EN 14354:2004

(Main)Wood-based panels - Wood veneer floor covering

Wood-based panels - Wood veneer floor covering

This document specifies definitions, requirements and test methods for wood veneer floor coverings for internal use. It gives guidance for the evaluation of conformity of the products to the requirements of this standard.

Wood-veneer floor coverings without finishing are excluded.

Holzwerkstoffe - Furnierte Fußbodenbeläge

Dieses Dokument legt Definitionen, Anforderungen und Prüfverfahren für furnierte Fußbodenbeläge zur Verwendung im Innenbereich fest. Sie gibt eine Anleitung zur Konformitätsbewertung der Produkte in Bezug auf die Anforderungen dieser Norm.

Furnierte Fußbodenbeläge ohne Oberflächenbehandlung sind ausgeschlossen.

Panneaux à base de bois - Revêtement de sol à placage bois

La présente norme européenne spécifie les définitions, les exigences et les méthodes d'essais des revêtements de sol à placage bois pour usage intérieur.

Lesne plošče – Leseni furnir za talne obloge

General Information

- Status

- Withdrawn

- Publication Date

- 07-Dec-2004

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 112 - Woodbased panels

- Drafting Committee

- CEN/TC 112/WG 7 - Semi-finished and finished products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-Jul-2017

- Completion Date

- 28-Jan-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 02-Aug-2017

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 1534:2020 - Wood flooring and parquet - Determination of resistance to indentation - Test method - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 14342:2005+A1:2008 - Wood flooring - Characteristics, evaluation of conformity and marking - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

Frequently Asked Questions

EN 14354:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Wood-based panels - Wood veneer floor covering". This standard covers: This document specifies definitions, requirements and test methods for wood veneer floor coverings for internal use. It gives guidance for the evaluation of conformity of the products to the requirements of this standard. Wood-veneer floor coverings without finishing are excluded.

This document specifies definitions, requirements and test methods for wood veneer floor coverings for internal use. It gives guidance for the evaluation of conformity of the products to the requirements of this standard. Wood-veneer floor coverings without finishing are excluded.

EN 14354:2004 is classified under the following ICS (International Classification for Standards) categories: 79.080 - Semi-manufactures of timber. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14354:2004 has the following relationships with other standards: It is inter standard links to EN 14354:2017, EN 13329:2000, EN 319:1993, EN 438-2:1991, EN 322:1993, EN 1534:2020, EN 1910:2016, EN ISO 2409:2020, EN ISO 10874:2012, EN 14342:2005+A1:2008, EN 14978:2006, EN 14354:2004/AC:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14354:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14354:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Holzwerkstoffe - Furnierte FußbodenbelägePanneaux a base de bois - Revetement de sol a placage boisWood-based panels - Wood veneer floor covering97.150Netekstilne talne oblogeNon-textile floor coverings79.080Polizdelki iz lesaSemi-manufactures of timberICS:Ta slovenski standard je istoveten z:EN 14354:2004SIST EN 14354:2005en01-marec-2005SIST EN 14354:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14354December 2004ICS 79.080English versionWood-based panels - Wood veneer floor coveringPanneaux à base de bois - Revêtement de sol à placageboisHolzwerkstoffe - Furnierte FußbodenbelägeThis European Standard was approved by CEN on 27 October 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14354:2004: ESIST EN 14354:2005

