EN 754-2:2024

(Main)Aluminium and aluminium alloys - Cold drawn rod/bar and tube - Part 2: Mechanical properties

Aluminium and aluminium alloys - Cold drawn rod/bar and tube - Part 2: Mechanical properties

This document specifies the mechanical property limits resulting from tensile testing applicable to aluminium and aluminium alloy cold drawn rod/bar and tube.

Technical conditions for inspection and delivery, including product and testing requirements, are specified in EN 754-1. Temper designations are defined in EN 515. The chemical composition limits for these materials are given in EN 573-3.

Aluminium und Aluminiumlegierungen - Gezogene Stangen und Rohre - Teil 2: Mechanische Eigenschaften

Dieses Dokument legt die Grenzwerte für die mechanischen Eigenschaften fest, die sich aus der Zugprüfung ergeben und für gezogenen Stangen und Rohre aus Aluminium und Aluminiumlegierungen gelten.

Die Technischen Lieferbedingungen, einschließlich Erzeugnis- und Prüfanforderungen, sind in EN 754 1 festgelegt. Die Bezeichnungen der Werkstoffzustände sind in EN 515 definiert. In EN 573 3 sind die Grenzen der chemischen Zusammensetzung für diese Werkstoffe angegeben.

Aluminium et alliages d’aluminium - Barres et tubes étirés - Partie 2 : Caractéristiques mécaniques

Le présent document spécifie les limites des caractéristiques mécaniques provenant de l’essai de traction applicables aux barres et tubes étirés en aluminium et alliages d’aluminium.

Les conditions techniques de contrôle et de livraison, y compris les exigences relatives aux produits et aux essais, sont spécifiées dans l’EN 754-1. La désignation des états métallurgiques est définie dans l’EN 515. Les limites de composition chimique de ces matériaux sont données dans l’EN 573-3.

Aluminij in aluminijeve zlitine - Hladno vlečene palice/drogovi in cevi - 2. del: Mehanske lastnosti

Ta dokument določa omejitve mehanskih lastnosti, ki izhajajo iz nateznega preskusa hladno vlečenih palic/drogov in cevi iz aluminija in aluminijevih zlitin.

Tehnični pogoji za pregled in dobavo, vključno z zahtevami glede izdelkov in preskušanja, so določeni v standardu EN 754-1. Oznake za popuščanje so opredeljene v standardu EN 515. Omejitve kemijske sestave za te materiale so navedene v standardu EN 573-3.

General Information

- Status

- Published

- Publication Date

- 26-Nov-2024

- Technical Committee

- CEN/TC 132 - Aluminium and aluminium alloys

- Drafting Committee

- WG 35 - Extruded products

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 27-Nov-2024

- Due Date

- 14-Feb-2025

- Completion Date

- 27-Nov-2024

Relations

- Effective Date

- 19-Jan-2023

Overview

EN 754-2:2024 - Aluminium and aluminium alloys - Cold drawn rod/bar and tube - Part 2: Mechanical properties is a CEN European Standard that defines the mechanical property limits for cold drawn aluminium rod, bar and seamless tube as determined by tensile testing. Published November 2024 (approved 26 Aug 2024), this document supersedes EN 754-2:2016 and is intended for suppliers, purchasers and testing laboratories working with cold-drawn aluminium products across the CEN member states.

Key topics and technical requirements

- Scope: Specifies mechanical property limits resulting from tensile testing for cold drawn rod/bar and tube. Properties refer to longitudinal test pieces unless otherwise agreed.

- Tensile testing: Mechanical values are obtained by tensile testing in accordance with EN ISO 6892-1; sampling and specimen preparation follow EN 754-1.

- Mechanical property tables: Detailed limits (in Tables 1–50) are provided for a wide range of alloys and tempers. These include tensile strength, 0.2% proof strength, elongation (A and A50 mm), and informational Brinell hardness (HBW).

- Tempers and conditions: Temper designations referenced to EN 515. The as-fabricated condition F may be used but does not guarantee mechanical properties. Annex A lists tempers used in the tables.

- Elongation conventions: The standard defines the use of elongation measured over a gauge length of 5.65√S (A) and the alternative 50 mm gauge (A50) where applicable.

- Alloy coverage and updates: EN 754-2:2024 adds several alloys compared with the previous edition (e.g., EN AW-1070A, EN AW-1350A, EN AW-2618A, EN AW-6005 series, EN AW-6061A, among others), broadening applicability.

Practical applications and users

- Who uses it: Aluminium mills, extruders, cold-drawing manufacturers, quality/control laboratories, purchasers and engineering designers specifying mechanical performance of cold drawn aluminium products.

- Typical uses: Material specification for shafts, fasteners, structural bars, tubes for heat exchangers, hydraulic components, and any application where predictable tensile properties of cold-drawn aluminium are required.

- Benefits: Ensures consistent mechanical performance, supports procurement and inspection criteria, and facilitates conformity and interchangeability across European markets.

