EN 15566:2009

(Main)Railway applications - Railway rolling stock - Draw gear and screw coupling

Railway applications - Railway rolling stock - Draw gear and screw coupling

This standard specifies the requirement of the draw gear and screw coupling for the end rolling stock which have to couple with other interoperable rolling stock (freight wagons, locomotives, passenger vehicles ...).

This standard covers the functionality construction, interfaces, testing including pass fail criteria for draw gear and screw coupling.

The standard describes three categories of classification of draw gear and screw coupling, (1 MN, 1,2 MN and 1,5 MN).

Bahnanwendungen - Schienenfahrzeuge - Zugeinrichtung und Schraubenkupplung

Diese Norm legt die Anforderungen an Zugeinrichtungen und Schraubenkupplungen für Endwagen fest, die mit anderen Schienenfahrzeugen des grenzüberschreitenden Verkehrs (Güterwagen, Lokomotiven, Reise¬zugwagen ...) gekuppelt werden müssen.

Diese Norm umfasst die Funktionalität, Bauweise, Schnittstellen und Prüfungen einschließlich der Abnahme¬kriterien für Zugeinrichtungen und Schraubenkupplungen.

In dieser Norm sind drei Kategorien von Zugeinrichtungen und Schraubenkupplungen beschrieben (1 MN, 1,2 1,2 MN aund 1,5 MN).

Applications ferroviaires - Matériel roulant ferroviaire - Organes de traction et tendeur d'attelage

La présente norme spécifie les exigences relatives aux organes de traction et tendeurs d'attelage pour un matériel roulant devant être couplé à un autre matériel roulant interopérable (wagons de marchandises, locomotives, voitures, etc.).

La présente norme couvre la fonctionnalité, la construction, les interfaces et les essais, y compris les critères de réussite/d'échec aux essais pour les organes de traction et les tendeurs d'attelage.

La norme décrit trois catégories pour les organes de traction et les tendeurs d'attelage (1 MN, 1,2 MN et 1,5 MN).

Železniške naprave - Železniška vozila - Vlečna naprava in vijačna spenjača

General Information

- Status

- Withdrawn

- Publication Date

- 27-Jan-2009

- Withdrawal Date

- 02-Nov-2010

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/WG 33 - Coupling devices

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Nov-2010

- Completion Date

- 03-Nov-2010

Relations

- Merged Into

EN 15566:2009+A1:2010 - Railway applications - Railway rolling stock - Draw gear and screw coupling - Effective Date

- 06-Sep-2010

- Amended By

EN 15566:2009/FprA1 - Railway applications - Railway rolling stock - Draw gear and screw coupling - Effective Date

- 15-Feb-2010

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 15566:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Railway rolling stock - Draw gear and screw coupling". This standard covers: This standard specifies the requirement of the draw gear and screw coupling for the end rolling stock which have to couple with other interoperable rolling stock (freight wagons, locomotives, passenger vehicles ...). This standard covers the functionality construction, interfaces, testing including pass fail criteria for draw gear and screw coupling. The standard describes three categories of classification of draw gear and screw coupling, (1 MN, 1,2 MN and 1,5 MN).

This standard specifies the requirement of the draw gear and screw coupling for the end rolling stock which have to couple with other interoperable rolling stock (freight wagons, locomotives, passenger vehicles ...). This standard covers the functionality construction, interfaces, testing including pass fail criteria for draw gear and screw coupling. The standard describes three categories of classification of draw gear and screw coupling, (1 MN, 1,2 MN and 1,5 MN).

EN 15566:2009 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering; 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15566:2009 has the following relationships with other standards: It is inter standard links to EN 15566:2009+A1:2010, EN 15566:2009/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15566:2009 is associated with the following European legislation: EU Directives/Regulations: 2001/16/EC, 2008/57/EC, 96/48/EC; Standardization Mandates: M/275, M/334. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15566:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen - Eisenbahnfahrzeuge - Zugeinrichtung und SchraubenkupplungApplications ferroviaires - Matériel roulant ferroviaire - Organes de traction et tendeur d'attelageRailway applications - Railway rolling stock - Draw gear and screw coupling45.060.10Tractive stockICS:Ta slovenski standard je istoveten z:EN 15566:2009SIST EN 15566:2009en01-april-2009SIST EN 15566:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15566January 2009ICS 45.040; 45.060.01 English VersionRailway applications - Railway rolling stock - Draw gear andscrew couplingApplications ferroviaires - Matériel roulant ferroviaire -Organes de traction et tendeur d'attelageBahnanwendungen - Schienenfahrzeuge - Zugeinrichtungund SchraubenkupplungThis European Standard was approved by CEN on 19 December 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15566:2009: ESIST EN 15566:2009

