EN 12392:2016+A1:2022

(Main)Aluminium and aluminium alloys - Wrought products and cast products - Special requirements for products intended for the production of pressure equipment

Aluminium and aluminium alloys - Wrought products and cast products - Special requirements for products intended for the production of pressure equipment

This European Standard specifies the material requirements and testing procedures applicable to wrought and cast aluminium and aluminium alloys intended for use in the production of pressure equipment.

This European Standard covers:

- the products forms, grades and tempers of wrought and cast aluminium and aluminium alloys which may be used for such applications together with data for wrought and cast alloys over their permissible working temperature ranges;

- the permissible alloys/ tempers covered by this are those given in Table A.1 and in B.1 for wrought alloys and in Table A.2 and in B.2 for castings;

- the technical conditions for inspection and delivery, mechanical property limits and tolerances on form and dimensions by reference to the appropriate European standards for the relevant wrought and cast aluminium and aluminium alloys, and

- additional requirements which are specific to pressure equipment applications.

It applies to hot-rolled plate, cold-rolled sheet/ strip/ circles, extruded or extruded and cold drawn rod/bar, tube, extruded open / hollow profiles, forgings and castings, by this standard are those given in Table A.1 for wrought alloys and in Table A.2 for castings.

It is the sole objective of this standard to cover materials only for pressure purposes and it excludes any elements of fabrication or fabrication methods for pressure equipment; such information can be found in the relevant standards listed in the "Bibliography" section.

Aluminium und Aluminiumlegierungen - Knet- und Gusserzeugnisse - Besondere Anforderungen an Erzeugnisse für die Fertigung von Druckgeräten

Diese Europäische Norm legt die Werkstoffanforderungen und Prüfverfahren für Knet- und Gusswerkstoffe aus Aluminium und Aluminiumlegierungen fest, die zur Fertigung von Druckgeräten vorgesehen sind.

Diese Europäische Norm umfasst:

— Erzeugnisformen, Sorten und Werkstoffzustände von Knet- und Gusswerkstoffen aus Aluminium und Aluminiumlegierungen, die für diese Anwendung eingesetzt werden dürfen, zusammen mit Daten für Knet- und Gusslegierungen über ihre zulässigen Arbeitstemperaturbereiche;

— !gestrichener Text"

— Technische Prüf- und Lieferbedingungen, Grenzwerte der mechanischen Eigenschaften sowie Grenzabmaße und Formtoleranzen mit Verweisung auf die zutreffenden Europäischen Normen für Knet- und Gusswerkstoffe aus Aluminium und Aluminiumlegierungen; und

— zusätzliche spezifische Anforderungen an die Anwendung in Druckgeräten.

!Sie gilt für warmgewalzte Platten, kaltgewalzte Bleche/Bänder/Ronden, stranggepresste oder stranggepresste und kaltgezogene Stangen und Rohre, für stranggepresste Voll- und Hohlprofile sowie für Schmiede- und Gussstücke. Die Werkstoffe und Anwendungsbereiche, die dieses Dokument abdeckt, sind in Anhang A, Tabelle A.1, für Knetlegierungen und in Tabelle A.2 für Gussstücke angegeben."

In dieser Europäischen Norm werden lediglich die für Druckgeräte vorgesehenen Werkstoffe aufgeführt, Herstellung oder Fertigungsverfahren für Druckgeräte werden nicht erfasst; Angaben dazu können den einschlägigen Normen entnommen werden, die unter „Literaturhinweise“ aufgelistet sind.

Aluminium et alliages d'aluminium - Produits corroyés et moulés - Exigences particulières pour les produits destinés à la fabrication des appareils à pression

La présente Norme européenne spécifie les exigences relatives aux matériaux et les modes opératoires d'essai applicables aux produits en aluminium et en alliages d'aluminium corroyés et moulés destinés à la fabrication d'appareils sous pression.

La présente Norme européenne couvre :

- les formes de produits, les nuances et les états métallurgiques de l'aluminium et des alliages d'aluminium corroyés et moulés, susceptibles d’être utilisés pour de telles applications, ainsi que les données relatives aux alliages corroyés et moulés sur leurs plages de température de fonctionnement admissibles ;

- "texte supprimé"

- les conditions techniques de contrôle et de livraison, les limites des caractéristiques mécaniques et les tolérances sur forme et dimensions, par référence aux Normes européennes appropriées pour l'aluminium et les alliages d'aluminium corroyés et moulés ; et

- les exigences supplémentaires spécifiques aux applications d'équipements sous pression.

Elle s’applique aux tôles laminées à chaud, aux tôles minces, bandes et disques laminés à froid, aux barres et aux tubes filés ou filés et étirés à froid, ainsi qu’aux sections filées, ouvertes et creuses, aux pièces forgées et aux pièces moulées. Les matériaux et domaines d'application, couverts par le présent document, sont ceux donnés dans l'Annexe A, Tableau A.1 pour les produits corroyés, et Tableau A.2 pour les pièces moulées.

La présente norme a pour seul objectif de couvrir les matériaux pour appareils à pression uniquement et elle exclut tout élément de fabrication ou procédé de fabrication relatif aux équipements sous pression ; de telles informations sont données dans les normes pertinentes énumérées dans la Bibliographie.

Aluminij in aluminijeve zlitine - Gnetne in ulite zlitine - Posebne zahteve za aluminijeve izdelke za izdelavo naprav, ki delajo pod tlakom

Ta evropski standard opredeljuje zahteve za materiale in preskusne postopke, ki se uporabljajo za gnetni in uliti aluminij ter aluminijeve zlitine, namenjene za uporabo pri izdelavi naprav, ki delajo pod tlakom.

Ta evropski standard zajema:

– proizvodne oblike, vrste in popuščena stanja gnetnega in ulitega aluminija ter aluminijevih zlitin, ki se lahko uporabljajo za tovrstno uporabo, skupaj s podatki za gnetne in ulite zlitine glede dovoljenega razpona delovne temperature;

– opredeljene dovoljene zlitine/popuščena stanja so za gnetne zlitine navedeni v preglednicah A.1 in B.1 ter za ulitke v preglednicah A.2 in B.2;

– tehnične pogoje za pregledovanje in dobavo, omejitve mehanskih lastnosti ter odstopanja glede oblike in mer na podlagi ustreznih evropskih standardov za ustrezen gnetni in uliti aluminij ter aluminijeve zlitine; in

– dodatne zahteve, posebej določene za uporabo naprav, ki delajo pod tlakom.