Related standards

- EN 754-1 - Technical conditions for inspection and delivery (product and testing requirements)

- EN 515 - Temper designations for aluminium alloys

- EN 573-3 - Chemical composition limits for wrought aluminium alloys

- EN ISO 6892-1 - Metallic materials - Tensile testing (method referenced)

EN 754-2:2024 provides the authoritative mechanical-property tables and testing conventions needed to specify, test and accept cold drawn aluminium rod/bar and tube in industrial and engineering applications.

Frequently Asked Questions

EN 754-2:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aluminium and aluminium alloys - Cold drawn rod/bar and tube - Part 2: Mechanical properties". This standard covers: This document specifies the mechanical property limits resulting from tensile testing applicable to aluminium and aluminium alloy cold drawn rod/bar and tube. Technical conditions for inspection and delivery, including product and testing requirements, are specified in EN 754-1. Temper designations are defined in EN 515. The chemical composition limits for these materials are given in EN 573-3.

This document specifies the mechanical property limits resulting from tensile testing applicable to aluminium and aluminium alloy cold drawn rod/bar and tube. Technical conditions for inspection and delivery, including product and testing requirements, are specified in EN 754-1. Temper designations are defined in EN 515. The chemical composition limits for these materials are given in EN 573-3.

EN 754-2:2024 is classified under the following ICS (International Classification for Standards) categories: 77.150.10 - Aluminium products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 754-2:2024 has the following relationships with other standards: It is inter standard links to EN 754-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 754-2:2024 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2025

Aluminij in aluminijeve zlitine - Hladno vlečene palice/drogovi in cevi - 2. del:

Mehanske lastnosti

Aluminium and aluminium alloys - Cold drawn rod/bar and tube - Part 2: Mechanical

properties

Aluminium und Aluminiumlegierungen - Gezogene Stangen und Rohre - Teil 2:

Mechanische Eigenschaften

Aluminium et alliages d'aluminium - Barres et tubes étirés - Partie 2: Caractéristiques

mécaniques

Ta slovenski standard je istoveten z: EN 754-2:2024

ICS:

77.150.10 Aluminijski izdelki Aluminium products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 754-2

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2024

EUROPÄISCHE NORM

ICS 77.150.10 Supersedes EN 754-2:2016

English Version

Aluminium and aluminium alloys - Cold drawn rod/bar

and tube - Part 2: Mechanical properties

Aluminium et alliages d'aluminium - Barres et tubes Aluminium und Aluminiumlegierungen - Gezogene

étirés - Partie 2 : Caractéristiques mécaniques Stangen und Rohre - Teil 2: Mechanische Eigenschaften

This European Standard was approved by CEN on 26 August 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 754-2:2024 E

worldwide for CEN national Members.

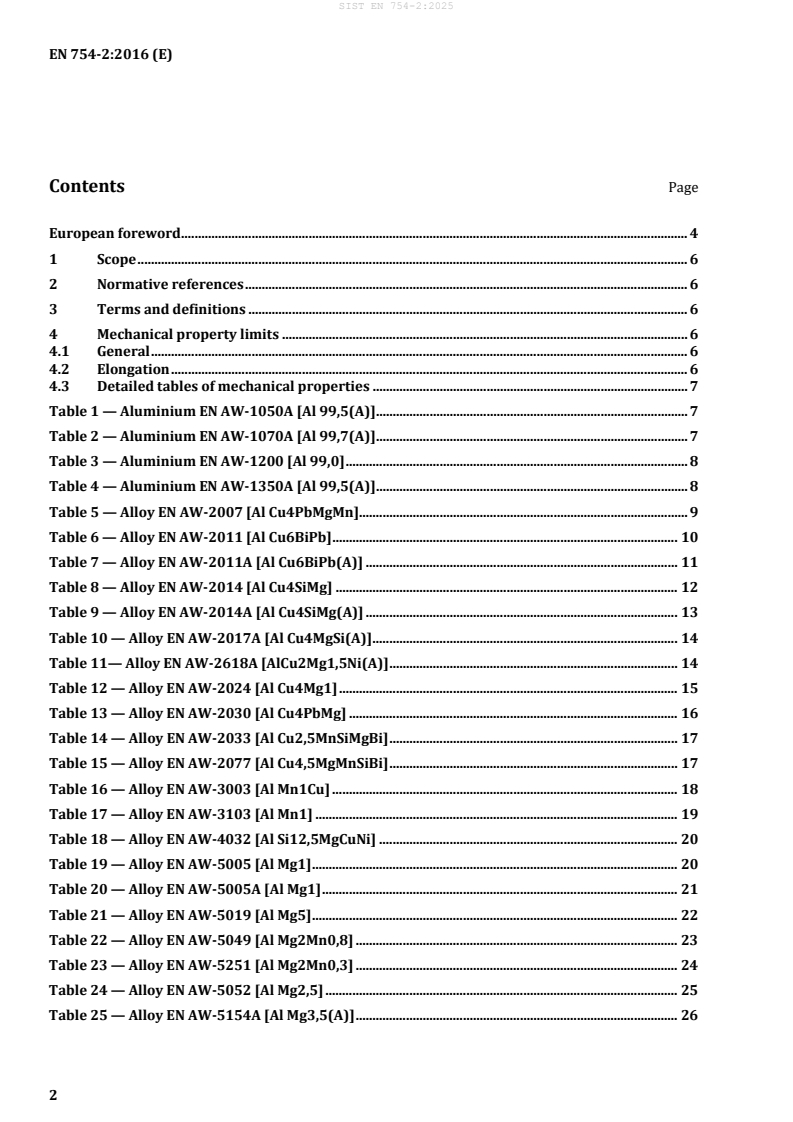

EN 754-2:2016 (E)

