EN 15605:2010

(Main)Copper and copper alloys - Inductively coupled plasma optical emission spectrometry

Copper and copper alloys - Inductively coupled plasma optical emission spectrometry

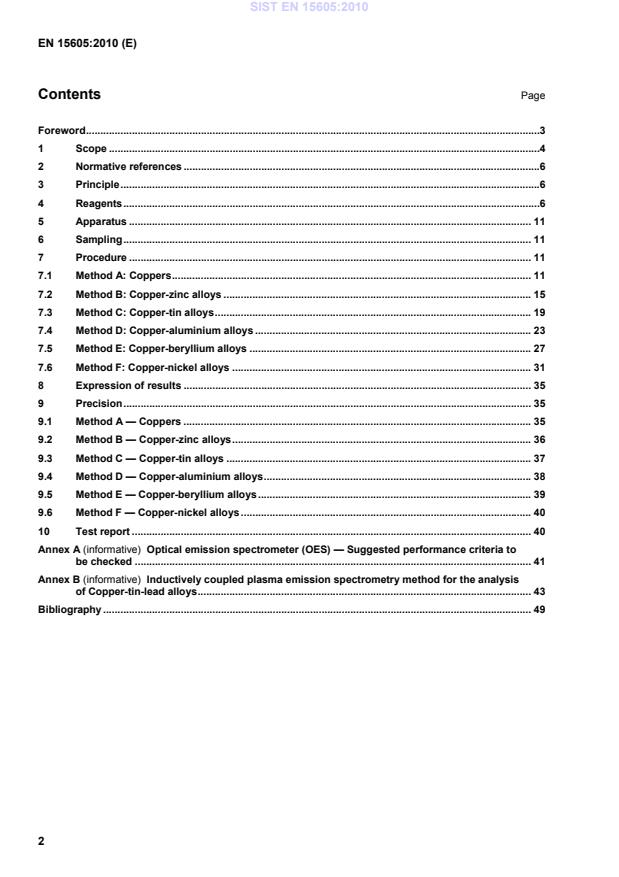

This European Standard specifies six inductively coupled plasma emission spectrometry methods (A to F) for the determination of alloying elements and impurities in copper and copper alloys in the form of unwrought, wrought and cast products.

A complementary method, for the analysis of Copper-tin-lead alloys, is described in Annex B (informative). The precision criteria concerning this method do not reach the suitable level, for all the elements specified (zinc and phosphorus, namely).

These methods are applicable to the elements listed in Tables 1 to 6 within the composition ranges shown: (...)

NOTE 1 The ranges specified for each method can be extended or adapted, for the determination of lower mass fractions.

NOTE 2 Other elements may be included. However such elements and their mass fractions should be carefully checked, taking into account interference, sensitivity, resolution and linearity criteria for each instrument and each wavelength.

Kupfer und Kupferlegierungen - Optische Emissionsspektrometrie mit induktiv gekoppelter Plasmaanregung

Diese Europäische Norm legt sechs Verfahren (A bis F) zur optischen Emissionsspektrometrie mit induktiv gekoppelter Plasmaanregung für die Analyse von Legierungselementen und Verunreinigungen in Kupfer und Kupferlegierungen fest, die als Gussstücke oder als plastisch oder nicht plastisch geformte Produkte vorliegen.

Ein zusätzliches Verfahren für die Analyse von Kupfer-Zinn-Blei-Legierungen ist in Anhang B (informativ) beschrieben. Die ermittelten Daten zur Präzision für dieses Verfahren waren nicht für alle Elemente ausreichend gut (Zink und Phosphor).

Cuivre et alliages de cuivre - Analyse par spectrométrie d'émission optique avec source à plasma induit par haute fréquence

La présente Norme européenne spécifie six méthodes par spectrométrie d'émission avec plasma induit par

haute fréquence (A à F) pour la détermination des éléments d'alliage et des impuretés dans le cuivre et les

alliages de cuivre sous la forme de produits non corroyés, corroyés et moulés.

Une méthode complémentaire, pour analyser les alliages cuivre-étain-plomb est décrite dans l’Annexe B

(informative). Les critères de fidélité de cette méthode n’atteignent pas le niveau requis pour tous les

éléments spécifiés (zinc et phosphore notamment).

