EN 12352:2006

(Main)Traffic control equipment - Warning and safety light devices

Traffic control equipment - Warning and safety light devices

This European Standard specifies the requirements for individual electrically operated light devices, called warning lights, emitting a continuous or regular intermittent light of a single colour which, by their colour and position alone, are used to warn, inform or guide road users. It specifies the requirements for visual, structural and operational performances and the relevant test methods to be used. These devices rely upon existing furniture to provide the mounting.

This European Standard is not applicable to lighting devices which convey messages by additional means (e.g. variable message signs) or which convey a mandatory instruction (e.g. traffic signals) or which are covered by vehicle lighting regulations.

This European Standard does not consider horizontal loads because it is the mounting to which they are fixed, which is not covered by this European Standard, which has to resist applied horizontal loads.

Anlagen zur Verkehrssteuerung - Warn- und Sicherheitsleuchten

Diese Europäische Norm legt die Anforderungen an elektrisch betriebene Einrichtungen, fest, die ein dauern-des

oder regelmäßig intermittierendes Licht einer einzelnen Farbe ausstrahlen, und die allein durch ihre Farbe

und ihre Position zur Warnung, Information oder Leitung von Verkehrsteilnehmern verwendet werden. Sie legt

außerdem die Anforderungen an die optische Leistung, die bautechnische Ausführung und die Betriebskenn-werte

sowie die entsprechenden Prüfverfahren fest. Diese Einrichtungen haben Befestigungsvorrichtungen.

Diese Europäische Norm gilt nicht für Leuchteinrichtungen, die Nachrichten auf irgendeine zusätzliche Weise

übermitteln (z. B. Wechselverkehrszeichen) oder die eine verbindliche Anweisung übermitteln (z. B. Verkehrs-zeichen)

oder die durch Bestimmungen über Fahrzeugscheinwerfer abgedeckt werden.

Diese Europäische Norm behandelt keine horizontalen Lasten wegen der Befestigungen, die nicht

Gegenstand dieser Norm sind, die aber die horizontalen Lasten aufnehmen.

Equipement de régulation du trafic - Feux de balisage et d'alerte

La présente Norme européenne spécifie les exigences pour les dispositifs lumineux électriques individuels, appelés feux d’alerte et émettant une lumière continue ou intermittente régulière monochrome et qui, en raison seulement de leur couleur et de leur emplacement, sont utilisés pour avertir, informer ou guider les usagers de la route. Elle spécifie également les exigences en matière de performances visuelles, structurelles et fonctionnelles, ainsi que les méthodes d'essai correspondantes à utiliser. Pour le montage, ces dispositifs reposent sur les équipements fixes existants.

La présente Norme européenne ne s’applique pas aux dispositifs lumineux qui transmettent des messages par des moyens supplémentaires (par exemple des panneaux à message variable), qui délivrent des instructions obligatoires (par exemple les feux de circulation) ou sont soumis à la réglementation en matière d'éclairage automobile.

La présente Norme européenne ne prend pas en compte les charges horizontales car c’est le support sur lequel les dispositifs sont fixés, lequel n’est pas couvert par la présente Norme européenne, qui doit résister aux charges horizontales appliquées.

Oprema za nadzor in vodenje cestnega prometa - Svetlobne signalne naprave (SSN)

General Information

- Status

- Withdrawn

- Publication Date

- 25-Apr-2006

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 226 - Road equipment

- Drafting Committee

- CEN/TC 226/WG 4 - Traffic control

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 19-Jun-2024

- Completion Date

- 14-Apr-2025

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 18-Jan-2023

Frequently Asked Questions

EN 12352:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Traffic control equipment - Warning and safety light devices". This standard covers: This European Standard specifies the requirements for individual electrically operated light devices, called warning lights, emitting a continuous or regular intermittent light of a single colour which, by their colour and position alone, are used to warn, inform or guide road users. It specifies the requirements for visual, structural and operational performances and the relevant test methods to be used. These devices rely upon existing furniture to provide the mounting. This European Standard is not applicable to lighting devices which convey messages by additional means (e.g. variable message signs) or which convey a mandatory instruction (e.g. traffic signals) or which are covered by vehicle lighting regulations. This European Standard does not consider horizontal loads because it is the mounting to which they are fixed, which is not covered by this European Standard, which has to resist applied horizontal loads.

