy reserves, the secondary braking performance shall be ensured

in the event of failure of that assistance.

Either by:

— the muscular energy of the driver alone; or

— by the muscular energy of the driver assisted by the energy reserves which are not affected by the

failure; and

For both cases, the force specified in 5.4.4 applied to the control not exceeding the prescribed maxima.

4.5.3.2 If the service braking force and transmission depend exclusively on the use, controlled by the

driver, of an energy source with an energy reserve, there shall be at least two completely independent

energy reserves;

— each provided with its own transmission likewise independent;

— each of them may act on the brakes of only two or more wheels so selected as to be capable of

ensuring by themselves the prescribed degree of secondary braking without endangering the

stability of the vehicle during braking; in addition;

— each of those energy reserves shall be equipped with a warning device. A single warning device can

be used, provided that it gives the level of the lowest of the two energy reserves.

In case of a compressed air reserve, at least on one of the air reservoirs of each service braking circuit a

device for draining and exhausting is required in an adequate and easily accessible position.

4.5.4 Where there are separate control devices for the service and secondary braking systems

simultaneous actuation of control devices shall not render both the service and secondary braking

systems inoperative, either when both braking systems are in good working order or when one of them

is faulty.

4.6 Requirements for energy sources and energy reserves

4.6.1 Where use is made of an energy source other than the muscular energy of the driver, only one

energy source is required, but the means by which the device constituting that source is driven shall

comply with points 4.1.1 and 4.1.2.

4.6.2 In the event of a failure of the energy source, the energy reserve(s), when installed, shall be

sufficient to stop the vehicle under the following conditions:

— after eight full-stroke actuations of the service braking system control device; the number of

actuations can be reduced to four, in case of a service braking system consisting of two independent

circuits;

— followed by a braking test at the ninth or fifth application with the efficiency prescribed for secondary

braking;

— under the testing conditions prescribed in point 5.4.

4.6.3 The capacity of energy sources shall meet the requirements specified in Annex A.

4.6.4 The capacity of energy reservoirs shall meet the requirements specified in Annex B.

4.6.5 Warning device for energy reserve

4.6.5.1 Where the prescribed secondary braking performance cannot be obtained without the use of

energy reserve, a warning device shall be provided. This device shall give an optical or acoustic signal

when the energy reserve in any part of the system falls below a threshold value. The latter value is the

pressure at which it shall be possible to apply the service braking control device a fifth time and obtain

the prescribed secondary braking performance,

— irrespective the loading condition of the vehicle; and

— without faults in the service-brake transmission; and

— with the brakes adjusted as closely as possible; and

— without recharging of the reservoir; and

— after four full-stroke actuations.

The warning device shall be directly and permanently connected to the circuit. When the engine is

running under normal operating conditions and there are no faults in the braking system, the warning

device shall give no signal except during the time required for charging the energy reservoir(s) after start-

up of the engine.

4.6.5.2 The acoustic device may be rendered inoperative while the parking braking system is applied

or, at the choice of the manufacturer, while the transmission selector is in the 'park' position or in both

cases.

4.6.6 In the event of an engine stop or a failure in the drive system of the energy source and where the

use of this energy source is essential for the operation of a braking system, the energy reserve, if provided,

shall be sufficient to bring the vehicle to a halt in the conditions prescribed for secondary braking.

Stopping the vehicle can be done either:

— by applying the service brake control; or

— by applying the secondary brake control; or

— by an automatic application of the secondary brake when the pressure supplied by the energy source

falls below the level specified in point 4.6.5.1.

4.6.7 If pneumatic or hydraulic auxiliary equipment is installed and in the event of damage to the source

of energy, the operation of the auxiliary equipment shall not cause the reserves of energy feeding the

braking systems to fall below the prescribed level and shall not cause that the prescribed performance

values for secondary braking cannot be reached.

4.7 Distribution of braking forces

4.7.1 The action of the service braking system shall be distributed appropriately between the

wheels/tracks of the same axle symmetrically in relation to the longitudinal median plane of the vehicle

and shall be verified in accordance with the conditions set out in point 5.2.6.

4.7.2 If the service braking system acts on all wheels or the drive wheels of the tracks of at least two

axles of the vehicle, the action shall be appropriately distributed among the axles. This condition is

deemed to be fulfilled for example:

— when at least two axles are connected by means of a clutch with no or limited slip characteristics

together when actuating the service brake;

— when the vehicle has a permanent four-wheel drive, without a differential between the connected

axles;

— when, for articulated vehicles of class I, II and III, an axle is subject to braking and the differential is

mounted between the service brake and the wheels/tracks, all wheels/tracks of that axle are deemed

to be braked when the activation of the service braking system automatically locks the differential of

that axle.

