EN 12697-26:2012

(Main)Bituminous mixtures - Test methods for hot mix asphalt - Part 26: Stiffness

Bituminous mixtures - Test methods for hot mix asphalt - Part 26: Stiffness

This European Standard specifies the methods for characterising the stiffness of bituminous mixtures by alternative tests, including bending tests and direct and indirect tensile tests. The tests are performed on compacted bituminous material under a sinusoidal loading or other controlled loading, using different types of specimens and supports.

The procedure is used to rank bituminous mixtures on the basis of stiffness, as a guide to relative performance in the pavement, to obtain data for estimating the structural behaviour in the road and to judge test data according to specifications for bituminous mixtures.

As this standard does not impose a particular type of testing device the precise choice of the test conditions depends on the possibilities and the working range of the used device.

For the choice of specific test conditions, the requirements of the product standards for bituminous mixtures should be respected.

The applicability of this document is described in the product standards for bituminous mixtures.

Asphalt - Prüfverfahren für Heißasphalt - Teil 26: Steifigkeit

Diese Europäische Norm legt die Verfahren zur Charakterisierung der Steifigkeit von Asphalt durch verschie-dene Prüfungen, einschließlich Biegeprüfungen und Prüfungen der direkten sowie der indirekten Zugfestigkeit fest. Die Prüfungen werden an verdichtetem Asphalt unter sinusförmiger oder einer anderen kontrollierten Belastung unter Verwendung verschiedener Probekörpertypen und Auflagerungen vorgenommen.

Das Verfahren dient zur Einstufung von Asphalt auf der Grundlage seiner Steifigkeit als Hinweis auf sein rela-tives Leistungsvermögen in der Fahrbahnbefestigung, um Daten zur Abschätzung des Tragverhaltens in der Straße zu erhalten und um die Prüfdaten nach den für Asphalt geltenden Festlegungen zu beurteilen.

Da diese Norm keinen bestimmten Prüfgerätetyp vorschreibt, hängt die genaue Auswahl der Prüfbedingungen von den Möglichkeiten und dem Arbeitsbereich des im betreffenden Fall verwendeten Prüfgeräts ab.

Bei der Auswahl der jeweiligen Prüfbedingungen sollten die Anforderungen der Produktnormen für Asphalt berücksichtigt werden.

Die Anwendbarkeit dieses Dokumentes ist in den Produktnormen für Asphalt beschrieben.

Mélanges bitumineux - Méthodes d'essai pour mélange hydrocarboné à chaud - Partie 26: Module de rigidité

La présente Norme européenne spécifie les méthodes de caractérisation de la rigidité des mélanges

hydrocarbonés à l'aide d'essais au choix, comprenant des essais de flexion et des essais de traction directe et

indirecte. Les essais sont réalisés sur un matériau bitumineux compacté soumis à une charge sinusoïdale ou

à d'autres charges contrôlées, utilisant différents types d'éprouvettes et de supports.

La procédure est utilisée pour classer les mélanges hydrocarbonés en fonction de leur module de rigidité,

pour servir de guide pour les performances relatives dans les chaussées, pour disposer de données utilisées

pour estimer le comportement structurel des chaussées et juger les résultats d'essais en fonction des

spécifications concernant les mélanges hydrocarbonés.

La présente norme n'imposant pas de type particulier d'appareillage d'essai, le choix spécifique des

conditions d'essai dépend des capacités et du domaine d’emploi de l'appareillage utilisé.

Pour le choix des conditions d'essai spécifiques, il convient de respecter les exigences des normes produit

sur les mélanges hydrocarbonés.

L'applicabilité du présent document est décrite dans les normes produit sur les mélanges hydrocarbonés.

Bitumenske zmesi - Preskusne metode za vroče asfaltne zmesi - 26. del: Togost

Ta evropski standard določa metode za karakterizacijo togosti bitumenskih zmesi z alternativnimi preskusi, skupaj s preskusi upogiba in preskusi direktne ter indirektne nateznosti. Preskusi se izvajajo na zgoščenem bitumenskem materialu pod sinusnim obremenjevanjem ali pod nadzorovanim obremenjevanjem z različnimi vrstami preskušancev in podpor. Postopek se uporablja za razvrščanje bitumenskih zmesi na podlagi togosti kot smernica v zvezi z relativnimi lastnostmi v voziščni konstrukciji za pridobivanje podatkov z namenom vrednotenja strukturnega obnašanja na cesti ter za ocenjevanje preskusnih podatkov glede na specifikacije bitumenskih zmesi. Ker ta standard ne predpisuje posebne preskusne naprave, je natančna izbira preskusnih pogojev odvisna od možnosti in delovnega obsega uporabljene naprave. Pri izbiri specifičnih preskusnih pogojev je treba upoštevati standarde za izdelke za bitumenske zmesi. Uporabnost tega dokumenta je opisana v standardih za izdelke za bitumenske zmesi.

