EN 1804-3:2006

(Main)Machines for underground mines - Safety requirements for hydraulic powered roof supports - Part 3: Hydraulic control systems

Machines for underground mines - Safety requirements for hydraulic powered roof supports - Part 3: Hydraulic control systems

This document specifies the safety requirements for hydraulic control devices, including hydraulic valves and

their control elements, valve combinations, control systems, pipes and hose assemblies, fittings, shut-off

devices, measuring devices, filters, built-in pressure limiting and check valves in legs and rams and water

spraying and dust suppression valves when used as specified by the manufacturer or his authorized

representative. Excluded are electronic control devices, pressure generators, and internal valves of legs and

rams (e.g. constant yield valves, see EN1804-2).

Some components are dealt with in other parts of this standard.

NOTE prEN1804-4 also applies to electro-hydraulic control devices. Part 4 also contains requirements for electrical

control elements of valves.

This document applies to hydraulic control devices at ambient temperatures from –10 °C to 60 °C.

This document identifies and takes into account:

- possible hazards which may be caused by the operation of hydraulic control devices;

- areas and operating conditions which may create such hazards;

- hazardous situations which may cause injury or may be damaging to health;

- hazards which may be caused by firedamp and/or combustible dusts.

This document describes methods for the reduction of these hazards.

A list of significant hazards covered appears in clause 4.

This document is applicable to all hydraulic control devices placed on the market for the first time after the

date of issue of this standard.

This document does not specify any additional requirements for:

- use in particularly corrosive environments;

- hazards occurring during construction, transportation, decommissioning;

- earthquakes.

Maschinen für den Bergbau unter Tage - Sicherheitsanforderungen an hydraulischen Schreitausbau - Teil 3: Hydraulische Steuerungen

Dieses Dokument legt die Sicherheitsanforderungen für die vom Hersteller oder seinem bevollmächtigten Vertreter vorgesehene bestimmungsgemäße Verwendung von hydraulischen Steuerungen fest. Hierzu gehören hydraulische Ventile mit ihren Betätigungseinrichtungen, Ventilkombinationen, Steuerungen, starre und flexible Leitungen, Armaturen, Absperreinrichtungen, Messeinrichtungen, Filter, in Stempel und Zylinder fest eingebaute Druckbegrenzungs- und Rückschlagventile sowie die Bedüsungsventile zur Staubbekämpfung. Ausgenommen sind die elektronischen Steuerungen, die Druckerzeuger und die inneren Ventile von Stempeln und Zylindern (z. B. Bodenventile, siehe EN 1804-2).

Einige Komponenten werden in anderen Teilen dieser Normenreihe behandelt.

ANMERKUNG Für elektrohydraulische Steuerungen gelten zusätzlich die Anforderungen nach prEN 1804-4. Der Teil 4 beinhaltet auch die Anforderungen an elektrische Betätigungseinrichtungen von Ventilen.

Dieses Dokument gilt für hydraulische Steuerungen, die bei Umgebungstemperaturen von -10 °C bis 60 °C eingesetzt werden.

Dieses Dokument identifiziert und berücksichtigt:

- die Gefährdungen, die durch hydraulische Steuerungen hervorgerufen werden können;

- die Gefahrenbereiche und die Betriebsbedingungen, die irgendeine Gefährdung verursachen können;

- die Situationen, die zu Gefährdungen führen können, die eine Verletzung oder Gesundheitsschädigung verursachen, und

- Gefahren, die durch Grubengas und/oder brennbare Stäube verursacht werden können.

Dieses Dokument beschreibt Methoden zur Reduzierung dieser Gefährdungen.

Abschnitt 4 enthält eine Liste der behandelten signifikanten Gefährdungen.

Dieses Dokument gilt für alle hydraulischen Steuerungen, die nach dem Ausgabedatum dieser Norm erstmalig in Verkehr gebracht werden.