Contents Page

European foreword . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Mechanical property limits . 6

4.1 General . 6

4.2 Elongation . 6

4.3 Detailed tables of mechanical properties . 7

Table 1 — Aluminium EN AW-1050A [Al 99,5(A)]. 7

Table 2 — Aluminium EN AW-1070A [Al 99,7(A)]. 7

Table 3 — Aluminium EN AW-1200 [Al 99,0] . 8

Table 4 — Aluminium EN AW-1350A [Al 99,5(A)]. 8

Table 5 — Alloy EN AW-2007 [Al Cu4PbMgMn]. 9

Table 6 — Alloy EN AW-2011 [Al Cu6BiPb] . 10

Table 7 — Alloy EN AW-2011A [Al Cu6BiPb(A)] . 11

Table 8 — Alloy EN AW-2014 [Al Cu4SiMg] . 12

Table 9 — Alloy EN AW-2014A [Al Cu4SiMg(A)] . 13

Table 10 — Alloy EN AW-2017A [Al Cu4MgSi(A)] . 14

Table 11— Alloy EN AW-2618A [AlCu2Mg1,5Ni(A)] . 14

Table 12 — Alloy EN AW-2024 [Al Cu4Mg1] . 15

Table 13 — Alloy EN AW-2030 [Al Cu4PbMg] . 16

Table 14 — Alloy EN AW-2033 [Al Cu2,5MnSiMgBi] . 17

Table 15 — Alloy EN AW-2077 [Al Cu4,5MgMnSiBi] . 17

Table 16 — Alloy EN AW-3003 [Al Mn1Cu] . 18

Table 17 — Alloy EN AW-3103 [Al Mn1] . 19

Table 18 — Alloy EN AW-4032 [Al Si12,5MgCuNi] . 20

Table 19 — Alloy EN AW-5005 [Al Mg1] . 20

Table 20 — Alloy EN AW-5005A [Al Mg1] . 21

Table 21 — Alloy EN AW-5019 [Al Mg5] . 22

Table 22 — Alloy EN AW-5049 [Al Mg2Mn0,8] . 23

Table 23 — Alloy EN AW-5251 [Al Mg2Mn0,3] . 24

Table 24 — Alloy EN AW-5052 [Al Mg2,5] . 25

Table 25 — Alloy EN AW-5154A [Al Mg3,5(A)] . 26

Table 26 — Alloy EN AW-5754 [Al Mg3] . 27

Table 27 — Alloy EN AW-5083 [Al Mg4,5Mn0,7] . 28

Table 28 — Alloy EN AW-5086 [Al Mg4] . 29

Table 29 — Alloy EN AW-6005 [AlSiMg] . 29

Table 30 — Alloy EN AW-6005A [Al SiMg(A)] . 30

Table 31 — Alloy EN AW-6005B [Al SiMg(B)] . 30

Table 32 — Alloy EN AW-6012 [Al MgSiPb] . 31

Table 33 — Alloy EN AW-6023 [Al Si1Sn1MgBi] . 31

Table 34 — Alloy EN AW-6026 [Al MgSiBi] . 32

Table 35 — Alloy EN AW-6050 [Al Si1,5FeMgNi] . 32

Table 36 — Alloy EN AW-6056 [Al Si1MgCuMn] . 33

Table 37 — Alloy EN AW-6060 [Al MgSi] . 33

Table 38 — Alloy EN AW-6061 [Al Mg1SiCu] . 34

Table 39 — Alloy EN AW-6061A [Al Mg1SiCu(A)] . 34

Table 40 — Alloy EN AW-6262 [Al Mg1SiPb] . 35

Table 41 — Alloy EN AW-6262A [Al Mg1SiSn(A)] . 35

Table 42 — Alloy EN AW-6063 [Al Mg0,7Si] . 36

Table 43 — Alloy EN AW-6063A [Al Mg0,7Si(A)] . 37

Table 44 — Alloy EN AW-6064A [Al Mg1SiBi] . 38

Table 45 — Alloy EN AW-6065 [Al Mg1Bi1Si] . 38

Table 46 — Alloy EN AW-6082 [Al Si1MgMn] . 39

Table 47 — Alloy EN AW-7020 [Al Zn4,5Mg1] . 39

Table 48 — Alloy EN AW-7022 [Al Zn5Mg3Cu] . 40

Table 49 — Alloy EN AW-7049A [Al Zn8MgCu(A)] . 40

Table 50 — Alloy EN AW-7075 [Al Zn5,5MgCu] . 41

Annex A (informative) List of tempers used in Tables 1 to 50 . 42

Bibliography . 44

EN 754-2:2016 (E)

European foreword

This document (EN 754-2:2024) has been prepared by Technical Committee CEN/TC 132 “Aluminium

and aluminium alloys”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2025, and conflicting national standards shall be

withdrawn at the latest by May 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 754-2:2016.