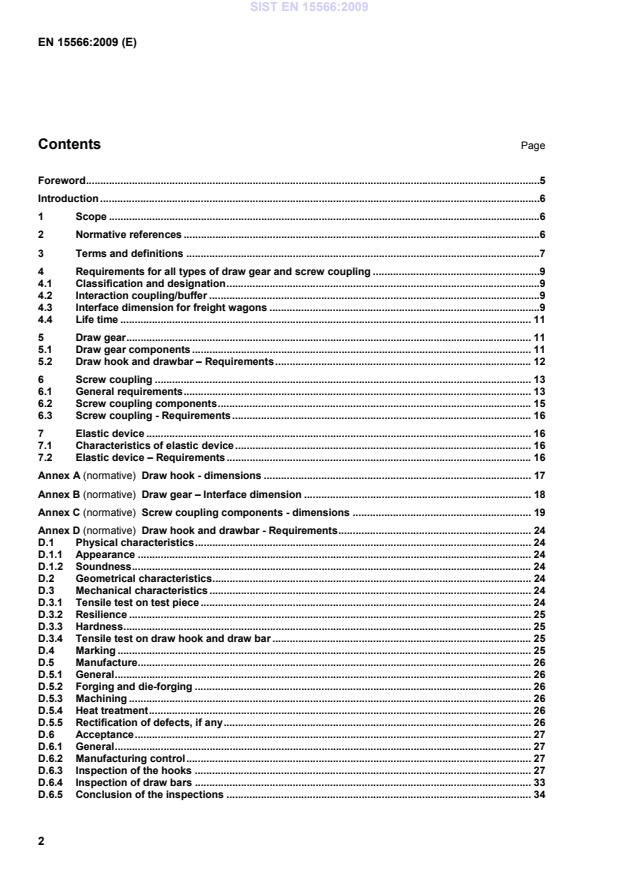

Draw hook - dimensions . 17 Annex B (normative)

Draw gear – Interface dimension . 18 Annex C (normative)

Screw coupling components - dimensions . 19 Annex D (normative)

Draw hook and drawbar - Requirements . 24 D.1 Physical characteristics . 24 D.1.1 Appearance . 24 D.1.2 Soundness . 24 D.2 Geometrical characteristics . 24 D.3 Mechanical characteristics . 24 D.3.1 Tensile test on test piece . 24 D.3.2 Resilience . 25 D.3.3 Hardness . 25 D.3.4 Tensile test on draw hook and draw bar . 25 D.4 Marking . 25 D.5 Manufacture . 26 D.5.1 General . 26 D.5.2 Forging and die-forging . 26 D.5.3 Machining . 26 D.5.4 Heat treatment . 26 D.5.5 Rectification of defects, if any . 26 D.6 Acceptance . 27 D.6.1 General . 27 D.6.2 Manufacturing control . 27 D.6.3 Inspection of the hooks . 27 D.6.4 Inspection of draw bars . 33 D.6.5 Conclusion of the inspections . 34 SIST EN 15566:2009

