EN 17691-1:2025

(Main)Components for BAC control loops - Valve and actuator assemblies - Part 1: Water-based HVAC applications

Components for BAC control loops - Valve and actuator assemblies - Part 1: Water-based HVAC applications

This document specifies requirements and test methods of valve-actuator assemblies in individual zone control of water-based HVAC applications.

This document does not apply to control valves of nominal diameter larger than DN50.

This document is applicable to pressure independent and pressure dependent control valve-actuator assemblies of relevant categories: 2-port, 3-port and 6-port valves (if they incorporate a control valve function).

Where a certain control loop as a combination of controller and valve-actuator assembly was assessed under EN 15500-1 [3], this document allows the assessment of the performance of combinations of that controller with different valve-actuator assemblies. The tests in this document ensure that valve/actuator assemblies, as components of control loops, can be replaced with products that provide comparable or better performance.

In hydronic system, valve-actuator assembly is a component of control loop that controls water flow rate according to the application control demand.

Komponenten für BAC‑Regelkreise - Armaturen und Antriebsbaugruppen - Teil 1: Wasserbasierte HLK‑Anwendungen

Dieses Dokument legt Anforderungen und Prüfverfahren für Regel- und Steuereinrichtungen für einzelne Räume oder Zonen bei wasserbasierten HLK Anwendungen fest.

Dieses Dokument ist nicht auf Regelventile mit einem Nenndurchmesser größer als DN 50 anwendbar.

Dieses Dokument ist auf druckunabhängige und druckabhängige Regel- und Steuereinrichtungen der folgenden wesentlichen Kategorien anwendbar: 2 Wege-, 3 Wege- und 6 Wege-Armaturen (sofern sie eine Stellgerätefunktion enthalten).

Wurde ein bestimmter Regelkreis als Kombination bestehend aus Regel- und Steuereinrichtungen nach EN 15500 1 [3] bewertet, ermöglicht dieses Dokument die Bewertung der Leistung von Kombinationen dieser Regler mit verschiedenen Regel- und Steuereinrichtungen. Die Prüfungen in diesem Dokument stellen sicher, dass Regel- und Steuereinrichtungen als Komponenten von Regelkreisen durch Produkte ersetzt werden können, die eine vergleichbare oder bessere Leistung bieten.

In Hydronik-Systemen ist die Regel- und Steuereinrichtung ein Bestandteil des Regelkreises, der die Wasserdurchflussmenge entsprechend den Anforderungen der Anwendung regelt.

Composants pour les boucles d’automatisation et de régulation du bâtiment (BAC) - Ensembles vannes et actionneurs - Partie 1: Applications CVC à eau

Le présent document spécifie les exigences et les méthodes d’essai des ensembles vanne-actionneur pour la régulation de zones individuelles dans les applications CVC à eau.

Ce document ne s’applique pas aux vannes de régulation d’un diamètre nominal supérieur à DN50.

Ce document s’applique aux ensembles vanne-actionneur de régulation dépendants et indépendants de la pression pour les catégories suivantes : vannes à 2 voies, 3 voies et 6 voies (si elles intègrent une fonction de vanne de régulation).

Là où une certaine boucle de régulation agissant en tant que combinaison d’un régulateur et d’un ensemble vanne-actionneur est évaluée conformément à EN 15500-1 [3], ce document permet d’évaluer les performances des combinaisons de ce régulateur avec différents ensembles vanne actionneur. Les essais présentés dans le présent document garantissent que les ensembles vanne actionneur, en tant que composants des boucles de régulation, peuvent être remplacés par des produits proposant des performances comparables ou supérieures.

Dans un système hydronique, l’ensemble vanne-actionneur est un composant de la boucle de régulation qui contrôle le débit d’eau en fonction de la demande de régulation de l’application.