Within its programme of work, Technical Committee CEN/TC 132 entrusted CEN/TC 132/WG 5

“Extruded and drawn products” to revise EN 754-2:2016.

— addition of EN AW-1070A, EN AW-1350A, EN AW-2618A. EN AW-2033, EN AW-2077, EN AW-4032,

EN AW-6005, EN AW-6005A, EN AW-6005B, EN AW-6023, EN AW-6050, EN AW-6056 and EN AW-

6061A alloys;

— addition of the terms required by the latest CCMC template;

— addition of Clause 3 compulsory from the latest CCMC template;

— deletion of former Clause 3.3 as part of the table of contents in this document.

EN 754 comprises the following parts under the general title “Aluminium and aluminium alloys — Cold

drawn rod/bar and tube”:

— Part 1: Technical conditions for inspection and delivery

— Part 2: Mechanical properties

— Part 3: Round bars, tolerances on dimensions and form

— Part 4: Square bars, tolerances on dimensions and form

— Part 5: Rectangular bars, tolerances on dimensions and form

— Part 6: Hexagonal bars, tolerances on dimensions and form

— Part 7: Seamless tubes, tolerances on dimensions and form

— Part 8: Porthole tubes, tolerances on dimensions and form

CEN/TC 132 affirms its policy that if a patentee refuses to grant licenses on standardized products under

reasonable and not discriminatory conditions, this product will be removed from the corresponding

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

EN 754-2:2016 (E)

1 Scope

This document specifies the mechanical property limits resulting from tensile testing applicable to

aluminium and aluminium alloy cold drawn rod/bar and tube.

Technical conditions for inspection and delivery, including product and testing requirements, are

specified in EN 754-1. Temper designations are defined in EN 515. The chemical composition limits for

these materials are given in EN 573-3.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 754-1:2016, Aluminium and aluminium alloys — Cold drawn rod/bar and tube — Part 1: Technical

conditions for inspection and delivery

3 Terms and definitions

No terms and definitions are listed in this document.

4 Mechanical property limits

4.1 General

The mechanical properties shall be in conformity with those specified in Table 1 to Table 50 or those

agreed upon between supplier and purchaser and stated in the order document.

Definitions of tempers are provided at Annex A of this document. For all alloys the condition F (as

fabricated) can be used, but without guaranteed mechanical properties.

Table 1 to Table 50 contain limits of mechanical property values obtained by tensile testing according to

EN ISO 6892-1. Test pieces sampling, location in the specimen and preparation shall be as given in

EN 754-1.

NOTE The mechanical properties refer to test pieces taken in the longitudinal direction. Mechanical properties

of test pieces taken in other directions can differ from those for the longitudinal direction quoted in this document.

Brinell hardness values given in Table 1 to Table 50 expressed as HBW values are for information only.

4.2 Elongation

If not otherwise agreed, the A value shall be used.

The A value for elongation is the % elongation measured over a gauge length of 5,65√S (where S is the

0 0

initial cross-sectional area of the test-piece), and expressed in percent.

For certain products the supplier may choose (if not otherwise specified in the order documents) to use

the elongation based on A Consequently, values for the A are included in the following tables.

50mm. 50mm

The A value is the elongation measured over a gauge length of 50 mm and expressed in percent.

50mm

4.3 Detailed tables of mechanical properties

Table 1 — Aluminium EN AW-1050A [Al 99,5(A)]

Drawn rod/bar

R R

A

Dimensions A

m p0,2

50mm

HBW

Temper mm %

MPa MPa %

Typical

value

a b min.

min.

D S min. max. min. max.

O, H111 ≤ 80 ≤ 60 60 95 - - 25 22 20

H14 ≤ 40 ≤ 10 100 135 70 - 6 5 30

H16 ≤ 15 ≤ 5 120 160 105 - 4 3 35

H18 ≤ 10 ≤ 3 145 - 125 - 3 3 43

Drawn tube

R R A

Wall thickness A

m p0,2 50mm

HBW

Temper t %

MPa MPa %

Typical

value

mm min.

min.

min. max. min. max.

O, H111 ≤ 20 60 95 - - 25 22 20

H14 ≤ 10 100 135 70 - 6 5 30

H16 ≤ 5 120 160 105 - 4 3 35

H18 ≤ 3 145 - 125 - 3 3 43

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

Table 2 — Aluminium EN AW-1070A [Al 99,7(A)]

Drawn rod/bar

R

R A

Dimensions A

m p0,2

50 mm

HBW

Temper mm %

MPa MPa %

Typical

value

a b

min.

D S min. max. min. max. min.

c

O, H111 ≤ 80 ≤ 80 50 95 - - 25 22 20

c

≤ 80 ≤ 80 90 135 70 - 6 5 30

H14

a

D = Diameter for round bar.

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar.

c

Properties may be obtained by press quenching.

EN 754-2:2016 (E)

Table 3 — Aluminium EN AW-1200 [Al 99,0]

Drawn rod/bar

Dimensions R R A A

HBW

m p0,2 50mm

Temper

mm %

MPa MPa % Typical

value

a b

min.

D S min. max. min. max.

min.

