CEN/TR 17330:2019

(Main)Guidelines for selection, use, care and maintenance of protective clothing against foul weather, wind and cold

Guidelines for selection, use, care and maintenance of protective clothing against foul weather, wind and cold

This document provides guidance to the employers or persons advising them such as suppliers of PPE or services, inspection, insurance companies etc.) in taking the necessary decisions regarding the selection, use, care and maintenance of protective clothing against foul weather, wind and cold, and is compliant with the applicable European legislation.

This document is not exhaustive in addressing all the safety concerns associated with the use of compliant protective equipment for protection against foul weather, wind and cold and other related risks.

This document does not address all the safety concerns, if any, associated with the use of this document by testing or repair facilities. It is the responsibility of the persons and organizations using this document and any other documents related to PPE:

- to conduct a risk assessment,

- to select the protective clothing and other PPE,

- to ensure that these provide a holistic protection; this can be achieved by not only assessing the risks, but also the work place and the work environment, and to determine the applicability of regulatory limitations prior to using this document for any designing, manufacturing, and testing.

Anleitungen für die Auswahl, Anwendung, Pflege und Erhaltung von Schutzkleidung gegen schlechtes Wetter, Wind und Kälte

Dieses Dokument stellt Arbeitgebern oder Personen, die sie beraten, wie z. B. Lieferanten von PSA oder Diensten, Inspektionen, Versicherungsgesellschaften usw., einen Leitfaden für notwendige Entscheidungen bei der Auswahl, Anwendung, Pflege und Erhaltung von Schutzkleidung gegen schlechtes Wetter, Wind und Kälte bereit und entspricht den geltenden europäischen Rechtsvorschriften.

Dieses Dokument ist nicht vollständig bei der Berücksichtigung sämtlicher Sicherheitsbedenken im Zusammenhang mit der Anwendung von konformen Schutzausrüstungen zum Schutz vor schlechtem Wetter, Wind und Kälte und anderen verbundenen Risiken.

Dieses Dokument behandelt nicht alle Sicherheitsbedenken, sofern vorhanden, die mit der Verwendung dieses Dokuments durch Prüf oder Reparatureinrichtungen verbunden sind. Es liegt in der Verantwortung der Personen und Organisationen, die dieses Dokument und alle anderen Dokumente im Zusammenhang mit der PSA verwenden,

- eine Risikobewertung durchzuführen,

- die Schutzkleidung und andere PSA auszuwählen und

- sicherzustellen, dass diese einen ganzheitlichen Schutz bieten; dies kann erreicht werden, indem nicht nur die Risiken, sondern auch der Arbeitsplatz und das Arbeitsumfeld bewertet und die Anwendbarkeit rechtlicher Beschränkungen vor der Verwendung dieses Dokuments für Auslegung, Herstellung und Prüfung bestimmt werden.

Guide pour la sélection, l’utilisation, l’entretien et la maintenance des vêtements de protection contre les intempéries, le vent et le froid

Le présent document fournit des recommandations aux employeurs ou aux personnes qui les conseillent, (comme les fournisseurs d'EPI ou de services, les sociétés d'inspection, les compagnies d'assurance, etc.), pour les aider à prendre les décisions nécessaires pour la sélection, l'utilisation, l'entretien et la maintenance des vêtements de protection contre les intempéries, le vent et le froid. Ce document est en conformité avec la législation européenne en vigueur.

Le présent document ne traite pas de façon exhaustive tous les problèmes de sécurité associés à l'utilisation d'équipements conformes de protection individuelle contre les intempéries, le vent, le froid et les autres risques connexes.

Le présent document ne traite pas, le cas échéant, l'ensemble des questions de sécurité associées à l'utilisation du présent document par des installations d'essai ou de réparation. Il incombe aux personnes et aux organismes qui utilisent ce document et tout autre document relatif aux EPI de :

réaliser une évaluation du risque ;

sélectionner les vêtements de protection et autres EPI ;

s'assurer qu'ils fournissent une protection complète, en évaluant non seulement les risques, mais aussi le lieu et l'environnement de travail, et de déterminer l'applicabilité des limitations règlementaires avant d'utiliser le présent document pour toute conception, fabrication et essai.

Smernice za izbiro, uporabo, nego in vzdrževanje varovalne obleke, ki varuje pred slabim vremenom, vetrom in mrazom

Ta dokument podaja navodila za izbiro, uporabo, nego in vzdrževanje varovalne obleke, ki varuje pred slabim vremenom, vetrom in mrazom, ter podaja dodatne informacije k standardu TR 15321.

General Information

- Status

- Published

- Publication Date

- 26-Feb-2019

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 27-Feb-2019

- Due Date

- 05-Jan-2019

- Completion Date

- 27-Feb-2019

Relations

- Effective Date

- 28-Jan-2026

Overview

CEN/TR 17330:2019 - "Guidelines for selection, use, care and maintenance of protective clothing against foul weather, wind and cold" is a CEN Technical Report published in 2019. It provides practical guidance for employers and advisors (suppliers, PPE services, inspection and insurance bodies) to make informed decisions about selection, use, care and maintenance of protective clothing for exposure to foul weather, wind and cold. The document is aligned with European legislation (notably Regulation (EU) 2016/425 on PPE) and is intended as a Selection-Use-Care-and-Maintenance (SUCAM) guideline rather than a prescriptive standard.