Uporablja se za vroče valjane plošče, hladno valjane pločevine/trakove/obroče, ekstrudirane ali ekstrudirane in hladno vlečene drogove/palice in cevi ter ekstrudirane odprte/votle profile, izkovke in ulitke, kot je navedeno v tem standardu v preglednici A.1 za gnetne zlitine in v preglednici A.2 za ulitke.

Ta standard obravnava izključno materiale, namenjene le za uporabo s tlakom, in ne zajema proizvodnih elementov ali proizvodnih metod za naprave, ki delajo pod tlakom; tovrstne informacije je mogoče najti v ustreznih standardih, navedenih v razdelku Literatura.

General Information

- Status

- Withdrawn

- Publication Date

- 19-Jul-2022

- Withdrawal Date

- 14-Oct-2025

- Technical Committee

- CEN/TC 132 - Aluminium and aluminium alloys

- Drafting Committee

- WG 31 - Terminology and general support

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 08-Oct-2025

- Completion Date

- 15-Oct-2025

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 14-Dec-2022

Frequently Asked Questions

EN 12392:2016+A1:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aluminium and aluminium alloys - Wrought products and cast products - Special requirements for products intended for the production of pressure equipment". This standard covers: This European Standard specifies the material requirements and testing procedures applicable to wrought and cast aluminium and aluminium alloys intended for use in the production of pressure equipment. This European Standard covers: - the products forms, grades and tempers of wrought and cast aluminium and aluminium alloys which may be used for such applications together with data for wrought and cast alloys over their permissible working temperature ranges; - the permissible alloys/ tempers covered by this are those given in Table A.1 and in B.1 for wrought alloys and in Table A.2 and in B.2 for castings; - the technical conditions for inspection and delivery, mechanical property limits and tolerances on form and dimensions by reference to the appropriate European standards for the relevant wrought and cast aluminium and aluminium alloys, and - additional requirements which are specific to pressure equipment applications. It applies to hot-rolled plate, cold-rolled sheet/ strip/ circles, extruded or extruded and cold drawn rod/bar, tube, extruded open / hollow profiles, forgings and castings, by this standard are those given in Table A.1 for wrought alloys and in Table A.2 for castings. It is the sole objective of this standard to cover materials only for pressure purposes and it excludes any elements of fabrication or fabrication methods for pressure equipment; such information can be found in the relevant standards listed in the "Bibliography" section.

This European Standard specifies the material requirements and testing procedures applicable to wrought and cast aluminium and aluminium alloys intended for use in the production of pressure equipment. This European Standard covers: - the products forms, grades and tempers of wrought and cast aluminium and aluminium alloys which may be used for such applications together with data for wrought and cast alloys over their permissible working temperature ranges; - the permissible alloys/ tempers covered by this are those given in Table A.1 and in B.1 for wrought alloys and in Table A.2 and in B.2 for castings; - the technical conditions for inspection and delivery, mechanical property limits and tolerances on form and dimensions by reference to the appropriate European standards for the relevant wrought and cast aluminium and aluminium alloys, and - additional requirements which are specific to pressure equipment applications. It applies to hot-rolled plate, cold-rolled sheet/ strip/ circles, extruded or extruded and cold drawn rod/bar, tube, extruded open / hollow profiles, forgings and castings, by this standard are those given in Table A.1 for wrought alloys and in Table A.2 for castings. It is the sole objective of this standard to cover materials only for pressure purposes and it excludes any elements of fabrication or fabrication methods for pressure equipment; such information can be found in the relevant standards listed in the "Bibliography" section.

EN 12392:2016+A1:2022 is classified under the following ICS (International Classification for Standards) categories: 77.150.10 - Aluminium products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12392:2016+A1:2022 has the following relationships with other standards: It is inter standard links to EN 12392:2016/FprA1, EN 12392:2016, EN 12392:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12392:2016+A1:2022 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 12392:2016+A1:2022 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2022

Aluminij in aluminijeve zlitine - Gnetne in ulite zlitine - Posebne zahteve za

aluminijeve izdelke za izdelavo naprav, ki delajo pod tlakom

Aluminium and aluminium alloys - Wrought products and cast products - Special

requirements for products intended for the production of pressure equipment

Aluminium und Aluminium-Legierungen - Knet- und Gusserzeugnisse - Besondere

Anforderungen an Erzeugnisse für die Fertigung von Druckgeräten

Aluminium et alliages d'aluminium - Produits corroyés et moulés - Exigences

particulières pour les produits destinés à la fabrication des appareils à pression

Ta slovenski standard je istoveten z: EN 12392:2016+A1:2022

ICS:

77.150.10 Aluminijski izdelki Aluminium products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12392:2016+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2022

EUROPÄISCHE NORM

ICS 77.150.10 Supersedes EN 12392:2016

English Version

Aluminium and aluminium alloys - Wrought products and

cast products - Special requirements for products intended

for the production of pressure equipment

Aluminium et alliages d'aluminium - Produits corroyés Aluminium und Aluminium-Legierungen - Knet- und

et moulés - Exigences particulières pour les produits Gusserzeugnisse - Besondere Anforderungen an

destinés à la fabrication des appareils à pression Erzeugnisse für die Fertigung von Druckgeräten

This European Standard was approved by CEN on 18 January 2016 and includes Amendment 1 approved by CEN on 21 February

2022.

This European Standard was corrected and reissued by the CEN-CENELEC Management Centre on 3 August 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12392:2016+A1:2022 E

worldwide for CEN national Members.