O, H111 ≤ 80 ≤ 60 70 105 - - 20 16 23

H14 ≤ 40 ≤ 10 110 145 80 - 5 4 37

H16 ≤ 15 ≤ 5 135 170 115 - 3 3 45

H18 ≤ 10 ≤ 3 150 - 130 - 3 3 50

Drawn tube

R R

m p0,2 A

Wall thickness A

50mm

HBW

MPa MPa

Temper t %

%

Typical

value

mm min. max. min. max. min.

min.

O, H111 ≤ 20 70 105 - - 20 16 23

H14 ≤ 10 110 145 80 - 5 4 37

H16 ≤ 5 135 170 115 - 3 3 45

H18 ≤ 3 150 - 130 - 3 3 50

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

Table 4 — Aluminium EN AW-1350A [Al 99,5(A)]

Drawn rod/bar

R R

A

Dimensions A

m p0,2 50 mm

HBW

Temper mm %

MPa Mpa %

Typical

value

a b

min.

D S min. max. min. max. min.

c

O, H111 ≤ 80 ≤ 80 60 95 - - 25 22 20

c

≤ 80 ≤ 80 90 135 70 - 6 5 30

H14

c

≤ 80 ≤ 80 145 - 125 - 3 3 40

H18

a

D = Diameter for round bar.

B

S = Width across flats for square and hexagonal bar, thickness for rectangular bar.

C

Properties may be obtained by press quenching.

Table 5 — Alloy EN AW-2007 [Al Cu4PbMgMn]

Drawn rod/bar

Dimensions R R

A

A

m p0,2

50mm

HBW

mm

Temper Mpa Mpa %

%

Typical

value

a b

D S min. max. min. max. min.

min.

≤ 30 ≤ 30 370 240 7 95

T3 c - -

-

30 < D ≤ 80 30 < S ≤ 80 340 220 6 95

T351 c ≤ 80 ≤ 80 370 - 240 - 5 3 95

Drawn tube

Wall thickness R R A A

m p0,2 50mm HBW

Temper t %

Mpa Mpa %

Typical

value

mm min.

min. max. min. max. min.

T3 c ≤ 20 370 - 250 - 7 5 95

T3510 c,

≤ 20 370 - 240 - 5 3 95

T3511 c

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

c

Properties may be obtained by press quenching.

EN 754-2:2016 (E)

Table 6 — Alloy EN AW-2011 [Al Cu6BiPb]

Drawn rod/bar

Dimensions R R A A

HBW

m p0,2 50mm

Temper

mm %

Mpa Mpa % Typical

value

a b

min.

D S min. max. min. max.

min.

≤ 40 ≤ 40 320 - 270 - 10 8 90

T3c 40 < D ≤ 50 40 < S ≤ 50 300 - 250 - 10 - 90

50 < D ≤ 80 50 < S ≤ 80 280 - 210 - 10 - 90

T8 ≤ 80 ≤ 80 370 - 270 - 8 6 110

Drawn tube

R R A

Wall thickness A

m p0,2 50mm

HBW

Temper t %

%

Mpa Mpa

Typical

value

mm min.

min.

min. max. min. max.

≤ 5 310 - 260 - 10 8 90

T3 c

5 < t ≤ 20 290 - 240 - 8 6 90

T8 ≤ 20 370 - 275 - 8 6 110

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

c

Properties may be obtained by press quenching.

Table 7 — Alloy EN AW-2011A [Al Cu6BiPb(A)]

Drawn rod/bar

A

R R

Dimensions A

50mm

m p0,2

HBW

Temper %

mm

Mpa Mpa %

Typical

value

min.

a b

min.

D S min. max. min. max.

≤ 40 ≤ 40 320 - 270 - 10 8 90

T3 c 40 < D ≤ 50 40 < S ≤ 50 300 - 250 - 10 - 90

50 < D ≤ 80 50 < S ≤ 80 280 - 210 - 10 - 90

T8 ≤ 80 ≤ 80 370 - 270 - 8 6 115

Drawn tube

R R

m p0,2

A

Wall thickness A

50mm

HBW

Mpa Mpa

Temper t %

%

Typical

value

mm min.

min.

min. max. min. max.

≤ 5 310 - 260 - 10 8 90

T3 c

5 < t ≤ 20 290 - 240 - 8 6 90

T8 ≤ 20 370 - 275 - 8 6 115

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

c

Properties may be obtained by press quenching

EN 754-2:2016 (E)

Table 8 — Alloy EN AW-2014 [Al Cu4SiMg]

Drawn rod/bar

Dimensions R R A

A

m p0,2 50mm

HBW

mm

Temper %

Mpa Mpa %

Typical

value

a b

D S min. max. min. max. min.

min.

O, H111 ≤ 80 ≤ 80 - 240 - 125 12 10 45

T3 ≤ 80 ≤ 80 380 - 290 - 8 6 110

T351 ≤ 80 ≤ 80 380 - 290 - 6 4 110

T4 ≤ 80 ≤ 80 380 - 220 - 12 10 110

T451 ≤ 80 ≤ 80 380 - 220 - 10 8 110

T6 ≤ 80 ≤ 80 450 - 380 - 8 6 140

T651 ≤ 80 ≤ 80 450 - 380 - 6 4 140

Drawn tube

R R A

Wall thickness A

m p0,2 50mm

HBW

Temper t %

Mpa Mpa

%

Typical

value

mm min.

min.

min. max. min. max.