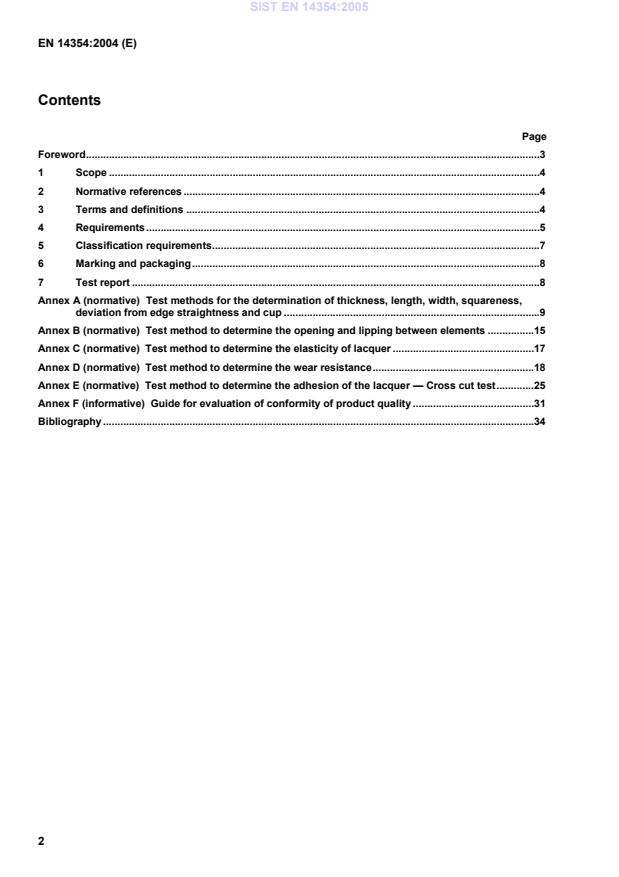

Test methods for the determination of thickness, length, width, squareness, deviation from edge straightness and cup.9 Annex B (normative)

Test method to determine the opening and lipping between elements.15 Annex C (normative)

Test method to determine the elasticity of lacquer.17 Annex D (normative)

Test method to determine the wear resistance.18 Annex E (normative)

Test method to determine the adhesion of the lacquer — Cross cut test.25 Annex F (informative)

Guide for evaluation of conformity of product quality.31 Bibliography.34

stability. EN 13329:2000, Laminate floor coverings — Specifications, requirements and test methods. EN 60454–2:1995, Specification for pressure-sensitive adhesive tapes for electrical purposes —Part 2: Methods of test (IEC 60454-2:1994). EN ISO 2409, Paints and varnishes — Cross cut test (ISO 2409:1992). 3 Terms and definitions For the purposes of this document, the following terms and definitions apply: 3.1 wood veneer floor covering rigid floor covering consisting of a substrate made from a wood-based panel, with a top layer of wood veneer and possibly a backing 3.2 top layer

finished upper wood layer, intended to be the visible side when the floor is installed 3.3 substrate core material of the wood veneer floor covering 3.4 backing layer opposite to the top layer SIST EN 14354:2005

Annex D. 4.2 General requirements The nominal dimensions shall be declared by the manufacturer at a given humidity. For appearance for evaluation of conformity, to be used when requested about product quality, the procedure in Annex F may be used. The wood veneers used for the top layer are hardwood or softwood species and shall be free from decay and insect attack. Variations of colour can occur under the influence of light. SIST EN 14354:2005

taverage -

t nominal ≤ ± 0,50 mm

Length l of the top layer in the same package l ≤ 1 500 mm: lmax – lmin

≤ 0,50 mm l >1 500 mm: lmax – lmin ≤ 0,30 mm/m lmean ≤ 1 mm

Width w of the top layer and square element wmax – wmin

≤ 0,20 mm w average – w nominal

≤ 0,1mm

wmean ≤ 0,5 mm

Length l and width w of squared elements

l = w

laverage – l nominal

≤ 0,10 mm

w average – w nominal

≤ 0,10 mm

lmax – lmin ≤ 0,20 mm w max – w min ≤ 0,20 mm Deviation of squareness qmax ≤ 0,20 mm Deviation from edge straightness of the top layer s smax ≤ 0,30 mm/m Cup fw in width direction fw max ≤ 0,20 %

fw average ≤ 0,15 % Annex A Lipping p pmax ≤ 0,15 mm

Opening between elements ≤ 0,20 mm Annex B Adhesion of the lacquer ≤ class 2

Annex E Tensile strength of the substratea

≥ 1,40 N/mm2 EN 319 Surface soundness ≥ 1,00 N/mm2 Annex D of EN 13329:2000

a For the mechanical assembly systems only (assembly system without glue).

4.3 Requirements on humidity variations To determine the capacity of a wood veneer floor covering to withstand ambient humidity variations, a test in a climate controlled chamber (according to EN 1910 and using the parameters defined in Table 2) shall be made. After testing, the wood veneer floor covering elements shall comply with the requirements in Table 2. SIST EN 14354:2005

climate B, –

condition n°2, – humid climate H2 – Annex A

5 Classification requirements 5.1 General Veneer floor coverings shall be classified as suitable for different levels of use, according to the performance requirements specified in Table 3, when tested with the methods given therein. Classification shall conform to the scheme specified in EN 685 (levels 21, 22, 23, 31, 32, 33). The use classification defined in the Table 3 had been fixed on the basis of the material (wood veneer) and the linked test methods. 5.2 Classification requirements for elements with lacquer finishing The classification requirements for elements with lacquer finishing are given in Table 3 Table 3 — Classification requirements for elements with finishing ex- factory Class 21 22 23 31 32 33 Symbol

