EN 14897:2006+A1:2007

(Main)Water conditioning equipment inside buildings - Devices using mercury low-pressure ultraviolet radiators - Requirements for performance, safety and testing

Water conditioning equipment inside buildings - Devices using mercury low-pressure ultraviolet radiators - Requirements for performance, safety and testing

This document specifies definitions, principles of construction, requirements and methods for testing the performance of UV devices for drinking water installations inside buildings which are permanently connected to the mains supply at the point of entry into a building or within the water distribution system inside the building.

UV devices in the sense of this standard are UV bactericidal treatment devices or UV disinfection devices.

Anlagen zur Behandlung von Trinkwasser innerhalb von Gebäuden - Geräte mit Quecksilberdampf-Niederdruckstrahlern - Anforderungen an Ausführung, Sicherheit und Prüfung

Dieses Dokument legt Begriffe, Grundsätze der Konstruktion, Anforderungen und Verfahren für die Prüfung der Leistungsanforderungen von UV-Geräten für Trinkwasserinstallationen innerhalb von Gebäuden, die fest am Eintrittspunkt des Wassers in die Hausinstallation angeschlossen oder in die weitere Installation integriert sind, fest.

UV-Geräte im Sinne dieser Norm sind UV-Geräte zur antibakteriellen Behandlung oder UV-Desinfektions-geräte.

Appareils de traitement d'eau à l'intérieur des bâtiments - Dispositifs utilisant des radiateurs à mercure et basse pression de rayonnement UV - Exigences de performance, de sécurité et essais

Oprema, ki se uporablja za pripravo pitne vode v stavbah - Naprave z živosrebrnimi nizkotlačnimi ultravijoličnimi sevalniki - Zahteve za delovanje, varnost in preskušanje

General Information

- Status

- Published

- Publication Date

- 12-Jun-2007

- Withdrawal Date

- 30-Dec-2007

- Technical Committee

- CEN/TC 164 - Water supply

- Drafting Committee

- CEN/TC 164/WG 13 - Water conditioning equipment inside buildings

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 10-Sep-2021

- Completion Date

- 11-Feb-2026

Not Harmonized89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14897:2006+A1:2007 (CEN) specifies requirements for water conditioning equipment inside buildings that use mercury low‑pressure ultraviolet (UV) radiators for microbial control. The standard covers definitions, principles of construction, performance, safety and testing methods for UV devices installed on drinking water systems permanently connected to the mains at the point of entry or within a building’s internal distribution system. It applies to both UV disinfection devices (designed to guarantee defined virus/bacteria reductions) and UV bactericidal treatment devices.

Key topics and technical requirements

- Performance requirement: Devices shall deliver a reduction equivalent fluence (REF) of at least 400 J/m² (40 mJ/cm²) at 254 nm within the defined operational range.

- Radiation chamber: Must be manufactured from corrosion‑resistant, UV‑resistant, drinking‑water‑safe materials; designed to avoid UV leakage (<400 nm) and allow easy servicing.

- UV lamps: Only low‑pressure mercury lamps with emissions above 240 nm (to prevent ozone formation) are permitted; lamp output characteristics used in type tests must be matched for production devices.

- Sensors & monitoring: UV disinfection devices require a device sensor for representative irradiance measurement; sensor performance (selectivity, calibration, linearity, drift) is specified in Annex A. Controllers must display irradiance, lamp service time and provide failure and flow‑related alarms, with capability to stop waterflow if limits are exceeded.

- Testing methods: Includes requirements for test rigs, biodosimetric measurements (use of biodosimeters and calibration per Annex B), minimum irradiance determination, processing test data, and establishing maximum flow rate (Qmax) and permissible operating range.

- Additional requirements: Labelling, user manual content, installation/operation/maintenance guidance (Annexes D–F), and conformity with relevant electrotechnical directives and CE marking.

Practical applications

- Ensures uniform UV disinfection performance and safety for point‑of‑entry and in‑building drinking water UV systems.

- Useful for validating product designs, type testing, factory production control and field acceptance testing.

- Supports specification of UV devices for hospitals, commercial buildings, multi‑family dwellings, laboratories and other critical indoor water installations where microbial control is required.

Who would use this standard

- UV device manufacturers (design, type testing, technical documentation)

- Water system integrators and installers (selection, installation, commissioning)

- Consulting engineers and spec writers (performance specifications)

- Regulators, certification bodies and testing laboratories (conformity assessment)

- Facility managers and water utilities (maintenance, operation and compliance)

Related standards and notes

- Normative reference: EN 1717 (protection against pollution of potable water by backflow).

- Devices must also comply with applicable national drinking water regulations and relevant EC Directives (CE marking).