This European Standard specifies the requirements for individual electrically operated light devices, called warning lights, emitting a continuous or regular intermittent light of a single colour which, by their colour and position alone, are used to warn, inform or guide road users. It specifies the requirements for visual, structural and operational performances and the relevant test methods to be used. These devices rely upon existing furniture to provide the mounting. This European Standard is not applicable to lighting devices which convey messages by additional means (e.g. variable message signs) or which convey a mandatory instruction (e.g. traffic signals) or which are covered by vehicle lighting regulations. This European Standard does not consider horizontal loads because it is the mounting to which they are fixed, which is not covered by this European Standard, which has to resist applied horizontal loads.

EN 12352:2006 is classified under the following ICS (International Classification for Standards) categories: 93.080.30 - Road equipment and installations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12352:2006 has the following relationships with other standards: It is inter standard links to EN 12352:2000, EN 12352:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12352:2006 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/111. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12352:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Traffic control equipment - Warning and safety light devicesOprema za nadzor in vodenje cestnega prometa - Svetlobne signalne naprave (SSN)Equipement de régulation du trafic - Feux de balisage et d'alerteAnlagen zur Verkehrssteuerung - Warn- und SicherheitsleuchtenTa slovenski standard je istoveten z:EN 12352:2006SIST EN 12352:2006en93.080.30ICS:SIST EN 12352:20021DGRPHãþDSLOVENSKI

STANDARDSIST EN 12352:200601-julij-2006

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12352April 2006ICS 93.080.30Supersedes EN 12352:2000

English VersionTraffic control equipment - Warning and safety light devicesEquipement de régulation du traffic - Feux de balisage etd'alerteAnlagen zur Verkehrssteuerung - Warn- undSicherheitsleuchtenThis European Standard was approved by CEN on 27 February 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12352:2006: E

