ENV ISO 14253-2:2001

(Main)Geometrical Product Specifications (GPS) - Inspection by measurement of workpieces and measuring equipments - Part 2: Guide to the estimation of uncertainty in GPS measurement, in calibration of measuring equipment and in product verification (ISO/TS 14253-2:1999)

Geometrical Product Specifications (GPS) - Inspection by measurement of workpieces and measuring equipments - Part 2: Guide to the estimation of uncertainty in GPS measurement, in calibration of measuring equipment and in product verification (ISO/TS 14253-2:1999)

Migrated from Progress Sheet (TC Comment) (2000-07-10): Will be a CR (BTS2 C 4/1996)

Geometrische Produktspezifikationen (GPS) - Prüfung von Werkstücken und Messgeräten durch Messungen - Teil 2: Leitfaden zur Schätzung der Unsicherheit von GPS-Messungen bei der Kalibrierung von Messgeräten und bei der Produktprüfung (ISO/TS 14253-2:1999)

Diese Technische Spezifikation enthält Leitlinien für die Einführung des Konzepts des "Leitfadens zur Angabe der Unsicherheit beim Messen" (abgekürzt GUM), welcher in der Industrie bei der Kalibrierung von Normalen und Messeinrichtungen im GPS-Bereich und bei der Messung von Werkstück-GPS-Merkmalen angewendet werden soll. Ziel ist es, eine vollständige Information darüber zu geben, wie die Angaben zur Unsicherheit ermittelt werden können, sowie die Schaffung einer Grundlage für den internationalen Vergleich von Messergebnissen und deren Unsicherheit (Beziehung zwischen Abnehmer und Hersteller).

Diese Technische Spezifikation soll ISO 14253-1 unterstützen und ist mit ISO 14253-1 für alle technischen Aufgaben in einem Unternehmen entsprechend der GPS-Spezifikationen (d. h. für Toleranzen der Merkmale von Werkstücken und den Werten der maximal zulässigen Abweichungen (MPE) für messtechnische Merkmale von Messeinrichtungen) nützlich.

Diese Technische Spezifikation führt eine Prozedur für das Unsicherheits-MAnagement - PUMA - ein. Es handelt sich um ein praktisches, iteratives, auf dem GUM basierendes Verfahren zur Schätzung der Unsicherheit ohne Änderung des Grundlagenkonzeptes von GUM und soll allgemein zur Schätzung der Messunsicherheit und zur Angabe der Unsicherheit in folgenden Teilen dienen:

¾ Einzelmessergebnisse,

¾ den Vergleich von zwei oder mehreren Messergebnissen,

¾ den Vergleich von Messergebnissen - eines oder mehrerer Werkstücke oder Messeinrichtungen - mit gegebenen Spezifikationen (d. h. die maximal zulässigen Abweichungen (MPE) eines messtechnischen Merkmals eines Messgerätes oder eines Normals und die Toleranzgrenzen eines Werkstückmerkmals usw.), um Übereinstimmung oder Nichtübereinstimmung mit der Spezifikation festzustellen.

Spécification géométrique des produits (GPS) - Vérification par la mesure des pièces et des équipements de mesure - Guide pour l'estimation de l'incertitude de mesure dans l'étalonnage des équipements de mesure et dans la vérification des produits (ISO/TS 14253-2:1999)

Geometrical Product Specifications (GPS) - Inspection by measurement of workpieces and measuring equipments - Guide to the estimation of uncertainty in GPS measurement, in calibration of measuring equipment and in product verification (ISO/TS 14253-2:1999)

General Information

- Status

- Withdrawn

- Publication Date

- 20-Mar-2001

- Withdrawal Date

- 14-Apr-2011

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 15-Apr-2011

- Completion Date

- 15-Apr-2011

Relations

- Effective Date

- 23-Apr-2011

Frequently Asked Questions

ENV ISO 14253-2:2001 is a standardization document published by the European Committee for Standardization (CEN). Its full title is "Geometrical Product Specifications (GPS) - Inspection by measurement of workpieces and measuring equipments - Part 2: Guide to the estimation of uncertainty in GPS measurement, in calibration of measuring equipment and in product verification (ISO/TS 14253-2:1999)". This standard covers: Migrated from Progress Sheet (TC Comment) (2000-07-10): Will be a CR (BTS2 C 4/1996)

Migrated from Progress Sheet (TC Comment) (2000-07-10): Will be a CR (BTS2 C 4/1996)

ENV ISO 14253-2:2001 is classified under the following ICS (International Classification for Standards) categories: 17.040.01 - Linear and angular measurements in general; 17.040.40 - Geometrical Product Specification (GPS). The ICS classification helps identify the subject area and facilitates finding related standards.