Dieses Dokument spezifiziert keine zusätzlichen Anforderungen für:

- den Gebrauch in besonders korrosiver Umgebung;

- Risiken bei Herstellung, Transport und Außerbetriebnahme;

für den Fall von Erdbeben

Machines pour mines souterraines - Exigences de sécurité concernant les soutènements marchants applicables aux piles - Partie 3: Systèmes de commande hydrauliques

Le présent document spécifie les exigences de sécurité concernant les systèmes de commande hydrauliques lorsqu’ils sont utilisés tel que spécifié par le fabricant ou son mandataire. Les systèmes de commande hydrauliques comprennent les soupapes hydrauliques et leurs organes de commande, les combinaisons de soupapes, systèmes de commande, tuyaux et ensembles flexibles, raccords, dispositifs d’arrêt et de mesure, filtres, soupapes de limitation de pression et clapets de non-retour intégrés aux étançons et vérins, soupapes de pulvérisation d’eau pour l’élimination des poussières. Sont exclus les systèmes de commande électroniques, les générateurs de pression ainsi que les soupapes internes des étançons et vérins (par exemple soupapes à coulissement constant, voir l’EN 1804-2).

Certains éléments sont traités dans d’autres parties de cette série de normes.

NOTE Les exigences du prEN 1804-4 s’appliquent également aux systèmes de commande électro-hydrauliques en complément des exigences du présent document. La Partie 4 comporte aussi des exigences relatives aux organes de commande électriques des soupapes.

Le présent document s’applique aux systèmes de commande hydrauliques à des températures ambiantes comprises entre -10 °C et 60 °C.

Le présent document identifie et tient compte :

- des phénomènes dangereux potentiels pouvant résulter de l’utilisation des systèmes de commande hydrauliques ;

- des zones dangereuses et des conditions d’utilisation susceptibles de créer un phénomène dangereux ;

- des situations potentiellement dangereuses et susceptibles d’entraîner des blessures ou de porter atteinte à la santé ; et

- des risques dus au grisou et/ou à des poussières inflammables.

Le présent document décrit des méthodes de réduction de ces phénomènes dangereux.

Une liste des phénomènes dangereux significatifs couverts est donnée à l’Article 4.

Le présent document est applicable à tous les systèmes de commande hydrauliques commercialisés pour la première fois après

Stroji za podzemne rudnike – Varnostne zahteve za hidravlično podporje – 3. del: Hidravlični krmilni sistemi

General Information

- Status

- Withdrawn

- Publication Date

- 25-Apr-2006

- Withdrawal Date

- 26-Jan-2010

- Technical Committee

- CEN/TC 196 - Machines for undergroung mines - Safety

- Drafting Committee

- CEN/TC 196/WG 3 - Hydraulic driven supports

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 27-Jan-2010

- Completion Date

- 27-Jan-2010

- Directive

- Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 28-Nov-2009

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Chile

Bureau Veritas certification services in Chile.

Bureau Veritas Peru

Bureau Veritas certification services in Peru.

BVQI Peru

Bureau Veritas certification in Peru.

Sponsored listings

Frequently Asked Questions

EN 1804-3:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Machines for underground mines - Safety requirements for hydraulic powered roof supports - Part 3: Hydraulic control systems". This standard covers: This document specifies the safety requirements for hydraulic control devices, including hydraulic valves and their control elements, valve combinations, control systems, pipes and hose assemblies, fittings, shut-off devices, measuring devices, filters, built-in pressure limiting and check valves in legs and rams and water spraying and dust suppression valves when used as specified by the manufacturer or his authorized representative. Excluded are electronic control devices, pressure generators, and internal valves of legs and rams (e.g. constant yield valves, see EN1804-2). Some components are dealt with in other parts of this standard. NOTE prEN1804-4 also applies to electro-hydraulic control devices. Part 4 also contains requirements for electrical control elements of valves. This document applies to hydraulic control devices at ambient temperatures from –10 °C to 60 °C. This document identifies and takes into account: - possible hazards which may be caused by the operation of hydraulic control devices; - areas and operating conditions which may create such hazards; - hazardous situations which may cause injury or may be damaging to health; - hazards which may be caused by firedamp and/or combustible dusts. This document describes methods for the reduction of these hazards. A list of significant hazards covered appears in clause 4. This document is applicable to all hydraulic control devices placed on the market for the first time after the date of issue of this standard. This document does not specify any additional requirements for: - use in particularly corrosive environments; - hazards occurring during construction, transportation, decommissioning; - earthquakes.

