prEN 1518

(Main)Non-destructive testing - Leak testing - Characterization of mass spectrometer leak detectors

Non-destructive testing - Leak testing - Characterization of mass spectrometer leak detectors

This document specifies terms and procedures for the characterization of mass spectrometer leak detectors (MSLD). It is not intended to give a complete set of specifications for an acceptance test but a description of procedures that can be used without particular calibration equipment.

The methods described in this document are applicable without restrictions to helium as the tracer gas. For other gases, additional precautions may be necessary.

These methods are applicable to commonly available MSLD, based on the present level of technology, which may be able to measure leakage rates down to 10−12 Pa⋅m3/s.

Zerstörungsfreie Prüfung - Dichtheitsprüfung - Charakterisierung von massenspektrometrischen Leckdetektoren

Dieses Dokument legt Begriffe und Verfahren für die Charakterisierung von massenspektrometrischen Leckdetektoren (MSLD) fest. Es soll kein kompletter Satz von Spezifikationen für einen Abnahmetest angegeben werden, sondern es werden Vorgehensweisen beschrieben, die ohne spezielle Kalibrierausrüstung angewendet werden können.

Die in diesem Dokument beschriebenen Methoden sind ohne Einschränkungen auf Helium als Prüfgas anwendbar. Für andere Gase können zusätzliche Vorsichtsmaßnahmen notwendig sein.

Die hier beschriebenen Methoden sind auf allgemein erhältliche MSLD des heutigen Standes der Technik anwendbar, die Leckageraten bis herab zu 10−12 Pa·m3/s messen können.

Essais non destructifs - Contrôle d’étanchéité - Caractérisation des détecteurs de fuite à spectrométrie de masse

Le présent document spécifie les méthodes et termes permettant de caractériser les détecteurs de fuites à spectrométrie de masse (DFSM). Il n’a pas pour objet de donner un ensemble complet de spécifications en vue d’un essai de réception, mais une description des procédures qui peuvent être utilisées sans équipement d’étalonnage particulier.

Les méthodes décrites dans le présent document sont applicables sans restriction à l’hélium utilisé comme gaz traceur. Pour d’autres gaz, des précautions supplémentaires peuvent être nécessaires.

Ces méthodes sont applicables aux DFSM couramment disponibles sur le marché, conçus suivant le niveau actuel de la technologie, et qui sont capables de mesurer des flux de fuite de 10−12 Pa⋅m3/s.

Neporušitvene preiskave - Preskus tesnosti – Karakterizacija masno-spektrometričnih detektorjev puščanja

General Information

- Status

- Not Published

- Publication Date

- 21-Dec-2026

- Technical Committee

- CEN/TC 138 - Non-destructive testing

- Drafting Committee

- CEN/TC 138/WG 6 - Leak testing

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Start Date

- 06-Feb-2025

- Due Date

- 28-Jan-2025

- Completion Date

- 06-Feb-2025

Relations

- Effective Date

- 20-Dec-2023

Overview

prEN 1518 (draft 2024) - prepared by CEN/TC 138 - provides standardized terms and procedures for the characterization of mass spectrometer leak detectors (MSLD) used in non-destructive leak testing. The document is intended as a practical set of methods that can be applied without special calibration equipment and is focused on commonly available MSLD technology. Methods are directly applicable to helium tracer gas; other tracer gases may require additional precautions. The standard updates and supersedes EN 1518:1998 and aligns terminology with EN ISO 20484:2017.

Key practical points covered by the standard include assessment of instrument sensitivity, minimum detectable leakage rate, and inlet pumping speed, for instruments capable of measuring leakage rates down to about 10−12 Pa·m3/s.

Key Topics

The standard is structured to support repeatable characterization and reporting. Core topics include:

- Terms and definitions: standardized vocabulary for MSLD components, operating modes and performance metrics (e.g., compression ratio, intrinsic pumping speed, optimum working pressure).

- Description of MSLD: general arrangement, main parts and operating principles for direct-flow and counterflow detectors.

- Apparatus and test arrangements: recommended leaks, test vessel and leak isolation arrangements, auxiliary pumping and materials considerations.