General Information

- Status

- Withdrawn

- Publication Date

- 06-Mar-2012

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 227 - Road materials

- Drafting Committee

- CEN/TC 227/WG 1 - Bituminous mixtures

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 20-Jun-2018

- Completion Date

- 11-Feb-2026

Relations

- Replaces

EN 12697-26:2004 - Bituminous mixtures - Test methods for hot mix asphalt - Part 26: Stiffness - Effective Date

- 27-Mar-2010

- Effective Date

- 08-Jul-2015

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 12697-26:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Bituminous mixtures - Test methods for hot mix asphalt - Part 26: Stiffness". This standard covers: This European Standard specifies the methods for characterising the stiffness of bituminous mixtures by alternative tests, including bending tests and direct and indirect tensile tests. The tests are performed on compacted bituminous material under a sinusoidal loading or other controlled loading, using different types of specimens and supports. The procedure is used to rank bituminous mixtures on the basis of stiffness, as a guide to relative performance in the pavement, to obtain data for estimating the structural behaviour in the road and to judge test data according to specifications for bituminous mixtures. As this standard does not impose a particular type of testing device the precise choice of the test conditions depends on the possibilities and the working range of the used device. For the choice of specific test conditions, the requirements of the product standards for bituminous mixtures should be respected. The applicability of this document is described in the product standards for bituminous mixtures.

This European Standard specifies the methods for characterising the stiffness of bituminous mixtures by alternative tests, including bending tests and direct and indirect tensile tests. The tests are performed on compacted bituminous material under a sinusoidal loading or other controlled loading, using different types of specimens and supports. The procedure is used to rank bituminous mixtures on the basis of stiffness, as a guide to relative performance in the pavement, to obtain data for estimating the structural behaviour in the road and to judge test data according to specifications for bituminous mixtures. As this standard does not impose a particular type of testing device the precise choice of the test conditions depends on the possibilities and the working range of the used device. For the choice of specific test conditions, the requirements of the product standards for bituminous mixtures should be respected. The applicability of this document is described in the product standards for bituminous mixtures.

EN 12697-26:2012 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12697-26:2012 has the following relationships with other standards: It is inter standard links to EN 12697-26:2004, EN 12697-26:2018, EN 12697-45:2020, EN 12697-27:2017, EN 12697-33:2019+A1:2022, EN 12697-31:2019, EN 12697-29:2020, EN 12697-6:2020, EN 12697-24:2012, EN 12697-45:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12697-26:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Asphalt - Prüfverfahren für Heißasphalt - Teil 26: SteifigkeitMélanges bitumineux - Méthodes d'essai pour mélange hydrocarboné à chaud - Partie 26: Module de rigiditéBituminous mixtures - Test methods for hot mix asphalt - Part 26: Stiffness93.080.20Materiali za gradnjo cestRoad construction materialsICS:Ta slovenski standard je istoveten z:EN 12697-26:2012SIST EN 12697-26:2012en,fr,de01-junij-2012SIST EN 12697-26:2012SLOVENSKI

STANDARDSIST EN 12697-26:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12697-26

March 2012 ICS 93.080.20 Supersedes EN 12697-26:2004English Version

Bituminous mixtures - Test methods for hot mix asphalt - Part 26: Stiffness

Mélanges bitumineux - Méthodes d'essai pour enrobés à chaud - Partie 26: Rigidité

Asphalt - Prüfverfahren für Heißasphalt - Teil 26: SteifigkeitThis European Standard was approved by CEN on 18 September 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12697-26:2012: ESIST EN 12697-26:2012