Sestavni deli za krmilno zanko BAC - Sklopi ventilov in aktuatorjev - 1. del: Aplikacije HVAC na vodni osnovi

General Information

- Status

- Published

- Publication Date

- 16-Dec-2025

- Technical Committee

- CEN/TC 247 - Controls for mechanical building services

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 17-Dec-2025

- Due Date

- 02-Mar-2026

- Completion Date

- 17-Dec-2025

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 17691-1:2025 (Components for BAC control loops)

EN 17691-1:2025 specifies requirements and test methods for valve‑actuator assemblies used in individual‑zone control of water‑based HVAC (hydronic) applications. The standard covers both pressure independent and pressure dependent assemblies for 2‑port, 3‑port and 6‑port valves (when they perform a control function). It does not apply to control valves with nominal diameter larger than DN50. The aim is to ensure valve/actuator assemblies can be interchanged in Building Automation and Control (BAC) loops while delivering comparable or better control performance.

Key topics and technical requirements

- Scope and exclusions: Applies to DN50 and smaller valve‑actuator assemblies for water‑based HVAC; includes PICV and conventional control valves.

- Performance metrics: Evaluation based on declared KPIs and measured properties including flow control characteristic and pressure dependency.

- Control performance scoring: Combination of flow control test output (expressed as RMSE) and pressure dependency test output. Note: pressure dependency > 50% results in loss of one performance class.

- Test methods & setup: Defines closed loop test setup, DUT (device under test) requirements, and test section requirements. Includes mandatory tests, test case definitions (flow characteristic, pressure dependency), and rules for product family testing.

- Interchangeability: Criteria and declarations that allow a valve‑actuator assembly to be replaced in a control loop with minimal effect on overall loop performance. Annex A provides an example interchangeability declaration.

- Terminology and interfaces: Clear definitions for control loop elements (sensor, controller, actuator, valve), travel, nominal flow coefficient (kvs), relative travel/flow, control signals (2‑point, 3‑point, modulating).

Practical applications and who uses this standard

- HVAC system designers & engineers: To select valve‑actuator assemblies that meet control accuracy and energy performance targets.

- Manufacturers & product managers: To test, declare KPIs, and demonstrate interchangeability with controllers tested under EN 15500‑1.

- Test laboratories & certification bodies: For repeatable measurement procedures and performance class assignment.

- Facility managers & specifiers: To ensure replacement components will maintain comfort, energy efficiency and compliance with regulatory energy requirements.

- System integrators: To verify compatibility of actuators and valves in hydronic BAC loops and avoid performance degradation.

Related standards

- EN 15500‑1:2017 - Electronic individual zone control equipment (controller assessments referenced).

- EN ISO 7345:2018, EN ISO 52000‑1:2017 - Applied for terminology and energy performance context.

EN 17691‑1:2025 supports predictable component interchangeability, consistent testing, and improved energy performance in water‑based BAC control loops.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 17691-1:2025 is a standard published by the European Committee for Standardization (CEN). Its full title is "Components for BAC control loops - Valve and actuator assemblies - Part 1: Water-based HVAC applications". This standard covers: This document specifies requirements and test methods of valve-actuator assemblies in individual zone control of water-based HVAC applications. This document does not apply to control valves of nominal diameter larger than DN50. This document is applicable to pressure independent and pressure dependent control valve-actuator assemblies of relevant categories: 2-port, 3-port and 6-port valves (if they incorporate a control valve function). Where a certain control loop as a combination of controller and valve-actuator assembly was assessed under EN 15500-1 [3], this document allows the assessment of the performance of combinations of that controller with different valve-actuator assemblies. The tests in this document ensure that valve/actuator assemblies, as components of control loops, can be replaced with products that provide comparable or better performance. In hydronic system, valve-actuator assembly is a component of control loop that controls water flow rate according to the application control demand.

This document specifies requirements and test methods of valve-actuator assemblies in individual zone control of water-based HVAC applications. This document does not apply to control valves of nominal diameter larger than DN50. This document is applicable to pressure independent and pressure dependent control valve-actuator assemblies of relevant categories: 2-port, 3-port and 6-port valves (if they incorporate a control valve function). Where a certain control loop as a combination of controller and valve-actuator assembly was assessed under EN 15500-1 [3], this document allows the assessment of the performance of combinations of that controller with different valve-actuator assemblies. The tests in this document ensure that valve/actuator assemblies, as components of control loops, can be replaced with products that provide comparable or better performance. In hydronic system, valve-actuator assembly is a component of control loop that controls water flow rate according to the application control demand.