- Reference conditions: ambient temperature, pressure and humidity for repeatable characterization.

- Test procedures and evaluation: procedures for determining minimum detectable leakage rate, minimum detectable concentration, inlet pumping speed, and treatment of background drift/noise and sensitivity.

- Results and reporting: defined evaluation methods and expressions for reporting detection limits, pumping speed and relevant instrument parameters.

Bold emphasis on repeatability and practical application: prEN 1518 prioritizes procedures that can be implemented in routine NDT environments without specialized calibration hardware.

Applications

prEN 1518 is intended for organizations involved in leak testing and instrumentation characterization, including:

- NDT laboratories validating MSLD performance for manufacturing or maintenance

- Equipment manufacturers documenting detector specifications and tuning procedures

- Quality and compliance teams establishing test protocols for helium leak detection

Typical applications include characterizing instrument response time, assessing background signal behavior (drift and noise), verifying sensitivity controls and quantifying the inlet pumping speed that affects test response.

Related Standards

- EN ISO 20484:2017 - Non-destructive testing - Leak testing - Vocabulary (terms referenced by prEN 1518)

- EN 1518:1998 - previous edition that prEN 1518 will supersede

For procurement, test planning and compliance, prEN 1518 should be used in conjunction with general NDT and leak testing guidance documents. The procedures are complementary to manufacturer instructions and national standards that govern test acceptance criteria.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

prEN 1518 is a draft published by the European Committee for Standardization (CEN). Its full title is "Non-destructive testing - Leak testing - Characterization of mass spectrometer leak detectors". This standard covers: This document specifies terms and procedures for the characterization of mass spectrometer leak detectors (MSLD). It is not intended to give a complete set of specifications for an acceptance test but a description of procedures that can be used without particular calibration equipment. The methods described in this document are applicable without restrictions to helium as the tracer gas. For other gases, additional precautions may be necessary. These methods are applicable to commonly available MSLD, based on the present level of technology, which may be able to measure leakage rates down to 10−12 Pa⋅m3/s.

This document specifies terms and procedures for the characterization of mass spectrometer leak detectors (MSLD). It is not intended to give a complete set of specifications for an acceptance test but a description of procedures that can be used without particular calibration equipment. The methods described in this document are applicable without restrictions to helium as the tracer gas. For other gases, additional precautions may be necessary. These methods are applicable to commonly available MSLD, based on the present level of technology, which may be able to measure leakage rates down to 10−12 Pa⋅m3/s.

prEN 1518 is classified under the following ICS (International Classification for Standards) categories: 19.100 - Non-destructive testing. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 1518 has the following relationships with other standards: It is inter standard links to EN 1518:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 1518 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2025

Neporušitveno preskušanje - Preskus tesnosti – Karakterizacija masno-

spektrometričnih detektorjev puščanja

Non-destructive testing - Leak testing - Characterization of mass spectrometer leak

detectors

Zerstörungsfreie Prüfung - Dichtheitsprüfung - Charakterisierung von

massenspektrometrischen Leckdetektoren

Essais non destructifs - Contrôle d’étanchéité - Caractérisation des détecteurs de fuite à

spectrométrie de masse

Ta slovenski standard je istoveten z: prEN 1518

ICS:

19.100 Neporušitveno preskušanje Non-destructive testing

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2024

ICS 19.100 Will supersede EN 1518:1998

English Version

Non-destructive testing - Leak testing - Characterization of

mass spectrometer leak detectors

Essais non destructifs - Contrôle d'étanchéité - Zerstörungsfreie Prüfung - Dichtheitsprüfung -

Caractérisation des détecteurs de fuite à spectrométrie Charakterisierung von massenspektrometrischen

de masse Leckdetektoren

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 138.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 1518:2024 E

worldwide for CEN national Members.

