EN 15389:2008

(Main)Industrial valves - Performance characteristics of thermoplastic valves when used as construction products

Industrial valves - Performance characteristics of thermoplastic valves when used as construction products

This European Standard specifies performance requirements and means for evaluation of conformity for valves of thermoplastic material, by reference to product standards, for use in building and civil engineering applications for the delivery of liquid and gaseous fluids.

It also contains information required for the purposes of regulatory marking.

NOTE For information, thermoplastic valves in conformity with this European Standard should be considered suitable for drinking water applications subject to either:

a) compliance with any national regulations in the country of intended destination, which can include testing if this is the demonstration of fitness for drinking water applications;

b) internal coating of the Product and subsequent testing if required by the national regulations in the intended country of destination.

Industriearmaturen - Anforderungen an die Gebrauchstauglichkeit von Armaturen aus Thermoplasten bei Verwendung als Bauprodukte

Diese Europäische Norm legt unter Verweisung auf Produktnormen Anforderungen an die Gebrauchstauglichkeit (Leistungsanforderungen) sowie Verfahren für die Konformitätsbewertung von Armaturen aus Thermoplasten fest, die in Bauwerken des Hoch- und des Tiefbaus für den Transport von flüssigen und gasförmigen Medien verwendet werden.

Sie enthält außerdem Angaben, die für die vorgeschriebene Kennzeichnung erforderlich sind.

ANMERKUNG Zur Information, Armaturen aus Thermoplasten in Übereinstimmung mit dieser Europäischen Norm sollten für Verwendungen bei Trinkwasser, vorbehaltlich des Folgenden, geeignet sein:

a) Übereinstimmung mit jeglichen nationalen Regelungen im beabsichtigten Bestimmungsland; das kann eine Prüfung einschließen, falls diese den Beweis für die Gebrauchstauglichkeit für Verwendungen bei Trinkwasser darstellt;

b) Innenbeschichtung des Produktes und anschließende Prüfung, falls von den nationalen Regelungen des beab¬sichtigten Bestimmungslandes gefordert.

Robinetterie industrielle - Caractéristiques de performance des appareils de robinetterie thermoplastiques utilisés comme produits de construction

En se référant aux normes de produit, le présent document spécifie des exigences de performance et des

moyens permettant d’évaluer la conformité des appareils de robinetterie en matériaux thermoplastiques

utilisés dans les bâtiments et le génie civil pour l’alimentation en fluides liquides et gazeux.

Il comporte également des informations requises pour les besoins du marquage réglementaire.

NOTE Pour information, il convient que les appareils de robinetterie en thermoplastiques conformes à la présente

Norme Européenne soient considérés comme appropriés pour des applications avec de l’eau potable soumises soit :

a) à la conformité à des réglementations nationales en vigueur dans le pays de destination prévu, qui peut comporter

des essais s’il s’agit de la démonstration de l’aptitude à l’emploi pour des applications en eau potable ;

b) à revêtement interne du produit et des essais correspondants si cela est exigé par les réglementations nationales

dans le pays de destination prévu.

Industrijski ventili - Zahteve glede primernosti uporabe ventilov iz plastomerov kot gradbenih elementov

General Information

- Status

- Published

- Publication Date

- 20-May-2008

- Withdrawal Date

- 29-Nov-2008

- Technical Committee

- CEN/TC 69 - Industrial valves

- Drafting Committee

- CEN/TC 69/WG 16 - Plastic valves

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 05-Feb-2024

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Refers

EN ISO 16137:2006 - Industrial valves - Check valves of thermoplastics materials (ISO 16137:2006) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 16139:2006 - Industrial valves - Gate valves of thermoplastics materials (ISO 16139:2006) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 16135:2006 - Industrial valves - Ball valves of thermoplastics materials (ISO 16135:2006) - Effective Date

- 28-Jan-2026

- Refers

EN ISO 21787:2006 - Industrial valves - Globe valves of thermoplastics materials (ISO 21787:2006) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15389:2008 - "Industrial valves - Performance characteristics of thermoplastic valves when used as construction products" (CEN) specifies performance requirements and conformity evaluation methods for valves made of thermoplastic materials used in building and civil engineering systems for delivery of liquids and gases. It also provides the information needed for regulatory marking (CE marking) and guidance on applicability for drinking water systems (subject to national regulations or internal coating and testing).