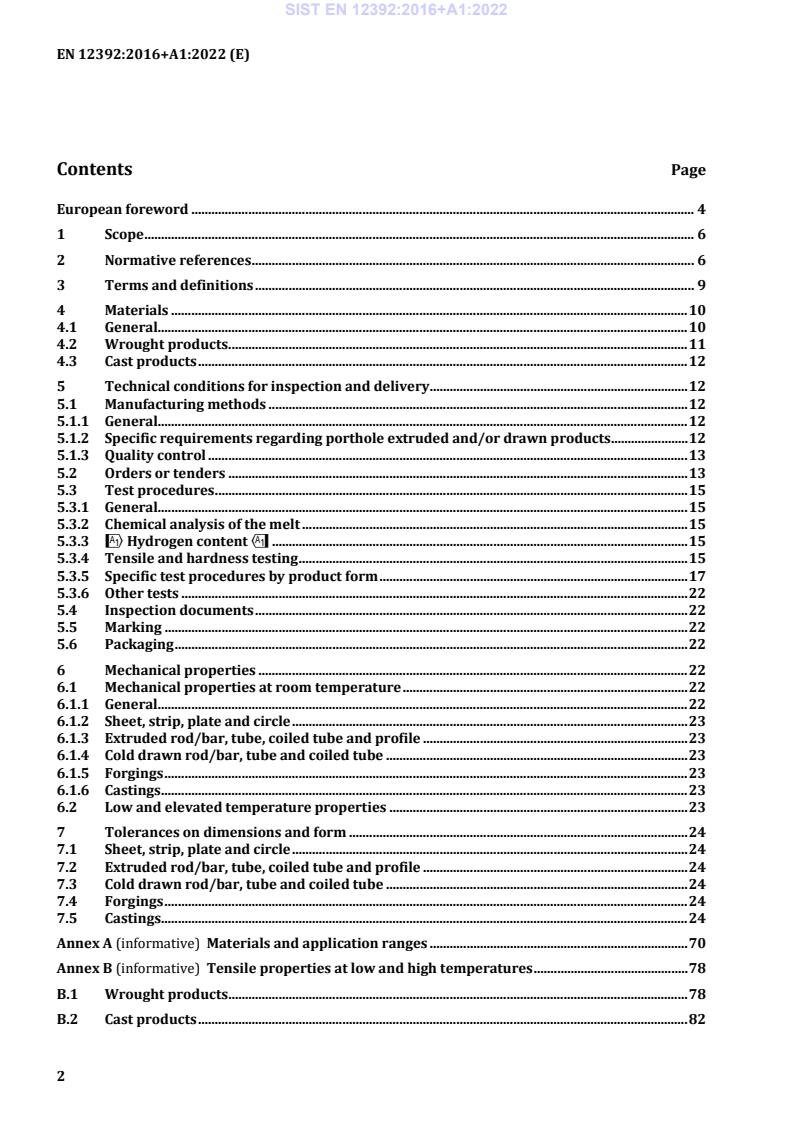

Contents Page

European foreword . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 9

4 Materials . 10

4.1 General. 10

4.2 Wrought products . 11

4.3 Cast products . 12

5 Technical conditions for inspection and delivery . 12

5.1 Manufacturing methods . 12

5.1.1 General. 12

5.1.2 Specific requirements regarding porthole extruded and/or drawn products . 12

5.1.3 Quality control . 13

5.2 Orders or tenders . 13

5.3 Test procedures . 15

5.3.1 General. 15

5.3.2 Chemical analysis of the melt . 15

5.3.3 !Hydrogen content" . 15

5.3.4 Tensile and hardness testing . 15

5.3.5 Specific test procedures by product form . 17

5.3.6 Other tests . 22

5.4 Inspection documents . 22

5.5 Marking . 22

5.6 Packaging . 22

6 Mechanical properties . 22

6.1 Mechanical properties at room temperature . 22

6.1.1 General. 22

6.1.2 Sheet, strip, plate and circle . 23

6.1.3 Extruded rod/bar, tube, coiled tube and profile . 23

6.1.4 Cold drawn rod/bar, tube and coiled tube . 23

6.1.5 Forgings . 23

6.1.6 Castings . 23

6.2 Low and elevated temperature properties . 23

7 Tolerances on dimensions and form . 24

7.1 Sheet, strip, plate and circle . 24

7.2 Extruded rod/bar, tube, coiled tube and profile . 24

7.3 Cold drawn rod/bar, tube and coiled tube . 24

7.4 Forgings . 24

7.5 Castings . 24

Annex A (informative) Materials and application ranges . 70

Annex B (informative) Tensile properties at low and high temperatures . 78

B.1 Wrought products . 78

B.2 Cast products . 82

Annex C (normative) ! Empirical conversion between values of A and A " . 86

Annex ZA (informative) !Relationship between this European Standard and the essential

safety requirements of Directive 2014/68/EU aimed to be covered" . 90

Bibliography . 91

European foreword

This document (EN 12392:2016+A1:2022) has been prepared by Technical Committee CEN/TC 132

“Aluminium and aluminium alloys”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2023, and conflicting national standards shall

be withdrawn at the latest by January 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes !EN 12392:2016".

This document includes Amendment 1 approved by CEN on 21 February 2022.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directive(s).

For relationship with EU Directive !2014/68/EU", see informative Annex ZA, which is an integral

part of this document.

Comparing to EN 12392:2000 the following modifications were implemented in EN 12392:2016:

— modification of the scope (extension to cast aluminium and aluminium alloys) (Clause 1);

— new normative references (Clause 2);

— new definitions (Clause 3): melt, casting, forging, tube;

— modification of Clause 4 “Materials” which covers Wrought products and Cast products;

— modification of Clause 5 “Technical conditions for inspection and delivery”: new requirements for

Manufacturing methods, Orders or tenders, Test procedures, Inspection documents, Marking,

Packaging;

— modification of Clause 6 “Mechanical properties”: different specifications are included at room

temperature and low and elevated temperature properties;

— modification of Clause 7 “Tolerances on dimensions and form”: inclusions of Tables 1 to 37;

— deletion of Clause 8 “Elevated temperature properties” (initially in 2000 version);

— new Annex A (Informative) “Materials and application range”;

— new Annex B (Informative) “Tensile properties at low and high temperature;

— new Annex ZA (Informative) “Relationship with EU Directive 2014/68”;

— new references into Bibliography.