O, H111 ≤ 20 - 240 - 125 12 10 45

T3 ≤ 20 380 - 290 - 8 6 110

T3510,

≤ 20 380 - 290 - 6 4 110

T3511

T4 ≤ 20 380 - 240 - 12 10 110

T4510,

≤ 20 380 - 240 - 10 8 110

T4511

T6 ≤ 20 450 - 380 - 8 6 140

T6510,

≤ 20 450 - 380 - 6 4 140

T6511

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

Table 9 — Alloy EN AW-2014A [Al Cu4SiMg(A)]

Drawn rod/bar

R R A

Dimensions A

m p0,2 50mm

HBW

Temper mm %

Mpa Mpa %

Typical

value

a b

min.

D S min. max. min. max. min.

O, H111 ≤ 80 ≤ 80 - 240 - 125 12 10 45

T3 ≤ 80 ≤ 80 380 - 290 - 8 6 110

T351 ≤ 80 ≤ 80 380 - 290 - 6 4 110

T4 ≤ 80 ≤ 80 380 - 220 - 12 10 110

T451 ≤ 80 ≤ 80 380 - 220 - 10 8 110

T6 ≤ 80 ≤ 80 450 - 380 - 8 6 140

T651 ≤ 80 ≤ 80 450 - 380 - 6 4 140

Drawn tube

R R A

Wall thickness A

m p0,2 50mm

HBW

Temper t %

Mpa Mpa %

Typical

value

mm min.

min. max. min. max. min.

O, H111 ≤ 20 - 240 - 125 12 10 45

T3 ≤ 20 380 - 290 - 8 6 110

T3510,

≤ 20 380 - 290 - 6 4 110

T3511

T4 ≤ 20 380 - 240 - 12 10 110

T4510,

≤ 20 380 - 240 - 10 8 110

T4511

T6 ≤ 20 450 - 380 - 8 6 140

T6510,

≤ 20 450 - 380 - 6 4 140

T6511

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

EN 754-2:2016 (E)

Table 10 — Alloy EN AW-2017A [Al Cu4MgSi(A)]

Drawn rod/bar

R R A

Dimensions A

m p0,2 50mm

HBW

Temper mm %

Mpa Mpa %

Typical

value

a b

min.

min.

D S min. max. min. max.

O, H111 ≤ 80 ≤ 80 - 240 - 125 12 10 45

T3 c ≤ 80 ≤ 80 400 - 250 - 10 8 105

T351 c ≤ 80 ≤ 80 400 - 250 - 8 6 105

Drawn tube

R R A

Wall thickness A

m p0,2 50mm

HBW

Temper t %

Mpa Mpa %

Typical

value

mm min.

min. max. min. max. min.

O, H111 ≤ 20 - 240 - 125 12 10 45

T3 c ≤ 20 400 - 250 - 10 8 105

T3510 c,

≤ 20 400 - 250 - 8 6 105

T3511 c

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

c

Properties may be obtained by press quenching

Table 11— Alloy EN AW-2618A [AlCu2Mg1,5Ni(A)]

Drawn rod/bar

R R

A

Dimensions A

m p0,2

50 mm

HBW

Temper mm %

MPa MPa %

Typical

value

a b

min.

D S min. max. min. max. min.

c

≤ 80 ≤ 80 410 - 330 - 7 5 130

T6

a

D = Diameter for round bar.

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar.

c

Properties may be obtained by press quenching.

Table 12 — Alloy EN AW-2024 [Al Cu4Mg1]

Drawn rod/bar

R R A

Dimensions A

m p0,2 50mm

HBW

Temper mm %

MPa MPa %

Typical

value

a b

min.

D S min. max. min. max. min.

O, H111 ≤ 80 ≤ 80 - 250 - 150 12 10 47

≤ 10 ≤ 10 425 310 10 8 120

T3 - -

10 < D ≤ 80 10 < S ≤ 80 425 290 9 7 120

T351 ≤ 80 ≤ 80 425 - 310 - 8 6 120

T6 ≤ 80 ≤ 80 425 - 315 - 5 4 125

T651 ≤ 80 ≤ 80 425 - 315 - 4 3 125

T8 ≤ 80 ≤ 80 455 - 400 - 4 3 130

T851 ≤ 80 ≤ 80 455 - 400 - 3 2 130

Drawn tube

R R A

Wall thickness A

m p0,2 50mm

HBW

Temper t %

MPa MPa %

Typical

value

mm min.

min. max. min. max. min.

O, H111 ≤ 20 - 240 - 140 12 10 47

≤ 5 440 290 10 8 120

T3 - -

5 < t ≤ 20 420 270 10 8 120

T3510,

≤ 20 420 - 290 - 8 6 120

T3511

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

EN 754-2:2016 (E)

Table 13 — Alloy EN AW-2030 [Al Cu4PbMg]

Drawn rod/bar

R R A A

Dimensions

m p0,2 50mm

HBW

Temper %

mm

MPa MPa %

Typical

value

a b min.