Key topics and technical requirements

- Risk assessment: Guidance on assessing environmental and task-related risks (wind chill, humidity, temperature) to determine protection needs.

- Selection criteria: Choosing garments and ensembles based on user needs, work environment, compatibility with other PPE, and ergonomic fit.

- Performance and integrity: Consideration of materials, seams, closures and ensemble integrity to ensure functional protection.

- Use and training: Introducing protective clothing into service, wearer trials, training users on correct donning, doffing and limitations.

- Care (cleaning & storage): Recommended approaches to cleaning, drying, labeling and storing protective clothing to preserve performance and hygiene.

- Maintenance & inspection: Routine and scheduled inspections, record keeping, criteria for repair or withdrawal from service, and disposal.

- Field evaluation & monitoring: In-service evaluation, frequency of cleaning, and monitoring for deterioration or ageing.

- Annexes: Informative annexes include lists of relevant EN/EN ISO standards (Annex A), detailed risk assessment guidance (Annex B), and example Arctic case scenarios (Annex C).

Practical applications & users

Who uses CEN/TR 17330:2019:

- Employers and health & safety managers developing PPE programs for outdoor, maritime, construction, transport, utilities or emergency-response workers exposed to foul weather, wind and cold.

- PPE suppliers, distributors and procurement teams evaluating product suitability.

- Inspection, testing and maintenance service providers setting protocols for care and repair.

- Insurance and occupational health advisors assessing compliance and risk mitigation.

Practical uses:

- Building workplace PPE policies, checklists and training materials.

- Specifying garment ensembles that balance thermal protection, wind/water resistance and ergonomics.

- Establishing cleaning, inspection and lifecycle management procedures to maintain PPE performance and compliance.

Related standards

- Annex A lists EN and EN ISO standards relevant to weather, wind and cold protective clothing and test methods. CEN/TR 17330:2019 should be used alongside Regulation (EU) 2016/425 and applicable national workplace safety legislation.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

CEN/TR 17330:2019 is a technical report published by the European Committee for Standardization (CEN). Its full title is "Guidelines for selection, use, care and maintenance of protective clothing against foul weather, wind and cold". This standard covers: This document provides guidance to the employers or persons advising them such as suppliers of PPE or services, inspection, insurance companies etc.) in taking the necessary decisions regarding the selection, use, care and maintenance of protective clothing against foul weather, wind and cold, and is compliant with the applicable European legislation. This document is not exhaustive in addressing all the safety concerns associated with the use of compliant protective equipment for protection against foul weather, wind and cold and other related risks. This document does not address all the safety concerns, if any, associated with the use of this document by testing or repair facilities. It is the responsibility of the persons and organizations using this document and any other documents related to PPE: - to conduct a risk assessment, - to select the protective clothing and other PPE, - to ensure that these provide a holistic protection; this can be achieved by not only assessing the risks, but also the work place and the work environment, and to determine the applicability of regulatory limitations prior to using this document for any designing, manufacturing, and testing.

This document provides guidance to the employers or persons advising them such as suppliers of PPE or services, inspection, insurance companies etc.) in taking the necessary decisions regarding the selection, use, care and maintenance of protective clothing against foul weather, wind and cold, and is compliant with the applicable European legislation. This document is not exhaustive in addressing all the safety concerns associated with the use of compliant protective equipment for protection against foul weather, wind and cold and other related risks. This document does not address all the safety concerns, if any, associated with the use of this document by testing or repair facilities. It is the responsibility of the persons and organizations using this document and any other documents related to PPE: - to conduct a risk assessment, - to select the protective clothing and other PPE, - to ensure that these provide a holistic protection; this can be achieved by not only assessing the risks, but also the work place and the work environment, and to determine the applicability of regulatory limitations prior to using this document for any designing, manufacturing, and testing.

CEN/TR 17330:2019 is classified under the following ICS (International Classification for Standards) categories: 13.340.10 - Protective clothing. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TR 17330:2019 has the following relationships with other standards: It is inter standard links to EN ISO 13688:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TR 17330:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2019

Smernice za izbiro, uporabo, nego in vzdrževanje varovalne obleke, ki varuje pred

slabim vremenom, vetrom in mrazom

Guidelines for selection, use, care and maintenance of protective clothing against foul

weather, wind and cold

Anleitungen für die Auswahl, Anwendung, Pflege und Erhaltung von Schutzkleidung

gegen schlechtes Wetter, Wind und Kälte

Guide pour la sélection, l’utilisation, l’entretien et la maintenance des vêtements de

protection contre les intempéries, le vent et le froid

Ta slovenski standard je istoveten z: CEN/TR 17330:2019

ICS:

13.340.10 Varovalna obleka Protective clothing

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TR 17330

TECHNICAL REPORT

RAPPORT TECHNIQUE

February 2019

TECHNISCHER BERICHT

ICS 13.340.10

English Version

Guidelines for selection, use, care and maintenance of

protective clothing against foul weather, wind and cold

Guide pour la sélection, l'utilisation, l'entretien et la Anleitungen für die Auswahl, Anwendung, Pflege und

maintenance des vêtements de protection contre les Erhaltung von Schutzkleidung gegen schlechtes

intempéries, le vent et le froid Wetter, Wind und Kälte

This Technical Report was approved by CEN on 8 February 2019. It has been drawn up by the Technical Committee CEN/TC 162.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 17330:2019 E

worldwide for CEN national Members.

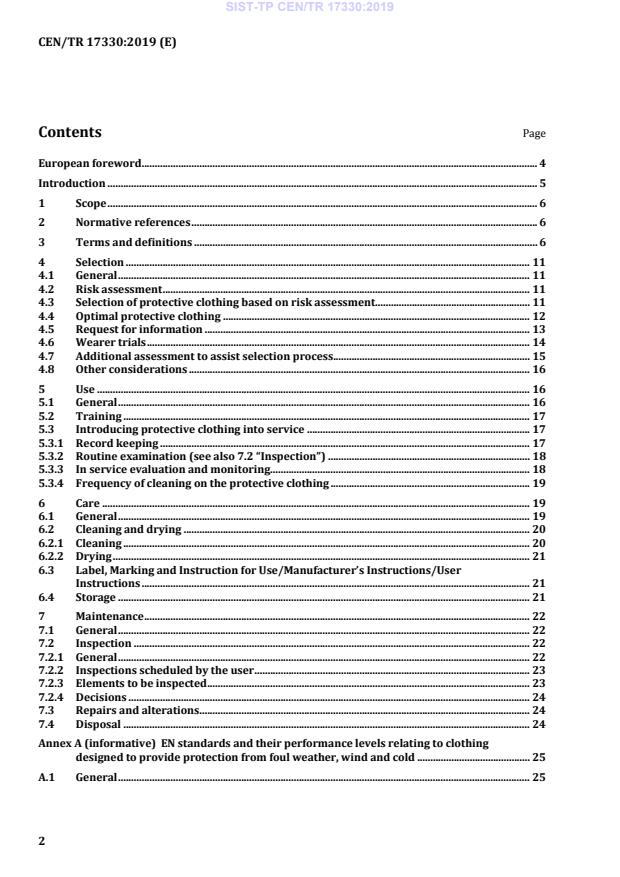

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Selection . 11

4.1 General . 11

4.2 Risk assessment . 11

4.3 Selection of protective clothing based on risk assessment . 11

4.4 Optimal protective clothing . 12

4.5 Request for information . 13

4.6 Wearer trials . 14

4.7 Additional assessment to assist selection process. 15

4.8 Other considerations . 16

5 Use . 16

5.1 General . 16

5.2 Training . 17

5.3 Introducing protective clothing into service . 17

5.3.1 Record keeping . 17

5.3.2 Routine examination (see also 7.2 “Inspection”) . 18

5.3.3 In service evaluation and monitoring. 18

5.3.4 Frequency of cleaning on the protective clothing . 19

6 Care . 19

6.1 General . 19

6.2 Cleaning and drying . 20

6.2.1 Cleaning . 20

6.2.2 Drying . 21

6.3 Label, Marking and Instruction for Use/Manufacturer’s Instructions/User

Instructions . 21

6.4 Storage . 21

7 Maintenance . 22

7.1 General . 22

7.2 Inspection . 22

7.2.1 General . 22

7.2.2 Inspections scheduled by the user . 23

7.2.3 Elements to be inspected . 23

7.2.4 Decisions . 24

7.3 Repairs and alterations. 24

7.4 Disposal . 24

Annex A (informative) EN standards and their performance levels relating to clothing

designed to provide protection from foul weather, wind and cold . 25

A.1 General . 25

A.2 Standards describing performance requirements for protective clothing or

materials . 25

A.2.1 Product Standards . 25

A.2.2 Test methods . 25

Annex B (informative) Risk assessment . 27

Annex C (informative) Guidance on some investigated Artic case scenarios . 29

C.1 Case Scenario1 . 29

C.2 Case Scenario 2 . 30

Bibliography . 34

European foreword

This document (CEN/TR 17330:2019) has been prepared by Technical Committee CEN/TC 162

“Protective clothing including hand and arm protection and lifejackets”, the secretariat of which is held

by DIN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Regulation (EU) 2016/425 indicates that PPE placed on the market complies with the essential health

and safety requirements, and not necessarily with the various relevant EN or EN ISO standards.

Nevertheless nearly all PPE meet the essential requirements of the standards, as harmonized standards

give presumption of conformity with the requirements of the Directive.