Screw coupling and component parts - Requirements . 36 E.1 Material . 36 E.2 Physical characteristics. 36 E.2.1 Appearance . 36 E.2.2 Soundness . 36 E.2.3 Additional requirements for screw couplings . 36 E.3 Geometrical characteristics . 37 E.3.1 General . 37 E.3.2 Dimensions limited either by 2 unmachined or rough-machined surfaces or by one unmachined or rough-machined surface . 37 E.3.3 Dimensions limited by two machined surfaces . 37 E.4 Mechanical characteristics . 37 E.4.1 Heat treatment . 37 E.4.2 Hardness . 38 E.4.3 Fracture test on link (tensile test on finished part) . 38 E.4.4 Resilience . 38 E.4.5 Requirements for screw coupling . 38 E.5 Marking . 40 E.6 Manufacture . 42 E.6.1 General . 42 E.6.2 Preparation of the materials . 42 E.6.3 Manufacture of the component parts . 42 E.7 Acceptance . 44 E.7.1 General . 44 E.7.2 Inspection of the manufacture . 44 E.8 Inspection of the materials, component parts and screw couplings . 44 E.8.1 General . 44 E.8.2 Submission for acceptance . 44 E.8.3 Grouping into batches . 45 E.8.4 Advice of submission for acceptance . 45 E.8.5 Nature and proportion of the tests . 46 E.8.6 Sampling and preparation of the samples and test pieces . 47 E.8.7 Carrying out of the checks and tests . 50 E.9 Completion of inspections . 52 E.10 Delivery . 52 E.10.1 Protection against oxidation . 52 E.10.2 Packing . 52 Annex F (normative)

Elastic device - Requirements . 53 F.1 Rubber elastomer or other elastomer elastic device . 53 F.1.1 General . 53 F.1.2 Metal inserts requirements . 53 F.1.3 Elastomer requirements . 53 F.1.4 Static test. 55 F.1.5 Endurance test . 55 F.1.6 Bonding . 57 F.1.7 Inspection and Tests . 58 F.1.8 Markings . 58 F.2 Friction spring/Ring spring . 59 F.2.1 Manufacturer's marks . 59 F.2.2 Flexibility test . 59 F.2.3 Endurance test . 60 Annex G (normative)

Additional tests on semi-finished products . 61 G.1 Scope and field of application . 61 G.2 Macrographic examination . 61 G.2.1 General . 61 SIST EN 15566:2009

Relationship between this European Standard and the Essential Requirements of EU Directive 96/48/EC, as modified by Directive 2004/50/EC . 63 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2001/16/EC of the European Parliament and of the Council of 19 March 2001 on the interoperability of the trans-European conventional rail system, as modified by EU Directive 2004/50/EC of 29 April 2004 . 64 Bibliography . 66

EN 10025 (allparts), Hot rolled products of structural steels EN 10045-1, Metallic materials — Charpy impact test — Part 1: Test method EN 10079, Definition of steel products EN 10083-1, Steels for quenching and tempering — Part 1: General technical delivery conditions EN 10083-2, Steels for quenching and tempering — Part 2: Technical delivery conditions for non alloy steels EN 10083-3, Steels for quenching and tempering — Part 3: Technical delivery conditions for alloy steels EN 10204:2004, Metallic products — Types of inspection documents EN 10228-3, Non-destructive testing of steel forgings — Part 3: Ultrasonic testing of ferritic or martensitic steel forgings EN ISO 377, Steel and steel products — Location and preparation of samples and test pieces for mechanical testing (ISO 377:1997) EN ISO 868, Plastics and ebonite — Determination of indentation hardness by means of a durometer (Shore hardness) (ISO 868:2003) EN ISO 6506-1, Metallic materials — Brinell hardness test — Part 1: Test method (ISO 6506-1:2005) SIST EN 15566:2009

Key: Y

force in kN X

stroke in mm We

stored energy in kJ Wa

absorbed energy in kJ Figure 1 — Force-stroke diagram for stored and absorbed energy 3.8 working capacity stored energy under test conditions 3.9 damping A ratio of absorbed energy divided by stored energy NOTE It is calculated using the following equation: SIST EN 15566:2009

is the absorbed energy; We

is the stored energy. 3.10 minimum breaking load minimum load which may lead to mechanical failure 4 Requirements for all types of draw gear and screw coupling 4.1 Classification and designation Coupling systems are classified according to their minimum breaking load as specified in Table 1. Table 1 — Classification of coupling by designation of the minimal breaking load Coupling system designation Minimum breaking load of the screw coupling

