EN 1888-1:2018

(Main)Child care articles - Wheeled child conveyances - Part 1: Pushchairs and prams

Child care articles - Wheeled child conveyances - Part 1: Pushchairs and prams

This European Standard specifies the safety requirements and test methods for pushchairs and prams, designed for the carriage of one or more children, up to 15 kg each and up to 20 kg for any integrated platform on which a child can stand.

This European Standard does not cover toys, baby carriers fitted with wheels; pushchairs and prams propelled by a motor and pushchairs and prams designed for children with special needs.

Where a pushchair or pram or any part of the pushchair or pram has several functions or can be converted into another function it is due to comply with relevant standard(s).

Artikel für Säuglinge und Kleinkinder - Transportmittel auf Rädern für Kinder - Teil 1: Kinderwagen und Kinderwagenaufsätze

Diese Europäische Norm legt die sicherheitstechnischen Anforderungen an und die Prüfverfahren für Kindersportwagen und Kinderwagen fest, die für die Beförderung eines Kindes oder mehrerer Kinder bis jeweils 15 kg und bis zu 20 kg für eine integrierte Plattform, auf der ein Kind stehen kann, vorgesehen sind.

Diese Europäische Norm gilt nicht für Spielzeugkinderwagen, Babytragehilfen mit Rädern; motorbetriebene Kindersportwagen und Kinderwagen sowie Kindersportwagen und Kinderwagen, die für Kinder mit besonderen Bedürfnissen hergestellt sind.

Wenn ein Kindersportwagen oder Kinderwagen mehrere Funktionen besitzt oder zum Zweck einer anderen Funktion umgebaut werden kann, muss er die Anforderungen der jeweiligen Normen erfüllen.

Articles de puériculture - Voitures d’enfant - Partie 1 : Poussettes et landaus

La présente Norme européenne spécifie les exigences de sécurité et les méthodes d’essai relatives aux poussettes et landaus destinés au transport d’un ou plusieurs enfants, pesant jusqu’{ 15 kg chacun, et jusqu’{ 20 kg pour toute plate-forme intégrée sur laquelle un enfant peut se tenir debout.

La présente Norme européenne ne concerne ni les jouets, ni les porte-enfants munis de roues, ni les poussettes et landaus propulsés par un moteur, ni les poussettes et landaus destinés aux enfants ayant des besoins spécifiques.

Lorsqu’une poussette ou un landau ou toute partie de cette poussette ou ce landau possède plusieurs fonctions ou peut être converti(e) en une autre fonction, il/elle doit être conforme à ou aux normes pertinentes.

Izdelki za otroke - Otroški vozički - 1. del: Otroški vozički s sedežem in otroški vozički s košaro

Ta osnutek evropskega standarda določa varnostne zahteve in preskusne metode za otroške vozičke, namenjene prevozu enega ali več otrok, ki tehtajo do 15 kg, pri čemer lahko na morebitno pritrjeno ploščad stopi otrok, ki tehta do 20 kg.

Ta osnutek evropskega standarda ne zajema igrač, nakupovalnih vozičkov, opreme za nošenje otroka, opremljene s kolesi, otroških vozičkov, ki jih poganja motor, in vozičkov, namenjenih otrokom s posebnimi potrebami.

Kadar obstajajo dodatni izdelki, ki se pritrdijo na otroški voziček, naj bi se izvedla analiza nevarnosti in tveganj, da se opredelijo vse morebitne nevarnosti.

Kadar ima otroški voziček ali kateri koli del otroškega vozička več funkcij ali ga je mogoče spremeniti v drugo funkcijo, mora biti skladen z ustreznimi standardi.

General Information

- Status

- Withdrawn

- Publication Date

- 18-Dec-2018

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 252 - Child use and care articles

- Drafting Committee

- CEN/TC 252/WG 3 - Wheeled transportation

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 20-Apr-2022

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 26-Dec-2018

- Effective Date

- 19-Jan-2023

- Effective Date

- 04-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 25-Dec-2019

Frequently Asked Questions

EN 1888-1:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Child care articles - Wheeled child conveyances - Part 1: Pushchairs and prams". This standard covers: This European Standard specifies the safety requirements and test methods for pushchairs and prams, designed for the carriage of one or more children, up to 15 kg each and up to 20 kg for any integrated platform on which a child can stand. This European Standard does not cover toys, baby carriers fitted with wheels; pushchairs and prams propelled by a motor and pushchairs and prams designed for children with special needs. Where a pushchair or pram or any part of the pushchair or pram has several functions or can be converted into another function it is due to comply with relevant standard(s).