ENV ISO 14253-2:2001 has the following relationships with other standards: It is inter standard links to EN ISO 14253-2:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ENV ISO 14253-2:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2002

Geometrical Product Specifications (GPS) - Inspection by measurement of

workpieces and measuring equipments - Guide to the estimation of uncertainty in

GPS measurement, in calibration of measuring equipment and in product

verification (ISO/TS 14253-2:1999)

Geometrical Product Specifications (GPS) - Inspection by measurement of workpieces

and measuring equipments - Part 2: Guide to the estimation of uncertainty in GPS

measurement, in calibration of measuring equipment and in product verification (ISO/TS

14253-2:1999)

Geometrische Produktspezifikationen (GPS) - Prüfung von Werkstücken und

Messgeräten durch Messungen - Teil 2: Leitfaden zur Schätzung der Unsicherheit von

GPS-Messungen bei der Kalibrierung von Messgeräten und bei der Produktprüfung

(ISO/TS 14253-2:1999)

Spécification géométrique des produits (GPS) - Vérification par la mesure des pieces et

des équipements de mesure - Guide pour l'estimation de l'incertitude de mesure dans

l'étalonnage des équipements de mesure et dans la vérification des produits (ISO/TS

14253-2:1999)

Ta slovenski standard je istoveten z: ENV ISO 14253-2:2001

ICS:

17.040.01 Linearne in kotne meritve na Linear and angular

splošno measurements in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CORRECTED 2002-03-27

Foreword

The text of the Technical Specification from Technical Committee ISO/TC 213 "Dimensional and

geometrical product specifications and verification" of the International Organization for

Standardization (ISO) has been taken over as a European Prestandard by Technical Committee

CEN/TC 290 "Dimensional and geometrical product specification and verification", the

secretariat of which is held by AFNOR.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of

the following countries are bound to announce this European Prestandard: Austria, Belgium,

Czech Republic, Denmark, Finland, France, Germany, Greece, Iceland, Ireland, Italy,

Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and the United

Kingdom.

Endorsement notice

The text of the International Technical Specification ISO/TS 14253-2:1999 has been approved

by CEN as a European Prestandard without any modifications.

NOTE Normative references to International Standards are listed in annex ZA (normative).

In other circumstances, particularly when there is an urgent market requirement for such

documents, a technical committee may decide to publish other types of normative document:

- an ISO Publicly Available Specification (ISO/PAS) represents an agreement

between technical experts in an ISO working group and is accepted for publication if

it is approved by more than 50 % of the members of the parent committee casting a

vote;

- an ISO Technical Specification (ISO/TS) represents an agreement between the

members of a technical committee and is accepted for publication if it is approved

by 2/3 of the members of the committee casting a vote.

An ISO/PAS or ISO/TS is reviewed every three years with a view to deciding whether it can be

transformed into an International Standard.

Attention is drawn to the possibility that some of the elements of this Technical Specification may

be the subject of patent rights. ISO shall not be held responsible for identifying any or all such

patent rights.

ISO/TS 14253-2 was prepared by Technical Committee ISO/TC 213, Dimensional and

geometrical product specifications and verification.

ISO 14253 consists of the following parts, under the general title, Geometrical product

specifications (GPS) – Inspection by measurement of workpieces and measuring equipment:

- Part 1: Decision rules for proving conformance or non-conformance with

specification

- Part 2: Guide to the estimation of uncertainty in GPS measurement, in calibration of

measuring equipment and in product verification [Technical Specification]

- Part 3: Procedures for evaluating the integrity of uncertainty in measurement values

Annexes A to D of this Technical Specification are for information only.

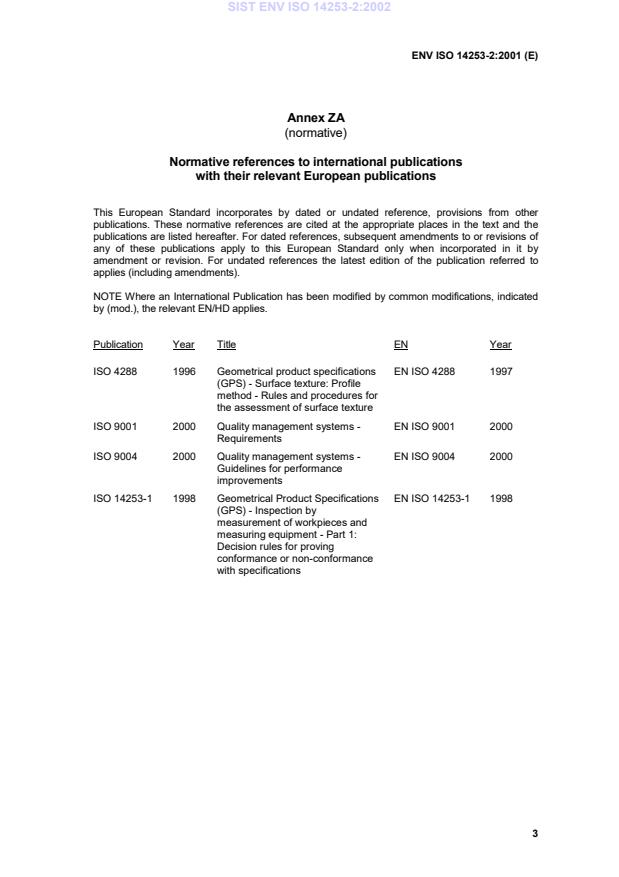

Annex ZA

(normative)

Normative references to international publications

with their relevant European publications

This European Standard incorporates by dated or undated reference, provisions from other

publications. These normative references are cited at the appropriate places in the text and the

publications are listed hereafter. For dated references, subsequent amendments to or revisions of

any of these publications apply to this European Standard only when incorporated in it by

amendment or revision. For undated references the latest edition of the publication referred to

applies (including amendments).