!This Amendment 1 to EN 12392:2016 covers the following major subjects:

— replacement of all textual elements considered as business relationship items such as “to be agreed

between customer and supplier” and not allowed in harmonized standards by formal textual

elements allowed for harmonized standards and worded as “to be defined before placing an order”

and/or “to be stated on the order”;

— introduction of new alloys together with relevant information at specific related sections and/or

tables;

— re-introduction of famous and very used A/A50 conversion table for elongation;

— application of most recent European legislation directive (Annex ZA)."

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This European Standard specifies the material requirements and testing procedures applicable to

wrought and cast aluminium and aluminium alloys intended for use in the production of pressure

equipment.

This European Standard covers:

— the products forms, grades and tempers of wrought and cast aluminium and aluminium alloys

which may be used for such applications together with data for wrought and cast alloys over their

permissible working temperature ranges;

— !deleted text"

— the technical conditions for inspection and delivery, mechanical property limits and tolerances on

form and dimensions by reference to the appropriate European standards for the relevant wrought

and cast aluminium and aluminium alloys, and

— additional requirements which are specific to pressure equipment applications.

!It applies to hot-rolled plate, cold-rolled sheet/ strip/ circles, extruded or extruded and cold drawn

rod/bar, tube, extruded open / hollow profiles, forgings and castings. The materials and application

ranges covered by this document are those given in Annex A, Table A.1 for wrought alloys and Table A.2

for castings."

It is the sole objective of this standard to cover materials only for pressure purposes and it excludes any

elements of fabrication or fabrication methods for pressure equipment; such information can be found

in the relevant standards listed in the “Bibliography” section.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

!EN 485-1:2016, Aluminium and aluminium alloys — Sheet, strip and plate — Part 1: Technical

conditions for inspection and delivery

EN 485-3:2003, Aluminium and aluminium alloys — Sheet, strip and plate — Part 3: Tolerances on

dimensions and form for hot-rolled products

EN 485-4:1993, Aluminium and aluminium alloys — Sheet, strip and plate — Part 4: Tolerances on shape

and dimensions for cold-rolled products

EN 586-1:1997, Aluminium and aluminium alloys — Forgings — Part 1: Technical conditions for

inspection and delivery

EN 586-3:2001, Aluminium and aluminium alloys — Forgings — Part 3: Tolerances on dimensions and

form

EN 754-1:2016, Aluminium and aluminium alloys — Cold drawn rod/bar and tube — Part 1: Technical

conditions for inspection and delivery

EN 754-2:2016, Aluminium and aluminium alloys — Cold drawn rod/bar and tube — Part 2: Mechanical

properties

EN 754-3:2008, Aluminium and aluminium alloys — Cold drawn rod/bar and tube — Part 3: Round bars,

tolerances on dimensions and form

EN 754-4:2008, Aluminium and aluminium alloys — Cold drawn rod/bar and tube — Part 4: Square bars,

tolerances on dimensions and form

EN 754-5:2008, Aluminium and aluminium alloys — Cold drawn rod/bar and tube — Part 5: Rectangular

bars, tolerances on dimensions and form

EN 754-6:2008, Aluminium and aluminium alloys — Cold drawn rod/bar and tube — Part 6: Hexagonal

bars, tolerances on dimensions and form

EN 754-7:2016, Aluminium and aluminium alloys — Cold drawn rod/bar and tube — Part 7: Seamless

tubes, tolerances on dimensions and form

EN 754-8:2016, Aluminium and aluminium alloys — Cold drawn rod/bar and tube — Part 8: Porthole

tubes, tolerances on dimensions and form

EN 755-1:2016, Aluminium and aluminium alloys— Extruded rod/bar, tube and profiles — Part 1:

Technical conditions for inspection and delivery

EN 755-2:2016, Aluminium and aluminium alloys — Extruded rod/bar, tube and profiles — Part 2:

Mechanical properties

EN 755-3:2008, Aluminium and aluminium alloys — Extruded rod/bar, tube and profiles — Part 3: Round

bars, tolerances on dimensions and form

EN 755-4:2008, Aluminium and aluminium alloys — Extruded rod/bar, tube and profiles — Part 4:

Square bars, tolerances on dimensions and form

EN 755-5:2008, Aluminium and aluminium alloys — Extruded rod/bar, tube and profiles — Part 5:

Rectangular bars, tolerances on dimensions and form

EN 755-6:2008, Aluminium and aluminium alloys — Extruded rod/bar, tube and profiles — Part 6:

Hexagonal bars, tolerances on dimensions and form

EN 755-7:2016, Aluminium and aluminium alloys — Extruded rod/bar, tube and profiles — Part 7:

Seamless tubes, tolerances on dimensions and form

EN 755-8:2016, Aluminium and aluminium alloys — Extruded rod/bar, tube and profiles — Part 8:

Porthole tubes, tolerances on dimensions and form

EN 755-9:2016, Aluminium and aluminium alloys — Extruded rod/bar, tube and profiles — Part 9:

Profiles, tolerances on dimensions and form

EN 941:2014, Aluminium and aluminium alloys — Circle and circle stock for the production of general

applications — Specifications

EN 1370:2011, Founding — Examination of surface condition

EN 1371-1:2011, Founding — Liquid penetrant testing — Part 1: Sand, gravity die and low pressure die

castings

EN 1559-1:2011, Founding — Technical conditions of delivery — Part 1: General

EN 1559-4:2015, Founding — Technical conditions of delivery — Part 4: Additional requirements for

aluminium alloy castings

EN 1779:1999, Non-destructive testing — Leak testing — Criteria for method and technique selection

EN 2004-1:1993, Aerospace series — Test methods for aluminium and aluminium alloy products — Part

1: Determination of electrical conductivity of wrought aluminium alloy products

EN 2101:1991, Aerospace series — Chromic acid anodizing of aluminium and wrought aluminium alloys