This European Standard specifies the safety requirements and test methods for pushchairs and prams, designed for the carriage of one or more children, up to 15 kg each and up to 20 kg for any integrated platform on which a child can stand. This European Standard does not cover toys, baby carriers fitted with wheels; pushchairs and prams propelled by a motor and pushchairs and prams designed for children with special needs. Where a pushchair or pram or any part of the pushchair or pram has several functions or can be converted into another function it is due to comply with relevant standard(s).

EN 1888-1:2018 is classified under the following ICS (International Classification for Standards) categories: 97.190 - Equipment for children. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1888-1:2018 has the following relationships with other standards: It is inter standard links to EN 1888:2012, EN 1888-1:2018+A1:2022, EN 71-1:2026, EN 71-3:2019+A2:2024, EN 71-2:2011+A1:2014, EN 71-1:2014+A1:2018, EN 1888-2:2018+A1:2022, EN 1888-2:2018, EN 1888-1:2018/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1888-1:2018 is associated with the following European legislation: EU Directives/Regulations: 812/2013, 814/2013; Standardization Mandates: M/264. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1888-1:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Artikel für Säuglinge und Kleinkinder - Transportmittel auf Rädern für Kinder - Teil 1: Kinderwagen und KinderwagenaufsätzeArticles de puériculture - Voitures d'enfant - Partie 1 : Poussettes et landausChild care articles - Wheeled child conveyances - Part 1: Pushchairs and prams97.190Otroška opremaEquipment for childrenICS:Ta slovenski standard je istoveten z:EN 1888-1:2018SIST EN 1888-1:2019en,fr,de01-april-2019SIST EN 1888-1:2019SLOVENSKI

STANDARDSIST EN 1888:20121DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1888-1

December

t r s z ICS

{ yä s { r Supersedes EN

s z z zã t r s tEnglish Version

Child use and care articles æ Wheeled child conveyances æ Part

sã Pushchairs and prams Articles de puériculture æ Voitures d 5enfant æ Partie

s ã Poussettes et landaus

Artikel für Säuglinge und Kleinkinder æ Transportmittel auf Rädern für Kinder æ Teil

sã Kinderwagen und Kinderwagenaufsätze This European Standard was approved by CEN on

t u April

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s z z zæ sã t r s z ESIST EN 1888-1:2019