NOTE Where an International Publication has been modified by common modifications, indicated

by (mod.), the relevant EN/HD applies.

Publication Year Title EN Year

ISO 4288 1996 Geometrical product specifications EN ISO 4288 1997

(GPS) - Surface texture: Profile

method - Rules and procedures for

the assessment of surface texture

ISO 9001 2000 Quality management systems - EN ISO 9001 2000

Requirements

ISO 9004 2000 Quality management systems - EN ISO 9004 2000

Guidelines for performance

improvements

ISO 14253-1 1998 Geometrical Product Specifications EN ISO 14253-1 1998

(GPS) - Inspection by

measurement of workpieces and

measuring equipment - Part 1:

Decision rules for proving

conformance or non-conformance

with specifications

TECHNICAL ISO/TS

SPECIFICATION 14253-2

First edition

1999-12-01

Geometrical Product Specifications

(GPS) — Inspection by measurement of

workpieces and measuring equipment —

Part 2:

Guide to the estimation of uncertainty

in GPS measurement, in calibration

of measuring equipment and in product

verification

Spécification géométrique des produits (GPS) — Vérification par la mesure

des pièces et des équipements de mesure —

Partie 2: Guide pour l'estimation de l'incertitude dans les mesures GPS,

dans l'étalonnage des équipements de mesure et dans la vérification

des produits

Reference number

ISO/TS 14253-2:1999(E)

©

ISO 1999

ISO/TS 14253-2:1999(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 1999

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 734 10 79

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 1999 – All rights reserved

ISO/TS 14253-2:1999(E)

Contents Page

Foreword.iv

Introduction.v

1 Scope .1

2 Normative references .2

3 Terms and definitions .2

4 Symbols .6

5 Concept of the iterative GUM-method for estimation of uncertainty of measurement .7

6 Procedure for Uncertainty MAnagement — PUMA .8

7 Sources of errors and uncertainty of measurement.13

8 Tools for the estimation of uncertainty components, standard uncertainty and expanded

uncertainty.17

9 Practical estimation of uncertainty — Uncertainty budgeting with PUMA.26

10 Applications .30

Annex A (informative) Example of uncertainty budgets — Calibration of a setting ring.34

Annex B (informative) Example of uncertainty budgets — Design of a calibration hierarchy.41

Annex C (informative) Example of uncertainty budgets — Measurement of roundness .65

Annex D (informative) Relation to the GPS matrix model.71

Bibliography.73

© ISO 1999 – All rights reserved iii

ISO/TS 14253-2:1999(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

The main task of technical committees is to prepare International Standards. Draft International Standards adopted

by the technical committees are circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a technical

committee may decide to publish other types of normative document:

— an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in an

ISO working group and is accepted for publication if it is approved by more than 50 % of the members of the

parent committee casting a vote;

— an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting a

vote.

An ISO/PAS or ISO/TS is reviewed every three years with a view to deciding whether it can be transformed into an

International Standard.

Attention is drawn to the possibility that some of the elements of this Technical Specification may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TS 14253-2 was prepared by Technical Committee ISO/TC 213, Dimensional and geometrical product

specifications and verification.

ISO 14253 consists of the following parts, under the general title Geometrical product specifications (GPS) —

Inspection by measurement of workpieces and measuring equipment:

� Part 1: Decision rules for proving conformance or non-conformance with specification

� Part 2: Guide to the estimation of uncertainty in GPS measurement, in calibration of measuring equipment and

in product verification [Technical Specification]

� Part 3: Procedures for evaluating the integrity of uncertainty in measurement values

Annexes A to D of this Technical Specification are for information only.

iv © ISO 1999 – All rights reserved

ISO/TS 14253-2:1999(E)

Introduction

This Technical Specification is a global GPS technical report (see ISO/TR 14638:1995). This global GPS Technical

Report influences chain link 4, 5 and 6 in all chains of standards.

For more detailed information of the relation of this report to other standards and the GPS matrix model, see

annex D.

This Technical Specification is developed to support ISO 14253-1. This Technical Specification establishes a

simplified, iterative procedure of the concept and the way to evaluate and determine uncertainty (standard

uncertainty and expanded uncertainty) of measurement, and the recommendations of the format to document and

report the uncertainty of measurement information as given in "Guide to the expression of uncertainty in

measurement" (GUM). In most cases only very limited resources are necessary to estimate uncertainty of

measurement by this simplified, iterative procedure, but the procedure may lead to a slight overestimation of the

uncertainty of measurement. If a more accurate estimation of the uncertainty of measurement is needed, the more

elaborated procedures of the GUM must be applied.

