EN 1930:2011

(Main)Child use and care articles - Safety barriers - Safety requirements and test methods

Child use and care articles - Safety barriers - Safety requirements and test methods

This European Standard specifies the safety requirements and test methods for child safety barriers for domestic indoor use which are designed to be fitted across openings to limit a child's access inside the home and to prevent young children up to 24 months of age passing through.

This European Standard does not apply to products designed to be fitted across windows.

Artikel für Säuglinge und Kleinkinder - Kinderschutzgitter - Sicherheitstechnische Anforderungen und Prüfverfahren

Diese Europäische Norm legt die sicherheitstechnischen Anforderungen und die Prüfverfahren für Kinder-Schutzgitter zur Verwendung im Wohnbereich fest; diese sind an Öffnungen so zu befestigen, dass die Zu-gangsmöglichkeiten eines Kindes innerhalb des Hauses eingeschränkt sind, um so Kinder im Alter bis 24 Monaten am Durchgang zu hindern. Diese Europäische Norm gilt nicht für Produkte, die an Fenstern zu befestigen sind.

Articles de puériculture - Barrières de sécurité - Exigences de sécurité et méthodes d'essai

La présente Norme européenne spécifie les exigences de sécurité et les méthodes d'essai applicables aux barrières de sécurité pour enfants, à usage domestique intérieur, destinées à être montées en travers des ouvertures afin de restreindre l'accès des enfants à certaines zones à l'intérieur du domicile. Ces barrières sont destinées à empêcher le passage aux enfants en bas âge et jusqu'à 24 mois. La présente Norme européenne ne s'applique pas aux produits destinés à être montés en travers des fenêtres.

Izdelki za otroke - Varnostne pregrade - Varnostne zahteve in preskusne metode

Ta evropski standard določa varnostne zahteve in preskusne metode za otroške varnostne pregrade za domačo uporabo v notranjih prostorih, ki so zasnovane za namestitev na odprtine in s katerimi se otrokom v bivalnih prostorih omeji dostop, otrokom, mlajšim od 24 mesecev, pa prehod.

General Information

- Status

- Published

- Publication Date

- 06-Dec-2011

- Withdrawal Date

- 29-Jun-2012

- Technical Committee

- CEN/TC 252 - Child use and care articles

- Drafting Committee

- CEN/TC 252/WG 4 - Early learning and protection

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 22-Jan-2018

- Completion Date

- 09-Feb-2026

- Directive

- 2001/95/EC - General product safety

Relations

- Replaces

EN 1930:2000/A1:2005 - Child care articles - Safety barriers - Safety requirements and test methods - Effective Date

- 14-Dec-2011

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

Overview

EN 1930:2011 - Child use and care articles - Safety barriers - Safety requirements and test methods (CEN) specifies safety requirements and reproducible test methods for domestic indoor child safety barriers (safety gates) intended to restrict access and prevent children up to 24 months passing through. It is a hazard‑based European Standard (published December 2011) and does not apply to products fitted across windows.

Key topics and technical requirements

- Scope & age limit: Devices for domestic indoor openings; protects children up to 24 months; excludes window barriers.

- Hazard analysis: Mechanical, chemical, thermal and additional hazards (e.g., tool use, toy attachments) are covered.

- Test equipment & tolerances: Tolerances are specified for forces (±5%), masses (±0.5%), dimensions (±1 mm) and angles (±2°). Relationship 10 N = 1 kg may be used for mass/force conversion.

- Probes & templates: Defined fixtures for reproducible testing:

- Hip probe (new in 2011 edition).

- Foothold template (transparent 10 mm strip with grid).

- Finger probes with hemispherical ends - diameters 5 mm, 7 mm and 12 mm.

- Finger probe for mesh (conical form).

- Ball chain loop and spherical mass (spherical mass ~2.5 kg; ball diameter ≈ 3.2 mm) for security tests.

- Small parts cylinder to assess ingestible components.

- Test frame: rigid 100 mm × 100 mm steel construction; max deflection 1 mm under 1 000 N load.

- Specific hazard tests: protective height, gap measurements, opening/closing durability and safety, finger entrapment, shearing/crushing, protrusions, choking/ingestion, suffocation, hazardous edges/points, structural integrity and impact tests (including rattle and impactor tests introduced or improved in this edition).

- Product information & marking: Requirements for durable marking, purchase information and clear instructions, including warnings.

Applications & who uses this standard

- Manufacturers and designers of indoor safety gates - to design products that meet EU safety expectations.