EN 10204:2004, Metallic products — Types of inspection documents

EN 12020-1:2008, Aluminium and aluminium alloys — Extruded precision profiles in alloys EN AW-6060

and EN AW-6063 — Part 1: Technical conditions for inspection and delivery

EN 12020-2:2016, Aluminium and aluminium alloys — Extruded precision profiles in alloys EN AW-6060

and EN AW-6063 — Part 2: Tolerances on dimensions and form

EN 12020-2:2016/AC:2017, Aluminium and aluminium alloys — Extruded precision profiles in alloys EN

AW-6060 and EN AW-6063 — Part 2: Tolerances on dimensions and form

EN 12258-1:2012, Aluminium and aluminium alloys — Terms and definitions — Part 1: General terms

EN 12681:2003, Founding — Radiographic examination

EN 13957:2008, Aluminium and aluminium alloys — Extruded round, coiled tube for general applications

— Specification

EN 13958:2008, Aluminium and aluminium alloys — Cold drawn, round, coiled tube for general

applications — Specification

EN 14361:2004, Aluminium and aluminium alloys — Chemical analysis — Sampling from metal melts

EN 14726:2019, Aluminium and aluminium alloys — Chemical analysis — Guideline for spark optical

emission spectrometric analysis

EN ISO 148-1:2016, Metallic materials — Charpy pendulum impact test — Part 1: Test method

(ISO 148-1:2016)

EN ISO 3452-1:2021, Non-destructive testing — Penetrant testing — Part 1: General principles

(ISO 3452-1:2021)

EN ISO 6506-1:2014, Metallic materials — Brinell hardness test — Part 1: Test method (ISO 6506-1:2014)

EN ISO 6892-1:2019, Metallic materials — Tensile testing — Part 1: Method of test at room temperature

(ISO 6892-1:2019)

EN ISO 8062:2007, Castings — System of dimensional tolerances and machining allowances (ISO 8062)

EN ISO 8492:2013, Metallic materials — Tube — Flattening test (ISO 8492:2013)

EN ISO 8493:2004, Metallic materials — Tube — Drift-expanding test (ISO 8493:1998)

EN ISO 8495:2013, Metallic materials — Tube — Ring-expanding test (ISO 8495:2013)

EN ISO 8496:2013, Metallic materials — Tube — Ring tensile test (ISO 8496:2013)

ISO 9591:2004, Corrosion of aluminium alloys — Determination of resistance to stress corrosion cracking

ASTM B548:2003, Standard Test Method for Ultrasonic Inspection of Aluminium-Alloy Plate for Pressure

Vessels

ASTM B594:2019, Standard Practice for Ultrasonic Inspection of Aluminium-Alloy Wrought Products

ASTM E112:2013, Standard Test Methods for Determining Average Grain Size

ASTM E215:2016, Standard Practice for Standardizing Equipment for Electromagnetic Testing of

Seamless Aluminum-Alloy Tube"

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 12258-1 and the following

apply.

3.1

heat-treatment batch or lot

quantity of products of the same alloy or purity grade of alloy, form, thickness or cross-section and

produced in the same way and heat-treated in one furnace load; or such products solution-treated and

subsequently precipitation treated in one furnace load

Note 1 to entry: More than one solution-treatment batch can be included in one ageing furnace load.

Note 2 to entry: For heat treatment in a continuous furnace (vertical or horizontal), the products continuously

heat-treated during a specified time (e.g. 8 h) can be considered as one heat treatment lot.

Note 3 to entry: For forgings, a heat-treatment lot may consist of a group of forgings of similar size and shape.

3.2

inspection lot

consignment, or a part thereof, submitted for inspection, comprising products of the same grade or

alloy, form, thickness or cross-section, and processed in the same manner

Note 1 to entry: For forgings, an inspection lot may consist of a group of forgings of similar size and shape.

3.3

melt

quantity of molten metal that has simultaneously undergone the same preparatory treatment in the

furnace before the casting operation

3.4

cast

quantity of products cast simultaneously from the same melt

3.5

casting

product at or near finished shape, formed by solidification of the metal in a mould or a die

!

Note 1 to entry: Casting is also the process in which molten metal is poured into a mould and solidified."

Note !2" to entry: Pressure die-cast products are excluded from the scope of the present standard.

Note !3" to entry: The mould of concern can be a single use mould (sand) or a permanent mould (e.g. cast

iron or steel).

!deleted text"

3.6

forging

wrought product formed by hammering or pressing, typically when hot, such as open die forging, drop

or closed die forging or seamless rolled ring forging

3.7

tube

hollow, wrought product with a uniform cross-section, with only one enclosed void and with a uniform

wall thickness, supplied in straight lengths or in coiled form

Note 1 to entry: Cross-sections are in the shape of circles, ovals, squares, rectangles, equilateral triangles or

regular polygons and can have rounded corners, provided the inner and outer cross-sections are concentric and

have the same form and orientation.

3.8

operating temperature range

temperature range at which the material is exposed during its use

4 Materials

4.1 General

The materials covered by this standard are to be used in a wide range of pressure equipment operating

over diverse range of both pressure and temperature. The range of applications extends from relatively

low pressure automotive equipment such as heat exchangers to heavy duty applications including

unfired pressure vessels and piping used in pressure equipment. !As a result, the standard covers an

extensive range of aluminium product forms, alloys and tempers as follows:"

— sheet, strip, plate and circles (EN 485, EN 941);

— cold drawn rod/bar and tube (EN 754);

— extruded rod/bar, tube and profiles (EN 755);

— precision profiles (EN 12020);

— extruded coiled tube (EN 13957);

— cold drawn coiled tube (EN 13958);

— forgings (EN 586);

— castings (EN 1706).

Materials (alloys and tempers), which may be used in compliance with the present standard are listed

in Tables 1, A.1 and A.2, together with their welding characteristics, main field of application and

operating temperature ranges.

!deleted text"

!If the pressure equipment is operating above room temperature for times exceeding 100 h, then the

long time behaviour of the material according to Annex B, Tables B.1 to B.4 will need to be taken into

consideration."

!Materials to be used for welded components shall be produced with a hydrogen level no greater

than 0,2 ml per 100 g aluminium, or an equivalent value/level determined by an alternative agreed

method."