Ces méthodes sont applicables aux éléments listés dans les Tableaux 1 à 6 dans les domaines de

composition indiqués :

Baker in bakrove zlitine - Optična emisijska spektrometrija z induktivno sklopljeno plazmo

Ta evropski standard določa šest metod emisijske spektrometrije z induktivno sklopljeno plazmo (od A do F) za določevanje legirnih elementov in nečistoč v bakru in bakrovih zlitinah v obliki negnetenih, gnetenih in ulitih polizdelkov. Komplementarna metoda za analizo kositrovih svinčenih zlitin je opisana v Dodatku B (informativni). Merila natančnosti, ki zadevajo to metodo, niso na primerni ravni za vse navedene elemente (in sicer cink in fosfor).

General Information

- Status

- Published

- Publication Date

- 20-Jul-2010

- Technical Committee

- CEN/TC 133 - Copper and copper alloys

- Drafting Committee

- CEN/TC 133/WG 10 - Methods of analysis

- Current Stage

- 9020 - Submission to 2 Year Review Enquiry - Review Enquiry

- Start Date

- 15-Jan-2026

- Completion Date

- 15-Jan-2026

Relations

- Effective Date

- 24-Jul-2010

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15605:2010 - published by CEN - specifies six inductively coupled plasma optical emission spectrometry (ICP-OES / ICP emission spectrometry) methods (Methods A–F) for determining alloying elements and impurities in copper and copper alloys (unwrought, wrought and cast products). The standard defines sample dissolution, calibration and measurement practice for reliable chemical analysis and includes an informative Annex B covering a complementary method for copper‑tin‑lead alloys (precision for some elements is limited).

Key topics and technical requirements

- Analytical principle: Acid dissolution of a test portion (hydrochloric and nitric acids), addition of an internal reference element, nebulization of the sample solution into an ICP plasma and measurement of emission intensities.

- Methods covered:

- Method A - Coppers

- Method B - Copper‑zinc alloys

- Method C - Copper‑tin alloys

- Method D - Copper‑aluminium alloys

- Method E - Copper‑beryllium alloys

- Method F - Copper‑nickel alloys

- Elemental ranges: The standard lists applicable elements and mass‑fraction ranges in Tables 1–6 (examples: Zn in brass ~10–42 %, Sn in bronzes ~3–16 %, Be in Cu‑Be alloys ~0.08–4 %, Ni in Cu‑Ni ~7–35 %, Al in Cu‑Al ~6–14 %). NOTE: ranges can be extended to lower mass fractions with appropriate checks.

- Quality and performance: Requires analytical‑grade reagents, defined calibration procedures, use of an internal standard and instrument performance checks (Annex A suggests OES performance criteria). Precision criteria are specified per method; Method G (Cu‑Sn‑Pb, Annex B) is informative because precision for some elements (e.g., Zn, P) is not fully satisfactory.

- Normative references: Includes ISO 1811‑1 and ISO 1811‑2 for sampling and sample preparation.

Applications and users

- Who uses it: Metallurgical laboratories, commercial testing labs, OEMs and manufacturers of copper alloys, quality control and inspection teams, materials engineers, R&D and failure analysis specialists.

- Practical uses:

- Chemical composition certification and batch release of copper alloys

- Incoming material inspection and supplier qualification

- Process control in alloy production and casting

- Material qualification for electrical, marine, automotive and aerospace components

- Trace impurity analysis for compliance and material specifications

- Benefits: Provides standardized ICP‑OES procedures to improve comparability of results, ensure traceable alloy analysis and support regulatory/contractual acceptance.

Related standards

- ISO 1811‑1, ISO 1811‑2 - selection and preparation of samples for chemical analysis (normative references in EN 15605:2010).

- See Annex A of EN 15605 for suggested optical emission spectrometer performance checks.

Keywords: EN 15605:2010, copper and copper alloys, ICP‑OES, inductively coupled plasma optical emission spectrometry, copper alloy analysis, alloying elements, impurities, methods A–F.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 15605:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Copper and copper alloys - Inductively coupled plasma optical emission spectrometry". This standard covers: This European Standard specifies six inductively coupled plasma emission spectrometry methods (A to F) for the determination of alloying elements and impurities in copper and copper alloys in the form of unwrought, wrought and cast products. A complementary method, for the analysis of Copper-tin-lead alloys, is described in Annex B (informative). The precision criteria concerning this method do not reach the suitable level, for all the elements specified (zinc and phosphorus, namely). These methods are applicable to the elements listed in Tables 1 to 6 within the composition ranges shown: (...) NOTE 1 The ranges specified for each method can be extended or adapted, for the determination of lower mass fractions. NOTE 2 Other elements may be included. However such elements and their mass fractions should be carefully checked, taking into account interference, sensitivity, resolution and linearity criteria for each instrument and each wavelength.