The reader should be aware that if PPE is intended for use at a workplace, national and European

legislation intended to ensure the safety of employees usually applies. When one mentions PPE, it must

meet the requirements of Regulation (EU) 2016/425.

All annexes are informative.

Introduction

This document has the aim to serve as guideline and checklist for companies preparing their own

protective clothing program based on risk analysis.

The information in this document has been produced to assist users, employers and purchasers (or the

person who advises the employer) in making the necessary decisions regarding the selection, use, care

and maintenance of protective clothing, for employees exposed to risks related to foul weather, wind

and cold.

The purpose of this technical report is to establish a guideline for protective clothing against foul

weather, wind and cold with the goal to evaluate and reduce the safety risks and potential health risks

associated with poorly maintained, contaminated, or damaged protective clothing. This Selection, Use,

Care and Maintenance guideline (SUCAM) provides best practice, answers, criteria, and options related

to foul weather, wind and cold to the persons that are selecting or using protective clothing through its

life cycle with respect to protection.” The main topics that an employer needs to consider are

highlighted in this document. Many paragraphs of the document contain bullet-lists as examples and

options that may need to be considered.

The annexes give additional details that are necessary to describe hazards and risks, the value of the

test methods for the end user, etc.

Annex A gives details of the current EN or EN ISO Standards relating to clothing designed to provide

protection from foul weather, wind and cold.

Please be aware of and consider compatibility with other items of PPE that both protect against foul

weather, wind and cold, but consider other risks as well.

For European legislation on PPE see Regulation (EU) 2016/425 of the European Parliament and of

Council of 9 March 2016 on personal protective equipment.

1 Scope

This document provides guidance to the employers or persons advising them such as suppliers of PPE

or services, inspection, insurance companies etc.) in taking the necessary decisions regarding the

selection, use, care and maintenance of protective clothing against foul weather, wind and cold, and is

compliant with the applicable European legislation.

This document is not exhaustive in addressing all the safety concerns associated with the use of

compliant protective equipment for protection against foul weather, wind and cold and other related

risks.

This document does not address all the safety concerns, if any, associated with the use of this document

by testing or repair facilities. It is the responsibility of the persons and organizations using this

document and any other documents related to PPE:

— to conduct a risk assessment,

— to select the protective clothing and other PPE,

— to ensure that these provide a holistic protection; this can be achieved by not only assessing the

risks, but also the work place and the work environment, and to determine the applicability of

regulatory limitations prior to using this document for any designing, manufacturing, and testing.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 13688:2013, Protective clothing — General requirements (ISO 13688:2013)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

ageing

change of one or more initial properties of protective materials during the passage of time

[SOURCE: EN ISO 13688:2013, 3.1]

3.2

air permeability

AP

velocity of an air flow passing perpendicularly through a test specimen under specified conditions of

test area, pressure drop and time

Note 1 to entry: AP is expressed in millimetres per second.

[SOURCE: EN ISO 9237:1995, 3.1, modified: abbreviation added as admitted term and Note 1 to entry

added]

3.3

care

provisions for cleaning, decontamination and storage of the protective clothing

3.4

cold environment

environment characterized by the combination of humidity and wind (wind-chill effect) at air

temperature equal to or less than −5 °C

[SOURCE: EN 342:2017, 3.1]

3.5

compatibility

ability of clothing (protective clothing and other clothing) to be used in conjunction with other parts of

PPE

3.6

cool environment

environment characterized by the combination of humidity and wind (wind cooling effect) at air

temperatures above - 5°C

[SOURCE: EN 14058:2017, 3.1]

3.7

deterioration

downgrading of the effectiveness or physical characteristics of textile materials due to use, care,

maintenance or storage conditions

3.8

ensemble

combination or assembly of multiple items that are individually compliant and provide protection to the

head, upper torso together with arms and hands, the lower torso together with feet, and respiratory

protection, and that together fulfil all the requirements

3.9

ergonomics

scientific discipline concerned with the understanding of interactions among human and other

elements of a system, and the profession that applies theory, principles, data and methods to design in

order to optimize human well-being and overall system performance

[SOURCE: EN ISO 26800:2011, 2.2, accepted term and note to entry deleted]

3.10

field evaluation

non-laboratory assessment of an ensemble, ensemble element, or item

3.11

fit

quality, state, and manner in which clothing, when worn, relates to the individual human body or other

PPE

3.12

garment

individual component of a clothing ensemble covering a part of the body, except separate garment for

head, hands and feet and providing protection against hypothermia

[SOURCE: EN 342:2017, 3.2]

3.13

hardware

non-fabric items used in protective clothing including those made of metal or plastic, e.g. fasteners, rank

markings, buttons, zippers

[SOURCE: EN 469:2005, 3.7]

3.14

hazard

situation which can be the cause of harm or damage to the health of the human body

[SOURCE: EN ISO 13688:2013, 3.2, modified: Note 1 to entry deleted]

3.15

hygiene

any practice or activity that you do to keep protective clothing healthy and clean

3.16

insulation required

IREQ

required resultant thermal insulation calculated on the basis of the thermal parameters of the

environment (e. g. air temperature, mean radiant temperature, air velocity, relative humidity) and the

body metabolism

[SOURCE: EN 14058:2017, 3.6.3, modified: term split into term and acronym, Note 1 to entry deleted]

3.17

integrity

construction of the protective clothing that ensures the proper functioning of the protective clothing

Note 1 to entry: Seams, zippers and other closures provide integrity if they constitute solid barriers which

ensure suitable protection while offering some flexibility by design.