4.2 Wrought products

!Applicable alloys and the chemical compositions for wrought products are given in Tables 1 and 2.

The chemical compositions of aluminium and aluminium alloys are specified in percentage by mass.

Limits for impurities are expressed as maxima that also will apply to alloying elements unless

expressed as a range. Aluminium is specified as a minimum for unalloyed aluminium, and as a

remainder for aluminium alloys."

!All grades of wrought aluminium and alloys shall have a lead (Pb), tin (Sn) and bismuth (Bi) content

not exceeding 0,015 0 % by mass, per each element. For particularly safety-sensitive applications (e.g.

high volumes at high pressure), lower values shall be agreed and stated on the order.

Wrought products in aluminium and aluminium alloys used for welded parts of pressure vessels that

are subjected to cold forming (e.g. rolled shells and heads) shall have a specified minimum A value after

fracture measured on a gauge length as follows:

LS= 5,65 (4.2-1)

oo

and ≥ 14 % in the longitudinal or transverse direction.

Wrought products in aluminium and aluminium alloys used for parts of pressure vessels that are not

subjected to cold forming (e.g. straight flanges and nozzles) shall have a specified minimum elongation

after fracture measured on a gauge length as follows:

LS= 5,65 (4.2-2)

oo

and ≥ 10 % in the longitudinal or transverse direction.

The conversion of A values into A and vice versa shall be carried out as specified in Annex C.

When using minimum A values converted from A values as requirements, the converted A value

50 50

shall be taken from Table C.1 then rounded up to the next whole number (example: a converted value

A of 12,2 % shall be implemented as a minimum requirement of A value by 13 %).

EXAMPLE 1 A 12,5 mm wide rectangular test piece prepared from rolled sheet with a thickness of 2,0 mm.

Then the cross sectional area of this test piece is 25 mm , and the corresponding gauge length for a proportional

test piece is 28,3 mm. The measured value of A is 13,0 % which corresponds to an approximate elongation

value for A of 17,0 %.

EXAMPLE 2 An elongation value for A of 24,0 % measured on a proportional test piece with a gauge length of

35,7 mm. This corresponds to an approximate elongation value for A of 20,4 %, measured on a 12,5 mm wide

rectangular test piece with a thickness of 3,2 mm. The cross sectional area of this test piece is 40 mm .

EXAMPLE 3 A wrought material in thickness 12,0 mm selected for a part to be cold deformed and welded

during fabrication. The tensile test samples shall be either:

— a proportional test sample with a cross section of 150 mm and a gauge length of 69,2 mm, for which the

minimum elongation value A of 14 % will apply, or,

— a non-proportional test sample with a cross section of 150 mm and a gauge length of 50 mm. In this case the

minimum A50 value to apply will be 20 %, as rounded up to the next whole number from the indicated value of

19,1 % in Table C.1."

4.3 Cast products

!Applicable alloys and the chemical compositions for cast products are given in Table 3." The

chemical compositions of aluminium and aluminium alloys are specified in percentage by mass.

!Limits for impurities are expressed as maxima which will also apply to all alloying elements unless

expressed as a range."

5 Technical conditions for inspection and delivery

5.1 Manufacturing methods

5.1.1 General

The provisions of EN 485-1 (sheets, strips and plates), EN 941 (circles), EN 755-1 (extruded rods/bars,

tubes and profiles), EN 754-1 (cold drawn rods/bars, and tubes), EN 12020-1, EN 13957, EN 13958,

EN 586-1 (forgings incl. seamless rolled rings), EN 1559-1 (Founding) and EN 1559-4 (Founding) apply

with the amendments and additions specified in 5.2 to 5.5 below.

!The manufacturing methods used shall be left to the discretion of the producer." In addition, there

shall be no obligation on the supplier to use the same processes or process route for subsequent or

similar orders.

!When the manufacturing method to be used is restricted or fixed, it shall be stated on the purchase

order (see 5.2)."

5.1.2 Specific requirements regarding porthole extruded and/or drawn products

!Regarding porthole extruded and/or drawn products, limitations for safe application of such

products are given in Tables 4 and 5:"

— Table 4 applies to porthole extruded tube (EN 755-8), porthole extruded and drawn tube

(EN 754-8), porthole extruded hollow profiles (EN 755-9) and porthole extruded precision profiles

(EN 12020) and may be used up to and including an outside diameter !of 600 mm (DN 600) and

a maximum thickness (t) of 20 mm";

— Table 5 applies to porthole extruded coiled tube (EN 13957) and porthole extruded and drawn

coiled tube EN 13958 and may be used up to and including an outside !diameter 50 mm (DN 50)

and a maximum thickness (t) of 5 mm".

!The stated values for maximum allowable pressure (PS) and volume (V) disclosed in Tables 4 and 5

are limitations superseding those required by European Legislation for Pressure Equipment.

The purchaser is responsible to cascade the relevant design elements of the final equipment to the

producer.

As a result, the purchaser shall, when placing an order with the producer (material manufacturer),

provide the following information to ensure that the correct Hazard Category and adequate quality

assurance is applied to the particular combination of criteria:

— the type of pressure equipment being considered (vessel or piping acc. European Legislation for

Pressure Equipment and intended use);

— the state of the fluid in the equipment (gas or liquid);

— the hazard group of the fluid (acc. to European Legislation for Pressure Equipment);

— maximum pressure for which the equipment is designed (PS);

— confirmation that the completed equipment assembly is pressure tested."

!NOTE 1 Some further comment is necessary on the methods of extrusion used for tube and hollow profiles. In

particular seamless extrusion produces a product that does not contain any seams or weld lines in the product

cross-section. On the other hand, extruded products manufactured using a porthole or bridge die contains at least

one longitudinal weld or seam. The presence of such welds or seams can be a major concern on products that are

to be used for e.g. pressure vessels since the weld/seam could lead to premature failure of the vessel under

pressure."

NOTE 2 In addition despite rigorous process control during the extrusion process, there is no definitive non-

destructive test method that can provide total assurance of the integrity of the welds in the product cross-section.

In view of the safety implications of using porthole products, it is necessary to provide guidelines in this standard

as to the permitted product areas where porthole products may or may not be used.