(MN) Minimum breaking load in traction of the draw gear and draw hook

(MN) 1 MN 0,85 1 1,2 MN 1,02 1,2 1,5 MN 1,35 1,5

The coupling links shall be designed to break first in case of overloading. For shunting operations, the draw gear shall allow a 0,05 MN compressive load on the draw hook. For rescue operations, the draw gear of locomotives shall allow a 0,3 MN compressive load on the draw hook. 4.2 Interaction coupling/buffer To ensure that the train is able to negotiate curves at 150 m radius safely, the static characteristics of draw gears and buffers should be coordinated. NOTE Refer to prEN 15839 for details. 4.3 Interface dimension for freight wagons Support plate interface dimensions for fixing of draw gear on freight wagons are defined in Figure 2. NOTE For other railway vehicles, the arrangement could be different. Draw gear assemblies shall be interchangeable. The interchangeability only applies to complete draw gear assemblies, not to single draw gear parts. SIST EN 15566:2009

Key a distance to the buffer fixing plate b 140 mm for mounting the draw gear from the front of the headstock Figure 2 — Support plate - Interface dimension for freight wagons NOTE The centreline of the draw gear (screw coupling) is also the centreline of the automatic coupler. SIST EN 15566:2009

Table 3 — Condition of dynamic tests Operational requirements Range of forces to be applied Lifecycle in years Survival probability% Safety factorfN Designation Step 1 Step 2

1MN ∆F1=200 kN ∆F2=675 kN

1,2 MN ∆F1=240 kN ∆F2=810 kN

1,5 MN ∆F1=300 kN ∆F2=1015 kN

N1 in cycles N2 in cycles 20 97,5 1,7 All 106 1,45x103 30 97,5 1,7 All 1,5x106 2,15x103

The dynamic tests have to be carried out on 3 draw gears without elastic device. The 3 samples all have to endure the tests without showing any damage. They shall not show any cracks and the tensile strength shall not drop below 1 000 kN. NOTE ERRI Report B51/RP 27 describes one possible way testing all force transferring components of a draw gear including the assembled draw gear, draw hook and screw coupler. 5 Draw gear 5.1 Draw gear components Draw gear assembly see Figure 3. The interface dimensions of the draw gear are given in Annex A and Annex B. Components of a standard draw gear are: Draw hook see Figure A.1 Drawbar interface dimensions see Figure B.1 Joint pin interface dimensions see Figure B.2 Elastic device see 7 Support plate see Figure 2 SIST EN 15566:2009

Key 1 Draw hook 2 Drawbar 3 Joint pin 4 Support plate 5 Elastic device 6 Underframe Figure 3 —Draw gear - Assembly 5.2 Draw hook and drawbar – Requirements Requirements are defined in Annex D. SIST EN 15566:2009

Key 1 Coupling hook pin 2 Coupling links 3 Screw 4 Trunnion for ball handle (T-bar) 5 Handle (T-bar) housing 6 Hinged ball handle (T-bar) 7 Trunnion 8 D-shackle

D1 Greatest length for the fully loosened coupling ()105986+− mm D2 Smallest length for the fully tightened coupling ()10750± mm

Figure 4 — Standard screw coupling with non-loosening hinged ball handle SIST EN 15566:2009

Key 1 Coupling hook pin 2 Coupling links 3 Screw 4 Trunnion for handle (T-bar) with top-mounted rest 5 Handle (T-bar) housing 6 Hinged handle (T-bar) 7 Trunnion 8 D-shackle

D1 Greatest length for the fully loosened coupling ()105986+− mm D2 Smallest length for the fully tightened coupling ()10750± mm

Figure 5 — Standard screw coupling with hinged handle with non-loosening upper rest 6.2 Screw coupling components Component parts of a standard screw coupling are: Coupling hook pin see Figure C.1 Coupling link see Figure C.2 Screw

see Figure C.3 Trunnion for ball handle (T-bar) see Figure C.4 Trunnion for handle (T-bar) with top-mounted rest

see Figure C.5 SIST EN 15566:2009

see Figure C.6 Hinged handle (T-bar)

see Figure C.7 Hinged ball handle (T-bar)

see Figure C.8 Trunnion

see Figure C.9 D-shackle

see Figure C.10 Dimensions of screw coupling components shall be as given in Annex C. Note The interchangeability of the hinged-handle (Figure C.7) is linked to the trunnion with the top-mounted rest (Figure C.5) 6.3 Screw coupling - Requirements Requirements are defined in Annex E. 7 Elastic device 7.1 Characteristics of elastic device a) Final force after a stroke of 50 mm to 60 mm obligatory minimum value 400 kN recommended minimum value 550 kN b) Pre-compression obligatory minimum value 10 kN recommended minimum value 20 kN c) Static storage capacity We