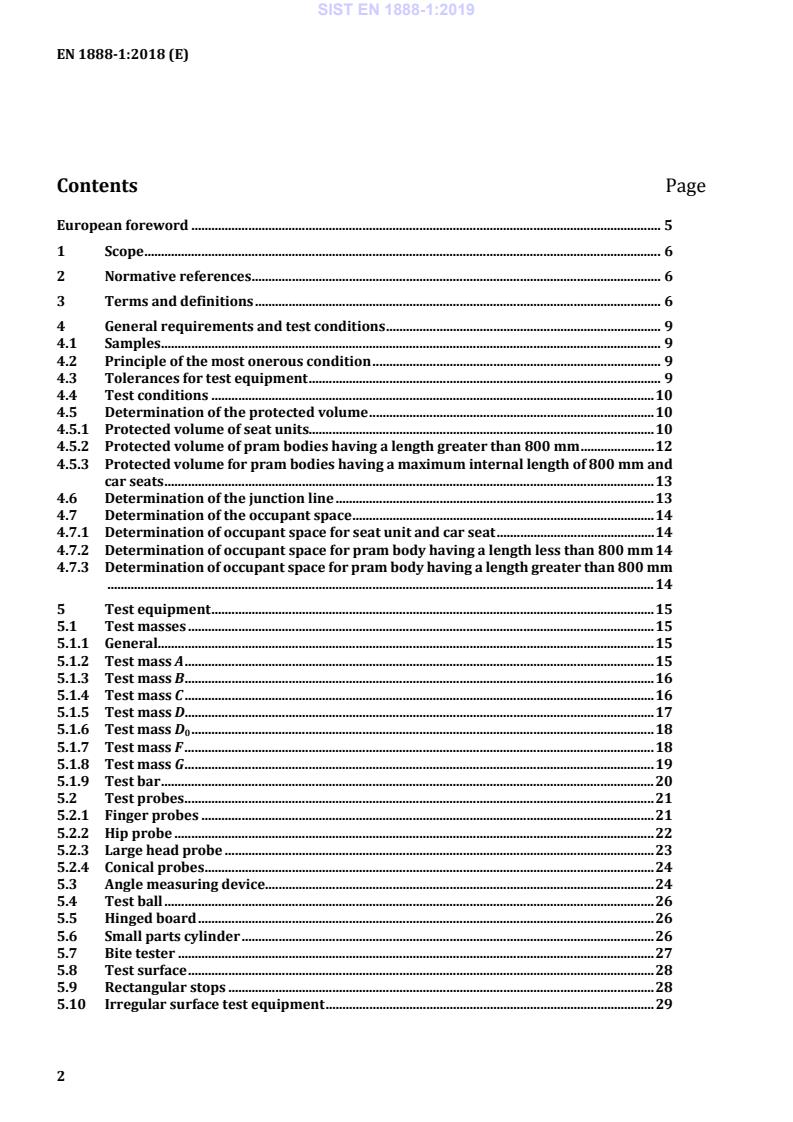

Rationales . 69 A.1 General. 69 A.2 Chemical hazards (see Clause 6) . 69 A.3 Thermal hazards (see Clause 7) . 69 A.4 Mechanical hazards (see Clause 8) . 69 A.4.1 General. 69 A.4.2 Protective function (see 8.1) . 69 A.4.3 Entrapment hazards (see 8.2) . 69 A.4.4 Hazards from moving parts (see 8.3) . 70 A.5 Entanglement hazards (see 8.4) . 71 A.6 Choking and ingestion hazards (see 8.5) . 72 A.7 Suffocation hazards (see 8.6) . 72 A.8 Hazardous edges and protrusions (see 8.7) . 72 A.9 Parking and braking devices (see 8.8) . 72 A.10 Stability (see 8.9) . 72 A.11 Structural integrity (see 8.10) . 72 A.12 Purchase information (see 10.3) . 73 Annex B (informative)

Examples of articulated arms to maintain the vehicle on the rig for the irregular surface test . 74 Annex C (informative)

Guideline for the application of 8.3.5.1.1.3 “Unintentional release of locking mechanism(s)” . 76 C.1 Relevant definitions . 76 C.2 Guidelines for the application of 8.3.5.1.1.3 “Unintentional release of locking mechanism(s)” . 76 C.2.1 General. 76 C.2.2 Products fitted with one single operating device (products that may be fold using only one hand) . 76 C.2.3 Products fitted with two operating devices . 77 C.2.4 Products having three or more operating devices . 78 C.2.5 Products covered by different requirements . 78 Annex D (informative)

Examples of moving parts of the canopies inside 100 mm from the pivot point . 80 D.1 Case A . 80 D.2 Case B . 81 D.3 Case C . 82 Annex E (informative)

Translation of Warnings in different European languages . 83 Annex F (informative)

A–deviations . 109 Annex G (informative)