D S min. max. min. max. min.

≤ 30 ≤ 30 370 240 7 5 115

c

T3 - -

30 < D ≤ 80 30 < S ≤ 80 340 220 6 - 115

c

T351 ≤ 80 ≤ 80 370 - 240 - 5 3 115

Drawn tube

Wall thickness R R A A

m p0,2 50mm HBW

Temper t %

MPa MPa %

Typical

value

mm min.

min. max. min. max. min.

c

T3 ≤ 20 370 - 240 - 7 5 115

c

T3510

≤ 20 370 - 240 - 5 3 115

c

T3511

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

c

Properties may be obtained by press quenching

Table 14 — Alloy EN AW-2033 [Al Cu2,5MnSiMgBi]

Drawn rod/bar

R R

Dimensions A A

50 mm

m p0,2 HBW

Temper

mm % %

MPa MPa Typical

a b

Value

D S min. max. min. max. min. min.

≤ 30 ≤ 30 370 - 240 - 7 - 100

c

T3

30 < D ≤ 80 30 < D ≤ 60 340 - 220 - 7 - 100

c

T351 ≤ 80 ≤ 60 370 - 240 - 5 - 100

c

T8 ≤ 80 ≤ 60 370 - 270 - 8 - 100

a

D = Diameter for round bar.

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar.

c

Properties may be obtained by press quenching

Table 15 — Alloy EN AW-2077 [Al Cu4,5MgMnSiBi]

Drawn rod/bar

R R A

Dimensions

A

m p0,2 50mm

HBW

Temper mm %

MPa MPa %

Typical

value

a b

min.

min.

D S min. max. min. max.

c

T6

≤ 80 ≤ 60 480 - 400 - 5 - 130

c

T651

a

D = Diameter for round bar

b

S = Width across flats for square and hexagonal bar, thickness for rectangular bar

c

Properties may be obtained by press quenching

------

...

표준 EN 754-2:2024는 알루미늄 및 알루미늄 합금의 냉간 인발 봉/막대 및 튜브의 기계적 특성을 규정한 문서로, 이 표준은 알루미늄 제품의 기계적 성질에 대한 신뢰할 수 있는 기준을 제시합니다. 이 문서는 인장 시험에 따른 기계적 성질의 한계를 명시하고 있어, 알루미늄과 알루미늄 합금의 냉간 인발 봉 및 튜브의 품질 관리를 위한 중요한 기초 자료로 활용될 수 있습니다. 표준의 강점은 기계적 성질에 대한 명확한 기준을 제공하는 점이며, 이를 통해 산업 종사자들이 보다 일관된 품질의 제품을 생산할 수 있도록 지원합니다. 또한, EN 754-1에서 규정된 검사 및 납품의 기술적 조건, 제품 및 시험 요구사항의 통합으로 인해, 사용자가 쉽게 이해하고 적용할 수 있는 체계를 마련하고 있습니다. 또한, EN 515에서 정의된 템퍼 구분 및 EN 573-3에서 제공하는 화학 조성 한계에 따른 자료의 연계는 사용자가 특정 제품의 성능을 확보하는 데 필수적인 정보를 제공합니다. 따라서 EN 754-2:2024는 알루미늄 및 알루미늄 합금 산업에 종사하는 다양한 분야에서 필수적으로 참고해야 할 표준으로 자리 잡을 것입니다.

Die Norm EN 754-2:2024 behandelt die mechanischen Eigenschaften von kaltgezogenen Stäben, Riegeln und Rohren aus Aluminium und Aluminiumlegierungen und legt damit spezifische Grenzwerte fest, die aus Zugversuchen resultieren. Diese detaillierte Norm ist von enormer Bedeutung für Hersteller und Anwender in der Metallindustrie, da sie sicherstellt, dass die Produkte den erforderlichen mechanischen Eigenschaften entsprechen und somit die Qualität und Sicherheit in Anwendungen garantieren. Ein herausragendes Merkmal der Norm ist ihre Präzision bei der Definition der mechanischen Eigenschaften, die für kaltgezogene Aluminium- und Aluminiumlegierungsprodukte essenziell sind. Durch die Festlegung von klaren Grenzwerten für die Zugfestigkeit, Dehnbarkeit und andere relevante mechanische Eigenschaften ermöglicht die EN 754-2:2024 eine verlässliche Qualitätssicherung und verbessert die Standardisierung in der Produktion. Dies ist besonders wichtig in Branchen, wo hohe Materialanforderungen bestehen, wie zum Beispiel im Automobil- und Maschinenbau. Zusätzlich verweisen technische Bedingungen für die Inspektion und Auslieferung auf die Norm EN 754-1, die die Produkt- und Prüfanforderungen spezifiziert. Zusammen mit den Temperbezeichnungen der EN 515 und den chemischen Zusammensetzungsgrenzen der EN 573-3 bildet die EN 754-2:2024 ein umfassendes Regelwerk, das weitreichende Anwendbarkeit und Akzeptanz in der Industrie garantiert. Die Relevanz dieser Norm erstreckt sich über verschiedene Anwendungsbereiche, da sie nicht nur die Qualität von Aluminiumprodukten sichert, sondern auch Mitbewerbern hilft, sich an einen gemeinsamen Standard zu orientieren. Die Einhaltung dieser Norm kann somit Wettbewerbsvorteile schaffen und Vertrauen bei Endkunden aufbauen. Insgesamt stellt die EN 754-2:2024 eine unverzichtbare Grundlage für die Herstellung und Anwendung von kaltgezogenen Aluminium- und Aluminiumlegierungsprodukten dar und trägt entscheidend zur Förderung von Innovation und Effizienz in der Branche bei.