!NOTE 3 Transverse extrusion seams (charge welds) are generally not permitted in extruded or

extruded/drawn products used for pressure equipment. However, the use of transverse extrusion seams for

coiled tubes according to EN 13957 and EN 13958 is allowed, provided that the integrity of the extrusion seams is

ensured by adequate quality assurance/testing procedures based on the recommendations given in Table 5 and

stated on the order."

!NOTE 4 It needs to be highlighted that, beside the limits for nominal size DN and thickness t, Tables 4 and 5

provide additional limitations regarding pressure PS, volume V and testing procedures. The purchaser can decide

to use porthole extrusion for products exceeding the stated limits/hazard categories but this has to be stated on

the order with defined quality assurance / testing procedures."

5.1.3 Quality control

!All inspection and tests required by the relevant European standard and/or the particular

specification shall be undertaken prior to shipment of the product. Any additional inspection required

shall be stated on the purchase order (see 5.2)."

5.2 Orders or tenders

The order or tender documents shall define the product required and contain the following minimum

information:

a) the type and form of the product. In the case of tube whether extruded, cold drawn or coiled, it is

also essential to state the method of extrusion to be used i.e. seamless or porthole (see also point i)

below);

b) reference to this particular Standard EN 12392;

c) the dimensions and shape of the particular product required;

1) plate: thickness, width and length;

2) sheet: thickness, width and length;

3) strip: thickness width and coil dimensions;

4) circles: thickness and diameter;

5) round tube: method of production, outside (OD) or inside (ID) diameter, wall thickness (WT),

and length;

NOTE 1 Two of the OD/ID/WT dimensions may be given tolerances but not all three.

6) coiled round tube: outside (OD) or inside (ID) diameter, wall thickness (WT), coil dimensions

and tube length if required in straight lengths;

NOTE 2 Two of the OD/ID/WT dimensions may be given tolerances but not all three.

7) round bar: diameter and length;

8) square and hexagonal bar: width across flats and length;

9) rectangular bar: width, thickness and length;

10) extruded profiles and hollow sections: drawing of cross section and length;

11) forgings (open-die forgings, closed-die forgings and seamless rolled rings): reference to

drawing or finished size;

12) castings: reference to a drawing.

d) the product tolerances on dimensions and form together with particular reference to the relevant

European standard for the specific product concerned;

e) quantity required: whether it is weight, number of pieces, total length and the quantity tolerance on

the total amount of the order;

f) product certification requirement with particular reference to EN 10204:2004;

g) identification marking requirements;

h) surface finish requirements particularly details of any surface treatments to be carried out;

i) the order shall clearly show if the ordered product is to be produced by the porthole extrusion

method. In case of porthole extrusion, additional information as expressed in 5.1.2 shall be

provided;

j) !any other special requirements (e.g. grain size). This applies to particular requirements such as

flattening test, leak test, ultrasonic test, etc., which shall be expressly stated together with the

criteria to which the material shall be verified."

k) any additional inspection to be carried out prior to delivery;

l) surface protection oil requirements;

m) packaging methods to be used;

!n) manufacturing method if restricted or fixed."

5.3 Test procedures

5.3.1 General

This subclause covers only chemical composition and tensile / hardness testing which are common to

all the products. The remaining test procedures and methods are given in the sections dealing with the

individual products.

Regarding the standards to be used for testing, the EN or EN ISO standards shall be used whenever

possible. !However, other standards such as ASTM may be used when compatible EN or EN ISO are

not available."

!Unless otherwise stated on the purchase order, the following test procedures disclosed in the

following sections shall apply."

5.3.2 Chemical analysis of the melt

The samples for chemical analysis shall be taken at the time of casting or melting in accordance with

EN 14361 and EN 14726. At least one specimen shall be taken from each melt. The methods of analysis

used should be at the discretion of the supplier or by agreement between the supplier and purchaser.

For castings, chemical analysis shall be carried out on samples taken from the same melt as the castings;

the samples shall be cooled quickly enough to minimize any segregation effects. !The frequency of

sampling depends on the particular process of concern." The frequency, for example, may vary from

one sample per charge to one sample per piece or per shift.

5.3.3 !Hydrogen content

The hydrogen level shall be measured on liquid metal during casting or through an agreed alternative

method stated on the order."

5.3.4 Tensile and hardness testing

The methods used shall be in compliance with EN ISO 6892-1 for tensile testing and EN ISO 6506-1 for

Brinell hardness testing. !Other methods of hardness testing e.g. Webster method can be used when

stated in the order with defined frequency of testing and minimum acceptable values."

Tensile testing shall be carried out as specified in EN 485-1, EN 754-1, EN 755-1, EN 586-1, EN 1559-1,

or EN 1559-4, as applicable, noting the following:

a) frequency of test:

1) for sheet, strip and plate at least one test-piece shall be taken from each cast represented in

each inspection lot, or heat-treatment lot where applicable, of 10 000 kg or part thereof. For

single plate or coil weighing more than 10 000 kg each, only one test-piece per plate or coil

shall be taken;

2) for extruded or extruded and cold drawn products;

i) for profiles and hollow sections having a nominal mass of up to and including 1 kg/m, a

minimum of one test piece shall be taken from each cast represented in each inspection or

heat treatment lot of 1000 kg or part thereof.

ii) for profiles and hollow sections having a nominal mass of over 1 kg/m and up to 5 kg/m, a

minimum of one test piece shall be taken from each cast represented in each inspection or

heat treatment lot of 2000 kg or part thereof.

3) for extruded and cold drawn tube (in straight lengths or coiled);

i) for tube produced by the porthole extrusion method, a minimum of one tensile test shall be

taken for every 1000 kg or part thereof for each inspection or heat treatment lot.

ii) for tube produced by the seamless extrusion method to be used for heavy duty

applications, unfired pressure vessels, or piping used in pressure equipment, a minimum

of two tensile tests shall be taken for each 1000 kg or part thereof for each cast

represented in every inspection or heat treatment lot.