Child restraint systems: arrangement of approval marks . 110 Bibliography . 111

t Ů s {á and conflicting national standards shall be withdrawn at the latest by December

t Ů s {ä Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN shall not be held responsible for identifying any or all such patent rights. This document supersedes EN 1888:2012. In comparison with this EN 1888:2012, the significant technical changes relate to the following issues: a) chemical hazards; b) entrapment hazards; c) hazards from moving parts; d) entanglement hazards; e) parking device test method; f) stability of the vehicle; g) introduction of an informative Annex E giving relevant translations for warning sentences; h) introduction of an informative Annex D giving information on the assessment of moving parts of canopies; i) introduction of an informative Annex G giving information on the arrangement of approval marks for car seats. In November 2014, the European Working Group decided to split EN 1888 into different parts to clearly treat in a different way, new products or new functions of wheeled child conveyances. EN 1888 is currently composed with the following parts: — EN 1888-1, Child care articles — Wheeled child conveyances — Part 1: Pushchairs and prams; — EN 1888-2, Child care articles — Wheeled child conveyances — Part 2: Pushchairs for children above 15 kg up to 22 kg. EN 1888 therefore becomes EN 1888-1 and is only applicable to pushchairs and prams. It will be used as a reference in future parts. According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 1888-1:2019

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp

3.1 wheeled child conveyance vehicle designed for the carriage of one or more children which can be manually steered while being pushed or pulled 3.2 pushchair vehicle comprising a chassis and one or more seat units or car seats Note 1 to entry: Referred to as the “vehicle” for the purpose of this standard. 3.3 pram vehicle comprising a chassis and one or more pram bodies Note 1 to entry: Referred to as the “vehicle” for the purpose of this standard. 3.4 integrated platform integral part of the vehicle designed to support an additional child in a standing position SIST EN 1888-1:2019

{ kg according to Regulation ECE R44 (group 0) or Regulation ECE R s t { Note 1 to entry: Child Restraint Systems are covered by UNECE regulations. Note 2 to entry: Arrangement of approval marks is shown in Annex G 3.8 type B car seat Child Restraint System (CRS) used for children up to 13 kg according to Regulation ECE R44 (group 0+) or Regulation ECE R s t { Note 1 to entry:

Child Restraint Systems are covered by UNECE regulations. Note 2 to entry: Arrangement of approval marks is shown in Annex G. 3.9 pram body structure with essentially vertical and continuous sides and ends with an internal base designed to transport one or more children in a primarily horizontal position 3.10 protected volume volume accessible by the child (occupant) when sitting or lying in the pushchair or pram, where specific safety requirements are necessary 3.11 junction line intersection of the seat and the backrest 3.12 restraint system system to restrain the child within the vehicle 3.13 crotch restraint device positioned between the child’s legs to prevent the child from sliding forwards 3.14 harness anchorage point device suitable for the attachment of an additional child’s harness SIST EN 1888-1:2019

Key 1 origin from which the protected volume has been defined (mid-point of the junction line, on the uncompressed upper surface of the seat unit) 2 seat 3 back rest 4 leg rest Figure 1 — Protected volume for seat units The space located behind the backrest is excluded from the protected volume. Where a vehicle is suitable for two or more children the space located behind the backrest shall be considered if it enters another protected volume. The space underneath the seat and underneath the leg rest is excluded from the protected volume, except for a 50 mm wide band measured from the outermost edge of the seat/leg rest sides where the seat/leg rest is not fitted with lateral protections of a height greater than 50 mm (textile or any rigid component) (see Figure 2). SIST EN 1888-1:2019

Key 1 space to be checked 2 space not to be checked 3 leg rest 4 seat 5 backrest Figure 2 — Effect of lateral protection on the determination of the protected volume 4.5.2 Protected volume of pram bodies having a length greater than 800 mm The protected volume of pram bodies having a length greater than 800 mm shall be determined in accordance with Figure 3. The 550 mm height shall be measured in accordance with 8.1.2.2. The surface underneath the pram body is excluded from the protected volume. Dimensions in millimetres

Figure 3 — Protected volume for pram bodies having a length greater than 800 mm SIST EN 1888-1:2019

Key LL junction line 1 backrest 2 seat Figure 4 — Junction line When the seat unit is in the form of a hammock, then a theoretical junction line, “LL”, is determined as shown in Figure 5.

Key LL junction line L vertical projection of C on the hammock Figure 5 — Junction line for seat unit in form of a hammock NOTE The junction line may vary when the backrest is adjusted to different positions. SIST EN 1888-1:2019

Figure 6 — Occupant space for seat unit and car seat 4.7.2 Determination of occupant space for pram body having a length less than 800 mm For vehicles designed only for children under 6 months of age, pram bodies with a maximum internal length of 800 mm, the occupant space is considered to be the volume of the inner upper surface that supports the child and the inner surface of the sides and ends of the pram body. See Figure 7.