3.18

maintenance

preservation from loss or deterioration by applying procedures for inspection, repair and ultimate

removal from service

3.19

outer shell material

outermost material of which the protective clothing is made

[SOURCE: EN 342:2017, 3.11]

3.20

protective clothing

clothing which covers or replaces personal clothing and which is designed to provide protection against

one or more hazards

[SOURCE: EN ISO 13688:2013, 3.4]

3.21

resistance to water penetration

WP

hydrostatic pressure supported by a material as a measure of the opposition to the passage of water

through material

Note 1 to entry: WP is expressed in pascal.

[SOURCE: EN 342:2017, 3.9]

3.22

resultant effective thermal insulation

I

cler

thermal insulation from skin to outer clothing surface under defined conditions measured with or

calculated for a moving manikin determined in relation to the naked body surface area

Note 1 to entry: I is expressed in square metres Kelvin per watt

cler

[SOURCE: EN 342:2017, 3,8]

3.23

risk

probability of a specific undesired event occurring so that a hazard is realized

[SOURCE: EN ISO 13688:2013, 3.2]

3.24

risk assessment

overall process that identifies hazards, estimates the potential severity of injury or damage to health,

estimates the likelihood of occurrence of injury or danger to health determines the protective clothing

against cold and cool and other protection measures required

3.25

selection

process of determining the type of protective equipment (garments) that is necessary for the required

protection

3.26

tensile strength

force at which a fibre or fabric will break when pulled in one dimension

3.27

textile fabric

planar structure consisting of yarns or fibres

3.28

thermal lining

non-watertight layer providing thermal insulation

[SOURCE: EN 14058:2017, 3.4]

3.29

thermal resistance

insulation

R

ct

temperature difference between the two faces of a material divided by the resultant heat flux per unit

area in the direction of the gradient

Note 1 to entry: It is a quantity specific to textile materials or composites, which determines the dry heat flux

across a given area in response to a steady applied temperature gradient. The dry heat flux can consist of one or

more conductive, convective and radiant components.

Note 2 to entry: The thermal resistance is expressed in square metres kelvin per watt.

[SOURCE: EN ISO 11092:2014, 2.1]

3.30

trousers

element of the protective ensemble that provides protection to the lower torso and legs, excluding the

ankles and feet

3.31

use

application of protective clothing including its limitations

3.32

verified independent service provider

ISP

independent service provider verified by a third-party certification organization and who conducts, as

individual or combined services, advanced inspection, advanced cleaning, basic repair, or advanced

repair

3.33

water vapour resistance

R

et

water vapour pressure difference between the two faces of a material divided by the resultant

evaporative heat flux per unit area in the direction of the gradient

Note 1 to entry: It is a quantity specific to textile materials or composites, which determines the “latent”

evaporative heat flux across a given area in response to a steady applied water vapour pressure gradient. The

evaporative heat flux can consist of both diffusive and convective components.

Note 2 to entry: The water vapour resistance is expressed in square metres pascal per watt.

[SOURCE: EN ISO 11092:2014, 2.2]

4 Selection

4.1 General

The process of selecting protective clothing can be divided into a number of steps with the goal of

providing protective clothing against foul weather, wind and cold and related risks that are suitable and

appropriate for the intended use (job and/or task) and fulfil the requirements of the European

legislation, note that national legislation can apply as well. Not only selection procedures are required

but also for use, care and maintenance of protective clothing against foul weather, wind and cold used

by the employees.

Selection is the starting point when determining the need for protective clothing. The selection should

not be limited to their section as a decision can be broader based on use, cleaning, maintenance, etc.

It is the obligation of the manufacturer, for certified protective clothing and according to EN ISO 13688,

to give clear instructions about use, care and maintenance of the clothing to be followed up by the

employee and employer. These instructions specify the methods and means of cleaning and drying.

4.2 Risk assessment

Prior to starting the selection process of protective clothing against foul weather, wind and cold, the

organization performs a risk assessment. A risk assessment is a dynamic process and is not limited to

the present situation. The risk assessment include but needs not be limited to, the hazards and work

conditions that can be encountered in each task in foul weather, wind and cold environment based on

the following:

— Step 1: Identify the hazards (Annex B).

In identifying the hazard it is important to understand both the intensity and time of exposure.