This document specifies the safety requirements for hydraulic control devices, including hydraulic valves and their control elements, valve combinations, control systems, pipes and hose assemblies, fittings, shut-off devices, measuring devices, filters, built-in pressure limiting and check valves in legs and rams and water spraying and dust suppression valves when used as specified by the manufacturer or his authorized representative. Excluded are electronic control devices, pressure generators, and internal valves of legs and rams (e.g. constant yield valves, see EN1804-2). Some components are dealt with in other parts of this standard. NOTE prEN1804-4 also applies to electro-hydraulic control devices. Part 4 also contains requirements for electrical control elements of valves. This document applies to hydraulic control devices at ambient temperatures from –10 °C to 60 °C. This document identifies and takes into account: - possible hazards which may be caused by the operation of hydraulic control devices; - areas and operating conditions which may create such hazards; - hazardous situations which may cause injury or may be damaging to health; - hazards which may be caused by firedamp and/or combustible dusts. This document describes methods for the reduction of these hazards. A list of significant hazards covered appears in clause 4. This document is applicable to all hydraulic control devices placed on the market for the first time after the date of issue of this standard. This document does not specify any additional requirements for: - use in particularly corrosive environments; - hazards occurring during construction, transportation, decommissioning; - earthquakes.

EN 1804-3:2006 is classified under the following ICS (International Classification for Standards) categories: 73.100.10 - Tunnelling and tubbing equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1804-3:2006 has the following relationships with other standards: It is inter standard links to EN 1804-3:2006+A1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1804-3:2006 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/BC/CEN/91/1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1804-3:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Machines for underground mines - Safety requirements for hydraulic powered roof supports - Part 3: Hydraulic control systemsMachines pour mines souterraines - Exigences de sécurité concernant les soutenements marchants applicables aux piles - Partie 3: Systemes de commande hydrauliquesMaschinen für den Bergbau unter Tage - Sicherheitsanforderungen an hydraulischen Schreitausbau - Teil 3: Hydraulische SteuerungenTa slovenski standard je istoveten z:EN 1804-3:2006SIST EN 1804-3:2006en73.100.10Oprema za gradnjo predorov in podzemnih železnicTunnelling and tubbing equipmentICS:SLOVENSKI

STANDARDSIST EN 1804-3:200601-oktober-2006

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1804-3April 2006ICS 73.100.10 English VersionMachines for underground mines - Safety requirements forhydraulic powered roof supports - Part 3: Hydraulic controlsystemsMachines pour mines soterraines - Exigences de sécuritéconcernant les soutènements applicables aux piles - Partie3: Systèmes de commande hydrauliquesMaschinen für den Bergbau unter Tage -Sicherheitsanforderungen an hydraulischen Schreitausbau- Teil 3: Hydraulische SteuerungenThis European Standard was approved by CEN on 23 August 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1804-3:2006: E