Key 1 occupant space Figure 7 — Occupant space for pram body having a length less than 800 mm 4.7.3 Determination of occupant space for pram body having a length greater than 800 mm For pram bodies with a internal length greater than 800 mm, the occupant space is considered to be the volume of the inner upper surface that supports the child and the inner surface of the sides and ends of the pram body up to 550 mm above. See Figure 8. SIST EN 1888-1:2019

Key 1 occupant space Figure 8 — Occupant space for pram body having a length greater than 800 mm 5 Test equipment 5.1 Test masses 5.1.1 General Unless otherwise specified, the test masses shall be those given in

wä sä t to

wä sä {. Any damage to fabric which may occur as a result of abrasion by the test masses during tests shall be ignored. Damage can be minimized by using a convenient means of protection of negligible mass. Where damage is not caused by abrasion by the test masses it constitutes a structural failure. Test masses may be fitted with additional handles for carrying purposes, as long as the centre of gravity is not changed and mass remains within tolerances and the test procedure is not affected. 5.1.2 Test mass A Test mass A is a rigid cylinder (160 ± 5) mm in diameter and (300 ± 5) mm in height, having a mass of

+ 0, 1/0) kg and with its centre of gravity in the centre of the cylinder. All edges shall have a radius of (5 ± 1) mm. Two anchorage points shall be provided, positioned (150 ± 2,5) mm from the base and at 180° to each other around the circumference as shown in Figure

{. SIST EN 1888-1:2019

Key 1 radius: (5 ± 1) mm 2 two anchorage points Figure 9 — Test mass A 5.1.3 Test mass B Test mass B is a rigid cylinder (200 ± 5) mm in diameter and (300 ± 5) mm in height, having a mass of (15 + 0, 1/0) kg and with its centre of gravity in the centre of the cylinder. All edges shall have a radius of (5 ± 1) mm. Two anchorage points shall be provided, positioned (150 ± 2,5) mm from the base and at 180° to each other around the circumference (see Figure 10). Dimensions in millimetres

Key 1 radius: (5 ± 1) mm 2 two anchorage points Figure 10 — Test mass B 5.1.4 Test mass C Test mass C is a rigid plate (600 ± 5) mm long and (180 ± 5) mm wide, having a minimum thickness of 5

+ 0, 1/0) kg hinged along the centre line (see Figure 11). SIST EN 1888-1:2019

Key 1 hinge line Figure 11 — Test mass C 5.1.5 Test mass D Test mass D

é 0Č1) kg (sŠŠ FiguŮŠ 1É). DimŠnsions in millimŠtŮŠs

TolŠŮŘncŠs: u dimŠnsions é É mm; u ŘnglŠs é É°; u whŠŮŠ shownČ coŮnŠŮ ŮŘdii shŘll bŠ (10 é 1) mm. Figure 12 — Test mass D SIST EN 1888-1:2019

Tolerances: — dimensions ± 2 mm; — angles ± 2 °; — where shown, corner radii shall be (10 ± 1) mm. Figure 13 — Test mass D0 5.1.7 Test mass F Test mass F is a rigid cylinder (180 ± 5) mm in diameter and (300 ± 5) mm in height, having a mass of (13 + 0, 1/0) kg and with its centre of gravity in the centre of the cylinder. All edges shall have a radius of (5 ± 1) mm. Two anchorage points shall be provided. These shall be positioned (150 ± 2,5) mm from the base and at 180° to each other around the circumference (see Figure 14). SIST EN 1888-1:2019