— Step 2: Estimate the risk

R = LE ××S (see Annex B) based on the task. (1)

where

R is the risk

L is the likelihood

E is the time of exposure

S is the severity of the risk;

— Step 3: Ensure that prevention options (technical, organisational, etc.) have been exhausted before

choosing PPE.

— Step 4: Decide on precautions to mitigate risks.

— Step 5: Record findings and implement them.

— Step 6: Review risk assessment and update if necessary.

Annex A gives references to some of the recommended documents on this subject.

4.3 Selection of protective clothing based on risk assessment

If the risks are identified following the risk assessment (Annex B) it is important that the appropriate

personal protective equipment is selected taking into account that:

— the standard or method chosen, which will provide the protection required, (see Annex C) are

identified;

— the level(s) of protection required (for the relevant parts of the body) in relative or absolute terms

for each item of protective clothing is (are) determined;

— the risk and experience of the previously used protective clothing against foul weather, wind and

cold risks are assessed;

— the compatibility with other PPE is identified.

Annex C provides guidelines and examples of hazards and applicable standards.

Figure 1 — Acquisition of protective clothing based on risk assessment

4.4 Optimal protective clothing

Selection of optimal over best protective clothing is a better option because over-protection might lead

to a lack of comfort. In addition to ambient air temperature, factors such as work intensity, humidity,

precipitation, wind speed, radiation and clothing worn while working can lead to cold stress.

Employers are expected to be sensitive to these factors as people working in uncomfortable

environments are more likely to behave unsafely because their ability to take decisions and their

performance of manual tasks deteriorates. For example:

— employees might not wear personal protective equipment properly in cold environments,

increasing the risks for cold stress;

— an employee's ability to concentrate on a given task can decrease, which increases the risk of errors

occurring;

— muscle cooling leads to decreased balance abilities and increasing risks of slipping and falling.

At the same time, the worker is expected to be protected from hazards, therefore a balance between

health or comfort, and the long and short-term risks protection is the best approach. To achieve this, the

following can be done:

— identify the hazards that employees might face and then engineer out or reduce the hazard level;

— define the optimal protective clothing;

the optimal protective clothing depends on a number of factors:

— number of garment layers to balance comfort and protection needed for different tasks;

— garment construction can increase or decrease the perception of comfort;

— fabric weight is a critical factor in determining on-the-job comfort, the heavier the fabric the

less comfort is offered;

— breathability of fabric.

Breathability of fabric is frequently measured by its vapour resistance (R ). For example, the

et

European Standard EN 343 on material comfort rating (Clothing for protection against foul

weather) sets various classes as follows:

— Class 1 materials have R values greater than 40 m Pa/W, and are considered to be

et

impermeable, i.e. they offer no perceivable comfort to the wearer;

2 2

— Class 2 materials have R values between 25 m Pa/W and 40 m Pa/W, and are rated as

et

medium performance, offering some breathable performance. The majority of products on

the market are of this class;

2 2

— Class 3 materials have R values between 15 m Pa/W and 25 m Pa/W;

et

— Class 4 materials have R values smaller than or equal to 15 m Pa/W.·

et

Fabrics without membrane or coating will always have better breathability.

The thermal comfort is not only affected by the PPE but also by all worn clothing items.

4.5 Request for information

When purchasing purposes of protective clothing against foul weather, wind and cold, it is important

that:

— market research is carried out to determine products that are available (for properties see Table 1);

— information on performance levels is obtained from the potential suppliers and from manufacturer

information;

— protective clothing against foul weather, wind and cold as covered by the Regulation (EU)

2016/425 on personal protective equipment is selected;

— compatibility of all items of PPE to be used is ensured.

Annex A provides a list of the relevant EN standards for clothing designed to protect against foul

weather, wind and cold.

4.6 Wearer trials

Where a field evaluation (wearer trials) of protective clothing against foul weather, wind and cold is

conducted, the organization establishes criteria to ensure a systematic method of comparing products

in a manner related to their intended use and assessing their performance relative to the organization's

expectations, by well-defined criteria is the best approach. The purpose of a wearer trial is to assess the

compatibility and the ergonomic practicality of the protective clothing against foul weather, wind and

cold risks. Obtaining feedback from the intended users is of extreme importance at this stage, as such

information will provide valuable data relating to the practical performance of the protective clothing,

and also give confidence to the users, thus ensuring that the selected items are used.

NOTE In hazardous working situations CE-marked protective clothing is used.

When conducting wearer trials, the following issues should be considered:

— comfort and ability:

— can the user perform all the movements and take the working positions as he will have to when

performing his task? Can this be done without compromising the wearer's safety?

— is there any constraint on the user's access to parts of his working place, e.g. climbing on

ladders or passing through narrow openings? Can he do this without putting himself in danger

and without damaging his CPC (cold protective clothing) or other equipment?

— will the use of the CPC lead to a considerable decrease of work time?