The standard EN 754-2:2024 addresses the critical area of mechanical properties for aluminium and aluminium alloys, specifically focusing on cold drawn rod/bar and tube products. The clear delineation of mechanical property limits derived from tensile testing is a noteworthy strength of this standard. By providing precise specifications, the standard ensures that manufacturers can consistently produce aluminium and alloy products that meet stringent quality and performance criteria. Moreover, this document complements prior standards, such as EN 754-1, which outlines the technical conditions for inspection and delivery, ensuring a comprehensive framework for quality assurance. The integration of relevant temper designations from EN 515 further enhances the standard’s applicability, allowing users to select appropriate materials based on their mechanical properties and temper states. Another significant aspect is the alignment with chemical composition limits defined in EN 573-3, which ensures that users can assess not only the mechanical properties but also the suitability of materials for specific applications. This holistic approach makes EN 754-2 highly relevant for professionals involved in the manufacturing and testing of aluminium and aluminium alloy products, as it facilitates compliance with industry requirements and promotes reliability in product performance. In summary, EN 754-2:2024 serves as a critical resource in the standardization of mechanical properties for cold drawn aluminium and aluminium alloy products, bolstering the overall integrity of the manufacturing process and enhancing confidence among stakeholders in the engineering and materials sectors.

La norme SIST EN 754-2:2025 se concentre sur les limites des propriétés mécaniques des tiges, barres et tubages en aluminium et en alliages d'aluminium, obtenues à partir de tests de traction. Ce document joue un rôle crucial en définissant des caractéristiques mécaniques précises qui sont essentielles pour garantir la performance et la fiabilité des produits en aluminium. L'une des forces de cette norme réside dans sa capacité à fournir des critères clairs et mesurables, ce qui est essentiel pour les fabricants et les utilisateurs finaux. Grâce à la standardisation des tests de traction, latente dans la norme, les entreprises peuvent s’assurer de la qualité et de la durabilité des matériaux qu'elles utilisent. De plus, la norme est alignée avec les autres documents tels que EN 754-1, qui précise les conditions techniques d’inspection et de livraison, ainsi qu’EN 515 pour les désignations de température, renforçant ainsi la cohérence au sein des standards relatifs aux produits en aluminium. La pertinence de la norme EN 754-2:2024 est manifeste dans un contexte industriel où la sécurité et la performance sont primordiales. En caractérisant succinctement les propriétés mécaniques, la norme aide non seulement à améliorer la compréhension des produits en aluminium, mais elle facilite également la comparaison entre différents alliages et processus de fabrication. Par conséquent, la norme rencontre des besoins croissants pour des matériaux fiables et de haute qualité dans diverses applications, notamment notamment dans l’aéronautique, l’automobile ou la construction. En résumé, la norme SIST EN 754-2:2025 est un document de référence essentiel qui cadre les propriétés mécaniques des tiges, barres et tubages en aluminium. Elle assure la conformité, la qualité et la fiabilité des matériaux, consolidant ainsi sa place dans l’ensemble des normes techniques pour les alliages d'aluminium.

SIST EN 754-2:2025は、アルミニウムおよびアルミニウム合金の冷間引き抜きロッド/バーとチューブの機械的特性に関する重要な標準です。この文書は、引張試験に基づく機械的特性の限界を明確に規定しており、アルミニウムおよびその合金の加工における精度と信頼性を保証します。 この標準の範囲は明確であり、具体的な試験方法とそれに基づく機械的特性の定義が含まれているため、業界関係者にとって非常に重要です。標準は、機械的特性の評価を標準化することにより、安全性やパフォーマンスを確保するための指針を提供します。特に、引張試験結果の限界値が定められていることにより、メーカーや顧客は製品の品質を簡単に確認できるようになります。 SIST EN 754-2:2025は、検査および納品の技術的条件も定義しており、EN 754-1に基づいた製品および試験要件が含まれています。この点においても、アルミニウムおよびアルミニウム合金の業界標準化に寄与しており、全体的なプロセスの透明性を向上させています。さらに、温度に関する指定がEN 515で定義されており、化学組成の限界についてはEN 573-3で規定されるため、この標準は包括的なフレームワークを提供しています。 この標準は、アルミニウム製品の設計、製造、品質管理において、効率的な運用が求められる現代の製造業において特に重要です。標準化された機械的特性の基準に基づくことで、生産者は製品の整合性を保ちながら、顧客のニーズにも応えることが可能になります。全体として、SIST EN 754-2:2025は、アルミニウム材料の機械的特性に関する確固たる基盤を築くための不可欠な文書です。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...