EN 17691-1:2025 is classified under the following ICS (International Classification for Standards) categories: 91.140.10 - Central heating systems; 91.140.30 - Ventilation and air-conditioning systems; 97.120 - Automatic controls for household use. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17691-1:2025 has the following relationships with other standards: It is inter standard links to EN ISO 52000-1:2017, EN 15500-1:2017, EN ISO 7345:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17691-1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Sestavni deli za krmilno zanko BAC - Sklopi ventilov in aktuatorjev - 1. del:

Aplikacije HVAC na vodni osnovi

Components for BAC control loops - Valve and actuator assemblies - Part 1: Water-

based HVAC applications

Komponenten für BAC-Regelkreise - Armaturen und Antriebsbaugruppen - Teil 1:

Wasserbasierte HLK-Anwendungen

Composants pour les boucles d’automatisation et de régulation du bâtiment (BAC) -

Ensembles vannes et actionneurs - Partie 1: Applications CVC à eau

Ta slovenski standard je istoveten z: EN 17691-1:2025

ICS:

91.140.10 Sistemi centralnega Central heating systems

ogrevanja

91.140.30 Prezračevalni in klimatski Ventilation and air-

sistemi conditioning systems

97.120 Avtomatske krmilne naprave Automatic controls for

za dom household use

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17691-1

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2025

EUROPÄISCHE NORM

ICS 97.120

English Version

Components for BAC control loops - Valve and actuator

assemblies - Part 1: Water-based HVAC applications

Composants pour les boucles d'automatisation et de Komponenten für BAC-Regelkreise - Armaturen und

régulation du bâtiment (BAC) - Ensembles vannes et Antriebsbaugruppen - Teil 1: Wasserbasierte HLK-

actionneurs - Partie 1: Applications CVC à eau Anwendungen

This European Standard was approved by CEN on 10 November 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17691-1:2025 E

worldwide for CEN national Members.