- Testing laboratories and certification bodies - to perform reproducible mechanical and safety tests.

- Regulators and market surveillance - to assess compliance and withdraw unsafe products.

- Retailers and procurement teams - to specify compliant products for sale.

- Child safety consultants and installers - to understand functional limits and safe use guidance.

Related standards

- EN 71‑2 (Safety of toys - Flammability) - referenced for flammability aspects.

- EN 71‑3 (Safety of toys - Migration of certain elements) - referenced for chemical migration concerns.

Keywords: EN 1930:2011, child safety barriers, safety gates, CEN standard, test methods, safety requirements, domestic indoor safety barriers.

Frequently Asked Questions

EN 1930:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Child use and care articles - Safety barriers - Safety requirements and test methods". This standard covers: This European Standard specifies the safety requirements and test methods for child safety barriers for domestic indoor use which are designed to be fitted across openings to limit a child's access inside the home and to prevent young children up to 24 months of age passing through. This European Standard does not apply to products designed to be fitted across windows.

This European Standard specifies the safety requirements and test methods for child safety barriers for domestic indoor use which are designed to be fitted across openings to limit a child's access inside the home and to prevent young children up to 24 months of age passing through. This European Standard does not apply to products designed to be fitted across windows.

EN 1930:2011 is classified under the following ICS (International Classification for Standards) categories: 97.190 - Equipment for children. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1930:2011 has the following relationships with other standards: It is inter standard links to EN 1930:2000/A1:2005, EN 1930:2000, EN 71-2:2020+A1:2025, EN 71-3:2019+A2:2024, prEN 1930, prEN 1930. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1930:2011 is associated with the following European legislation: EU Directives/Regulations: 2001/95/EC; Standardization Mandates: M/264. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1930:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