4.8 Specific requirements for hydraulic braking systems using brake fluid

4.8.1 The requirements of this section only apply in the case that the braking circuits are independent

from any other hydraulic circuit from the vehicles. In the case that the braking system is using mineral

oil from other circuits on the vehicle, such as the transmission, the warning signals from that other circuit

are deemed to satisfy the requirements of this section.

4.8.2 The filling ports of the fluid reservoir(s) shall be readily accessible; in addition, the fluid reservoir

shall be so made that the level of the reserve fluid can be easily checked without the containers having to

be opened. Where this last condition is not fulfilled, the red warning signal specified in point 4.10.1.1 shall

draw the driver's attention to any fall in the level of reserve fluid liable to cause a failure of the braking

system.

4.8.3 A failure in the hydraulic transmission where the prescribed service braking performance cannot

be obtained shall be signalled to the driver by a device comprising a red warning signal, as specified in

point 4.10.1.1. Alternatively, the lighting up of this device when the fluid in the reservoir is below a certain

level specified by the manufacturer shall be permitted.

4.8.4 The type of fluid to be used in the hydraulic transmission of braking systems shall be identified

by the symbol in accordance with Figure 1 or 2 of ISO 9128:2006. The symbol shall be affixed within

100 mm of the filling ports of the fluid reservoirs. Additional information may be provided by the

manufacturers. This requirement only applies to vehicles having a separate filling port for the brake fluid.

4.9 Specific requirements for the electric transmission of the parking brake system

4.9.1 In the case of an electrical failure in the control or a break in the wiring within the electric control

transmission external to the control unit(s), excluding the energy supply:

4.9.1.1 It shall remain possible to apply the parking braking system from the driver's seat and thereby

be capable of holding the laden vehicle stationary on an 8 % up or down gradient;

4.9.1.2 When the vehicle is moving:

— on Class I, II and III vehicles the parking brake may automatically apply with the specified

performance set out in point 5.6; or

— on Class IV vehicles any unintended actuation of the parking brake system at a vehicle speed

above 10 km/h shall be prevented.

4.9.2 An automatic actuation of the parking braking system is allowed when the vehicle is stationary,

provided that the performance for parking braking is achieved and, once applied, the parking braking

system remains engaged independently of the status of the ignition (start) switch.

4.9.3 It shall also be possible to release the parking braking system, if necessary, by the use of tools

and/or an auxiliary device carried/fitted on the vehicle.

4.9.4 A break in the wiring within the electric transmission, or an electric failure in the control device

of the parking braking system shall be signalled to the driver by the yellow warning signal specified in

point 4.10.1.2. When caused by a break in the wiring within the electric control transmission, this yellow

warning signal shall be signalled not later than on actuation of the relevant braking control.

4.9.5 Auxiliary equipment may be supplied with energy from the electric transmission of the parking

braking system provided that the supply of energy is sufficient to allow the actuation of the parking

braking system in addition to the vehicle electrical load under non-fault conditions.

4.9.6 After the ignition/start switch which controls the electrical energy for the braking equipment has

been switched off and/or the key removed, it shall remain possible to apply the parking braking system,

whereas releasing shall be prevented. Release of the parking braking is permitted if the control shall be

mechanically unlocked.

4.9.7 In case that the parking brake has been intentionally activated by the driver, the release of the

parking brake shall always require an intentional action by the driver.

4.10 Warning signals for brake failure

4.10.1 Vehicles that provide warning signals shall provide optical brake failure warning signals, as

follows:

4.10.1.1 A red warning signal, indicating hydraulic or pneumatic failures, within the vehicle braking

equipment. The symbol shall be according Figure 1a) of point 4.10.1.4.

4.10.1.2 Where applicable, a yellow warning signal, indicating an electrically detected fault within the

vehicle braking equipment, which is not indicated by the warning signal mentioned in point above. The

symbol shall be according Figure 1b) of point 4.10.1.4.

4.10.1.3 The status of the parking brake shall be indicated by the red warning signal specified in

point 4.10.1.1 or alternatively, a separate red warning signal for the parking brake status with a symbol

according to Figure 1c) of point 4.10.1.4 can be provided.

4.10.1.4 Symbols (preferred) for braking functions:

a) b) c)

ISO 3767-1:2016 13.7 ISO 3767-1:2016 13.7 ISO 3767-1:2016 13.8

Figure 1 — Symbols for braking functions

4.10.2 Except where stated otherwise:

4.10.2.1 A specified failure shall be signalled to the driver by the above-mentioned warning signal(s)

not later than on actuation of the relevant braking control device.