obligatory minimum value 10 kJ minimum value in respect of wagons to be equipped with 1,5 MN 20 kJ d) Absorption rate: obligatory minimum value 0,3 The tests have to be carried out within a temperature range of 10°C to 25°C. The decompression period shall follow the compression period immediately, and the maximum speed of movement of the drawbar in either direction shall not exceed 5 cm per second. After a total release of the elastic device, the conditions shall return to those prevailing initially. 7.2 Elastic device – Requirements Requirements are defined in Annex F. SIST EN 15566:2009

Draw hook - dimensions Dimensions in millimetres

Key Buffer stroke

a 105 530 150 575 Figure A.1 — Draw hook The draw hook thickness in Figure A.1 section C-C does not include the marking on the surface. Including the marking, the maximum thickness shall be 61 mm. NOTE The draw hook itself is described in ERRI standard drawings 100M 3220 0001. The ERRI drawing is held by UIC. SIST EN 15566:2009

Draw gear – Interface dimension Dimensions in millimetres

Figure B.1 — Drawbar with shackle and safety device Dimensions in millimetres

Figure B.2 — Joint pin SIST EN 15566:2009

Screw coupling components - dimensions Dimensions in millimetres

Figure C.1 — Coupling hook pin Dimensions in millimetres

Figure C.2 — Coupling link SIST EN 15566:2009

Figure C.3 — Screw

Dimensions in millimetres

Figure C.4 — Trunnion for ball handle (T-bar) SIST EN 15566:2009

Figure C.5 — Trunnion for handle (T-bar) with top-mounted rest Dimensions in millimetres

Figure C.6 — Handle (T-bar) housing SIST EN 15566:2009

Figure C.7 — Hinged handle (T-bar) Figure C.8 — Hinged ball handle (T-bar)

Dimensions in millimetres

Figure C.9 — Trunnion SIST EN 15566:2009

Figure C.10 — D-shackle SIST EN 15566:2009

Draw hook and drawbar - Requirements D.1 Physical characteristics D.1.1 Appearance The parts or sections of parts rough forged or die-forged shall have smooth, carefully trimmed surfaces completely free of oxides. The surface condition of sections for which machining is prescribed shall comply with the conditions laid down in the order or is appended documents, or demonstrated by the specimens or standards previously acceptance-tested by the customer. There shall be no deficiencies, sharp angles or accidental tool marks on the materials used. Rough or machined connecting radii shall be well formed and free from scoring. D.1.2 Soundness The parts shall be sound throughout and show no defect such as folds, flaws, or cracks of any kind. D.1.2.1 Macroscopic examination The macroscopic examination carried out on a polished cross-section as defined in Figure D.1 shall not reveal any cavity or gap. D.1.2.2 Macro graphic examination After etching, the macro graphic image taken on the section indicated in Figure D.1 shall be of uniform colour and free from any pronounced trace of segregation. D.2 Geometrical characteristics The shapes, dimension and their tolerances shall be those stipulated in the order or its appended documents. D.3 Mechanical characteristics D.3.1 Tensile test on test piece The results of the elastic limit, tensile strength and elongation test measured for the hook, in delivery condition shall be in accordance with the material indicated in the drawings. If stipulated in the order or its appended documents, a second test piece intended to undergo normalization heat treatment may be taken. The values to be obtained shall be specified by the customer. SIST EN 15566:2009