Key topics and technical requirements

- Scope and purpose: Defines how thermoplastic valves should be assessed when treated as construction products in buildings and civil engineering installations.

- Mechanical strength & nominal pressure (PN): Establishes how to determine the valve’s nominal pressure PN for thermoplastics (using long‑term hydrostatic data and classification per EN ISO 9080 and EN ISO 12162, and methods in ISO 9393-2).

- Tightness (leakage): Requires gas and liquid tightness testing (no leakage allowed) following ISO 9393-2 procedures.

- Dimensional tolerances: Manufacturer must declare connection dimensions and tolerances; measurements per EN ISO 3126.

- Durability and working life: Valves meeting the standard and with declared PN are deemed to have a reasonable economic working life (expected to match the service life of the network).

- Reaction to fire: Where regulated, reaction-to-fire classification per EN 13501-1 and tests per EN 13823.

- Dangerous substances: Materials must not release hazardous substances above limits set by relevant material standards or national regulations.

- Handle overload safeguard & noise: Specific requirements for handle overload protection and declaration of maximum design flow velocity (noise depends on system flow).

- Conformity assessment: Covers initial type testing, factory production control (FPC), and procedures for one‑off/low‑quantity products. Annex ZA links requirements to EU Construction Products Directive and CE marking rules.

Practical applications and users

Who benefits from EN 15389:2008:

- Valve manufacturers - for product design, declaration of PN, test programs and CE marking evidence.

- Specifiers and consultants - to set performance requirements for thermoplastic valves in building and civil engineering projects.

- Testing laboratories and certifiers - to carry out required tests (pressure strength, leakage, fire reaction, dimensional checks).

- Installers and system designers - to select valves with appropriate PN, durability and declared flow/noise characteristics.

- Regulators and compliance officers - to verify CE marking, conformity assessment and suitability for potable water per national rules.

Related standards (selection)

- EN ISO 9080 - long‑term hydrostatic strength of thermoplastics

- EN ISO 12162 - thermoplastics material classification (MRS)

- ISO 9393-2 - pressure test methods for thermoplastic valves

- EN ISO 3126 - dimensional measurement for plastics components

- EN 13501-1 / EN 13823 - reaction to fire classification and tests

- EN ISO 16135–16139, EN ISO 21787 - product standards for specific valve types (ball, butterfly, gate, globe, check, diaphragm)

EN 15389:2008 is essential for ensuring thermoplastic industrial valves meet performance, safety and regulatory requirements when used as construction products in building and civil engineering systems.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15389:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Industrial valves - Performance characteristics of thermoplastic valves when used as construction products". This standard covers: This European Standard specifies performance requirements and means for evaluation of conformity for valves of thermoplastic material, by reference to product standards, for use in building and civil engineering applications for the delivery of liquid and gaseous fluids. It also contains information required for the purposes of regulatory marking. NOTE For information, thermoplastic valves in conformity with this European Standard should be considered suitable for drinking water applications subject to either: a) compliance with any national regulations in the country of intended destination, which can include testing if this is the demonstration of fitness for drinking water applications; b) internal coating of the Product and subsequent testing if required by the national regulations in the intended country of destination.

This European Standard specifies performance requirements and means for evaluation of conformity for valves of thermoplastic material, by reference to product standards, for use in building and civil engineering applications for the delivery of liquid and gaseous fluids. It also contains information required for the purposes of regulatory marking. NOTE For information, thermoplastic valves in conformity with this European Standard should be considered suitable for drinking water applications subject to either: a) compliance with any national regulations in the country of intended destination, which can include testing if this is the demonstration of fitness for drinking water applications; b) internal coating of the Product and subsequent testing if required by the national regulations in the intended country of destination.