This simplified, iterative procedure of the GUM methods is intended for GPS measurements, but may be used in

other areas of industrial (applied) metrology.

Uncertainty of measurement and the concept of handling uncertainty of measurement being of importance to all the

technical functions in a company, this Technical Specification relates to e.g. management function, design and

development function, manufacture function, quality assurance function, metrology function, etc.

This Technical Specification is of special importance in relation to ISO 9000 quality assurance systems, where

it is a requirement that the uncertainty of measurement is known [e.g. 4.11.1, 4.11.2 a) and 4.11.2 b) of

ISO 9001:1994].

In this Technical Specification the uncertainty of the result of a process of calibration and a process of

measurement is handled in the same way:

� calibration is treated as "measurement of metrological characteristics of a measuring equipment or a

measurement standard";

� measurement is treated as "measurement of geometrical characteristics of a workpiece".

Therefore, in most cases no distinction is made in the text between measurement and calibration. The term

"measurement" is used as a synonym for both.

© ISO 1999 – All rights reserved v

TECHNICAL SPECIFICATION ISO/TS 14253-2:1999(E)

Geometrical product specifications (GPS) — Inspection by

measurement of workpieces and measuring equipment —

Part 2:

Guide to the estimation of uncertainty in GPS measurement, in

calibration of measuring equipment and in product verification

1 Scope

This Technical Specification gives guidance on the implementation of the concept of "Guide to the estimation of

uncertainty in measurement" (in short GUM) to be applied in industry for the calibration of (measurement)

standards and measuring equipment in the field of GPS and the measurement of workpiece GPS-characteristics.

The aim is to promote full information on how to achieve uncertainty statements and provide the basis for

international comparison of results of measurements and their uncertainties (relationship between purchaser and

supplier).

This Technical Specification is intended to support ISO 14253-1. This Technical Specification and ISO 14253-1 are

beneficial to all technical functions in a company in the interpretation of GPS specifications (i.e. tolerances of

workpiece characteristics and values of maximum permissible errors (MPE) for metrological characteristics of

measuring equipment).

This Technical Specification introduces the Procedure for Uncertainty MAnagement (PUMA), which is a practical,

iterative procedure based on the GUM for estimating uncertainty of measurement without changing the basic

concepts of the GUM and is intended to be used generally for estimating uncertainty of measurement and giving

statements of uncertainty for:

� single results of measurement;

� comparison of two or more results of measurement;

� comparison of results of measurement — from one or more workpieces or pieces of measurement equipment

— with given specifications [i.e. maximum permissible errors (MPE) for a metrological characteristic of a

measurement instrument or measurement standard, and tolerance limits for a workpiece characteristic, etc.],

for proving conformance or non-conformance with the specification.

The iterative method is based basically on an upper bound strategy, i.e. overestimation of the uncertainty at all

levels, but the iterations control the amount of overestimation. Intentional overestimation — and not under-

estimation — is necessary to prevent wrong decisions based on measurement results. The amount of

overestimation shall be controlled by economical evaluation of the situation.

The iterative method is a tool to maximize profit and minimize cost in the metrological activities of a company. The

iterative method/procedure is economically self-adjusting and is also a tool to change/reduce existing uncertainty in

measurement with the aim of reducing cost in metrology (manufacture). The iterative method makes it possible to

compromise between risk, effort and cost in uncertainty estimation and budgeting.

© ISO 1999 – All rights reserved 1

ISO/TS 14253-2:1999(E)

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this Technical Specification. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this Technical Specification are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 1:1975, Standard reference temperature for industrial length measurements.

ISO 4288:1996, Geometrical Product Specifications (GPS) — Surface texture: Profile method — Rules and

procedures for the assessment of surface texture.

ISO 9001:1994, Quality systems — Model for quality systems in design, development, production, installation and

servicing.

ISO 9004-1:1994, Quality management and quality system elements — Part 1: Guidelines.

ISO 14253-1:1998, Geometrical Product Specification (GPS) — Inspection by measurement of workpieces and

measuring instruments — Part 1: Decision rules for proving conformance or non-conformance with specifications.

1)

ISO 14253-3:— , Geometrical Product Specification (GPS) — Inspection by measurement of workpieces and

measuring instruments — Part 3: Procedures for evaluating the integrity of uncertainty of measurement values.

ISO 14660-1:1999, Geometrical Product Specification (GPS) — Geometric features — Part 1: General terms and

definitions.

Guide to the expression of uncertainty in measurement (GUM).BIPM, IEC, IFCC,ISO,IUPAC,IUPAP,OIML,

1st edition, 1995.

International Vocabulary of Basic and General Terms in Metrology (VIM). BIPM, IEC, IFCC, ISO, IUPAC, IUPAP,

OIML, 2nd edition, 1993.

3 Terms and definitions

For the purposes of this Technical Specification, the terms and definitions given in ISO 14253-1, ISO 14660-1, VIM,

GUM and the following apply.