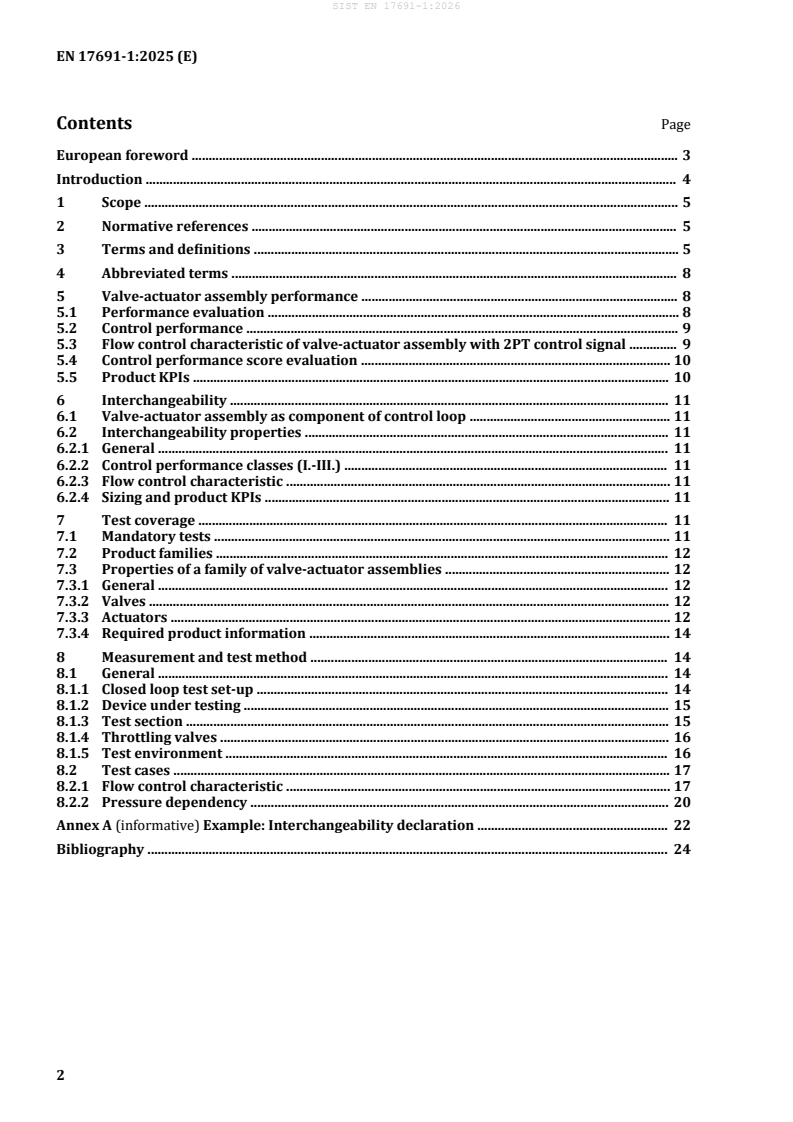

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Abbreviated terms . 8

5 Valve-actuator assembly performance . 8

5.1 Performance evaluation . 8

5.2 Control performance . 9

5.3 Flow control characteristic of valve-actuator assembly with 2PT control signal . 9

5.4 Control performance score evaluation . 10

5.5 Product KPIs . 10

6 Interchangeability . 11

6.1 Valve-actuator assembly as component of control loop . 11

6.2 Interchangeability properties . 11

6.2.1 General . 11

6.2.2 Control performance classes (I.-III.) . 11

6.2.3 Flow control characteristic . 11

6.2.4 Sizing and product KPIs . 11

7 Test coverage . 11

7.1 Mandatory tests . 11

7.2 Product families . 12

7.3 Properties of a family of valve-actuator assemblies . 12

7.3.1 General . 12

7.3.2 Valves . 12

7.3.3 Actuators . 12

7.3.4 Required product information . 14

8 Measurement and test method . 14

8.1 General . 14

8.1.1 Closed loop test set-up . 14

8.1.2 Device under testing . 15

8.1.3 Test section . 15

8.1.4 Throttling valves . 16

8.1.5 Test environment . 16

8.2 Test cases . 17

8.2.1 Flow control characteristic . 17

8.2.2 Pressure dependency . 20

Annex A (informative) Example: Interchangeability declaration . 22

Bibliography . 24

European foreword

This document (EN 17691-1:2025) has been prepared by Technical Committee CEN/TC 247 “Building

Automation, Controls and Building Management”, the secretariat of which is held by SNV.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2026, and conflicting national standards shall be

withdrawn at the latest by June 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document is part of a series of standards on components of building automation and control loop.

A list of all parts in a series can be found on the CEN website.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Tu�rkiyé and the United

Kingdom.

Introduction

Various EU Directives and national regulations regarding energy saving and energy performance of

buildings require proof of energy éfficiéncy.

These requirements and rising energy costs are encouraging owners and occupiers of buildings to

reduce their energy consumption. The cost for energy will be a critical factor in property rental and sale

in the future.

Building Automation and Controls (BAC) have a strong impact on the energy performance of a building.

This is shown in the existing Building Automation and Control (BAC) standards (mainly EN ISO 52120-1

[1], CEN ISO/TR 52120-2 [2]). The standards also show the importance of BAC quality to achieve the

desired comfort (e.g. human health and productivity) at maximum éfficiéncy via control accuracy, BAC

functions and BAC strategies.

For the measurement of the control accuracy (CA value) based on European Standard EN ISO 52120-1

[1], CEN ISO/TR 52120-2 [2], EN 15500-1 [3] and its accompanying Technical Report CEN/TR 15500-2

[4], a controller is tested as part of a control loop, consisting of the loop elements room temperature

sensor / controller / actuator / valve shown in Figure 1:

Key

1 application of a control loop (example water flow heating system)

2 sensor temperature

3 controller

4 actuator

5 valve

Figure 1 — Control loop elements

Both the controller as well as components contribute to the overall performance of a control loop.