4.10.2.2 The warning signal(s) shall remain displayed as long as the failure or status persists and the

ignition (start) switch is in the “on” (run) position.

4.10.2.3 The warning signal(s) shall be not flashing. Flashing of the warning signal specified in 4.10.1.1

is allowed to indicate a failure in the braking system, when the same symbol is used in a non-flashing

mode to indicate the status of an applied parking brake.

4.10.3 The warning signals shall be visible, even by daylight; the satisfactory condition of the signals

shall be easily verifiable by the driver from the driver's seat; the failure of a component of the warning

devices shall not entail any loss of the braking system's performance.

4.11 Vehicles fitted with spring brakes

4.11.1 Use of a spring brake as service brake

A spring braking system may be used as a service braking system on Class I vehicles, provided that:

— the driver can graduate the braking action;

— with the spring brakes adjusted as closely as possible, it shall be possible to actuate the

brake 10 times within a minute with the engine running at idle speed (brake applications distributed

evenly within this period);

— with the spring brakes adjusted as closely as possible, it shall be possible to actuate the service

braking system 6 times starting with a pressure not higher than the cut-in pressure of the energy

source. During this test the energy storage devices shall not be fed. In addition, any energy storage

for auxiliary equipment shall be isolated;

— the spring brakes shall be designed in such a way that they are not subject to failure under fatigue;

— a small variation in any of the pressure limits which may occur in the spring compression chamber

feed circuit shall not cause a significant variation in the braking force.

4.11.2 Use of a spring brake as secondary brake

A spring braking system may be used as secondary braking system independently of the vehicle

maximum design speed, provided that the driver can graduate the braking action and that the

performance requirements set out in point 5.5.2 are fulfilled. Exceptionally, in the case of Class I vehicles

that use spring brakes, which control is of the ON/OFF type (e.g. a knob or a switch) and do not allow the

driver to graduate the braking action, as secondary braking system, the following requirements shall be

met:

— the driver shall be able to actuate the spring brakes control from the driving seat, while keeping at

least one hand on the steering control;

— the secondary braking performance prescribed in point 5.5.2 shall be fulfilled.

The prescribed performance shall be obtained without deviation of the vehicle from its course, without

abnormal vibrations and without wheel-locking.

4.11.3 Pressure requirements

4.11.3.1 The pressure in the spring compression chamber at which the springs begin to actuate the

brakes, the latter being adjusted as closely as possible, shall not be greater than 80 % of the minimum

level of the normal available pressure.

4.11.3.2 When the pressure in the line feeding energy to the spring compression chamber - excluding

lines of an auxiliary release device using a fluid under pressure - falls to the level at which the brake parts

begin to move, an optical or audible warning device in the towing vehicle shall be actuated. Provided this

requirement is met, the warning device may comprise the warning signal specified in point 4.10.1.1.

4.11.3.3 The feed circuit to the spring compression chamber shall either include an own energy

reserve or shall be fed from at least two independent energy reserves or from one energy source.

4.11.3.4 Auxiliary equipment may only draw its energy from the feed line for the spring brake

actuators under the condition that its operation, even in the event of damage to the energy source, cannot

cause the energy reserve for the spring brake actuators to fall below a level from which one release of the

spring brake actuators is possible.

4.11.3.5 In any case, during re-charging of the braking system from zero pressure, the spring brakes

shall remain fully applied, irrespective of the position of the control device, until the pressure in the

service braking system is sufficient to ensure at least the prescribed secondary braking performance of

the laden vehicle, using the service braking system control device.

4.11.3.6 Once applied, the spring brakes shall not release unless there is sufficient pressure in the

service braking system to at least provide a residual braking performance of 1,3 m/s by application of

the service braking control device.

4.11.4 Auxiliary release system

4.11.4.1 A spring braking system shall be so designed that, in the event of a failure in that system, it is

still possible to release the brakes. This may be achieved by the use of an auxiliary release device

(pneumatic, hydraulic, mechanical, etc.).

4.11.4.2 Auxiliary release devices using an energy reserve for releasing shall draw their energy from

an energy reserve which is independent from the energy reserve normally used for the spring braking

system. The pneumatic or hydraulic fluid in such an auxiliary release device may act on the same piston

surface in the spring compression chamber which is used for the normal spring braking system under the

condition that the auxiliary release device uses a separate line. The junction of this line with the normal

line connecting the control device with the spring brake actuators shall be at each spring brake actuator

immediately before the port to the spring compression chamber, if not integrated in the body of th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...