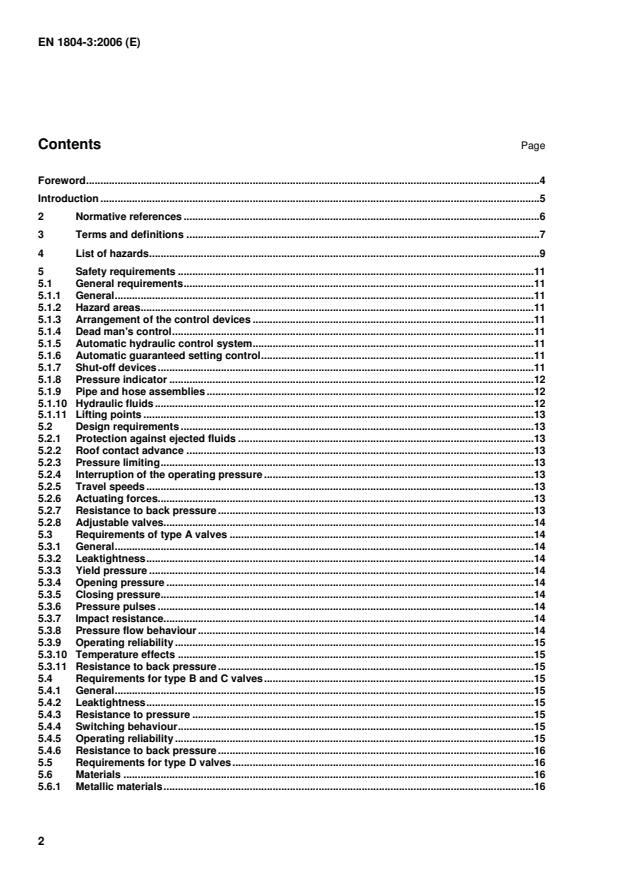

List of hazards.9 5 Safety requirements.11 5.1 General requirements.11 5.1.1 General.11 5.1.2 Hazard areas.11 5.1.3 Arrangement of the control devices.11 5.1.4 Dead man's control.11 5.1.5 Automatic hydraulic control system.11 5.1.6 Automatic guaranteed setting control.11 5.1.7 Shut-off devices.11 5.1.8 Pressure indicator.12 5.1.9 Pipe and hose assemblies.12 5.1.10 Hydraulic fluids.12 5.1.11 Lifting points.13 5.2 Design requirements.13 5.2.1 Protection against ejected fluids.13 5.2.2 Roof contact advance.13 5.2.3 Pressure limiting.13 5.2.4 Interruption of the operating pressure.13 5.2.5 Travel speeds.13 5.2.6 Actuating forces.13 5.2.7 Resistance to back pressure.13 5.2.8 Adjustable valves.14 5.3 Requirements of type A valves.14 5.3.1 General.14 5.3.2 Leaktightness.14 5.3.3 Yield pressure.14 5.3.4 Opening pressure.14 5.3.5 Closing pressure.14 5.3.6 Pressure pulses.14 5.3.7 Impact resistance.14 5.3.8 Pressure flow behaviour.14 5.3.9 Operating reliability.15 5.3.10 Temperature effects.15 5.3.11 Resistance to back pressure.15 5.4 Requirements for type B and C valves.15 5.4.1 General.15 5.4.2 Leaktightness.15 5.4.3 Resistance to pressure.15 5.4.4 Switching behaviour.15 5.4.5 Operating reliability.15 5.4.6 Resistance to back pressure.16 5.5 Requirements for type D valves.16 5.6 Materials.16 5.6.1 Metallic materials.16

Tests for verification of the safety requirements.22 A.1 Load tests.22 A.1.1 General.22 A.1.2 Lifting points.22 A.1.3 Testing of type A valves.22 A.1.4 Testing of type B valves.27 A.1.5 Testing of type C valves.30 A.1.6 Testing of type D valves.31 Annex B (normative)

Deviations from EN 982:1996.32 B.1 General.32 B.2 5.1.7 (EN 982:1996).32 B.3 5.3.4.1.3 Contamination control (EN 982:1996).33 B.4 5.3.4.3.2 Failure (EN 982:1996).33 B.5 5.3.6 Sequence control (EN 982:1996).33 B.6 7.3.4.1 Non-electrical control mechanisms (EN 982:1996).33 Annex ZA (informative)

Relationship between this

European

Standard and the Essential Requirements

of the EU Machinery Directive 98/37/EC.34 Bibliography.35

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

1 In preparation

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this document. When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of the other standards for machines that have been designed and built according to the provisions of this type C standard.

The extent to which hazards are covered is indicated in the scope of this document.

While preparing this document, it was assumed that:

only trained and competent persons operate the machine; ¾ components without specific requirements are; a) designed in accordance with the usual engineering practice and calculation code; b) of sound mechanical construction; c) free of defects; ¾ components are kept in good working order; ¾ a negotiation took place between the user and the manufacturer concerning the use of the machinery.

NOTE prEN1804-4 also applies to electro-hydraulic control devices. Part 4 also contains requirements for electrical control elements of valves. This document applies to hydraulic control devices at ambient temperatures from –10 °C to 60 °C. This document identifies and takes into account:

possible hazards which may be caused by the operation of hydraulic control devices; ¾ areas and operating conditions which may create such hazards; ¾ hazardous situations which may cause injury or may be damaging to health; ¾ hazards which may be caused by firedamp and/or combustible dusts. This document describes methods for the reduction of these hazards. A list of significant hazards covered appears in clause 4. This document is applicable to all hydraulic control devices placed on the market for the first time after the date of issue of this standard. This document does not specify any additional requirements for:

use in particularly corrosive environments; ¾ hazards occurring during construction, transportation, decommissioning; ¾ earthquakes. 2 Normative references The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any amendments) applies. EN 853, Rubber hoses and hose assemblies — Wire braid reinforced hydraulic type — Specification EN 854, Rubber hoses and hose assemblies — Textile reinforced hydraulic type — Specification EN 855, Plastic hoses and hose assemblies — Thermoplastics textile reinforced hydraulic type —Specification EN 856, Rubber hoses and hose assemblies — Rubber-covered spiral wire reinforced hydraulic type — Specification