A controller can be used in combination with different control loop elements, if they fulfil the

requirements of the interfaces to each other, and if the basic characteristics of the replaced control loop

elements are the same.

The EN 17691 series [5] and EN 17690-1 [6] will cover the different components used in conjunction

with a BAC controller. All these components contribute to the control accuracy of a control loop. These

standards will contribute to classify the components.

1 Scope

This document spécifiés requirements and test methods of valve-actuator assemblies in individual zone

control of water-based HVAC applications.

This document does not apply to control valves of nominal diameter larger than DN50.

This document is applicable to pressure independent and pressure dependent control valve-actuator

assemblies of relevant categories: 2-port, 3-port and 6-port valves (if they incorporate a control valve

function).

Where a certain control loop as a combination of controller and valve-actuator assembly was

assessed under EN 15500-1 [3], this document allows the assessment of the performance of

combinations of that controller with different valve-actuator assemblies. The tests in this document

ensure that valve/actuator assemblies, as components of control loops, can be replaced with products

that provide comparable or better performance.

In hydronic system, valve-actuator assembly is a component of control loop that controls water flow

rate according to the application control demand.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 7345, Thermal performance of buildings and building components - Physical quantities and

definitions (ISO 7345:2018)

EN 15500-1, Energy Performance of Buildings - Control for heating, ventilating and air conditioning

applications - Part 1: Electronic individual zone control equipment - Modules M3-5, M4-5, M5-5

EN ISO 52000-1, Energy performance of buildings - Overarching EPB assessment - Part 1: General

framework and procedures (ISO 52000-1:2017)

3 Terms and definitions

For the purposes of this document, the terms and définitions given in EN ISO 7345, EN ISO 52000-1,

EN 15500-1 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

control loop

loop that consists of sensors for measurement, controller, actuators, valves and communication of

variables

Note 1 to entry: Controlled variables are transmitted from the sensors to the controller. The controller interprets

the signals and generates appropriate manipulated variables based on set-points, which it transmits to the

actuators. Process changes due to disturbances result in new sensor signals identifying the state of the process,

which are again transmitted to the controller.

3.2

control valve

component with the ability to change the fluid flow rate

3.3

actuator

component that is responsible for changing the position of the closure member of the control valve,

based on a signal from a controller

3.4

linear motion control valve

control valve with a linear motion closure member

EXAMPLE globe valve, gate valve

3.5

valve-actuator assembly

assembly of valve and actuator that forms the device under test (DUT)

3.6

closed position

H , φ

0 0

position of the control valve where the flow passageway is at the minimum

3.7

open position

H , φ

max max

position of the control valve where the flow passageway is at the maximum

3.8

travel

H, φ

displacement of the closure member

Note 1 to entry: Travel is expressed in mm.

3.9

nominal travel

H , φ

100 100

displacement of the closure member from the closed position to the fully open position

Note 1 to entry: Nominal travel is in mm.

3.10

relative travel

h

ratio of the travel at a given opening compared to the nominal travel

Note 1 to entry: Relative travel is in %.

3.11

nominal flow capacity

Q

flow capacity at the open position

Note 1 to entry: Nominal flow capacity is in m /h.

3.12

relative flow capacity

ratio of the capacity at a given opening compared to the nominal capacity

Note 1 to entry: Relative flow capacity is expressed in %.

3.13

valve-actuator assembly flow presetting

Qm /h

flow capacity value that can be preset in a valve-actuator assembly (3.5), where presetting can be made

on a valve or an actuator (3.3)

Note 1 to entry: Valve-actuator presetting is expressed in m /h, %.

3.14

nominal flow coefficient

k

vs

basic coéfficiént used to state flow capacity of a control valve (3.2) at fully open position (3.7)

Note 1 to entry: Nominal flow coéfficiént is expressed in m /h.