3.1

black box model for uncertainty estimation

method of/model for uncertainty estimation in which the output value of a measurement is obtained in the same unit

as the input (stimuli), rather than by measurement of other quantities functionally related to the measurand

NOTE 1 In the black box model — in this Technical Specification — the uncertainty components are assumed additive, the

influence quantities is transformed to the unit of the measurand and the sensitivity coefficients are equal to 1.

NOTE 2 In many cases a complex method of measurement may be looked upon as one simple black box with stimulus in

and result out from the black box. When a black box is opened, it may turn out to contain several "smaller" black boxes and/or

several transparent boxes.

NOTE 3 The method of uncertainty estimation remains a black box method even if it is necessary to make supplementary

measurements to determine the values of influence quantities in order to make corresponding corrections.

1) To be published.

2 © ISO 1999 – All rights reserved

ISO/TS 14253-2:1999(E)

3.2

transparent box model for uncertainty estimation

method of/model for uncertainty estimation in which the value of a measurand is obtained by measurement of other

quantities functionally related to the measurand

3.3

measuring task

quantification of a measurand according to its definition

3.4

basic measurement task (basic measurement)

measurement task(s) which form the basis for evaluation of more complicated characteristics of a workpiece or a

measuring equipment

NOTE Examples of a basic measurement are:

a) one of several individual measurements of the deviation from straightness of a feature of a workpiece;

b) one of the individual measurements of error of indication of a micrometer when measuring the range of error of indication.

3.5

overall measurement task

complicated measuring task, which is evaluated on the basis of several and maybe different basic measurements

NOTE Examples of an overall measuring task are:

a) the measurement of straightness of a feature of a workpiece;

b) the range of error of indication of a micrometer.

3.6

expanded uncertainty (of a measurement)

U

[3.16 of ISO 14253-1:1998 and 2.3.5 of GUM:1995]

NOTE U (capital) always indicates expanded uncertainty of measurement.

3.7

true uncertainty

U

A

uncertainty of measurement that would be obtained by a perfect uncertainty estimation

NOTE 1 True uncertainties are by nature indeterminate.

NOTE 2 See also 8.8.

3.8

conventional true uncertainty — GUM uncertainty

U

c

uncertainty of measurement estimated completely according to the more elaborate procedures of GUM

NOTE 1 The conventional true uncertainty of measurement may differ from an uncertainty of measurement estimated

according to this Technical Specification.

NOTE 2 See also 8.8.

© ISO 1999 – All rights reserved 3

ISO/TS 14253-2:1999(E)

3.9

approximated uncertainty

U

EN

uncertainty of measurement estimated by the simplified, iterative method

NOTE 1 The index N indicates that U is assessed by iteration number N. The designation U may be used without indication

EN E

of the iteration number, when it is without importance to know the number of iterations.

NOTE 2 See also 8.8.

3.10

target uncertainty (for a measurement or calibration)

U

T

uncertainty determined as the optimum for the measuring task

NOTE 1 Target uncertainty is the result of a management decision involving e.g. design, manufacturing, quality assurance,

service, marketing, sales and distribution.

NOTE 2 Target uncertainty is determined (optimized) taking into account the specification [tolerance or maximum

permissible error (MPE)], the process capability, cost, criticality and the requirements of 4.11.1, 4.11.2 of ISO 9001:1994, 13.1

of ISO 9004-1:1994 and ISO 14253-1.

NOTE 3 See also 8.8.

3.11

required uncertainty of measurement

U

R

uncertainty required for a given measurement process and task

NOTE See also 6.2. The required uncertainty may be specified by, for example, a customer.

3.12

uncertainty management

process of deriving an adequate measurement procedure from the measuring task and the target uncertainty by

using uncertainty budgeting techniques

3.13

uncertainty budget (for a measurement or calibration)

statement summarizing the estimation of the uncertainty components that contributes to the uncertainty of a result

of a measurement

NOTE 1 The uncertainty of the result of the measurement is unambiguous only when the measurement procedure (including

the measurement object, measurand, measurement method and conditions) is defined.

NOTE 2 The term "budget" is used for the assignment of numerical values to the uncertainty components, their combination

and expansion, based on the measurement procedure, measurement conditions and assumptions.

3.14

uncertainty contributor

xx

source of uncertainty of measurement for a measuring process

3.15

limit value (variation limit) for an uncertainty contributor

a

xx

absolute value of the extreme value(s) of the uncertainty contributor, xx

4 © ISO 1999 – All rights reserved

ISO/TS 14253-2:1999(E)

3.16

uncertainty component

u

xx

standard uncertainty of the uncertainty contributor, xx

NOTE The iteration method uses the designation u for all uncertainty components. This is not consistent with the present

xx

version of GUM which sometimes uses the designation s for uncertainty components evaluated by A evaluation and the

xx

designation u for uncertainty components evaluated by B evaluation.

xx

3.17

influence quantity of a measurement instrument

characteristic of a measuring instrument that affects the result of a measurement performed by the instrument

3.18

influence quantity of a workpiece

characteristic of a workpiece that affects the result of a measurement performed on that workpiece

© ISO 1999 – All rights reserved 5

ISO/TS 14253-2:1999(E)

4 Symbols

For the purposes of this Technical Specification, the generic symbols given in Table 1 apply.