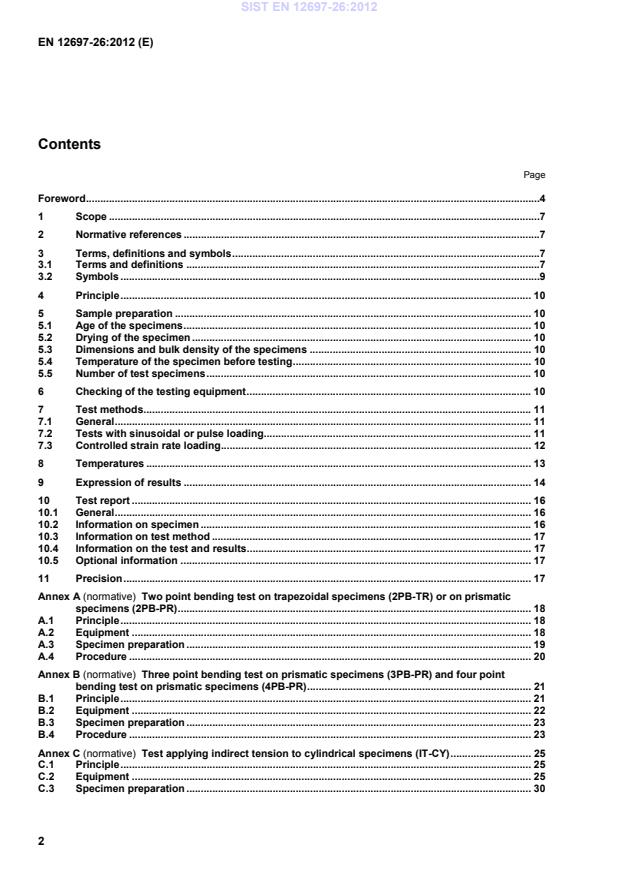

Two point bending test on trapezoidal specimens (2PB-TR) or on prismatic specimens (2PB-PR) . 18A.1Principle . 18A.2Equipment . 18A.3Specimen preparation . 19A.4Procedure . 20Annex B (normative)

Three point bending test on prismatic specimens (3PB-PR) and four point bending test on prismatic specimens (4PB-PR) . 21B.1Principle . 21B.2Equipment . 22B.3Specimen preparation . 23B.4Procedure . 23Annex C (normative)

Test applying indirect tension to cylindrical specimens (IT-CY) . 25C.1Principle . 25C.2Equipment . 25C.3Specimen preparation . 30SIST EN 12697-26:2012

Direct tension-compression test on cylindrical specimens (DTC-CY) . 33D.1Principle. 33D.2Equipment . 33D.3Specimen preparation . 33D.4Mode of operation . 34Annex E (normative)

Test applying direct tension to cylindrical specimens (DT-CY) or to prismatic specimens (DT-PR) . 36E.1Principle. 36E.2Equipment . 36E.3Specimen preparation . 36E.4Mode of operation . 37E.5Derivation of the master-curve . 38E.6Determination of the stiffness modulus for the fixed loading time . 41Annex F (normative)

Test applying Cyclic indirect tension to cylindrical specimens (CIT-CY) . 42F.1Principle. 42F.2Equipment . 42F.3Specimen preparation . 44F.4Mode of operation . 45Annex G (informative)

Derivation of the master curve . 47G.1Principle. 47G.2Theoretical background . 48G.3Experimental data . 49G.4Test report . 50

prEN 12697-45, Bituminous mixtures — Test methods for hot mix asphalt — Part 45: Saturation ageing tensile stiffness (SATS) conditioning test prEN 12697-46, Bituminous mixtures — Test methods for hot mix asphalt — Part 46: Low temperature cracking and properties by uniaxial tension tests EN 12697-47, Bituminous mixtures — Test methods for hot mix asphalt — Part 47: Determination of the ash content of natural asphalts prEN 12697-48, Bituminous mixtures — Test methods for hot mix asphalt — Part 48: Inter-layer bond strength1) prEN 12697-49, Bituminous mixtures — Test methods for hot mix asphalt — Part 49: Skid resistance of asphalt in the laboratory1) prEN 12697-50, Bituminous mixtures — Test methods for hot mix asphalt — Part 50: Scuffing resistance of surface course1) According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

1) In preparation SIST EN 12697-26:2012

εσ=E SIST EN 12697-26:2012

the height of a cylindrical specimen, in millimetres (mm); k the load area factor; l0 the original length of the measurement area in millimetres (mm); ∆l the elongation of the measurement area in micrometers (µm); L the span length between outer supports in bending tests, in millimetres (mm); t the loading time, in seconds (s); Θ the test temperature, in degrees celsius (°C); z the displacement, in millimetres (mm); f the test frequency in Hertz (Hz); 1 the applied stress, in megapascals (MPa); 0 the applied strain, in micrometer per meter or in microstrain (µm/m); ω the angular speed, in radians per second (rad/s); Φ the phase angle, in degrees (°); γ the form factor which is a function of specimen size and form (1/mm or mm-1); µ the mass factor which is a function of the mass of the specimen and the mass of the movable parts that influence the resultant force by their inertial effects (in g); ν the Poisson's ratio; ∅ the diameter of a cylindrical specimen, in millimetres (mm). SIST EN 12697-26:2012