This European Standard specifies six inductively coupled plasma emission spectrometry methods (A to F) for the determination of alloying elements and impurities in copper and copper alloys in the form of unwrought, wrought and cast products. A complementary method, for the analysis of Copper-tin-lead alloys, is described in Annex B (informative). The precision criteria concerning this method do not reach the suitable level, for all the elements specified (zinc and phosphorus, namely). These methods are applicable to the elements listed in Tables 1 to 6 within the composition ranges shown: (...) NOTE 1 The ranges specified for each method can be extended or adapted, for the determination of lower mass fractions. NOTE 2 Other elements may be included. However such elements and their mass fractions should be carefully checked, taking into account interference, sensitivity, resolution and linearity criteria for each instrument and each wavelength.

EN 15605:2010 is classified under the following ICS (International Classification for Standards) categories: 77.120.30 - Copper and copper alloys. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15605:2010 has the following relationships with other standards: It is inter standard links to CEN/TS 15605:2007, EN 12492:2000, EN 960:1994. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15605:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.SOD]PRKupfer und Kupferlegierungen - Optische Emissionsspektrometrie mit induktiv gekoppelter PlasmaanregungCuivre et alliages de cuivre - Analyse par spectrométrie d'émission optique avec source à plasma induit par haute fréquenceCopper and copper alloys - Inductively coupled plasma optical emission spectrometry77.120.30Baker in bakrove zlitineCopper and copper alloysICS:Ta slovenski standard je istoveten z:EN 15605:2010SIST EN 15605:2010en,de01-oktober-2010SIST EN 15605:2010SLOVENSKI

STANDARDSIST-TS CEN/TS 15605:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15605

July 2010 ICS 77.120.30 Supersedes CEN/TS 15605:2007English Version

Copper and copper alloys - Inductively coupled plasma optical emission spectrometry

Cuivre et alliages de cuivre - Analyse par spectrométrie d'émission optique avec source à plasma induit par haute fréquence

Kupfer und Kupferlegierungen - Optische Emissionsspektrometrie mit induktiv gekoppelter Plasmaanregung This European Standard was approved by CEN on 12 June 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15605:2010: ESIST EN 15605:2010

Optical emission spectrometer (OES) — Suggested performance criteria to be checked . 41Annex B (informative)

Inductively coupled plasma emission spectrometry method for the analysis of Copper-tin-lead alloys . 43Bibliography . 49 SIST EN 15605:2010

CEN/TS 15605, Copper and copper alloys — Inductively coupled plasma optical emission spectrometry In comparison with the first edition of CEN/TS 15605:2007, the following significant technical changes were made: Revision from a Technical Specification to a European Standard; Method G (specifying the analysis of Copper-tin-lead alloys) is edited under an informative basis (see An-nex B), taking into account the mediocrity of the precision criteria related to this method; Precision criteria for methods A and E were added; Precision criteria for methods B, C, D and F were improved and up-dated. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom. SIST EN 15605:2010

% min. max. Sn 0,02 0,60 Pb 0,02 0,60 Zn 0,02 0,60 Fe 0,01 0,60 Ni 0,01 0,60 Mn 0,01 0,60 Al 0,02 0,60 P 0,01 0,40 Be 0,01 0,60 Co 0,01 0,60 Cd 0,01 0,60

Table 2 — Copper-zinc alloys Element Mass fraction

% min. max. Sn

0,05

2,00 Pb

0,03

4,00 Zn 10,00 42,00 Fe

0,01

5,00 Ni

0,02

4,00 Mn

0,01

6,00 P

0,01

0,40 Al

0,02

9,00 As

0,01

0,20

% min. max. Sn 3,00 16,00 Pb 0,01

9,00 Zn 0,03

6,00 Fe 0,01

1,00 Ni 0,05

7,00 Mn 0,01

0,40 P 0,01

0,60 Al 0,01

0,50 Sb 0,02

1,60 As 0,02

0,25

Table 4 — Copper-aluminium alloys Element Mass fraction

% min. max. Sn 0,02

0,50 Pb 0,03

0,50 Zn 0,03

1,00 Fe 0,05

7,00 Ni 0,10

8,00 Mn 0,01

5,00 Al 6,00 14,00 Cd 0,01

0,50 Mg 0,002

0,15

Table 5 — Copper-beryllium alloys Element Mass fraction

% min. max. Sn 0,02 0,20 Pb 0,01 0,20 Zn 0,03 0,20 Fe 0,03 0,30 Ni 0,04 2,50 Mn 0,006 0,15 Al 0,03 0,20 Be 0,08 4,00 Co 0,03 4,00 SIST EN 15605:2010