Table 1 — Generic symbols

Symbol Description

a

limit value for a distribution

a

limit value for an error or uncertainty contributor (in the unit of the result of measurement, of the measurand)

xx

a* limit value for an error or uncertainty contributor (in the unit of the influence quantity)

xx

linear coefficient of thermal expansion

�

b

coefficient for transformation of a to u

xx xx

C correction (value)

d

resolution of a measurement equipment

E

Young's modulus

ER error (value of a measurement)

G function of several measurement values [G( X , X , . X , .)]

1 2 i

h hysteresis value

k

coverage factor

m number of standard deviations in the half of a confidence interval

MR measurement result (value)

n number of .

N number of iterations

Poisson's number

�

p number of total uncorrelated uncertainty contributors

r number of total correlated uncertainty contributors

correlation coefficient

�

TV true value of a measurement

u, u standard uncertainty (standard deviation)

i

s

standard deviation of a sample

x

s

x standard deviation of a mean value of a sample

u combined standard uncertainty

c

u standard deviation of uncertainty contributor xx — uncertainty component

xx

U expanded uncertainty of measurement

U true uncertainty of measurement

A

U conventional true uncertainty of measurement

C

U approximated uncertainty of measurement (number of iteration not stated)

E

U approximated uncertainty of measurement of iteration number N

EN

U required uncertainty

R

U target uncertainty

T

U uncertainty value (not estimated according to GUM or this Technical Specification)

V

X measurement result (uncorrected)

X measurement result (in the transparent box model of uncertainty estimation)

i

Y measurement result (corrected)

6 © ISO 1999 – All rights reserved

ISO/TS 14253-2:1999(E)

5 Concept of the iterative GUM-method for estimation of uncertainty of measurement

Applying the GUM method completely one will find a conventional true uncertainty of measurement, U .

C

The simplified, iterative method/procedure of this Technical Specification is to achieve estimated uncertainties of

measurements, U by overestimating the influencing uncertainty components/contributors (U W U ). The process

E E C

of overestimating provides "worst-case-contributions" at the upper bound from each known or predictable

uncertainty contributor, thus ensuring results of estimations "on the safe side", i.e. not underestimating the

uncertainty of measurement. The simplified, iterative method of this Technical Specification is based on the

following:

� all uncertainty contributors are identified;

� it is decided which of the possible corrections shall be made (see 8.4.6);

� the influence on the uncertainty of the result of measurement from each contributor is evaluated as a standard

uncertainty u , called the uncertainty component;

xx

NOTE As a convention in the iterative method the influence of each contributor must be converted into the unit of the

measurand — using relevant physical equations/formulae and sensibility coefficients.

� an iteration process, PUMA (see clause 6);

� the evaluation of each of the uncertainty components (standard uncertainties) u can take place either by type

xx

A-evaluation or by type B-evaluation;

� type B-evaluation is preferred — if possible — in the first iteration in order to get a rough uncertainty estimate

to establish an overview and to save cost;

� the total effect of all contributors (called the combined standard uncertainty) is calculated by the formula:

22 2 2

uu��u�u� .�u (1)

c1xx2 x3 xn

� the formula (1) is only valid for a black box model of the uncertainty estimation and when the components u

xx

are all uncorrelated (for more details and other formulas see 8.6 and 8.7);

� for simplification the only correlation coefficients between contributors considered are

� =1, –1, 0 (2)

if the uncertainty components are not known to be uncorrelated, full correlation is assumed, either � =1 or� 1.

Correlated components are added arithmetically before put into the formula above (see 8.5 and 8.6);

� the expanded uncertainty U is calculated by the formula:

Uk��u (3)

c

where k =2; k is the coverage factor (see also 8.8);

The simplified, iterative method normally will consist of at least two iterations of estimating the components of

uncertainty.

a) The first very rough, quick and cheap iteration has the purpose of identifying the largest components of

uncertainty (see Figure 1);

b) The following iterations — if any — only deal with making more accurate "upper bound" estimates of the largest

components to lower the estimate of the uncertainty (u and U) to a possible acceptable magnitude.

c

© ISO 1999 – All rights reserved 7

ISO/TS 14253-2:1999(E)

The simplified and iterative method may be used for two purposes:

a) Management of the uncertainty of measurement for a result of a given measurement process (can be used for

the results from a known measuring process or for comparison of two or more of such results) — see 6.2.

b) Uncertainty management for a measuring process. Development of an adequate measuring process i.e.

U u U — see 6.3.