4) for forgings including seamless rolled rings;

i) for forgings weighing up to 2 kg at least one test piece shall be taken from each inspection

lot or heat treatment lot of 1000 kg or part thereof;

ii) for forgings weighing over 2 kg and up to and including 10 kg, a minimum of one test piece

shall be taken from each inspection or heat treatment lot of 2000 kg or part thereof;

iii) for forgings weighing over 10 kg, a minimum of one test piece shall be taken from each

inspection or heat treatment lot of 3000 kg or part thereof.

5) for castings;

Depending on agreement between supplier and purchaser !and stated on the order", this

can be:

i) one test piece for each part;

ii) one test piece for each melting charge in case of temper designation “F”;

iii) one test piece for each melting charge and heat treatment lot.

!Position, orientation, dimensions and cooling rate of the tensile test pieces shall be stated in

the purchase order. The test pieces may be cast:"

— separately from the castings but from the same melt and in a special mould (made from the

same material as the castings themselves);

— at the same time as the castings i.e. the test piece is attached to the casting itself.

!Note: in both cases, the cooling rate of the test samples shall be adjusted to achieve a

microstructure compatible with the castings particularly in critical areas which may be

subject to subsequent heat treatment."

iv) !If test pieces are taken from castings, then their geometry, location, test frequency and

relevant values shall be determined before starting the production. Test pieces should be

taken from areas with a wall thickness between 5 mm and 25 mm."

v) For round test pieces the minimum diameter shall be 4,0 mm. Refer to the footnotes in

!Tables 37 and 38" for yield strength, tensile strength values and for elongation

values.

!deleted text"

The minimum tensile values required shall be in accordance with this Standard and these

values shall be used in conjunction with the design standard for the particular casting in

question. Mechanical properties at specified positions in the part may be adjusted by the

foundry to higher values as the minimal values given in !Table 37 and 38". !These

positions shall be determined before the start of the production."

b) yield strength measurement:

1) Rp0,2 shall be measured for all alloys, and

2) for aluminium grades EN AW-1080A, EN AW-1070A and EN AW-1050A, in temper O, H111 or

H112, Rp1,0 (proof stress at 1 % permanent elongation) shall also be measu

...

기사 제목: EN 12392:2016+A1:2022 - 알루미늄 및 알루미늄 합금 - 가공 제품과 주조 제품 - 압력장비 생산을 위한 특수 요구사항 기사 내용: 이 유럽 표준은 압력장비 생산에 사용되는 가공 및 주조 알루미늄 및 알루미늄 합금에 적용되는 자재 요구사항과 시험 절차를 명시합니다. 이 유럽 표준은 다음을 다룹니다: - 압력장비에 사용될 수 있는 가공 및 주조 알루미늄 및 알루미늄 합금의 제품 형태, 등급 및 경화상태, 그리고 허용 가능한 작업 온도 범위에 대한 가공 및 주조 합금 데이터; - 이 표준에서 다루는 허용 가능한 합금/경화상태는 가공 합금에 대해 표 A.1 및 B.1에 나와 있으며, 주조합금에 대해서는 표 A.2 및 B.2에 나와 있습니다; - 적절한 유럽 표준에 대한 참조를 통해 가공 및 주조 알루미늄 및 알루미늄 합금의 검사 및 공급 기술 조건, 기계적 성질 제한 및 형태 및 치수에 대한 허용 오차; - 압력장비 적용에 특정한 추가 요구사항. 이 표준은 열간압연 판, 냉간압연 시트/스트립/원형, 압출 또는 압출 및 냉간 당긴 막대/바, 튜브, 압출 개방/공백 프로파일, 단조 및 주조에 적용되며, 이 표준에서는 가공 합금의 경우 표 A.1, 주조의 경우 표 A.2에서 제시한 것만 적용됩니다. 이 표준의 유일한 목적은 압력용 재료만을 다루는 것이며, 압력장비의 제작요소나 제작 방법은 제시된 "참고 문헌" 섹션에 나열된 관련 표준에서 찾을 수 있습니다.

記事のタイトル:EN 12392:2016+A1:2022 - アルミニウムとアルミニウム合金 - 加工品と鋳造品 - 圧力機器の製造に使用される製品に対する特別な要件 記事の内容:このヨーロッパ標準は、圧力機器の製造に使用される加工品および鋳造品のアルミニウムおよびアルミニウム合金の材料要件および試験手順を指定しています。 このヨーロッパ標準は、以下の内容をカバーしています: - これらの応用に使用できる加工品および鋳造アルミニウムおよびアルミニウム合金の製品形状、等級および硬度状態と、許容作業温度範囲で製造される加工および鋳造合金のデータ; - この標準でカバーされる許容合金/硬度状態は、加工合金については表A.1およびB.1で、鋳造については表A.2およびB.2で指定されています; - 関連するヨーロッパ標準に基づいて、加工および鋳造アルミニウムおよびアルミニウム合金に対する検査および納品の技術条件、機械的特性の制限および形状および寸法に対する公差に関する参照を含む; - 圧力機器応用に特有の追加要件。 この標準は、熱圧鋼板、冷間圧延シート/ストリップ/サークル、押出または押出および冷間引き成形ロッド/バー、チューブ、押出し開放/中空プロファイル、鍛造および鋳造に適用されます。加工合金の場合、表A.1で示されるものであり、鋳造の場合、表A.2で示されるものが適用されます。 この標準の唯一の目的は、圧力目的のための材料のみをカバーすることであり、圧力機器の製造または製造方法の要素は、"参考文献"セクションにリストされている関連する標準で見つけることができます。

EN 12392:2016+A1:2022 is a European Standard that specifies material requirements and testing procedures for wrought and cast aluminum and aluminum alloys used in the production of pressure equipment. The Standard covers various product forms, grades, and tempers of aluminum and aluminum alloys, as well as the technical conditions for inspection, delivery, and mechanical properties. It also includes additional requirements specific to pressure equipment applications. The Standard applies to hot-rolled plates, cold-rolled sheets/strips/circles, rods/bars, tubes, profiles, forgings, and castings. However, it does not cover fabrication or fabrication methods for pressure equipment, which can be found in other relevant standards listed in the "Bibliography" section.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...