Key 1 radius (5 ± 1) mm 2 anchorage points Figure 14 — Test mass F 5.1.8 Test mass G Test mass G comprises two identical parts made of steel and with the dimensions given in Figure 15. Each part shall have a mass of (10 +

kg. SIST EN 1888-1:2019

Key 1 Side view 2 Front view Figure 15 — Test mass G The distance between the two identical parts of test mass G shall be adjusted in accordance with the shape and dimensions of the integrated platform that is tested. A rigid bar of negligible mass shall be used to maintain the test mass along the integrated platform and both parts shall be maintained apart from each other by any connecting means of negligible mass. 5.1.9 Test bar Rigid square bar with a cross section of (25 × 25) mm, having a length greater than the length of the pram body and a mass of 0,75 kg. SIST EN 1888-1:2019

Key 1 hemispherical end 2 scribed line around circumference 3 Ø 5 mm 7 mm and 12 mm Figure 16 — Probes with hemispherical end 5.2.1.2 Shape assessment probe Probe made from plastics or other hard, smooth material with the dimensions shown in Figure 17. Dimensions in millimetres

Figure 17 — Shape assessment probe SIST EN 1888-1:2019

Figure 18 — conical probe for mesh The tolerance on the radius is ± 0,2 mm. 5.2.2 Hip probe The hip probe shall be made from plastics or other hard, smooth material with the dimensions given in Figure

s {. SIST EN 1888-1:2019

Key H handgrip Tolerances on dimensions: — 65 (0 / –0,5) mm — 105 (0 /–0,5) mm All other dimensions shall be ± 1 mm. Figure 19 — Hip probe 5.2.3 Large head probe The large head probe shall be made from plastic or other hard smooth material, with dimensions as shown in Figure 20. SIST EN 1888-1:2019

Key 1 handgrip All dimensions shall be ± 1 mm. Figure 20 — Large head probe 5.2.4 Conical probes Probes made from plastics or other hard smooth material of diameters (12 + 0,1/0) mm, (25 0 / –0,1) mm and (45 + 0,1 / 0) mm with one conical end (with an angle of 30°), that can be mounted on a force measuring device (see Figure 21). Dimensions in millimetres

Figure 21 — Conical probes 5.3 Angle measuring device Í

{ kg articulated steel device used to measure the angle between the seat and the backrest (see Figure 22). SIST EN 1888-1:2019

Key 1 part to be placed onto the seat surface made of steel 2 part to be placed onto the backrest surface made of steel 3 hinge pin made of steel E

± 50) g F mass:(4501 ± 50) g G mass of hinge axle: (17 ±

mm

± 0,1) kg dimensions tolerance: ± 2 mm All edges shall be chamfered. Figure 22 — Angle measuring device SIST EN 1888-1:2019

Key 1 hole Ø 3 mm 2 steel cable Ø 1,5 mm 3 tube Ø 25 mm 4 tube Ø 25 mm 5 steel cable Ø1,5 mm 6 cable ends cycle type 7 total length = 13 tubes Length of each tube: 60 mm Figure 23 — Hinged board 5.6 Small parts cylinder Cylinder having dimensions as shown in Figure 24. SIST EN 1888-1:2019

Figure 24 — Small parts cylinder 5.7 Bite tester The bite tester, see Figure 25, consists of two sets of teeth, see Figure 26, made from H13 high chrome tool steel or equivalent and hardened to 45-50 Rockwell C. There are two teeth at the top and two at the bottom of the bite tester, positioned so that the vertical centre line of one pair of teeth is (1 ± 0,1) mm in front of the centre line of the other set of teeth. In the fully closed position, the teeth shall overlap each other by (1 ± 0,1) mm. The outer most corners of the teeth shall have a radius of (0,3 ± 0,1) mm. The teeth shall be mounted so as to pivot about a point (50 ± 1) mm from the rear most pair of teeth and positioned so that when closed the centre lines of the two pairs of teeth are parallel to each other. The bite tester shall be equipped with a stop to prevent the distance between the teeth from exceeding (28 ± 1) mm when fully opened. The closing force of the teeth shall be set at (50 ± 5) N. The bite tester shall be provided with a guide to prevent items entering further into the fully opened jaws by more than (17 ± 1) mm. The bite tester shall be equipped with a means whereby a force of (50 ± 5) N may be applied along its centre line in a direction tending to pull the teeth off the sample. SIST EN 1888-1:2019

Key 1 position of guide 2 pivot point Figure 25 — Bite tester Dimensions in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...