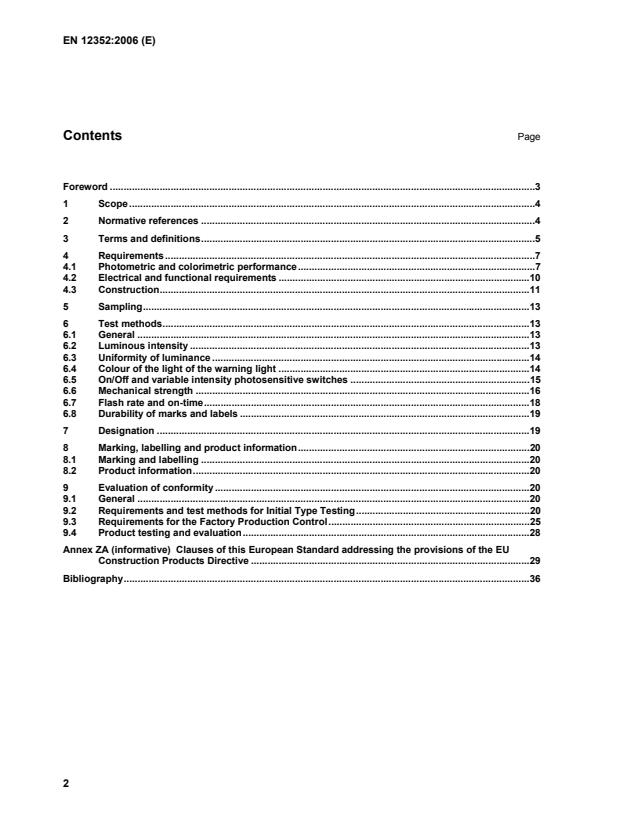

Foreword.3 1 Scope.4 2 Normative references.4 3 Terms and definitions.5 4 Requirements.7 4.1 Photometric and colorimetric performance.7 4.2 Electrical and functional requirements.10 4.3 Construction.11 5 Sampling.13 6 Test methods.13 6.1 General.13 6.2 Luminous intensity.13 6.3 Uniformity of luminance.14 6.4 Colour of the light of the warning light.14 6.5 On/Off and variable intensity photosensitive switches.15 6.6 Mechanical strength.16 6.7 Flash rate and on-time.18 6.8 Durability of marks and labels.19 7 Designation.19 8 Marking, labelling and product information.20 8.1 Marking and labelling.20 8.2 Product information.20 9 Evaluation of conformity.20 9.1 General.20 9.2 Requirements and test methods for Initial Type Testing.20 9.3 Requirements for the Factory Production Control.25 9.4 Product testing and evaluation.28 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.29 Bibliography.36

50293, Electromagnetic compatibility — Road traffic signal systems — Product standard EN 60068-2-1, Environmental testing — Part 2: Tests — Test A: Cold (IEC 60068-2-1:1990) EN 60068-2-2, Basic environmental testing procedures — Part 2: Tests — Test B: Dry heat (IEC 60068-2-2:1974 + IEC 60068-2-2A:1976) EN 60529, Degree of protection provided by enclosures (IP code) (IEC 60529:1989) EN 60598-1:2004, Luminaires — Part 1: General requirements and tests (IEC 60598-1:2003 + Corrigendum 2004, modified) CIE 15, Colorimetry CIE 17-4:1987, International lighting vocabulary CIE 39.2, Recommendations for surface colours for visual signalling CIE 54.2:2001, Retroflection — Definition and measurement CIE 69, Methods of characterizing illuminance meters and luminance meters — Performance, characteristics and specifications HD 384.4, Electrical installation of buildings — Part 4: Protection for safety HD 638, Road traffic signal systems Council Directive 73/23/EEC of 19 February 1973 on the harmonization of the laws of Member States relating to electrical equipment designed for use within certain voltage limits

-

( + d)(

= efftt,ttIttI121220∫

(1) t2, t1 are time instants at which I (t)d = Ieff

3.2 horizontal plane (360° warning lights only) plane which passes through the photometric centre of the warning light when the warning light is in its normal operating position 3.3 light emitting surface single continuous area of surface emitting light 3.4 minimum reference luminous intensity IRmin required minimum (effective) luminous intensity, at the nominal voltage, measured on the reference axis or in the reference plane 3.5 minimum area luminous intensity IAmin minimum permissible (effective) luminous intensity, at the nominal voltage, within the area of the specified angle ranges excluding the reference axis or the reference plane NOTE This is expressed as a percentage of IRmin in Table 1. 3.6 maximum area luminous intensity IAmax maximum permissible (effective) luminous intensity at the nominal voltage, measured at any point within the specified in angle ranges including the reference axis or the reference plane 3.7 minimum voltage luminous intensity IUmin minimum permissible (effective) luminous intensity, at the minimum voltage specified by the manufacturer, measured at any point within the specified angle ranges including the reference axis or the reference plane NOTE This is expressed as a percentage of IRmin in Table 1. 3.8 rated voltage voltage of the electrical power supply (battery or mains) as specified by the manufacturer

3.17 Factory Production Control (FPC) permanent internal control of production exercised by the manufacturer 3.18 batch quantity of a product manufactured with no change in raw material, equipment, settings or operation as defined in the FPC system of the manufacturer 3.19 individual (and non-series) where manufacturing process is different to the manufacturers usual process