Machines for underground mines — Safety requirements for hydraulic powered roof supports — Part 4: Electro-hydraulic control systems EN 13463-1:2001, Non-electrical equipment for potentially explosive atmospheres — Part 1: Basic method and requirements EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003) EN ISO 6743-4:2001, Lubricants, industrial oils and related

products (class L) — Classification — Part

4: Family H (Hydraulic systems) (ISO

6743-4:1999). ISO 1219-1 Fluid power systems and components — Graphic symbols and circuit diagrams — Part 1: Graphic symbols ISO 6805:1994, Rubber hoses and hose assemblies for underground mining — Wire-reinforced hydraulic types for coal mining — Specification ISO 7745:1989 Hydraulic fluid power — Fire-resistant (FR) fluids — Guidelines for use

3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 1804-1:2001, EN 1804-2:2001,

prEN 1804-4:2004 and the following apply: 3.1 hydraulic control devices system required to control all the functions of the hydraulic powered roof supports 3.2 pressures 3.2.1 maximum permissible working pressure maximum hydraulic pressure at which a hydraulic component may be operated (see EN 1804-2:2001)

3.2.2 setting pressure hydraulic pressure in the legs and support rams on completion of the setting procedure. This pressure is supplied by the hydraulic system (see EN 1804-2:2001)

opening pressure of a pressure limiting valve hydraulic pressure at which a valve begins to open and hydraulic fluid is passing through it (see Figure A.2 and 5.3.4) 3.2.5 closing pressure pressure at which the valve is closed and the flow of hydraulic fluid is shut off (see Figure A.2 and 5.3.5)

3.3

valves devices for controlling the hydraulic functions (see EN 1804-2:2001)

3.3.1

type A valves (pressure limiting valves) limit the internal hydraulic pressure of actuators

3.3.2 type B valves (e.g. check valves) shut off the hydraulic fluid directly from the actuators

3.3.3 type C valves (e.g. directional control valves) in their neutral position, block off the supply pressure to the actuators . When these valves are operated, the hydraulic fluid is switched to the actuators or is used to control other valves

3.3.4 type D valves all those valves that cannot be classified specifically in one of the types A to C. These may be special types of valves or integrated types (e.g. valve combinations and control systems)

3.4 types of control systems 3.4.1 adjacent control system type of control system in which the individual functions of

one support unit are manually operated from an adjacent support unit 3.4.2 unit sequence control system control system in which a functional sequence, (e.g. lowering - advancing - setting) operates in one single support unit 3.4.3 automatic guaranteed setting control type of control system where the setting function of legs and/or support rams is operated automatically, at least until the rated value of the setting pressure of legs and/or support rams in the support unit has been attained

function that remains active for as long a pushbutton is pressed

3.6 intended roof support yield parameters parameter of the valves that is maintained at the intended yield of the hydraulic roof support

List of hazards The following list of hazards relates in all points to continuous operation and to installation and maintenance. This list contains the hazards and hazardous situations, as far as they are dealt with in this document, identified by risk assessment significant for this type of machinery and which require action to eliminate or reduce risk.

- machine parts or work pieces, e.g. - accumulation of energy inside the machinery, e.g.:

1.1 Crushing hazard 1.3 5.1.2, 5.2.5, 5.4, 5.5 1.2 Shearing hazard

5.1.2, 5.2.5, 5.4, 5.5 1.3 Cutting or severing hazard

5.1.2, 5.2.5, 5.4, 5.5 1.9 High pressure fluid injection or ejection hazard 1.3.2 5.1.3, 5.1.9, 5.2.1, 5.3, 5.4, 5.5 2 Electrical hazards due to:

2.4 Electrostatic phenomena 1.5.2 5.6 7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery

7.1 Hazards from contact with or inhalation of harmful fluids, gases, mists, fumes, and dusts 1.1.3, 1.5.13, 1.6.5 5.2.2 7.2 Fire or explosion hazard 1.5.6, 1.5.7 5.1.10, 5.6 8 Hazards generated by neglecting ergonomic principles in machinery design, e.g. hazards from:

8.1 Unhealthy postures or excessive effort 1.1.2d, 1.1.5, 1.6.2, 1.6.4 5.1.3, 5.2.6 8.2 Inadequate consideration of hand-arm or foot-leg anatomy 1.1.2d, 2.2 5.1.3, 5.2.6 8.3 Neglected use of personal protection equipment 1.1.2e 5.2.1, 5.2.8, 5.3, 5.4, 5.5 10 Unexpected start-up, unexpected overrun/overspeed (or any similar malfunction) from:

5.1.4, 5.1.6, 5.2.7, 5.2.8, 5.3, 5.4, 5.5, 5.6 13 Failure of the power supply 1.2.6 5.2.4 17 Falling or ejected objects or fluids 1.3.3 5.1.9, 5.2.3, 5.3, 5.4, 5.5, 5.6 26 Insufficient instructions for the driver/operator 3.6 5.1.3, 5.1.6, 5.1.8, 5.2.5 27 Mechanical hazards and hazardous events

27.4 From insufficient mechanical strength of parts 4.1.2.3 5.2.3, 5.3, 5.4, 5.5, 5.6 27.8 From abnormal conditions of assembly/testing/use/maintenance 4.4.1, 4.4.2d 5.1.11 34 Mechanical hazards and hazardous events due to:

34.1 Inadequate mechanical strength – inadequate working coefficients 6.1.2 5.2.3, 5.3, 5.4, 5.5, 5.6

Absence or incorrect installation of starting and stopping devices

5.1.4, 5.1.5

Absence or incorrect installation of power supply shut-off devices

5.1.7

EN 982 except for the deviations listed in normative Annex B. Hydraulic control systems of hydraulic powered roof supports which are designed according to this part of EN 1804 shall also meet the requirements of the other parts of EN 1804, if relevant. Hydraulic control systems of hydraulic powered roof supports should comply as appropriate with

EN ISO 12100-1:2003 and EN ISO 12100-2:2003 for hazards which are not covered in this document.

5.1.2 Hazard areas Hydraulic control devices shall be designed and positioned so that it is not necessary for personnel to be located in the area of the operated support units. (e.g. by operating with adjacent control system according to 3.3.1) 5.1.3 Arrangement of the control devices Hydraulic control devices shall be designed and located so that they cannot be operated unintentionally from the travel way. They shall not restrict the travel way (see 5.1.1 of EN 1804-1:2001). Information and warning devices (e.g. symbols, pressure indicators) shall be arranged so that they are clearly visible from the travel way. 5.1.4 Dead man's control The controls for operating the individual functions to move the hydraulic powered support (lowering, advancing, setting) shall interrupt the movement when the control is released. This also applies to other individual functions which may lead to the narrowing of the travel way and/or the alignment functions.

5.1.5 Automatic hydraulic control system The automatic hydraulic control system shall control the movement of the hydraulic powered supports (lowering, advancing and setting) only if they are fitted with pre-start warning and emergency stop devices. This also applies to other automatically hydraulic controlled functions which may lead to the narrowing of the travel way. Excluded from this requirement is the automatic guaranteed setting control.

5.1.6 Automatic guaranteed setting control The automatic guaranteed setting control shall not come into operation until a minimum pressure of 80 MPa (bar) is reached in the leg. The automatic guaranteed setting control shall be capable of being switched off.

5.1.7 Shut-off devices It shall be possible to isolate each support unit from the hydraulic pressure supply.

5.1.9 Pipe and hose assemblies Pipe and hose assemblies for hydraulic control systems of hydraulic roof supports shall be designed to withstand the maximum permissible working pressure in that system. Hose assemblies shall meet either conditions a) or b) as follows: a) Hose assemblies shall comply with the requirements of ISO 6805:1994. Additionally, type 4 hoses shall be extended to sizes DN 6 and DN 10 which will comply with the requirements listed in the Table 2. Table 2 — Maximum working pressure

Maximum working pressure MPa (bars) Pressure for additional

5 000a cycle test MPa (bars) Pressure at which all hoses are tested MPa (bars) DN 6 450 760 860 DN 10 380 655 800 a The test requirements shown above are additional to those test requirements for Type 4 hoses in ISO 6805:1994. Type 6 hose assemblies shall be pressure impulse tested either:

in accordance with the requirements of ISO 6805:1994 or;

¾ with 400 000 cycles at 1,33 times of the maximum working pressure at 100 °C. b) hose assemblies shall meet the mechanical requirements of EN 853, EN 854, EN 855, EN 856 and

EN 857. With type 2 ST (EN 853) and 4 SP (EN 856) hose assemblies which are subjected mainly to static loading, the maximum permissible working pressure may be increased to 1,4 times the nominal pressure given in EN 853 and EN 856.