Test method Level of use Domestic Commercial

Moderate General Heavy Moderate General Heavy

Resistance to indentation ≥≥≥≥ 10 N/mm2 ≥≥≥≥ 20 N/mm2 ≥≥≥≥ 30 N/mm2 ≥≥≥≥ 40 N/mm2 EN 1534 Thickness swelling ≤≤≤≤ 15 % ≤≤≤≤ 10 % EN 13329:2000Annex G Impact resistance (Elasticity) EC0 EC1 EC2 EC3 Annex C Wear resistance WR0 WR1 WR2 WR3 Annex D

Test methods for the determination of thickness, length, width, squareness, deviation from edge straightness and cup A.1 Scope This Annex specifies methods for measuring the thickness, length, width, squareness, deviation from edge straightness and cup of wood veneer floor covering elements. A.2 Sampling Take 5 elements at random. A.3 Conditioning Elements are measured without conditioning. If requested, the test pieces shall be stabilized to a constant mass in an atmosphere of (23 ± 2)°C and (50 ± 5) % relative humidity. Constant mass is considered to be reached when the results of two successive weighing operations, carried out at an interval of 24h, do not differ by more than 0,1 % of the mass of the test pieces. A.4 Test equipment A.4.1 Micrometer, sliding caliper or any other equivalent tool giving an accuracy of 0,05 mm. A.4.2 Sliding caliper or any other equivalent tool giving an accuracy of 0,01 mm. A.4.3 Square arms with lengths of 300 mm and having a maximum angular distortion of 0,02 mm at 300 mm. A.4.4 Steel ruler of length at least equal to the length of test specimen and having a maximum straightness deviation of 0,05 mm over 1 000 mm. A.4.5 Apparatus (T–assembly) for measuring width flatness consisting of a dial gauge accurate to ± 0,01 mm with a rounded tip with a radius of ≤ 5,5 mm, installed centrally in relation to three rounded supports with a radius of ≥ 5 mm. The supports shall be adjustable along a T-shaped assembly of bars to provide the required gauge length. The measurement d shall not be less than the width w of the test specimen minus 10 mm. The tip of the gauge in contact with the face of the test specimen shall apply a force of (1,0 ± 0,5) N. The mass of the apparatus shall not affect the flatness of the test specimen beyond the limit of the accuracy of the gauge.

See Figure A.1 for illustration. The instrument shall be set to zero against a suitable reference plate. SIST EN 14354:2005

Key a View A enlarged 1 Dial gauge 2 T-groove 3 Adjustable pin 4 Adjustable bridge Figure A.1 — Instrument for measuring the width flatness (Principle) A.4.6 Steel tape or ruler with an accuracy of ± 0,1 mm up to a length of 1,50 m, and ± 0,5 mm for longer lengths. A.4.7 Thickness gauges ranging from 0,5 mm to 0,10 mm in steps of 0,01, and from 0,10 mm to 0,50 mm in steps of 0,05 mm. A.5 Procedure A.5.1 Determination of thickness t

Measure the thickness t with a micrometer, or any other device of the equipment described in A.4.1, at a distance of 20 mm from the edges of the top layer, at points located in each corner and in the middle of each long side (only four corner points if the length is ≤ 600 mm), see Figure A.2. SIST EN 14354:2005

Figure A.2 — Measuring points for determination of thickness t A.5.2 Determination of length l For decorative pattern effects, measure the length of the elements with the test equipment described in A.4.2. For non decorative pattern effects, measure the length of the elements when shorter than 500 mm with the test equipment described in A.4.2 and for lengths equal to or longer than 500 mm, with the test equipment described in A.4.6. Measure the length l of the top layer along two lines parallel to the axis of the element and at a distance of 20 mm from the edges (see Figure A.3). Dimensions in millimetres

Figure A.3 — Measuring for determination of length l A.5.3 Determination of width w and dimensions of squared elements Measure the width w with a micrometer, or any of the other device in A.4.1 along two lines parallel to the sides or edges of the top layer, at a distance of 20 mm from the edges or sides and in the middle for elements with a length of > 600 mm (see Figure A.4). SIST EN 14354:2005

Figure A.4 — Measuring points for determination of width w A.5.4 Determination of deviation from squareness q Place one arm of the square (A.4.3) against one long side of the top layer of the element, and determine the maximum deviation to square at the small side. The same procedure is also done on the diagonally opposite corner (see Figure A.5).