% min. max. Sn 0,10

0,50 Pb 0,03

0,50 Zn 0,04

2,00 Fe 0,10

4,00 Ni 7,00 35,00 Mn 0,02

3,00 Al 0,02

0,50 NOTE 1 The ranges specified for each method can be extended or adapted, for the determination of lower mass frac-tions. NOTE 2 Other elements may be included. However such elements and their mass fractions should be carefully checked, taking into account interference, sensitivity, resolution and linearity criteria for each instrument and each wave-length. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated refer-ences, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 1811-1, Copper and copper alloys — Selection and preparation of samples for chemical analysis — Part 1: Sampling of cast unwrought products ISO 1811-2, Copper and copper alloys — Selection and preparation of samples for chemical analysis — Part 2: Sampling of wrought products and castings 3 Principle Dissolution of a test portion with hydrochloric and nitric acids. After suitable dilution and addition of an internal reference element, nebulization of the solution into an inductively coupled plasma emission spectrometer and measurement of the intensity of the emitted light, including that of the internal reference element. 4 Reagents During the analysis, use only reagents of recognised analytical grade and only distilled water or water of equivalent purity. The same reagents should be used for the preparation of calibration solutions and of sample solutions. 4.1 Hydrochloric acid, HCl (ρ = 1,19 g/ml) SIST EN 15605:2010

1 ml of this solution contains 1 mg of P. 4.29 Tin stock solution, 10 g/l Sn Weigh (5 ± 0,001) g of tin (Sn ≥ 99,99 %) and transfer into a 400 ml beaker. Add 50 ml of hydrochloric acid (4.1) and cover with a watch glass. Heat gently until the metal is dissolved. After cooling to room temperature, transfer the solution quantitatively into a 500 ml one-mark volumetric flask, dilute to the mark with water and mix well. 1 ml of this solution contains 10 mg of Sn. 4.30 Tin stock solution, 5 g/l Sn Weigh (2,5 ± 0,001) g of tin (Sn ≥ 99,99 %) and transfer into a 400 ml beaker. Add in 50 ml of hydrochloric acid (4.1) and cover with a watch glass. Heat gently until the metal is dissolved. After cooling to room tem-perature, transfer the solution quantitatively into a 500 ml one-mark volumetric flask, dilute to the mark with water and mix well. 1 ml of this solution contains 5 mg of Sn. SIST EN 15605:2010

7.1.3.1.3 Preparation of the 1 g/l calibration solutions Dilute accurately the 5 g/l calibration solutions (7.1.3.1.2) in order to obtain 1 g/l calibration solutions. Pipette exactly 20 ml of the 5 g/l calibration solutions (7.1.3.1.2) into 100 ml one-mark volumetric flasks each containing 5 ml of hydrochloric acid (4.1) and 5 ml of yttrium solution (4.34). Dilute to the mark with water and mix well. SIST EN 15605:2010

b 5 ml of a 0,1 g/l tin stock solution. m 1 ml of a 0,1 g/l phosphorus stock solution. c 5 ml of a 0,1 g/l lead stock solution. n 5 ml of a 0,1 g/l phosphorus stock solution.

d 2 ml of a 0,1 g/l lead stock solution. o 5 ml of a 0,1 g/l aluminium solution. e 2 ml of a 0,1 g/l zinc stock solution. p 2 ml of a 0,1 g/l aluminium stock solution.

f 5 ml of a 0,1 g/l zinc stock solution.

q 5 ml of a 0,1 g/l beryllium stock solution.

g 5 ml of a 0,1 g/l iron stock solution.

r 1 ml of a 0,1 g/l beryllium stock solution.

h 1 ml of a 0,1 g/l iron stock solution.

s 1 ml of a 0,1 g/l cobalt stock solution.

i 1 ml of a 0,1 g/l nickel stock solution. t 5 ml of a 0,1 g/l cobalt stock solution.

j 5 ml of a 0,1 g/l nickel stock solution. u 1 ml of a 0,1 g/l cadmium stock solution.

k 1 ml of a 0,1 g/l manganese stock solution. v 5 ml of a 0,1 g/l cadmium stock solution.