3.15

relative flow coefficient

ratio of the flow coéfficiént at a relative travel (3.10) to the nominal flow coefficient (3.14)

Note 1 to entry: Relative flow coéfficiént is expressed in %.

3.16

linear characteristic

Φ

characteristic where equal increments of relative travel (3.10) yield equal increments of relative flow

characteristic

3.17

modified equal percentage characteristic

Φ

characteristic which combines inherent linear and inherent equal percentage flow characteristic

3.18

control signal

Y

actuator (3.3) input signal

Note 1 to entry: Control signal is expressed in V, mA, …

3.19

nominal control signal

Y

control signal (3.18) value corresponding to valve-actuator position delivering nominal capacity / flow

coéfficiént

Note 1 to entry: Nominal control signal is expressed in V, mA, …

3.20

relative control signal

y

ratio of actual control signal and control signal (3.18) span: y = Y−Y /Y -Y

0 100 0

Note 1 to entry: Relative control signal is expressed in %.

3.21

root mean square error

RMSE

measure of the average difference between a statistical model’s predicted values and the actual values

Note 1 to entry: Mathematically, it is the standard deviation of the residuals. Residuals represent the distance

between the regression line and the data points.

4 Abbreviated terms

Abbreviation Explanation

VA valve-actuator assembly

HVAC heating, ventilation, air conditioning

PICV* pressure independent control valve

CV control valve (pressure dependent)

BAC building automation and controls

DUT device under testing

2PT 2-point controlled (on/ off)

3PT floating point device, 3-point controlled

MOA modulating device, steadily controlled

BUS digital, networked device, fiéld bus controlled

KPI key performance indicator

RMSE root mean square error

* In the market also referred to as PIBCV: Pressure Independent Balancing & Control Valve.

5 Valve-actuator assembly performance

5.1 Performance evaluation

Valve-actuator assemblies shall be evaluated based on performance properties. Performance properties

are based on tests described in this document and KPIs declared by manufacturer.

The common Formula (1) describes the flow rate where whole hydronic system itself has an influéncé

on actual flow rate as differential pressure across control valve-actuator assembly typically varies

during operation.

∆p

v

(1)

Q = k .

v

∆p

1bar

where

water flow

Q [m /h]

flow coéfficiént of the valve

k [m /h]

v

Δp [bar] differential pressure across the valve

v

Δp [bar] 1 bar differential pressure

1bar

5.2 Control performance

Control performance of valve-actuator assemblies shall be evaluated based on two performance

properties:

— flow control characteristic (see 8.2.1)

— pressure dependency (see 8.2.2).

Control performance test score shall be obtained by measurement output of flow control characteristic

(RMSE value) multiplied by the pressure dependency test output.

In addition, pressure dependency test result higher than 50 % results in a loss of one performance class.

Below examples (Table 1 and Table 2) showing final control performance assessment without and with

pressure dependency adjustment.

Table 1 — Example of control performance assessment for PICV

Test result

Flow control characteristic (RMSE) 4,2

a

3 %

Pressure dependency

a

1,03

Multiplier

Test score 4,3

a

The maximum value is 224 % as theoretical value for pressure dependent control valve.

Table 2 — Example of control performance assessment for pressure dependant CV

Test result

Flow control characteristic (RMSE) 4,2

a

55 %

Pressure dependency

a

1,55

Multiplier

6,5

Test score

+ additional class deduction

a

max value is 224 % as theoretical value for pressure dependent control valve

5.3 Flow control characteristic of valve-actuator assembly with 2PT control signal

Flow control characteristic of valve-actuator assembly with 2PT control signal is meaningless as it has

only two positions: open and closed one. However, it is important to be able to compare control

performance of such assembly as valve-actuator assemblies with 2PT control signal are commonly used

in real applications.

To allow comparison, this document spécifiés a reference RMSE values for valve-actuator assembly with

2PT control signal. They are based on comparison of ideal flow control characteristic (for both linear

with Φ value of 1 and Φ with value of 0,25) and theoretical charac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...