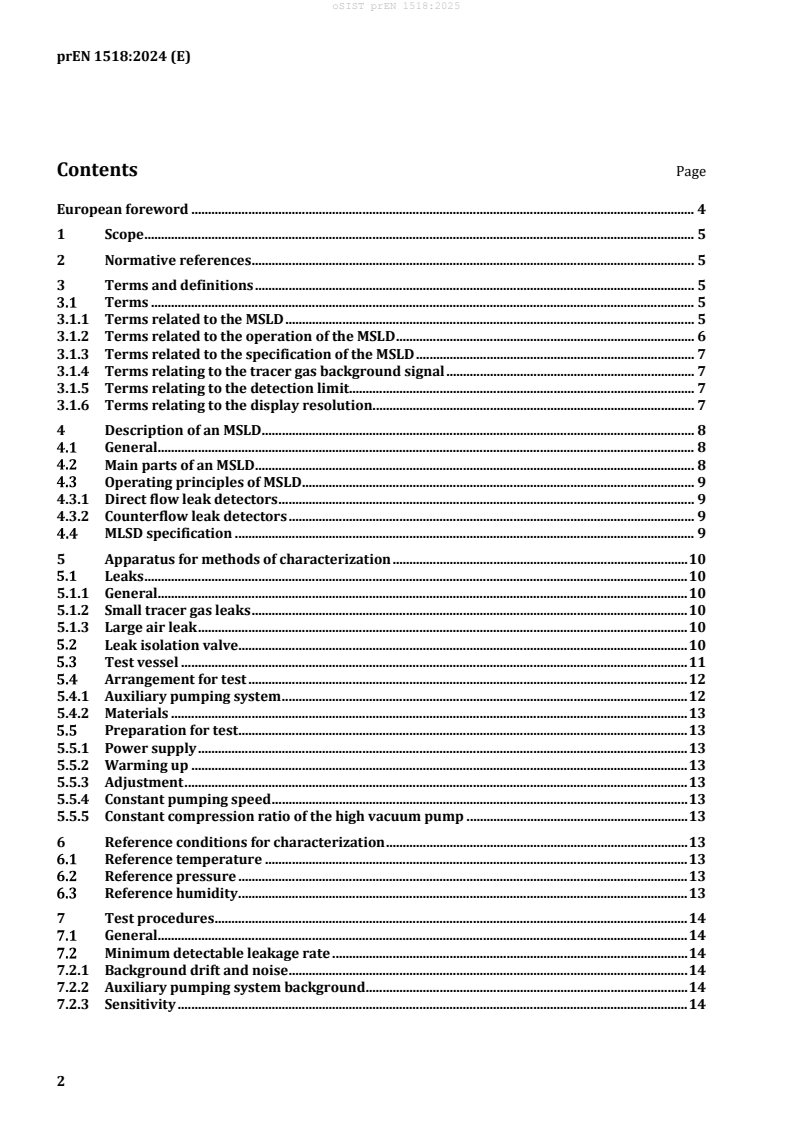

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

Terms . 5

3.1.1 Terms related to the MSLD . 5

3.1.2 Terms related to the operation of the MSLD . 6

3.1.3 Terms related to the specification of the MSLD . 7

3.1.4 Terms relating to the tracer gas background signal . 7

3.1.5 Terms relating to the detection limit. 7

3.1.6 Terms relating to the display resolution . 7

4 Description of an MSLD . 8

General. 8

Main parts of an MSLD . 8

Operating principles of MSLD . 9

4.3.1 Direct flow leak detectors . 9

4.3.2 Counterflow leak detectors . 9

MLSD specification . 9

5 Apparatus for methods of characterization . 10

Leaks . 10

5.1.1 General. 10

5.1.2 Small tracer gas leaks . 10

5.1.3 Large air leak . 10

Leak isolation valve. 10

Test vessel . 11

Arrangement for test . 12

5.4.1 Auxiliary pumping system . 12

5.4.2 Materials . 13

Preparation for test . 13

5.5.1 Power supply . 13

5.5.2 Warming up . 13

5.5.3 Adjustment . 13

5.5.4 Constant pumping speed . 13

5.5.5 Constant compression ratio of the high vacuum pump . 13

6 Reference conditions for characterization . 13

Reference temperature . 13

Reference pressure . 13

Reference humidity . 13

7 Test procedures . 14

General. 14

Minimum detectable leakage rate . 14

7.2.1 Background drift and noise . 14

7.2.2 Auxiliary pumping system background . 14

7.2.3 Sensitivity . 14

7.2.4 Time constant . 15

Minimum detectable concentration . 15

7.3.1 General . 15

7.3.2 Background drift and noise . 17

7.3.3 Background signal . 17

7.3.4 Sensitivity . 17

Inlet pumping speed for tracer gas . 18

8 Results . 18

Minimum detectable leakage rate . 18

8.1.1 Evaluation. 18

8.1.2 Expression of minimum detectable leakage rate . 20

Minimum detectable concentration . 20

8.2.1 Evaluation. 20

8.2.2 Expression of minimum detectable concentration . 21

Inlet pumping speed . 21

8.3.1 Evaluation. 21

8.3.2 Expression of inlet pumping speed . 22

9 Test report . 22

Bibliography . 24

European foreword

This document (prEN 1518:2024) has been prepared by Technical Committee CEN/TC 138 “Non-

destructive testing”, the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 1518:1998.

a) normative references have been updated;

b) clause “Terms and definitions” has been revised;

c) new Subclause 4.1, General, has been added;

d) Clause 5.2 has been updated;

e) in Clause 6.1, the ambient temperature has been adapted;

f) Clause 7 and 8 have been revised;

g) the test report has been revised;

h) the figures have been integrated in the text.

1 Scope

This document specifies terms and procedures for the characterization of mass spectrometer leak

detectors (MSLD). It is not intended to give a complete set of specifications for an acceptance test but a

description of procedures that can be used without particular calibration equipment.