Table 1 — Classes of warning lights Luminous intensity Angle ranges Nominal voltage Minimum voltage Class Area of light emitting surface in

cm2 Horizontal Vertical I Rmin in cd I Amin (% of IRmin) I Amax in cd I Umin (% of IRmin) L1 (See 4.1.2) 300° +5° to –5° 1 100 100 50 L2L ≥18 +7° to –7° +7° to –7° 25 25 100 25 L2H ≥18 +7° to –7° +7° to –7° 150 25 1 500 25 L3 ≥75 +10° to –10° +5° to –5° 2 50 100 25 L4(F2) ≥140 +10° to –10° +5° to –5° 43 25 100 15 L5 ≥140 +2° to –2° +2° to –2° 500 25 2 000 25 L6 ≥2 × 250 +10° to –10° +5° to –5° 10 25 100 12,5 L7 ≥250 +10° to –10° +5° to –5° 20 25 100 12,5 L8G ≥250 +7,5° to –7,5° +5° to –5° 25 25 100 12,5 L8L ≥250 +7,5° to –7,5° +5° to –5° 250 25 500 12,5 L8M ≥250 +7,5° to –7,5° +5° to –5° 500 25 1 500 12,5 L8H ≥250 +7,5° to –7,5° +5° to –5°

1 500 25 5 000 12,5 L9L ≥700 +1,5° to –1,5° +1,5° to –1,5° 500 25 2 000 12,5 L9M ≥700 +1,5° to –1,5° +1,5° to –1,5°

2 000 25 8 000 12,5 L9H ≥700 +1,5° to –1,5° +1,5° to –1,5° 20 000 25

40 000 12,5

4.1.2 Light emitting surface 4.1.2.1 For 360° warning lights (class L1) the minimum area of the lens projected in any horizontal direction shall be not less than 30 cm2 and the height of the lens shall be not less than 6 cm. 4.1.2.2 In all other classes (L2 to L9) the total area of the light emitting surface as indicated by the manufacturer shall be not less than the values given in Table 1 and shall comply with the requirements for uniformity of luminance (4.1.3). For the projection of the lens there shall be 2 classes P defined: class P0: no requirements; class P1: the projection is a roundel 4.1.3 Uniformity of luminance 4.1.3.1 There is no requirement for uniformity of luminance for warning lights in class L1. 4.1.3.2 The luminance of the light emitting surface of a warning light in classes L2 to L5 inclusive shall be such that, when tested in accordance with 6.3.1 and 6.3.2, the ratio of luminance Iout/Itotal is ≥0,17. 4.1.3.3 The luminance of the light emitting surface of a warning light in classes L6 to L9 inclusive shall be such that when tested in accordance with 6.3.1 and 6.3.3 the ratio of the luminance Lmin/ Lmax is ≥0,07.

class C yellow 2. Table 2 — Colours of warning lights Colour of warning light Equation Boundary C red

y = 0,290 y = 0,980 – x y = 0,320 red purple yellow C yellow 1 y = 0,387 y = 0,98 – x y = 0,727 x + 0,054 red white green C yellow 2 y = 0,380 y = 0,940 – x y = 0,500 red white green

4.1.5 Retro-reflective devices All warning lights shall meet the requirements of one of the following three classes R for retro-reflectivity: class R0: no requirements; class R1: shall not incorporate retro-reflective areas; class R2: shall be fitted with retro-reflectors of the colour within the limits of chromaticity specified for

C yellow class 2 in CIE 39.2. When projected in all horizontal directions for warning lights, of class L1 and in the direction of the principal axis for all other warning lights the retro-reflective area shall be at least a minimum of 50 cm2. For all retro-reflective areas the minimum coefficients of retro-reflection R' shall be as specified in Table 3 for ß1 when measured in accordance with CIE 54.2 with ß2 equal to 0.