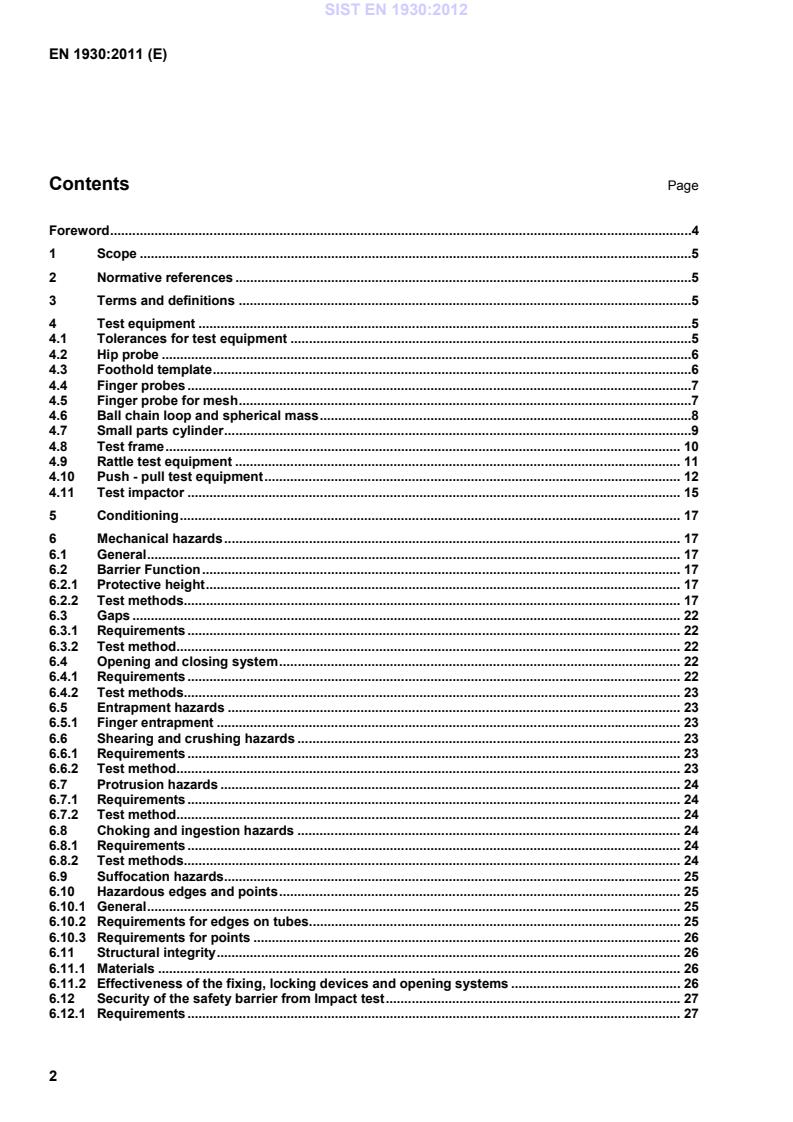

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Izdelki za otroke - Varnostne pregrade - Varnostne zahteve in preskusne metodeArtikel für Säuglinge und Kleinkinder - Kinderschutzgitter - Sicherheitstechnische Anforderungen und PrüfverfahrenArticles de puériculture - Barrières de sécurité - Exigences de sécurité et méthodes d'essaiChild use and care articles - Safety barriers - Safety requirements and test methods97.190Otroška opremaEquipment for childrenICS:Ta slovenski standard je istoveten z:EN 1930:2011SIST EN 1930:2012en,fr,de01-februar-2012SIST EN 1930:2012SLOVENSKI

STANDARDSIST EN 1930:2002/A1:2006SIST EN 1930:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1930

December 2011 ICS 97.190 Supersedes EN 1930:2000English Version

Child use and care articles - Safety barriers - Safety requirements and test methods

Articles de puériculture - Barrières de sécurité - Exigences de sécurité et méthodes d'essai

Artikel für Säuglinge und Kleinkinder - Kinderschutzgitter - Sicherheitstechnische Anforderungen und Prüfverfahren This European Standard was approved by CEN on 22 October 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1930:2011: ESIST EN 1930:2012

Rationales . 32 SIST EN 1930:2012

(10 ± 2) s for static load tests. The tests are described in terms of the application of forces. Masses can however be used. The relationship 10 N = 1 kg may be used for this purpose. Unless otherwise specified, the test forces may be applied by any suitable device which does not adversely affect the results. 4.2 Hip probe A probe made from plastics or other hard, smooth material with the dimensions given in Figure 1. Dimensions in millimetres

Figure 1 — Hip probe 4.3 Foothold template A strip of 10 mm thick transparent material cut to the shape as shown in Figure 2. The sides of the template shall be square to the faces. All edges and corners shall be left as machined without any radius. SIST EN 1930:2012

Key 1 triangular cells plotted on a 5 × 5 ± 0,2 grid Figure 2 — Template for foothold test (example of left hand template) Two templates are required to provide a left and right hand template. The markings shown in Figure 2 are on the bottom face of each template to avoid parallax errors. 4.4 Finger probes

Probes made from plastics or other hard, smooth material of diameters 5 mm, 7 mm and 12 mm with a full hemispherical end, which shall be capable of being mounted on a force-measuring device, so that the hemispherical end can be presented to the opening being assessed see Figure 3. Dimensions in millimetres

Key 1 spherical ends R2,5 (for 5 mm diameter) R3,5 (for 7 mm diameter) or R6 (for 12 mm diameter) 2 line scribed around circumference showing depth of penetration 3 ∅ (501,0−), ∅ (701,0−) or ∅ (121,00+) Figure 3 — 5 mm, 7 mm and 12 mm finger probes for gaps 4.5 Finger probe for mesh Probe for assessing mesh made from plastics or other hard, smooth material as shown in Figure 4 which is capable of being mounted on a force measuring device, so that the conical end can be presented to the opening being assessed. SIST EN 1930:2012

Figure 4 — Finger probe for mesh 4.6 Ball chain loop and spherical mass This equipment comprises a ball chain loop attached to a spherical mass at a common fixing point. The ball chain comprises maximum of 10 balls per 40 mm, equally distributed along the length of the chain when the chain is loaded with a mass of 2,5 kg.

The diameter of each ball is (3,2 ± 0,2) mm. Dimensions in millimetres

Figure 5 — Ball chain The ball chain loop is formed by the ball chain entering the spherical mass at a common fixing point with a ball from each side of the chain in contact with each other. The external peripheral length of the ball chain loop shall be 40050+ mm see Figure 6. A smooth spherical mass of (2,5 ± 0,05) kg and a diameter of 115 mm. SIST EN 1930:2012

Key 1 ball chain loop 2 spherical mass

3 common fixing point Figure 6 — Ball chain loop and spherical mass 4.7 Small parts cylinder Cylinder having the dimensions given in Figure 7. SIST EN 1930:2012