The HBW hardness values measured on parts after execution of the heat treatment shall fall within the ranges specified to those prescribed in the order and its appended documents or failing any relevant indication to those specified in EN 10083-1. D.3.4 Tensile test on draw hook and draw bar D.3.4.1 Test under half minimum breaking load After being subjected to a tensile load corresponding to half the minimum breaking load, the head of the hook shall not show any permanent distortion greater then 0,5 mm (dimension L, see Figure D.2). After having been subjected to a tensile load of half minimum breaking load, the draw bars shall not show any permanent distortion greater then 0,2% of the basic length. D.3.4.2 Test under minimum breaking load The hooks shall be able to withstand a tensile load corresponding to the minimum breaking load for 3 min without cracking or flaw. D.4 Marking The hooks and the draw bars shall be stamped with the type of marks and in the position specified in the order or its appended documents. At least, each part shall be stamped with the following marks: manufacturer's mark, batch number including the last two figures of the year of manufacture, leave an appropriate space on the hook and the draw bar for a possible request for marking by the ownership (stamped mark), (only for the hook), the minimum breaking load for 1,2 MN and 1,5 MN coupling. The position of the marking shall not affect the safety of the hook and draw bar. The marks shall be embossed by hot-working during the forging or die-forging operation. Draw gears with a higher minimum breaking load have to be marked to enable clear identification if mounted, for instance by attaching "1,5" upon the surface. U SIST EN 15566:2009

Any forging or die-forging operation giving rise to distortion of the metal in the cold state and, in particular, any cold upsetting or straightening operation shall be forbidden.

D.5.3 Machining Machining of the external and internal threads shall be carried out so that the threads are perfectly shaped, with no distortion.

The sharp parts formed at the beginning and end of the external and internal threads shall be removed.

D.5.4 Heat treatment The hooks, nuts shall undergo the heat treatment for normalization or hardening and tempering, stipulated in the order or its appended documents. The heat treatment operations shall be conducted to ensure uniformity of the characteristics throughout each part, also on all parts in the same batch.

Heating of the parts shall not give rise to their oxidation. It shall always be carried out fairly slowly, until the parts have reached a temperature of at least 400 °C. The temperature of the furnaces shall be checked by means of correctly-calibrated recording pyrometers arranged so that all zones of these furnaces can be checked and regulated accordingly. It shall be possible for the readings of the calibrated recording pyrometers to be made available to the inspector in charge of acceptance testing. The quenching baths shall be of sufficient capacity and equipped with a temperature regulation system.

D.5.5 Rectification of defects, if any No alterations or repairs may be undertaken without the prior agreement of the customer. The elimination of surface defects by removal of metal in the cold state (chiselling, filing, grinding or any other approved process) may be authorised subject to observing the dimensional tolerances and providing SIST EN 15566:2009

D.6.2 Manufacturing control It shall be possible for the customer's representative to ascertain, by any checks he may consider necessary, that the conditions of manufacture prescribed in this document with regard to the steels and the parts themselves, have been fully observed.

For this purpose, the manufacturing and inspection drawings shall be submitted to him and he shall be kept advised of any modifications made, also of any incidents occurring during manufacture.

Characteristics shall be checked on the finished parts. However, the materials intended for manufacturing the draw bars can be inspected and their characteristics checked before use. D.6.3 Inspection of the hooks D.6.3.1 Submission for acceptance D.6.3.1.1 Materials Should a special agreement exist to this effect, the rolled products shall be submitted as forged in the delivery condition stipulated by the manufacturer of the hooks in agreement with the customer. D.6.3.1.2 Parts The parts shall be submitted for acceptance after machining and heat treatment and before any application of a protective product against oxidation. D.6.3.2 Grouping into batches D.6.3.2.1 Materials Each batch shall comprise a maximum of 20 tonnes of products of the same section from the same cast. D.6.3.2.2 Parts Each batch shall comprise a maximum of 200 hooks, fitted where applicable, with their nuts, produced during the same operation and from the same manufacture. Hooks shall have respectively undergone the same heat treatment. SIST EN 15566:2009

D.6.3.4 Nature and extent of checks and tests D.6.3.4.1 Materials Each batch of steel produced under the conditions prescribed in D.6.3.2.1 shall, on submission for acceptance, be subjected to the checks and tests the nature and extent of which are stipulated in Table D.1 hereinafter. D.6.3.4.2 Parts Each batch of hooks shall, on submission for acceptance, be subjected to the checks and tests the nature and extent of which are stipulated in Table D.1 hereinafter. Table D.1 —Checks and tests Nature of the checks and tests Extent of the checks and tests Materials Checks on the characteristics stipulated in D.6.3.1.1 a 1 series of tests per batch Parts 1 to 200 for each additional batch chemical composition 1 per cast Appearance, dimensions, marking as indicated by the customer `s representative Macr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...