NOTE 1

Special requirements for underground hose assemblies with respect to their fire and electrical resistance properties, currently being developed by CEN/TC 305, should be taken into account. NOTE 2 Preferably, the requirements of option a) above should be met. a) pipes and hose assemblies shall be arranged, assembled and, if necessary, also fixed and protected so that external damage is minimized and ejecting fluids are deflected. 5.1.10 Hydraulic fluids Hydraulic control systems on roof supports for coal mines and other mines with potentially explosive atmospheres shall be designed for use with non-toxic and fire-resistant fluids in accordance with the SHCMOEI 7th report (see Bibliography). Hydraulic control systems shall be designed so that they may be used with: a) fire-resistant fluids of category HFA specified by the roof support

manufacturer in accordance with 6.2.1 of ISO 7745:1989 in conjunction with ISO 6743-4:2001; or b) water without additives (temperatures from + 5 °C to + 60 °C).

5.1.11 Lifting points Where lifting points are fitted to hydraulic control systems, they shall be suitable for their intended purpose. They shall be designed to have a calculated minimum factor of safety of 4 for the mean tensile strain in relation to their intended load carrying capacity. They shall be clearly and permanently marked with their load carrying capacity (e.g. by welding). 5.2 Design requirements 5.2.1 Protection against ejected fluids Hydraulic control systems shall be designed, located or guarded

to minimize the risk from ejection of fluid.

5.2.2 Roof contact advance Hydraulic control systems shall be designed so that the facility to advance the support unit in contact with the roof may be incorporated. 5.2.3 Pressure limiting Circuits of hydraulic control systems that are intended to be loaded

by convergence or by horizontal shear of the strata shall be capable of being protected against excessive pressures. Pressurized compartments which can be isolated shall be protected by pressure limiting valves.

5.2.4 Interruption of the operating pressure

Any interruption or restoration of the operating pressure shall not lead to unintentional movements of the support unit. 5.2.5 Travel speeds Hydraulic control systems shall be designed so that the speed of movement of individual parts of the support unit cannot exceed 30 cm/s. For canopies

and anti-spalling devices, this value applies to the extremities of the components. This requirement does not apply for operating areas of the support where the presence of people is excluded. 5.2.6 Actuating forces The actuating forces for the hand-operated hydraulic control systems shall not be less than 10 N nor exceed 160 N. 5.2.7 Resistance to back pressure Hydraulic control systems shall be capable of operating safely up to the maximum permissible back pressure in the return system.

5.3 Requirements of type A valves 5.3.1 General Type A valves shall meet the test requirements as defined in Annex A.

5.3.2 Leaktightness Type A valves shall be leaktight up to 94,5 % of the yield pressure.

5.3.3 Yield pressure The measured yield pressure of type A valves can differ by a maximum of ± 5 % from the specified yield pressure. This requirement applies to ambient and fluid temperatures of 20 °C to 40 °C.

5.3.4 Opening pressure The opening pressure at a flow rate of 0,04 l/min can exceed the specified yield pressure by a maximum of 5 %. 5.3.5 Closing pressure The closing pressure can fall below the specified yield pressure by a maximum of 10 %.

5.3.6 Pressure pulses Type A valves shall not fail when pressure pulses occur.

5.3.7 Impact resistance The function of type A valves shall not be impaired by mechanical impacts.

5.3.8 Pressure flow behaviour The volume flow of type A valves shall be as defined in Table A.1 and shall meet the intended roof support yield parameters. At a volume flow of > 0,04 l/min up to

60l/min, the opening pressure shall not exceed the yield pressure by more than 20 % nor fall below the yield pressure by more than 10 %. If volume flows

> 60 l/min are intended, this requirement shall apply. Generally, one valve is used. Where an arrangement of valves is used, at least one valve shall satisfy this requirement.

5.4 Requirements for type B and C valves 5.4.1 General Type B and C valves shall meet the test requirements given in Annex A.

5.4.2 Leaktightness Type B valves shall be leaktight in the closed position up to 1,5 times their maximum permissible working pressure.