Keywords: EN 14897:2006+A1:2007, UV disinfection devices, UV bactericidal treatment, mercury low‑pressure ultraviolet radiators, drinking water installations, reduction equivalent fluence, UV transmittance, biodosimeter.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

NSF International

Global independent organization facilitating standards development and certification.

QAI Laboratories

Building and construction product testing and certification.

Sponsored listings

Frequently Asked Questions

EN 14897:2006+A1:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water conditioning equipment inside buildings - Devices using mercury low-pressure ultraviolet radiators - Requirements for performance, safety and testing". This standard covers: This document specifies definitions, principles of construction, requirements and methods for testing the performance of UV devices for drinking water installations inside buildings which are permanently connected to the mains supply at the point of entry into a building or within the water distribution system inside the building. UV devices in the sense of this standard are UV bactericidal treatment devices or UV disinfection devices.

This document specifies definitions, principles of construction, requirements and methods for testing the performance of UV devices for drinking water installations inside buildings which are permanently connected to the mains supply at the point of entry into a building or within the water distribution system inside the building. UV devices in the sense of this standard are UV bactericidal treatment devices or UV disinfection devices.

EN 14897:2006+A1:2007 is classified under the following ICS (International Classification for Standards) categories: 13.060.20 - Drinking water; 91.140.60 - Water supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14897:2006+A1:2007 has the following relationships with other standards: It is inter standard links to EN 14897:2006, EN 1717:2025, EN 806-5:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14897:2006+A1:2007 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC, 98/83/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14897:2006+A1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Water conditioning equipment inside buildings - Devices using mercury low-pressure ultraviolet radiators - Requirements for performance, safety and testingAppareils de traitement d'eau a l'intérieur des bâtiments - Dispositifs utilisant des radiateurs a mercure et basse pression de rayonnement UV - Exigences de performance, de sécurité et essaisAnlagen zur Behandlung von Trinkwasser innerhalb von Gebäuden - Geräte mit Quecksilberdampf-Niederdruckstrahlern - Anforderungen an Ausführung, Sicherheit und PrüfungTa slovenski standard je istoveten z:EN 14897:2006+A1:2007SIST EN 14897:2006+A1:2007en,fr91.140.60Sistemi za oskrbo z vodoWater supply systems13.060.20Pitna vodaDrinking waterICS:SLOVENSKI

STANDARDSIST EN 14897:2006+A1:200701-september-2007

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14897:2006+A1

June 2007 ICS 13.060.20; 91.140.60 SupersedesEN 14897:2006English Version

Water conditioning equipment inside buildings - Devices using mercury low-pressure ultraviolet radiators - Requirements for performance, safety and testing

Appareils de traitement d'eau à l'intérieur des bâtiments - Dispositifs utilisant des radiateurs à mercure et basse pression de rayonnement UV - Exigences de performance, de sécurité et essais

Anlagen zur Behandlung von Trinkwasser innerhalb von Gebäuden - Geräte mit Quecksilberdampf-Niederdruckstrahlern - Anforderungen an Ausführung, Sicherheit und Prüfung This European Standard was approved by CEN on 10 May 2006 and includes Amendment 1 approved by CEN on 10 May 2007.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2007 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14897:2006+A1:2007: E

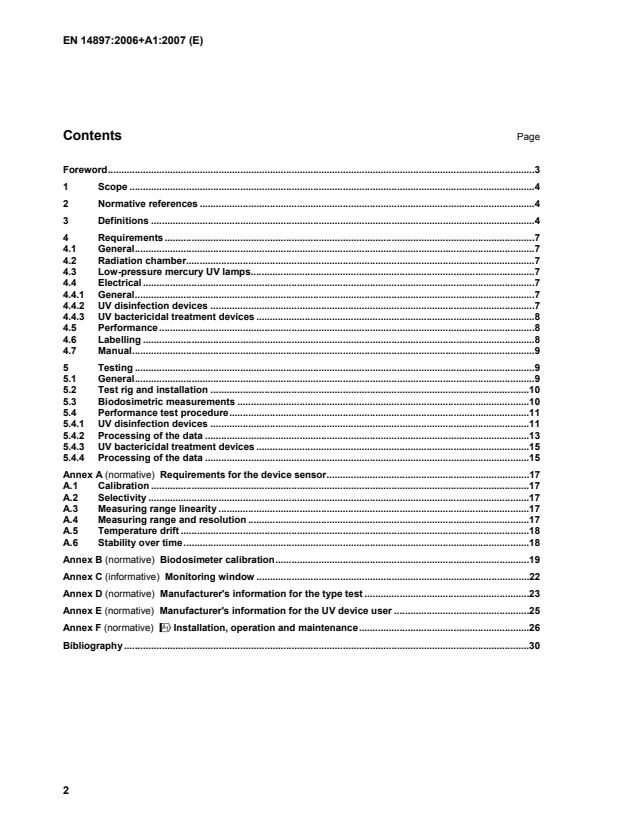

Requirements for the device sensor.17 A.1 Calibration.17 A.2 Selectivity.17 A.3 Measuring range linearity.17 A.4 Measuring range and resolution.17 A.5 Temperature drift.18 A.6 Stability over time.18 Annex B (normative)