The methods described in this document are applicable without restrictions to helium as the tracer gas.

For other gases, additional precautions may be necessary.

These methods are applicable to commonly available MSLD, based on the present level of technology,

−12 3

which may be able to measure leakage rates down to 10 Pa⋅m /s.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 20484:2017, Non-destructive testing — Leak testing — Vocabulary (ISO 20484:2017)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 20484:2017 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

Terms

3.1.1 Terms related to the MSLD

3.1.1.1

compression ratio

ratio of partial pressure of tracer gas with zero flow at the exhaust of the counterflow stages of the high

vacuum pump to the partial pressure at the inlet of the mass spectrometer (MS)

3.1.1.2

display

device which indicates visually the leakage rate measured

Note 1 to entry: The units in which the leakage rate is expressed can be selectable.

Note 2 to entry: The display can be analogue or quasi-analogue (continuous scale with definite divisions) or digital

(numbers with a definite number of digits) or a combination of both.

3.1.1.3

inlet pumping speed

volume rate of flow at the test port of an MSLD when the instrument is operating with the MS below its

maximum working pressure

Note 1 to entry: The inlet pumping speed can be different for different gases and different modes of operation. The

inlet pumping speed for the tracer gas determines the response time for the volume under test.

3.1.1.4

internal leak port

flange directly behind the inlet valve, used to connect a small leak for zero drift determination

3.1.1.5

intrinsic pumping speed

volume rate of flow of tracer gas at the inlet of the MS in a direct flow leak detector

3.1.1.6

ion collector

part of the MS where ions are collected and neutralized producing a current in the collector which is a

measure of the number of neutralized ions

3.1.1.7

sensitivity control

electrical hardware or software control which may be used to adjust the sensitivity of the instrument so

that a calibrated leak is indicated with its true leakage rate

3.1.1.8

sensitivity

ratio of the ion current at the output of the MS to the corresponding partial pressure of tracer gas inside

the MS

3.1.1.9

zero control

electrical hardware or software control which may be used to shift the output indication of the leak

detector, to a determined point of the scale range in use, usually zero

3.1.2 Terms related to the operation of the MSLD

3.1.2.1

peak

trace showing a maximum when the leak detector is scanned with respect to mass with gas

present, usually the tracer gas, to which the detector is tuned

3.1.2.2

peak

to set the scanning control (see 3.1.2.3) of a leak detector so that the output due to a given tracer

gas input is maximized

Note 1 to entry: It is a form of tuning (see 3.1.2.4).