Figure A.5 — Determination of squareness q SIST EN 14354:2005

Figure A.6 — Determination of edge straightness s A.5.6 Determination of cup fw

Figure A.7 — Determination of cup fw Adjust the supports along the T-assembly (A.4.5) of the bars according to the width of the element to evaluate (see Figure A.7). The distance between the centres of the supports shall not be less than the width w of the element reduced with 10 mm. Determine the maximum cup for each element. A.6 Calculation and expression of results A.6.1 Thickness t Calculate the mean value from the number of measurements taken. Record the maximum and the minimum individual values. Express the results in millimetres to the nearest 0,1 mm. A.6.2 Width w Calculate the mean value from the number of measurements taken. Record the maximum and the minimum individual values. Express the results in millimetres to the nearest 0,1 mm. SIST EN 14354:2005

test results; date of the test report. SIST EN 14354:2005

Test method to determine the opening and lipping between elements B.1 Scope This Annex specifies methods for measuring lipping and opening between elements. B.2 Sampling Take 8 elements as test pieces, chosen at random. B.3 Conditioning Elements are measured either without conditioning or, if requested, the test pieces shall be stabilised to a constant mass in an atmosphere of (23 ± 2) °C and (50 ± 5) % relative humidity. Constant mass is considered to be reached when the results of two successive weighing operations, carried out at an interval of 24 h, do not differ by more than 0,1 % of the mass of the test pieces. B.4 Test equipment B.4.1 A thickness gauge as described in A.4.7 or a T-assembly as described in A.4.5. B.4.2 A steel ruler or any other device, by which the first strip row shall be aligned and whose length is

≥ 2,50 m B 4.3 A test surface of appropriate size, rigid, horizontal and flat B.5 Procedure B.5.1 Assembling By hand force, firmly assemble the test pieces without using any glue, as in Figure B.1. The -- symbol indicates the 13 measuring points. SIST EN 14354:2005

Key 1 Steel ruler 2 Measuring points 3 Test pieces Figure B.1 — Measuring points to determine the opening and lipping between elements B.5.2 Measuring of lipping Measure the lipping with a thickness gauge or a T-assembly (see B.4), without applying any force to the elements at the 13 indicated points in Figure B.1. The measurement shall not be taken more than 5 mm from the joints’ edge. B.5.3 Measuring of openings Measure the opening with a thickness gauge between the elements at the

13 indicated points in Figure B.1. B.6 Calculation and expression of results Record the maximum individual value of lipping and openings. Express the results in millimetres to the nearest 0,05 mm. B.7 Test report The test report shall contain the following information: name and the address of the laboratory; name and address of the sponsor, if any, requesting the test; e sampling procedure and the identification of the sample; date of delivery; date of the test(s); type and full description of the elements; conditioning applied to the elements prior to testing; climate conditions within the laboratory during the test; reference to the methods and, if any, the deviations; a short description of the test equipment; test results; date of the test report. SIST EN 14354:2005

Test method to determine the elasticity of lacquer C.1 General Test in accordance with EN 438–2:1991, Clause 12 “Impact resistance with large diameter ball”, with the following modifications. C.2 Sampling Take five veneer floor covering elements, chosen at random. Take from each element one test piece measuring approximately 180 mm × 180 mm (or in case of smaller width than 180 mm, w mm × 180 mm).

C.3 Apparatus In addition to the apparatus specified in EN 438–2:1991, Clause 12, a flexible extruded polyethylene foam sub-layer of (3 ± 0,5) mm thickness, and with a density of (25 ± 5) kg/m3 is required. The zoom factor of the magnification glass shall be 10. The indicator fluid is a waterborne solution of 1 % methylene blue. C.4 Procedure On the five small test pieces carry out the large-diameter ball test in accordance with EN 438-2, on the steel plate with the foam but without the clamping frame. Adjust the drop height in steps of 50 mm, to determine the maximum height which does not produce cracks. For the evaluation of the result the magnification glass as well as the indicator fluid shall be us

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...