Biodosimeter calibration.19 Annex C (informative)

Monitoring window.22 Annex D (normative)

Manufacturer's information for the type test.23 Annex E (normative)

Manufacturer's information for the UV device user.25 Annex F (normative)

!Installation, operation and maintenance.26 Bibliography.30

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

NOTE The irradiance measured in UV disinfection devices by the UV device sensor

is mainly influenced by the lamp output, the transmittance of the water, and scaling/fouling of the protective quartz sleeves and the position of the lamps in the radiation chamber. 3.3 disinfection action of killing or inactivating all types of pathogenic bacteria to a specified degree of at least 99,999 % and all types of pathogenic viruses to a degree of at least 99,99 % using a UV disinfection device 3.4 bactericidal treatment action of inactivating or killing bacteria present in water to an unspecified degree using a UV bactericidal treatment device 3.5 fluence dose product of irradiance in W/m2 and exposure time in s, in J/m2 NOTE Fluence is the correct term from a strictly scientific point of view.

3.6 germicidal fluence fluence weighted with the germicidal UV sensitivity, in J/m2

3.19 UV lamp radiator which produces UV light 3.20 UV device general expression for products using UV light to irradiate water flow through, with the purpose of inactivating microrganisms being present in the water 3.21 UV disinfection device device designed to disinfect water 3.22 UV bactericidal treatment device device designed for bactericidal water treatment 3.23 turbidity reduction of optical transmittance of a liquid caused by the presence of undissolved matter 3.24 UV transmittance (% T100) spectral transmission rate at a wavelength of 254 nm at an optical path length in the medium of 100 mm, in % NOTE In general, the UV transmittance includes the influence of attenuation and absorption of the through passing medium. The UV transmittance is measured in the unfiltered sample in quartz cuvettes of at least 40 mm at a wavelength of 254 nm in a spectrophotometer and is given in %. 3.25 UV radiation (UV) electromagnetic radiation according to Table 1 Table 1 — UV radiation Type Wavelength nm UV-C > 100 ≤

280 UV-B > 280 ≤

315 UV-A > 315 ≤

400 NOTE

For bactericidal and disinfection purposes, part of the UV-C range is used.

NOTE Product intended for use in water supply systems should comply, when existing, with national regulations and testing arrangements that ensure fitness for contact with drinking water. The Member states, relevant regulators and the EC Commission agreed on the principles of a future unique European Acceptance Scheme (EAS), which would provide a common testing and approval arrangement at European level. If and when the EAS is adopted, European Product Standards will be amended by the addition of an Annex Z/EAS under Mandate M/136, which will contain formal references to the testing, certification and product marking requirements of the EAS. The mechanical design and the construction shall comply with the relevant requirements for the pressure present. Direct or indirect leaking of radiation from the radiation chamber to the environment with a wavelength below 400 nm shall be avoided. Radiation chambers shall be constructed in a way that they are easily serviceable. For UV disinfection devices, the radiation chamber shall be provided with a sensor for a representative

irradiation measurement. The location of the sensor shall be designed so that the irradiation measurement is not disturbed by gas bubbles or sediment deposits. 4.3 Low-pressure mercury UV lamps In order not to produce ozone, only lamps with a radiation range above 240 nm shall be used. !At the mercury resonance line of 254 nm shall be 85 % of the total radiation intensity in the UV-C range." Lamp(s) shall be marked with a designation of type. Only those lamps used for the type test shall be used in the UV device. The UV lamp(s) shall be approved for the device by the manufacturer or be equivalent to the approved type used at the type test. 4.4 Electrical 4.4.1 General For the electrotechnical design of UV devices, the relevant EC Directives and CE marking requirements shall be accomodated. Compliance with these EC Directives is a requirement of this standard. !deleted text" 4.4.2 UV disinfection devices 4.4.2.1 Controller The UV disinfection device shall be equipped with a controller, which provides the following functions: when switching on the device, the signal for the waterflow shall be delayed until the minimum irradiance is reached; operation and failure of the electrical function of each lamp shall be indicated; operation beyond the permissible limits of operation shall be indicated and a signal shall be provided which allows the waterflow to be stopped;