3.1.2.3

scan

to adjust the accelerating voltage (or other equivalent operating parameter) of a leak detector,

particularly across that range of voltage which includes the voltage necessary to produce a tracer gas

peak

3.1.2.4

tune

in leak detection, to adjust one or more of the controls of a leak detector so that its response to a

tracer gas is maximized

Note 1 to entry: Tuning by means of the scanning control only is called “peaking” (see 3.1.2.2).

3.1.3 Terms related to the specification of the MSLD

3.1.3.1

optimum working pressure

pressure in the MS, at which the minimum detectable concentration can be measured

3.1.3.2

maximum working pressure

pressure in the MS above which operation is no longer possible

3.1.3.3

maximum inlet pressure

maximum pressure at the test port at which the MSLD is able to detect leaks in a given mode of operation

Note 1 to entry: For an MSLD to be connected directly to a system under test, the total pressure in the system shall

be less than the maximum inlet pressure of the MSLD.

3.1.3.4

maximum gas load

maximum pV-throughput of all gases emerging from the test specimen that the MSLD can pump during

leak detection in a given mode of operation

Note 1 to entry: For component testing, the MSLD is normally ready for measurement when the desorption of

water vapour from the inner surfaces is less than the maximum gas load.

3.1.4 Terms relating to the tracer gas background signal

3.1.4.1

background signal drift

relatively slow change in background signal, given by the maximum change in a given period of time

3.1.4.2

background signal noise

relatively rapid change in background signal given by an average measure of scatter in a specified period

of time

3.1.5 Terms relating to the detection limit

3.1.5.1

minimum detectable concentration ratio

smallest concentration of a given tracer gas in an air mixture that can be detected unambiguously when

the mixture is fed into the MSLD at such a rate as that is at its optimum working pressure

3.1.5.2

resolving power

ratio of a given mass number to the peak width measured at a specified (for example 10 %) height of the

peak (in units of mass numbers)

3.1.6 Terms relating to the display resolution

3.1.6.1

display resolution

quantitative expression of the ability of the leakage rate-display device to distinguish meaningfully

between closely adjacent values of the leakage rate indicated

3.1.6.2

linear display resolution

constant difference between adjacent scale intervals expressed in % full scale indication

3.1.6.3

logarithmic display resolution

constant ratio between two adjacent scale intervals expressed as a percentage of the indicated value

4 Description of an MSLD

General

An MSLD has an integral high vacuum system for maintaining the sensing element (mass spectrometer)

at low operating pressure and for establishing a partial pressure related to the incoming gas flow. This

pressure is measured quantitatively by the mass spectrometer. Such instruments are able to selectively

measure the flow of a tracer gas. In most cases the tracer gas will be helium, flowing in/out of an object

through a leak.

MSLD are commonly operated in either direct or counterflow configurations. These are both illustrated

in Figure 2.

Main parts of an MSLD

An MSLD (see definition given in EN ISO 20484) consists basically of a mass spectrometer (MS) and a

high vacuum pumping system for:

— maintaining the MS under appropriate vacuum conditions;

— producing a definite partial pressure of tracer gas when a specific throughput of tracer gas enters the

leak detector.

An MSLD includes also a number of valves and pressure gauges to ensure the appropriate vacuum

conditions within the system.

The leakage rate output can be displayed in a number of ways, for example an electrical meter, or digital

displays of different types, such as with a logarithmic or linear display resolution. In addition, a digital

and/or analogue output is usually available, which shall be used for the test procedures in this document.

The general structure of an MSLD is described by the following list:

a) mass spectrometer:

— ion source;

— separation system;

— ion collector.

b) pumping system:

— inlet system;

— inlet line;

— inlet valve;

— pump valve;

— test port;

— vent valve;

— internal leak port.

c) sensitivity zero control.

d) display.

Operating principles of MSLD

4.3.1 Direct flow leak detectors

The leakage rate is given by the formula:

q

x

(1)

q pS⋅

x xx

where

is the pV-throughput of tracer gas;

q

x

is the intrinsic pumping speed;

S

x

is the partial pressure of tracer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...