EN 15389:2008 is classified under the following ICS (International Classification for Standards) categories: 91.140.70 - Sanitary installations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15389:2008 has the following relationships with other standards: It is inter standard links to EN ISO 16137:2006, EN ISO 3126:2005, EN ISO 16139:2006, EN ISO 16138:2006, EN ISO 16136:2006, EN ISO 16135:2006, EN ISO 21787:2006, EN ISO 12162:2009, EN 13501-1:2018, EN ISO 17781:2017, EN ISO 9080:2012, EN ISO 9001:2000, EN 13823:2020+A1:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15389:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/131, M/136. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15389:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Industrijski ventili - Zahteve glede primernosti uporabe ventilov iz plastomerov kot gradbenih elementovIndustriearmaturen - Anforderungen an die Gebrauchstauglichkeit von Armaturen aus Thermoplasten bei Verwendung als BauprodukteRobinetterie industrielle - Caractéristiques de performance des appareils de robinetterie thermoplastiques utilisés comme produits de constructionIndustrial valves - Performance characteristics of thermoplastic valves when used as construction products83.140.30Cevi, fitingi in ventili iz polimernih materialovPlastics pipes, fittings and valvesICS:Ta slovenski standard je istoveten z:EN 15389:2008SIST EN 15389:2008en01-september-2008SIST EN 15389:2008SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15389May 2008ICS 91.140.70 English VersionIndustrial valves - Performance characteristics of thermoplasticvalves when used as construction productsRobinetterie industrielle - Caractéristiques de performancedes appareils de robinetterie thermoplastiques utiliséscomme produits de constructionIndustriearmaturen - Anforderungen an dieGebrauchstauglichkeit von Armaturen aus Thermoplastenbei Verwendung als BauprodukteThis European Standard was approved by CEN on 18 April 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15389:2008: ESIST EN 15389:2008

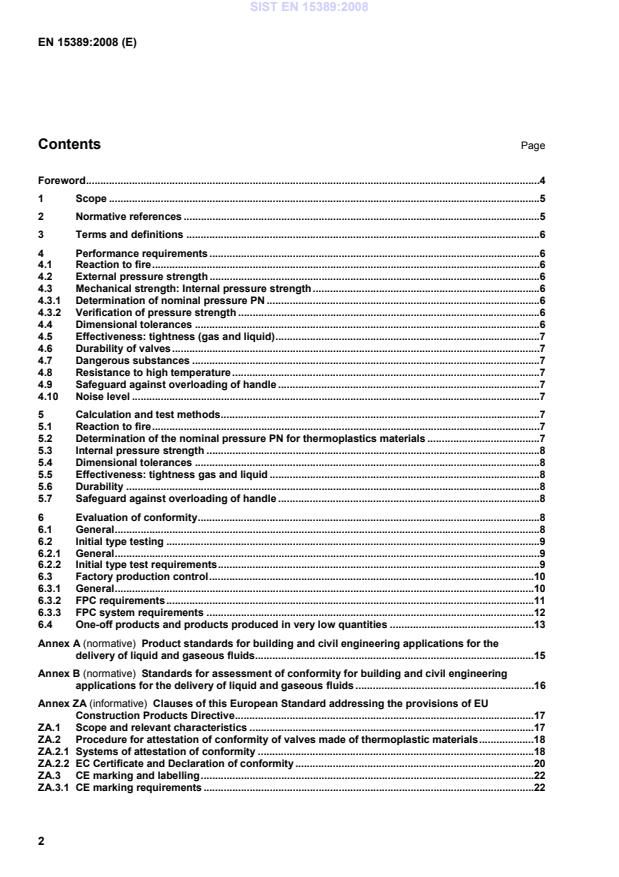

Product standards for building and civil engineering applications for the delivery of liquid and gaseous fluids.15 Annex B (normative)

Standards for assessment of conformity for building and civil engineering applications for the delivery of liquid and gaseous fluids.16 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of EU Construction Products Directive.17 ZA.1 Scope and relevant characteristics.17 ZA.2 Procedure for attestation of conformity of valves made of thermoplastic materials.18 ZA.2.1 Systems of attestation of conformity.18 ZA.2.2 EC Certificate and Declaration of conformity.20 ZA.3 CE marking and labelling.22 ZA.3.1 CE marking requirements.22 SIST EN 15389:2008

5.2 Determination of the nominal pressure PN for thermoplastics materials For thermoplastics materials the nominal pressure PN shall be determined as follows: a) determine the σLPL value in accordance with EN ISO 9080. Data provided by either the compound manufacturer or the product manufacturer shall be taken into account; SIST EN 15389:2008

Table 1 — Size groups Range of nominal diameters, dn Size group for thermoplastics material 1 DN ≤ 50 2 50 < DN ≤ 300 3 300 < DN

b) Type groups for valves as given in Table 2. Table 2 — Type groups Fitting group Type of valves 1 Ball valves 2 Diaphragm valves