flow-related alarm point(s). 4.4.2.2 Sensor For the measurement of the irradiation, a sensor shall be provided to ensure disinfection under consideration of possible changes in water UV transmittance and lamp performance. Requirements for the device sensor are given in Annex A. Where national regulations apply, a sensor and monitoring window may have to fulfil certain requirements. NOTE An example for a monitoring window is shown in Annex C. 4.4.3 UV bactericidal treatment devices The UV bactericidal treatment devices shall be equipped with a controller, which provides the following functions: operation and failure of the electrical function of the lamp(s) shall be indicated; general malfunction signal shall be provided. The following functions shall be displayed: device in function; service time of the UV lamps. 4.5 Performance The UV device shall apply a reduction equivalent fluence of at least 400 J/m2 at the end of the lamp service life for the specified flow rates and UV transmittance values. The performance is evaluated with a type test for which the manufacturer shall provide information in accordance with Annex D. 4.6 Labelling The information to be given on a nameplate, which shall be permanently fixed to the UV device and be legible when installed, shall be in accordance with Annex E.

operating diagram: transmittance vs. maximum admissible flow; water resulting from sampling (rinsing) shall be adequately disposed of to the provisions of EN 1717; replacement intervals for UV lamp(s), sensor (only for UV disinfection devices). 5 Testing 5.1 General The manufacturer shall provide the details and documentation described in Annex D. The device to be tested is checked for conformity to the documentation. The purpose of the type test is to verify that the UV fluence delivered by the device under test meets a reduction equivalent fluence of 400 J/m2 at the end of the lamp life, at the specified flow rates and transmittance values.

Parameters to be changed during the test are the flow rate of the water and the UV transmittance of the water for the test of UV bactericidal treatment devices and the flow rate, the transmittance and the lamp-output, for the test of UV disinfection devices. For the type test of UV disinfection devices the UV device shall be equipped with a sensor or with a specified monitoring window and a specified sensor if national regulation for these apply. The testing in the test rig comprises of five steps: checking the compliance of the device to be tested with the specifications; data collection during the test (flow rate, water temperature, electrical power consumption, .); radiation physics tests, i.e. determination of the irradiance (only for UV disinfection devices); microbiological test with the biodosimeter; evaluation of the UV device and specification of the operating range. The manufacturer shall provide data (flow rate versus UV transmittance), that give the testing points at which the UV fluence (400 J/m2) is reached at the end of the lamp service time and the percentage of UV output at the end of lamp service life (e.g. 70 %). The permissible operational range is determined by measurements of at least three test points which should cover the whole operational range.

The UV device to be tested shall have new lamps that have been in service for 100 h. The manufacturer shall provide an appropriate method to vary the output of the UV lamps.

Key 1 Water inlet with check valve 9 Pressure measurement device 2 Flow adjustment valve 10 Temperature measurement device 3 Dosing pump, sodium thiosulfate 11 Sampling point before UV device 4 Dosing pump, biodosimeter 12 Flowmeter 5 Sodium thiosulfate solution 13 Static mixer after UV device 6 Biodosimeter 14 Sampling point after UV device 7 Static mixer before UV device 15 Stopvalve 8 Measurement UV transmittance device in the flow Figure 1 — Test rig (schematic) 5.3 Biodosimetric measurements As soon as stable operating conditions for the test rig and the UV device at a test point are reached, the biodosimeter is added to the inlet flow. Optimum mixing is achieved by the static mixer (concentration of the biodosimeter after mixing about 106l-1

to 107 l-1). Take the samples after UV irradiation and also after a static mixer. During the test, there shall be continuous flow through the sampling ports. For each test point and measuring cycle, five samples shall be taken before and after UV irradiation respectively. The determination of the concentration of the biodosimeter as number of colony forming units (CFU) is done in triplicate using a decimal dilution series. Use the pour plate method with plate count agar. Incubate for (48 ± 4) h at (37 ± 1) °C. Use three agar plates (diameter 90 mm) of the dilution step that results in 20 to 200 colonies per plate. The arithmetric average of the three counts is multiplied by the dilution factor and converted into the decadic logarithm. This results in five lg-concentration before and five lg-concentration after UV irradiation, of which the arithmetric average is calculated (lg N0: before irradiation, lg N1: after irradiation). The standard deviation s of the five parallel samples shall not exceed ± 0,2. Otherwise the test conditions are not stable (hydraulics, dosing, mixing). By calculating lg(N/N0), the reduction at the test point is determined. In

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...