E T

6 Procedure for Uncertainty MAnagement — PUMA

6.1 General

The prerequisite for uncertainty budgeting and management is a clearly identified and defined measuring task; i.e.

the measurand to be quantified (a GPS characteristic of a workpiece or a metrological characteristic of a GPS

measuring equipment). The uncertainty of measurement is a measure of the quality of the measured value

according to the definitions of a GPS characteristic of the workpiece or a metrological characteristic of the GPS

measuring equipment given in GPS standards.

GPS standards define the "conventional true values" (see 1.20 of VIM:1993) of the characteristics to be measured

by chains of standards and global standards (see ISO/TR 14638). GPS standards in many cases also define the

ideal — or conventional true — principle of measurement (see 2.3 of VIM:1993), method of measurement (see 2.4

of VIM:1993), measurement procedure (see 2.5 of VIM:1003) and Standard "reference conditions" (see 5.7 of

VIM:1993).

Deviations from the standardized conventional true values of the characteristics, etc. (the ideal operator) are

contributing to the uncertainty of measurement.

6.2 Uncertainty management for a given measurement process

Management of the uncertainty of measurement for a given measuring task (box 1 of Figure 1) and for an existing

measurement process is illustrated in Figure 1. The principle of measurement (box 3), measurement method

(box 4), measurement procedure (box 5) and measurement conditions (box 6) are fixed and given or decided in this

case, and cannot be changed. The only task is to evaluate the consequence on the uncertainty of measurement. A

required U may be given or decided.

R

Using the iterative GUM method the first iteration is only for orientation, and to look for the dominant uncertainty

contributors. The only thing to do — in the management process in this case — is to refine the estimation of the

dominant contributors to come closer to a true estimate of the uncertainty components thus avoiding a too big

overestimate — if necessary.

Figure 1 — Uncertainty management for a result of measurement from a given measurement process

8 © ISO 1999 – All rights reserved

ISO/TS 14253-2:1999(E)

The procedure is as follows:

a) make a first iteration based preferably on a black box model of the uncertainty estimation process and set up a

preliminary uncertainty budget (boxes 7 to 9) leading to the first rough estimate of the expanded uncertainty,

U (box 10). For details about uncertainty estimation see 9. All estimates of uncertainties U are performed

E1 EN

as upper bound estimates;

b) compare the first estimated uncertainty, U , with the required uncertainty U (box A) for the actual measuring

E1 R

task

1) If U is acceptable (i.e. if U u U ), then the uncertainty budget of the first iteration has proven that the

E1 E1 R

given measurement procedure is adequate for the measuring task (box 11);

2) If U is not acceptable (i.e. if U > U ) or if there is no required uncertainty, but a lower and more true

E1 E1 R

value is desired, the iteration process continues;

c) before the new iteration, analyze the relative magnitude of the uncertainty contributors. In many cases a few

uncertainty components dominate the combined standard uncertainty and expanded uncertainty;

d) change the assumptions or improve the knowledge about the uncertainty components to make a more

accurate (see 3.5 of VIM:1993) upper bound estimation of the largest (dominant) uncertainty components (box

12).

Change to a more detailed model of the uncertainty estimation process or a higher resolution of the measuring

process (box 12);

e) make the second iteration of the uncertainty budget (boxes 7 to 9) leading to the second, lower and more

accurate (see 3.5 of VIM:1993) upper bound estimate of the uncertainty of measurement, U (box 10);

E2

f) compare the second estimated uncertainty U (box A) with uncertainty required U for the actual measuring

E2 R

task

1) if U is acceptable (i.e. if U u U ), then the uncertainty budget of the second iteration has proven that

E2 E2 R

the given measurement procedure is adequate to the measuring task (box 11);

2) if U is not acceptable (i.e. if U > U ), or if there is no required uncertainty, but a lower and more true

E2 E2 R

value is desired, then a third (and possibly more) iteration(s) is (are) needed. Repeat the analysis of the

uncertainty contributors [additional changes of assumptions, improve in knowledge, changes in modelling,

etc. (box 12)] and concentrate on the currently largest uncertainty contributors;

g) when all possibilities have been used for making more accurate (lower) upper bound estimates of the

measuring uncertainties without coming to an acceptable measuring uncertainty U u U , then it is proven,

EN R

that it is not possible to fulfil the given requirement U .

R

6.3 Uncertainty management for design and development of a measurement process/procedure

Uncertainty management in this case is performed to develop an adequate measurement procedure [measurement

of the geometrical characteristics of a workpiece or the metrological characteristics of a measuring equipment

(calibration)]. Uncertainty management is performed on the basis of a defined measuring task (box 1 in Figure 2)

and a given target uncertainty, U (box 2 in Figure 2). Definition of the measuring task and target uncertainty are

T

company policy decisions to be made at a sufficiently high management level. An adequate measurement

procedure is a procedure which results in an estimated uncertainty of measurement less than or equal to the target

uncertainty. If the estimated uncertainty of measurement is much less than the target uncertainty, the measurement

procedure may not be (economically) optimal for performing the measuring task (i.e. the measurement process is

too costly).