°C Stiffness, 10 °C, 3 s Stiffness, 10 °C, 300 s < 7,5 GPa ≥ 7,5

GPa < 1

GPa ≥ 1 GPa Strain amplitude

microstrain ≤10 100 50 – – 10 ≤ Θ < 20 – – 200 100 20 ≤ Θ ≤ 40 – – 300 200 7.3.3.3 Test loading times A series of tests shall be performed on the same specimen with various loading times and with the same maximum strain given in Table 1. Four loading times shall be used for at least one test temperature, and at least two loading times for the other test temperatures. 8 Temperatures The temperature of the climatic chamber, in the vicinity of the specimen, shall be equal to the specified temperature to ± 0,5 °C other than for the direct tension test for which the specific temperature conditions are given in Annex E. For each test temperature, the specimen shall be placed in the climatic chamber for at least 4 h before testing. SIST EN 12697-26:2012

mm–1 Mass factor, µ (g) 2PB-TR −−−−1212123213ln232212hhhh)hh()hb(hL mM+1350, a 2PB-PR

334bhL mM+4 3PB-PR

33343424bhLbhL≈ 2M+m 4PB-PR

−223243LAbhAL b ()()+ARmMXR4 bIT-CY and CIT-CY

)27,0(1+×νb – SIST EN 12697-26:2012

mm–1 Mass factor, µ (g) DTC-CY

24Dhπ mM+2 DT-CY DT-PR

1 0 a

For usual dimensions of specimens. b

()−−×=)33(1122222/LA/LXX/LALXR, 2lLA−=, X = co-ordinate at which the deflection is measured.

NOTE All dimensions in millimetres (mm); all masses in grams (g). 10 Test report The test report shall include the following information: 10.1 General a) name and address of the testing laboratory; b) a unique serial number for the test report; c) name of client; d) the number and date of this Standard; e) signature of person accepting technical responsibility for the test report; f) date of issue and age of the specimens at the time of testing (in days). 10.2 Information on specimen a) type and origin of bituminous mixture; b) method of manufacture of the bituminous mixture; c) method of compaction. SIST EN 12697-26:2012

Results relating to E*: (9 laboratories, 1 excluded by statistical tests): Average value 15 °C 10 Hz: E* = 15 233 MPa; repeatability, standard deviation: σr = 118 MPa; repeatability, limit 95 %: r = 335 MPa; reproducibility, standard deviation: σR = 969 MPa; reproducibility, limit 95 %: R = 2 740 MPa.

2) DELORME, J-L, J-F CORTE and J-L GOURDON. Exactitude experiments in tests relative to pavements. Revue Générale des Routes No. 713 2001/03. SIST EN 12697-26:2012

Two point bending test on trapezoidal specimens (2PB-TR) or on prismatic specimens (2PB-PR) A.1 Principle This annex describes a method for measuring the stiffness modulus of bituminous mixtures using cantilever bending test. A sinusoidal force, F = F0 × sin(ω × t), or a sinusoidal deflection, z = z0 × sin(ω × t), is applied to the head of a specimens glued at its base to a stand fixed to a rigid chassis. Force, F0, or deflection, z0, should be such that it causes a strain ε ≤ 50 × 10–6 in the most heavily stressed part of the specimen, which is supposed to correspond with the linear range of the bituminous mixture. On the basis of, F0, z0 and phase angle, Φ, the complex modulus is calculated at different temperatures and frequencies. A.2 Equipment A.2.1 Test machine enabling the application of sinusoidal dynamic deflection at the top of the specimen at least within the range of frequencies from 3 Hz to 30 Hz. The embedment of specimen stands in the rigid chassis shall be such that, for a given deflection, for a metal specimen, the strain, ε, measured on the test machine shall not be more than 5 % lower than the strain, ε, measured on a L-shaped frame made up of steel with a minimum thickness of 80 mm, under a force of about 50 N (see Figure A.1).

Key 1 deflection at head 2 supporting plate of the metal base of the embedment

3 embedment to be verified 4 test machine 5 L-shaped steel frame Figure A.1 — Verification of the embedment SIST EN 12697-26:2012

mm Prismatic specimens mm Trapezoidal specimens mm D ≤ 22 mm D > 22 mm D ≤ 14 mm 14 < D ≤ 22 mm 22 < D ≤ 40 mmB

56 ± 1 70 ± 1 70 ± 1 b 40 ± 1 80 ± 1 25 ± 1 25 ± 1 25 ± 1 e 40 ± 1 80 ± 1 25 ± 1 25 ± 1 50 ± 1 h 120 ± 1 240 ± 1 250 ± 1 250 ± 1 250 ± 1 NOTE D is the upper sieve size of the aggregate in the mixture, in millimetres (mm) A.3.2 Obtain the specimens by sawing from slabs made in the laboratory according EN 12697-33 or from slabs extracted from road surfaces having a thickness ≥ 60 mm. The longitudinal axis of the plate shall be parallel with the horizontal compaction axis of the mixture. A.3.3 Each specimen shall be glued by its base to a metal stand (see Figure A.3) in such a manner that this operation guarantees good geometrical positioning of the specimen in relation to its stand. The cap fixing the specimen to the alternating stress machine shall be gl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...