— ease and speed of putting on and taking off (donning-doffing):

— this is of high importance when the CPC has to be used in emergency situations or when the

chemical is so aggressive that the protection time offered by the CPC is limited when

contaminated;

— ease and extent of adjustability:

— in order to ensure the wearer's comfort and ease of movement, the suit should be equipped

with a system adjustable to the body measurements of the individual wearer;

— compatibility with all other items of PPE;

— time limits for use:

— the use of other PPE, e.g. self-contained breathing apparatus, might limit the wearing time of

the CPC;

— chemical resistance will be negatively affected by high temperatures and mechanical actions such

as flexing, rubbing etc. Breakthrough times obtained by laboratory test methods serve only as an

indicator to set time limits for real use.

Table 1 — Summary table of properties and wearability of protective clothing

Property Consideration Parameters (examples)

Sensibility Breathability Air permeability

Flexibility Water vapour permeability

Elasticity Water vapour resistance

Skin effects Thermal resistance

Weight

Thickness

Surface roughness

pH value

Ergonomics In wear at work Size

Fit

Weight

Freedom of movement and work

Friction against undergarments in walking

Durability In wear Tensile strength

In storage Tear strength

Abrasion resistance

Flex cracking

Seam resistance

Colour durability

Material ageing

Wash and care Single use Ease of cleaning

Washing Dimensional stability

Dry cleaning Pilling

Visual appearance

Absence of physical damages after cleaning

Performance preservation

4.7 Additional assessment to assist selection process

To assist any decision making process, additional assessment can be required:

— assessment of behaviour after laundry/cleaning. The selection of a garment certified after a higher

number of washing cycles is advisable, unless the garment does not fulfil the requirements

anymore;

— assessment of wear and tear. This assessment is useful to predict the material durability under

mechanical stress;

— thermal insulation assessment of behaviour after partially or fully wetted clothing. Considering that

a partially or fully wet garment (sweating/water impact) reduces the thermal insulation, causing a

severe risk to the worker, this investigation is recommended to prevent potential related risks;

— visibility of employee.

4.8 Other considerations

In order to establish the overall performance and the total cost of ownership of the protective clothing,

other considerations may be made:

— Is training offered as part of the procurement package (including training provided by third

parties)?

— Is a post procurement service offered?

— What quality assurance measures are in place prior to the delivery?

— What are the requirements for cleaning?

— What are the inspection and maintenance requirements?

— What are the replacement requirements and costs for components?

— What is the delivery time for standard and special sizes?

— What sizes are available?

— Are stock items held by the supplier?

— What are the collection and delivery arrangements?

— Should stock be held within the organization?

— How is the internal distribution to the users organized?

— How has the protective clothing to be safely disposed of?

— Can corporate/role identity be incorporated without affecting performance?

— Are quality assurance measures put in place by the supplier (e.g. certified quality management

system in accordance with EN ISO 9001)?

— If relevant, are quality assurance measures offered by the rental company?

When the outcome of a selection process results in the employer providing a number of items of

protective clothing for different tasks/activities, the user/wearer may (after being provided with

appropriate training) select the item(s) that provide the necessary protection at the time of use. Any

selection made at that stage is supposed to be based upon the risk assessment carried out by the

employer or based upon an informed dynamic risk assessment by the user at time of use.

5 Use

5.1 General

After the selection of the protective clothing, a number of stages should be followed to ensure its correct

use. This program has the goal to provide protective clothing against foul weather, wind and cold risks

that are suitable and appropriate for the intended use and to maintain such protective clothing in a safe,

usable condition. Periodic review of the hazard/risk assessment may need a revision of the use of PPE.

5.2 Training

European Directive 89/656/EEC (Section II Article 4 paragraph 8) requires that all employees/users

are trained how to use their protective clothing correctly, preferably prior to approve the equipment for

active use. These directions should be available to the employee. The training should include:

— information concerning limitations and capabilities of the protective clothing,

— what the protective clothing will protect from,

— what the protective clothing will not protect from,

— what the effects are (if any) of long term use,

— how to use, wear and inspect the protective clothing,

— the importance of complying with the manufacturers or suppliers instructions,

— how the care and maintenance procedures should be carried out,

— how to store the protective clothing when not in use,

— information concerning arrangements for handling, cleaning and decontamination,

— how to determine when the protective clothing is no longer fit for purpose,

— how to obtain replacements.

5.3 Introducing protective clothing into service

WARNING — When individual items of a protective clothing ensemble are replaced, care should be

taken to ensure that the required level of protection to the body is maintained.

5.3.1 Record keeping

In the overall management of protective clothing it is essential to build a full life history for each item,

from manufacture to disposal (PPE Use Directive 89/656/EEC, PPE Directive 89/686). This record

keeping, whether on the cost of maintenance or on issues during use of PPE, is beneficial to improve the

worker's protection and to understand the life of the PPE.