3 Butterfly valves 4 Other valves

6.2 Initial type testing 6.2.1 General Type tests shall be carried out on new products and whenever there is a change in design, in material and/or in production method, other than routine in-process adjustment and extension of the product range (see Table 3). A change of supplier of a material or stabiliser does not lead to a change in performance if the chemical composition remains the same. Material modifications within limits may be considered as a not change of material. The limits are as defined in the relevant material standards given in Annex B. For tests previously performed in accordance with the provisions of the standards listed in Annex A, as applicable, (same product, same characteristic(s), same test method, same system of attestation, etc.) the results may be taken into account. All characteristics given in Clause 4 shall be subject to calculation and/or initial type testing. 6.2.2 Initial type test requirements The initial type testing of the characteristics according to Clause 4 shall be performed in accordance with the sampling procedure given in Table 3. SIST EN 15389:2008

Table 3 — Type testing of valves Testing relevant to a Essential characteristics Requirement Clause of this European Standard I M E Sampling procedure (minimum sampling) Acceptance Reaction to fire 4.1 + + — Once/compound or formulation b see classification in EN 13501-1 External pressure strength 4.2 + + + See internal pressure strength Pass/fail Mechanical strength: Internal pressure strength 4.3 + + + One diameter/size group/ valve type group/compound or formulation Pass/fail Dimensional tolerances 4.4 + — + Once/size/valve/compound or formulation Pass/fail Effectiveness: tightness gas and liquid 4.5 + + + One diameter/size group/ valve type Pass/fail Durability of valves 4.6 + + + Once/compound or formulation By the classification of the long-term strength performance Dangerous substances 4.7 +

+

— See notes in Table ZA.1

Pass/fail Resistance to high temperature 4.8 + + + One diameter/size group/ valve group Declared values Safeguard against overloading of handle 4.9 + — + One diameter/size group/ valve group Pass/fail Noise level 4.10 + — + One diameter/size group/ valve group Noise emission declared as decibels a I is initial type test in case of new system;

M is change of material;

E is extension of the product range with new size group or fitting group.

+ denotes testing relevant for the characteristic-occurrence-combination. b In case of single burning item (SBI) test the vertical part is size 110 and the horizontal part size 40, which is then representative for all dimensions.

Test reports shall be kept by the manufacturer for at least 10 years after discontinuation of the product. 6.3 Factory production control 6.3.1 General The manufacturer shall establish, document and maintain an FPC system to ensure that the products placed on the market conform to the stated performance characteristics. The FPC system shall consist of procedures, regular inspections and tests and/or assessments and the use of the results to control raw and other incoming materials or components, equipment, the production process and the product. If the manufacturer has the component designed, manufactured, assembled, packed, processed and labelled by subcontracting, FPC of the original manufacturer may be taken into account. However, where subcontracting takes place, the manufacturer shall retain the overall control of the component and ensure that SIST EN 15389:2008

Pass/fail Dimensional tolerances 4.4 EN ISO 3126 or according to the manufacturers quality plan Once/batch Pass/fail Effectiveness. tightness gas and liquid 4.5 Indirect testing: see dimensional tolerances Once/batch Pass/fail Durability of valves 4.6 Indirect testing: see internal pressure strength, and check of compound or formulation

Once/batch Pass/fail

Dangerous substances 4.7 See notes in Table ZA.1 See notes in table ZA.1

Pass/fail Resistance to high temperature 4.8 Identification of compound or formulation Once/batch Tabulated values Safeguard against overloading of handle 4.9 Identification of compound or formulation Once/batch Pass/fail Noise level 4.10 Identification of compound or formulation Once/batch Noise emission declared as decibels

6.3.3 FPC system requirements 6.3.3.1 Personnel The responsibility, authority and the relationship between personnel that manages, performs or verifies work affecting product conformity, shall be defined. This applies in particular to personnel that need to initiate actions preventing product non-conformities from occurring, actions in case of non-conformities and to identify and register product conformity problems. Personnel performing work affecting product conformity shall be competent on the basis of appropriate education, training, skills and experience for which records shall be maintained. 6.3.3.2 Equipment All weighing, measuring and testing equipment necessary to achieve, or produce evidence of, conformity shall be calibrated or verified and regularly inspected according to documented procedures, frequencies and criteria. Control of monitoring and measuring devices shall comply with the appropriate clause of EN ISO 9001:2000. SIST EN 15389:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...