Type C valves shall be leaktight in all switching positions up to 1,5 times their maximum permissible working pressure. 5.4.3 Resistance to pressure Type B valves shall be capable of being loaded in the closed position up to 2 times the maximum permissible working pressures without bursting. Type C valves shall be capable of being loaded in all switching positions up to 2 times the maximum permissible working pressure without bursting. 5.4.4 Switching behaviour Type B and C valves, when switching, shall not produce pressure peaks greater than 1,5 times the permissible working pressure. 5.4.5 Operating reliability Type B and C valves shall continue to meet the requirements of 5.4.2 to 5.4.4 after 30 000 switching cycles.

5.6.4 Seals Seals of hydraulic control devices shall be suitable for their particular application, particularly with regard to dimensions, pressure range, compatibility with the fluid and temperature. Hydraulic control system seals shall meet the test requirements given in Annex A.

6 Verification of the safety requirements 6.1 Type testing One specimen of the hydraulic control devices shall be type-tested in accordance with Annex A. The test requirements given in Annex A shall be met. The following documents shall be made available for the type test:

user information; ¾ manufacturing drawings; ¾ drawings of welded parts; ¾ data relating to the material characteristics; ¾ specification of the seals used;

5.1.6 *see A.1.6 5.1.7 *Inspection/comparison with manufacturer's drawings

5.1.8 *Inspection/comparison with manufacturer's drawings 5.1.9 *Inspection/comparison with manufacturer's drawings and documentation 5.1.10 *Inspection of manufacturer’s test documentation 5.1.11 *see A.1.3.3 5.2.2 *Inspection/comparison with manufacturer's drawings 5.2.3 *Inspection/comparison with manufacturer's drawings 5.2.4 *Inspection/comparison with manufacturer's drawings 5.2.5 *Inspection together with support unit/comparison with manufacturer’s drawings 5.2.6 * Force measuring using a recording device 5.2.7 *Measurements/comparison with manufacturer’s drawings t 5.2.8 *Inspection/comparison with manufacturer's drawings 5.3.2 *see A.1.3.2 5.3.3 *see A.1.3.3 and A.1.3.4 5.3.4 *see A.1.3.3 and A.1.3.4 5.3.5 *see A.1.3.3 and A.1.3.4 5.3.6 *see A.1.3.5 5.3.7 *see A.1.3.6 5.3.8 *see A.1.3.7 5.3.9 *see A.1.3.8 5.3.11 *see A.1.3.9 5.4.2 *see A.1.4.2 and A.1.5.2 5.4.3 *see A.1.4.3 and A.1.5.3 5.4.4 *see A.1.4.5 and A.1.5.6 5.4.5 *see A.1.4.6 and A.1.5.4 5.4.6 *see A.1.4.4 and A.1.5.5 5.5 *see A.1.6 5.6.1 *Inspection/comparison with manufacturer’s material specification 5.6.2 *Inspection/comparison with manufacturer’s material specification 5.6.3 *Inspection/comparison with manufacturer’s material specification 5.6.4 *Comparison with manufacturer’s documentation *Type test

clause 6 of EN ISO 12100-2:2003 and clause 7. The user information shall be provided in one of the official languages of the country (limited to EU and EFTA) in which the hydraulic control system is to be used. The user information shall be the primary source of information on a complete hydraulic control system and shall contain all the information relating to its safe application and this shall be produced as an instruction handbook as specified in 6.5 of EN ISO 12100-2:2003. The user information in clause 7 of EN 1804-1:2001 also applies to EN 1804-2 and prEN 1804-42 and is complemented, as appropriate, by corresponding clauses in those parts. Care shall be taken to ensure that the user information is available to the user on receipt of the hydraulic control system. 7.2 Technical and application data 7.2.1 Introduction The user information shall describe the intended use of the hydraulic control system under normal conditions and for operations as described by the manufacturer. The operating instructions shall include all design and performance data necessary, either for the user or for the manufacturer of the hydraulic powered roof support, to make an assessment of suitability for use, in

particular applications and environments, and for the identification of any energy supply requirements and other ancillary facilities that may be needed.

7.2.2 General description This description shall explain in clear, easily understandable language and in logical sequence, the overall function of the hydraulic control system with all special features, markings and characteristics. General arrangement drawings and function block diagrams shall be provided as appropriate.

7.2.3 Performance data The principal dimensions, weights and performance data of the hydraulic control system shall be given.

7.2.4 Hydraulic data The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...