7.1.3.3 Spectrometric measurements of the calibration solutions Carry out the spectrometric measurements of the 1 g/l solutions identified P1, P2, P3 (see Table 7 and 7.1.3.1.3). For phosphorus use the 5 g/l calibration solutions (7.1.3.1.2). A simultaneous spectrometer shall be available for measurements using yttrium as "internal standard" (ratio mode). For phosphorus determination use "absolute intensity" taking into account that "Gaussian" measuring mode may also be recommended. For each calibration solution (including the "drift survey" solution) at least three integrations are necessary in order to calculate the mean ratioed intensities (mean absolute intensity for phosphorus). In order to control the drift of the spectrometer, analyse the "drift survey" solution (see Table 7 and 7.1.3.1.3) at least once for every five test portion solutions. Maximum drift allowed is given in Table 9. Table 9 — Drift survey for coppers Element Concentration range% Maximum drift % all 0,1 to 0,5 0,02

7.2.3.1.3 Preparation of the 1 g/l calibration solutions Dilute accurately the 5 g/l calibration solutions (7.2.3.1.2) in order to obtain 1 g/l calibration solutions. Pipette exactly 20 ml of the 5 g/l calibration solutions (7.2.3.1.2) into 100 ml one-mark volumetric flasks each containing 5 ml of hydrochloric acid (4.1) and 5 ml of yttrium solution (4.34). Dilute to the mark with water and mix well. SIST EN 15605:2010

b 3 ml of a 0,1 g/l lead stock solution. h 2 ml of a 0,1 g/l aluminium stock solution. c 1 ml of a 0,1 g/l iron stock solution. i 1 ml of a 0,5 mg/l aluminium stock solution.

d 2 ml of a 0,1 g/l nickel stock solution. j 1 ml of a 0,1 g/l arsenic stock solution. e 1 ml of a 0,1 g/l manganese stock solution. k 2 ml of a 0,1 g/l arsenic stock solution.

f 5 ml of a 0,1 g/l phosphorus stock solution.

l 5 ml of a 0,1 g/l arsenic stock solution.

7.2.3.2 Adjustment of the apparatus Start the inductively coupled plasma optical emission spectrometer and let it run for at least half an hour be-fore performing any measurements. Adjust all the instrumental parameters, each gas (outer, intermediate or central) flow rate, torch position, entrance slits, exit slits, photomultiplier tubes voltages (when appropriate), wavelengths of the analytical lines specified in Table 11, pre-spraying time and integrating time, according to the manufacturer's instructions, while aspirating (for each element) the highest concentration calibration solutions. Prepare the software for the measurement of the intensity of each analytical line and for the calculation of the corresponding mean value and relative standard deviation. Each time the internal standard is used (Y line 371,03 nm) prepare the software to calculate the ratio between each analyte intensity and internal standard intensity. SIST EN 15605:2010

7.2.3.3 Spectrometric measurements of the calibration solutions Carry out the spectrometric measurements of the 1 g/l solutions identified L1, L4, L6, L7 for all the elements except zinc (see Table 10 and 7.2.3.1.2). For phosphorus and arsenic use the 5 g/l calibration solutions (7.2.3.1.3). For zinc calibration follow, as indicated hereafter: Zinc contents between 10 % and 25 %: use L4, L6 and L7; Zinc contents between 25 % and 42 %: use L1, L4 and L6. A simultaneous spectrometer shall be available for measurements using yttrium as "internal standard" (ratio mode). For phosphorus and arsenic determination, use "absolute intensity" taking into account that "Gaussian" meas-uring mode may also be recommended. For each calibration solution (including the "drift survey" solution) at least three integrations are necessary in order to calculate the mean ratioed intensities (mean absolute intensity for phosphorus and arsenic). In order to control the drift of the spectrometer, analyse the "drift survey" solution (see Table 10 and 7.2.3.1.3) at least once for every five test portion solutions. Maximum drifts allowed are given in Table 12. Table 12 — Drift survey for copper-zinc alloys Element Concentration range % Maximum drift % all

0,5 to 2,0

0,05

2,0 to 10,0

0,1 10,0 to 50,0

0,2

7.3.3.1.3 Preparation of the 1 g/l calibration solutions Dilute accurately the 5 g/l calibration solutions (7.3.3.1.2) in order to obtain 1 g/l calibration solutions. Pipette exactly 20 ml of the 5 g/l calibration solutions (7.3.1.2) into a 100 ml one-mark volumetric flasks each containing 5 ml of hydrochloric acid (4.1) and 5 ml of yttrium solution (4.34). Dilute to the mark with water and mix well. SIST EN 15605:2010

b 3 ml of a 0,1 g/l zinc stock solution.

h 5 ml of a 0,1 g/l manganese stock solution

c 1 ml of a 0,1 g/l iron stock solution. i 5 ml of a 0,1 g/l aluminium stock solution d 5 ml of a 0,1 g/l nick

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...