The following records should be kept for protective clothing against foul weather, wind and cold risks:

— person to whom the element is issued;

— the specification of the protective clothing (manufacturer, month and year of manufacture, delivery

date;

— batch number, model and design, etc.;

— training records of operative personnel using the protective clothing, including the duration of

exposure to risks and the identity of the risks;

— the service history of the protective clothing (date of issue, name of wearer, .);

— information relating to care;

— cleaning;

— storage;

— records of cleaning and drying cycles (including repellence treatments);

— records of maintenance;

— inspection;

— damage and repair;

— disposal;

— problems arising from the use of the protective clothing.

NOTE These records will be easily available to the current user or his delegate.

5.3.2 Routine examination (see also 7.2 “Inspection”)

Each individual item of protective clothing should be examined before and after use, after washing or

after repair. Ideally the examinations should be carried out by the appropriately trained user, the

laundry, the manufacturer, the supplier of the protective clothing or other external organization.

Routine examinations should include the following visual non-destructive checks:

— appropriate working conditions (the garment should be dry before re-use);

— physical damage (punctures, holes, state of seams, rips, tears, cuts, missing hardware, shrinkage,

discoloration, state of membrane, wear of different layers, loss of fabric thickness (e.g. 25 %));

— damaged or missing accessories (reflective trimming, labelling);

— ongoing evaluation of system fit and interfaces/overlaps;

— registrations of the findings of visual inspection.

Appropriate action should be taken to remedy the observed deficiencies including cleaning, and any

necessary reparations or replacements.

5.3.3 In service evaluation and monitoring

A system should be in place to ensure that the performance of all protective clothing is constantly

evaluated and monitored. In order to know the level of protection, random testing on in-use garments

should be performed.

The items to be monitored may include:

— accident/injury statistics (including near accident);

— failure rates of protective clothing including trends for similar repairs;

— feedback from users;

— changes in working conditions and available protective clothing on the market;

— routine examination (described above), and

— registration of intensity of use only determines visual shortcomings of the clothing.

5.3.4 Frequency of cleaning on the protective clothing

Protective clothing against foul weather, wind and cold must be clean. Carry out cleaning procedure

determined by the manufacturer to ensure that protection is maintained. For cleaning instructions

see 7.2.

6 Care

6.1 General

Regulation (EU) 2016/425 on personal protective equipment stipulates that all protective clothing

must be provided with manufacturer information, including care instructions (both on a label attached

to the item and/or separately in a written document. Based on this information, the employer should

determine the arrangements for care and inform all parties involved (including the user). Employers

provide a means for having protective clothing against foul weather, wind and cold risks cleaned.

Care arrangements should include information on:

— cleaning;

— use of cleaning methods (washing, chemical, dry, steam or not treatable);

— person who carries out cleaning (professional or industrial cleaning is the preferred method, as

home cleaning can only be done under strict considerations);

— risks and benefits e.g. cross contamination, washing conditions, hygiene, temperature,

prewash, detergents and drying;

— causes for cleaning the items (visible contamination, smell and doubtful cases);

— necessity of re-application of finishes and/or treatments.

— visual inspection by specialist care or maintenance and/or manufacturer. In case of class 3

products the protective clothing shall be examined every year by the manufacturer.

— ageing;

— wear and tear;

— registration of intensity of use, cleaning and decontamination;

— frequency of use of clothing;

— quantity of cleaning and/or decontamination cycles;

— storage;

— parameters for the storage of the protective clothing (e.g. humidity, temperature, duration,

light);

— conditions for storing protective clothing, prior to use, when in use and when not in use,

respectively.

6.2 Cleaning and drying

6.2.1 Cleaning

The end users are responsible for the routine care and maintenance of their issued protective clothing.

Employers follow up the instructions of the manufacturer and user information for instructions on

washing and drying, dry cleaning, disinfection, re-impregnation, etc. that the manufacturer provided

with the protective clothing. It is recommended to clean new clothing (non- disposable) prior to first

use to ensure that no residues of production remain on the clothing.

Cleaning can be divided into two different levels, namely:

— routine cleaning (level 1):

light cleaning of ensembles or ensemble elements performed by the end user without taking the

elements out of service;

— advanced cleaning (level 2):

thorough cleaning of ensembles or elements by washing with cleaning agents (excluding bleach and

peroxides as they may affect the protection characteristics of the clothing).

Cleaning can be divided into different methods, namely:

— dry cleaning (can require re-impregnation),

— wet (washing) (can require re-impregnation),

— chemical (can require re-impregnation),

— steam (can require re-impregnation),

— other.

Good cleaning practice will ensure that:

— home washing is only allowed if the clothing is not soiled with hazardous substances;

— requirements for cleanliness are determined;

— there is limited deterioration to any components of the protective clothing and a preservation of

the integrity of protection;

— the items are visibly clean;

— the protective clothing is hygienically clean;

— no unpleasant odour remains;

— loading (weight of garments versus liquor –water and cleaning agent) of the washing machines is

such as to ensure effective cleaning and rinsing of the machines;

— there are no residues of the cleaning products and packing;

— the possibility of the size of the garment changing is limited;

— re-application of finishes/treatments is done according to the instructions of the su

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...