© ISO 1999 – All rights reserved 9

ISO/TS 14253-2:1999(E)

The PUMA, based on a given measuring task (box 1) and a given target uncertainty U (box 2), includes the

T

following (see Figure 2):

a) choose the principle of measurement (box 3) on the basis of experience and possible measurement

instruments present in the company;

b) set up and document a preliminary method of measurement (box 4), measurement procedure (box 5) and

measurement conditions (box 6) on the basis of experience and known possibilities in the company;

c) make a first iteration based preferably on a black box model of the uncertainty estimation process and set up a

preliminary uncertainty budget (boxes 7 to 9) leading to the first rough estimate of the expanded uncertainty,

U (box 10). For details about uncertainty estimation see clause 9. All estimates of uncertainties U are

E1 EN

performed as upper bound estimates;

d) compare the first estimated uncertainty, U , with the given target uncertainty, U (box A);

E1 T

1) if U is acceptable (i.e. if U u U ), then the uncertainty budget of the first iteration has proven that the

E1 E1 T

measurement procedure is adequate for the measuring task (box 11);

2) if U << U , then the measurement procedure is technically acceptable, but a possibility may exist to

E1 T

change the method and/or the procedure (box 13) in order to make the measuring process more cost

effective while increasing the uncertainty. A new iteration is then needed to estimate the resulting

measurement uncertainty, U (box 10);

E2

3) if U is not acceptable (i.e. if U > U ), the iteration process continues, or it is concluded that no

E1 E1 T

adequate measurement procedure is possible;

e) before the new iteration, analyze the relative magnitude of the uncertainty contributors. In many cases a few

uncertainty components pre-dominate the combined standard uncertainty and expanded uncertainty;

f) if U > U , then change the assumptions, the modelling or increase the knowledge about the uncertainty

E1 T

components (box 12) to make a more accurate (see 3.5 of VIM:1993) upper bound estimation of the largest

(dominant) uncertainty components;

g) make the second iteration of the uncertainty budget (boxes 7 to 9) leading to the second, lower and more

accurate (see 3.5 of VIM:1993) upper bound estimate of the uncertainty of measurement, U (box 10);

E2

h) compare the second estimated uncertainty U with the given target uncertainty, U (box A);

E2 T

1) if U is acceptable (i.e. if U u U ), then the uncertainty budget of the second iteration has proven that

E2 E2 T

the measurement procedure is adequate for the measuring task (box 11);

2) if U is not acceptable (i.e. if U > U ) then a third (and possibly more) iteration(s) is (are) needed.

E2 E2 T

Repeat the analysis of the uncertainty contributors (additional changes of assumptions, modelling and

increase in knowledge (box 12)) and concentrate on the currently largest uncertainty contributors;

i) when all possibilities has been used for making more accurate (lower) upper bound estimates of the measuring

uncertainties without coming to an acceptable measuring uncertainty U u U , then a change of the

EN T

measurement method or the measurement procedure or the conditions of measurement (box 13) is needed to

(possibly) bring down the magnitude of the estimated uncertainty, U . The iteration procedure starts again

EN

with a first iteration;

j) if changes in the measurement method or the measurement procedure or conditions (box 13) do not lead to an

acceptable uncertainty of measurement, the final possibility is to change the principle of measurement (box 14)

and start the above mentioned procedure again;

10 © ISO 1999 – All rights reserved

ISO/TS 14253-2:1999(E)

k) if change of the measuring principle and the related iterations described above do not lead to an acceptable

uncertainty of measurement the ultimate possibility is to change the measuring task and/or target uncertainty

(box 15) and start the above mentioned procedure again;

l) if change of measuring task or target uncertainty is not possible, it is demonstrated, that no adequate

measurement procedure exists (box 16).

© ISO 1999 – All rights reserved 11

ISO/TS 14253-2:1999(E)

Figure 2 — Procedure for Uncertainty of Measurement MAnagement (PUMA) for a measurement

process/procedure

12 © ISO 1999 – All rights reserved

ISO/TS 14253-2:1999(E)

7 Sources of errors and uncertainty of measurement

7.1 Types of errors

Different types of errors regularly shows up in measurement results.

� systematic errors;

� random errors;

� drift;

� outliers.

All errors are by nature systematic. When we see errors as non-systematic it is because the reason for the error is

not looked for or because the level of resolution is not sufficient. Systematic errors may be characterised by size

and sign (+ or�).

ER = MR� TV

where

ER is the error,

MR is the measurement result;

TV is thetruevalue.

Random errors are systematic errors caused by non-controlled random influence quantities. Random errors may be

characterized by the standard deviation and the type of distribution. The mean value of the random errors is often

considered as a basis for the evaluation of the systematic error (see Figure 3).

Key

1 Outlier

2 Dispersion 1

3 Dispersion 2

4 Systematic error 1

5 Systematic error 2

6 True value

Figure 3 — Types of errors in results of measurements

© ISO 1999 – All rights reserved 13

ISO/TS 14253-2:1999(E)

Drift is caused by a systematic influence of non-controlled influence quantities. Drift is often a time effect or a wear

effect. Drift may be characterized by change per unit time or per amount of u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...