Table 3 — Coefficients of retro-reflection Entrance angle 1 (2 = 0) Observation angle 12' Observation angle 20' Observation angle

1° 5° 50 cd × lx–1 × m2 35 cd × lx–1 × m2 3 cd × lx–1 × m2 15° 35 cd × lx–1 × m2 20 cd × lx–1 × m2 2 cd × lx–1 × m2

4.2 Electrical and functional requirements 4.2.1 Electrical requirements 4.2.1.1 Electrical safety Warning lights with a supply voltage in excess of 50 V and all warning lights with a lower rated supply voltage, but with parts having a higher voltage than 50 V shall fulfil the requirements of the Low Voltage Directive 73/23/EEC. 4.2.1.2 On/Off and variable intensity photosensitive switches 4.2.1.2.1 General Warning lights may be fitted with photosensitive devices to switch them on and off or to switch them between different levels of luminous intensity in response to ambient light conditions. When tested in accordance with 6.5.3, photosensitive switches shall not be actuated by a vertical plane illumination of 500 lx or less. 4.2.1.2.2 Photosensitive On/Off switches When tested in accordance with 6.5.2 automatic photosensitive switches shall comply with one of the following classes: class A0: no requirements; class A1: warning lights fitted with a photosensitive On/Off switch which operates automatically to switch the warning light both on and off within the range of ambient horizontal illuminance (see CIE 69) 250 lx minimum to 1 000 lx maximum. 4.2.1.2.3 Variable intensity photosensitive switch A warning light fitted with a photosensitive device to switch the warning light between operation at different luminous intensities that device shall operate automatically (both to increase and to decrease the luminous intensity) within the range of ambient open air light levels 500 lx minimum to 3 000 lx maximum when tested in accordance with 6.5.2. 4.2.1.3 Voltage indicator (battery operated warning lights only) Where a battery operated warning light is fitted with a device to indicate that the battery voltage is at or ap-proaching the minimum voltage, the voltage indication shall comply with one of the following classes: class I0: no requirements;

.rI = E)(2 (2) The angle subtended at the geometric centre of the warning light by the diameter of the detector aperture shall not be greater than 10 min of arc. The luminous intensity values measured shall be within ±5 % of the actual values.

CIE 15 with its light detector aligned on the reference axis (or radially on the reference plane for 360° warning lights). For flashing warning lights using Xenon discharge lamps, the detector system shall either be capable

6.5 On/Off and variable intensity photosensitive switches 6.5.1 General Photosensitive switches shall be tested both for operation in response to omni-directional natural light levels and for operation in response to uni-directional artificial light levels as specified in 6.5.2 and 6.5.3. 6.5.2 Natural ambient light test The warning light shall be tested in the open and shall either be placed on a smooth flat surface or supported in its normal operating position so that its photo-sensor has effectively unobstructed exposure to the full hemi-sphere of the sky. The height (H) of any obstruction above the support surface shall be such that the hori-zontal distance from the projected vertical axis of the warning light to the obstruction shall be not less than 7 m + 7 H (see Figure 1).

Figure 1 — Natural ambient light test The warning light shall be rotated about its vertical axis to find the two most critical switching orientations relative to sunrise and sunset. NOTE These orientations will give the greatest delay in switch operation in response to either rising or falling light levels.

corrected acceptance angles positioned so that its detector is exposed to the same unobstructed incident light as the test warning light. Provided that horizontal illuminance reaches the level required, the test may be conducted under cloud cover but not in extreme atmospheric conditions including those giving rise to abnormal spectral distribution at sun-set or sunrise. A measurement with an accuracy of ±20 % should be recorded for determining whether a warning light meets the test criteria in 4.2.1.2. 6.5.3 Uni-directional artificial light test The warning light shall either be placed on a smooth flat surface or otherwise supported in its normal operating position. An illuminating device capable of generating a directional beam (such as an automotive headlamp) and with a light source having a colour temperature between 2 800 °K and 3 500 °K shall be positioned on the reference axis (or reference plane for 360° warning lights) of the warning light and directed towards the warning light from such a distance that incident light may be regarded as a parallel beam (see Figure 2). Illuminance over that part of the test sample through which light reaches the photo-detector of the switch shall be homogenous to ±20 %.