Figure 7 — Small parts cylinder 4.8 Test frame A rigid construction made from 100 mm × 100 mm steel tube, having a vertical beam adjustable in the horizontal direction within the frame made from 100 mm × 100 mm steel tube, see Figure 8. The maximum deflection of the test frame and the adjustable vertical beam shall be 1 mm when a force of a 1 000 N is applied in the positions and directions given in Figure 8. The application of the forces shall be done in the sequence of F, F1 and F2 and take the measurements in the sequence M, M1 and M2. Smooth, planed beech pads of thickness (50 ± 1) mm shall be fixed to the surface of the vertical beams on to which the safety barrier is fitted. The vertical beams and beech pads shall, once adjusted, not move or twist during fitting and testing of the safety barrier. SIST EN 1930:2012

Front view and side view Key F force M measurement 1 beech pads 2 adjustable beam Figure 8 — Test frame 4.9 Rattle test equipment The apparatus, Figure 9, consists of a steel driving disc of 110 mm diameter, having a mass of 1 kg and capable of rotating at a speed of 12050+ rpm. The disc shall be mounted on the pivot support arm, pivoted at its base. The disc shall be linked to the safety barrier by means of a 200 mm link arm having a mass of (0,15 ± 0,02) kg. The link arm shall be freely pivoted on the disc. The centre of the pivot point for the link arm shall be located (45 ± 1) mm from the centre of the disc. The link arm shall be connected to the safety barrier by the use of any suitable means that allows the arm, at the point at which it attaches to the safety barrier, to pivot e.g. a clamp with pivot attachment. The distance between the pivot point of the support arm (4 and 7) and centre of the steel driving disc shall be 600 mm of the arm (2) see Figure 9, with a tolerance of ± 20 mm. The total mass of the test equipment shall be (11 ± 1) kg with the majority of the weight positioned within the base to prevent movement whilst in use. SIST EN 1930:2012

Key 1 driving disc 2 pivot support arm, which incorporates a drive mechanism from the motor to the driving disc 3 link arm 4 centre of rotation 5 clamp 6 base, which incorporates a drive mechanism (electric motor) 7 pivot points 8 movement of pivoting support arm Figure 9 — Rattle test equipment 4.10 Push - pull test equipment A 100 mm rigid clamp. The width shall be adjustable to the thickness of the top rail of the safety barrier to which forward, backward and horizontal forces are applied. SIST EN 1930:2012

Key 1 rigid clamp 2 centre line indicating direction and position for the application of the force 3 foam, to prevent undue damage 4 top of the barrier Figure 10 — Clamp pad SIST EN 1930:2012

Key 1 adjustable opening 2 test frame 3 beech pads 4 safety barrier 5 clam/pads 6 force applicator 7 support 8 force gauge 9 floor 10 adjustable height Figure 11 — Example of push-pull test apparatus top and side view SIST EN 1930:2012

Key 1 ball mounting 2 retaining device 3 basket ball 4 elastic cord 5 disc mass

6 rigid support structure Figure 12 — Test impactor SIST EN 1930:2012

Key

this shaded area denotes one triangle; four shaded areas denotes four covered triangles Figure 13 — Examples of obscured triangles indicating a foothold on a continuous structure 6.2.2.4 Non-continuous structure A foothold exists on a non-continuous structure if two or more triangles marked on the template are completely obscured between the edge of the template and both the bold lines of the template by the structure being checked. The two or more triangles on each side of the template shall have at least one side in common with each other, see Figure 14.

Key

this shaded area denotes one triangle Figure 14 — Examples of obscured triangles on a foothold on a non- continuous structure 6.2.2.5 Wire, thin structures and similar parts A foothold exists on a wire, thin structure and similar part if it projects across the bold lines on the template, see Figure 15. SIST EN 1930:2012

Key 1 denotes a wire, thin structure or similar part Figure 15 — Example of a foothold on a wire, thin structure and similar part 6.2.2.6 Footholds on a continuous structure at an angle less than 55°°°° Using either the left or right hand template, place the template with its marked face on any continuous structure inclined at an angle of less than 55° to the horizontal. Orientate either template, Figure 2, to check whether any four triangles are obscured indicating a foothold; see Figure 16 for examples. 6.2.2.7 Footholds on a non- continuous structure at an angle of less than 55°°°° Using either the left or right hand template place the template with its marked face on any non-continuous structure inclined at an angle of less than 55° to the horizontal. Orientate either template, see Figure 2, to check whether two or more triangles are obscured between the edges of the template and the bold lines on the template indicating a foothold; see Figure 17 for examples. 6.2.2.8 Footholds on wire, thin structures or similar parts at an angle less than 55°°°° Using either the left or right hand template, place the template with its marked face on any wire, thin structure or similar parts at an angle less than 55° to the horizontal. Check whether the wire, thin structure or similar part has a line of contact extending between the two bold lines marked along the t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...