Figure 2 — Uni-directional artificial light test The vertical illuminance shall be measured using an illuminance meter positioned in the light path between the illuminating light source and the photosensitive switch, normal to the incident light and as close to the warning light as possible. The illuminating light source and the test warning light shall both be switched on. The warning light shall be rotated about a vertical axis and the illuminance level of the light source adjusted to establish the lowest level of illuminance which will actuate the photosensitive switch to turn the warning light off. During rotational adjustment of the warning light position there shall be no obstruction to the light reaching the warning light. A measurement with an accuracy of ±20 % shall be recorded for determining whether a warning light meets the test criteria. 6.6 Mechanical strength 6.6.1 Impact test A 6.6.1.1 General The apparatus required for this test is shown in Figure 3 and shall be constructed exclusively of rigid materials, preferably steel. The pivot shall have no rotational resistance that would affect the results of the test and the support tube shall have a mass of between 3 kg and 4 kg distributed evenly along its length. There is a main test procedure for all warning lights of the appropriate class and a supplementary test procedure for lights having their optical components and battery housings combined in a single unit.

Key 1 warning light under test 2 support tube 3 pivot 4 drop path

5 impact plate 6 support 7 dimension of the plate 0,23 m × 0,04 m

Figure 3 — Side view impact test A 6.6.1.2 Main test procedure A fully assembled warning light including batteries (if applicable) shall be fixed to the support tube using fixings supplied or specified by the manufacturer. The support tube and warning light assembly shall then be positioned vertically and allowed to fall freely so that the lens of the warning light strikes the impact plate. 6.6.1.3 Supplementary test procedure The main test is repeated but with the impact plate repositioned so that the battery housing strikes the impact plate. 6.6.2 Impact test B 6.6.2.1 General The apparatus required comprises a solid steel ball mounted on a pendulum wire above a support surface as shown in Figures 4 and 5. The steel ball shall have a mass of 0,95 kg ‘± 0, 045 kg and shall be suspended by a steel pendulum wire 1,74 m in length and 1,3 mm in diameter (which is considered to be of negligible mass). The support surface shall be flat, horizontal and made of concrete.

Key

Key 1 solid steel ball 0,95 kg mass 1

solid steel ball 0,95 kg mass 2 steel wire 1,3 mm diameter 2

steel wire 1,3 mm diameter 3 pivot 3

pivot 4 support surface Figure 4

— Test light on support surface

Figure 5 — Test light on free standing stand 6.6.2.2 Test procedure Place the fully assembled warning light including batteries (if applicable) on the support surface in its normal operating position either by standing it directly on the surface (see Figure 4) or, where the warning light is not intended for free standing use, by mounting it on a suitable free standing stand (see Figure 5). a) Adjust the position of the ball so that it will strike the geometric centre of the warning light lens and so that at the point of impact the ball is vertically beneath the pivot. Raise the ball to the horizontal position B and release it. Repeat this procedure three times. b) Repeat the test described in a) for each lens. c) Adjust the ball to give an impact point at the centre of the battery compartment (this should be between batteries on warning lights with twin batteries). Raise the ball to the horizontal position B and release it. Perform this test for each side of the battery compartment. 6.6.3 Impact test C Allow the fully assembled warning light including batteries (if applicable) to fall freely twice, once so that the base impacts and once so that the side impacts, from a height of 1,2 m onto a level concrete floor. 6.7 Flash rate and on-time Flash rate shall be measured using a suitable timing device to determine the total number of complete on/off cycles in one minute. On-time shall be measured using a device capable of determining the interval between the two points at which the luminous intensity is equal to the effective intensity on both the increasing and decreasing phase of a single pulse.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...