EN 12697-22:2020

(Main)Bituminous mixtures - Test methods - Part 22: Wheel tracking

Bituminous mixtures - Test methods - Part 22: Wheel tracking

This document describes test methods for determining the susceptibility of bituminous materials to deform under load. The test is applicable to mixtures with upper sieve size less than or equal to 32 mm.

The tests are applicable to specimens prepared from asphalt mixtures that have either been manufactured in a laboratory or cut from a pavement; test specimens are held in a mould with their surface flush with the upper edge of the mould.

The susceptibility of bituminous materials to deform is assessed by the rut formed by repeated passes of a loaded wheel at constant temperature. Three alternative types of device can be used according to this standard: large-size devices, extra large-size devices and small-size devices. With large-size devices and extra large-size devices, the specimens are conditioned in air during testing. With small-size devices, specimens are conditioned, in either air or water.

NOTE Large-size and extra large-size devices are not suitable for use with cylindrical cores.

Asphalt - Prüfverfahren - Teil 22: Spurbildungstest

Dieses Dokument beschreibt Prüfverfahren zur Bestimmung der Verformungsanfälligkeit von Asphalt bei Belastung. Das Verfahren ist auf Asphalt mit einem Größtkorn von maximal 32 mm anwendbar.

Die Prüfungen sind auf aus Asphaltmischungen vorbereitete Probekörper anwendbar, die entweder in einem Labor hergestellt oder aus einer Fahrbahnbefestigung geschnitten wurden; die Probekörper werden so in Prüfformen gelegt, dass ihre Oberflächen mit der Oberkante der Form bündig abschließen.

Die Verformungsanfälligkeit von Asphalt wird anhand einer Spurrinne geprüft, die durch wiederholte Übergänge eines belasteten Rades bei konstanter Temperatur erzeugt wird. Nach dieser Norm können drei verschiedene Prüfgeräte verwendet werden: das Gerät mit besonders großem Rad, das Gerät mit großem Rad und das Gerät mit kleinem Rad. Bei Verwendung der Geräte mit großem und besonders großem Rad werden die Probekörper während der Prüfung an der Luft klimatisiert. Bei Verwendung des Geräts mit kleinem Rad werden die Probekörper entweder im Wasser oder an der Luft klimatisiert.

ANMERKUNG Die Geräte mit großem und besonders großem Rad sind nicht für die Prüfung von zylindrischen Bohrkernen geeignet.

Mélanges bitumineux - Méthodes d'essai - Partie 22 : Essai d’orniérage

Le présent document décrit les méthodes d’essais à suivre pour déterminer le comportement en déformation des matériaux bitumineux soumis à des charges roulantes. Cet essai s’applique aux mélanges dont les plus grandes dimensions granulaires sont inférieures ou égales à 32 mm.

Ces procédures peuvent être mises en œuvre sur des éprouvettes de mélange bitumineux qui ont été fabriquées en laboratoire ou prélevées sur une chaussée ; les éprouvettes sont placées dans un moule, leur surface affleurant la partie supérieure du moule.

Le comportement en déformation des matériaux bitumineux est évalué par la profondeur de l’ornière qui se forme suite à des passages répétés d’une charge roulante à température constante. Trois types de dispositifs peuvent être utilisés conformément à la présente norme : des dispositifs de grandes dimensions, des dispositifs extra-larges et des dispositifs de petites dimensions. Avec les dispositifs de grandes dimensions et les dispositifs extra-larges, les éprouvettes sont conditionnées à l’air pendant l’essai. Avec les dispositifs de petites dimensions, elles sont conditionnées soit à l’air, soit dans l’eau.

NOTE Les dispositifs de grandes dimensions et les dispositifs extra-larges ne sont pas adaptés pour l’essai d’éprouvettes cylindriques.

Bitumenske zmesi - Preskusne metode - 22. del: Preskus nastajanja kolesnic

General Information

- Status

- Withdrawn

- Publication Date

- 25-Feb-2020

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 227 - Road materials

- Drafting Committee

- CEN/TC 227/WG 1 - Bituminous mixtures

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 20-Dec-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 04-Mar-2020

- Effective Date

- 01-Nov-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 24-Aug-2022

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 12697-22:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Bituminous mixtures - Test methods - Part 22: Wheel tracking". This standard covers: This document describes test methods for determining the susceptibility of bituminous materials to deform under load. The test is applicable to mixtures with upper sieve size less than or equal to 32 mm. The tests are applicable to specimens prepared from asphalt mixtures that have either been manufactured in a laboratory or cut from a pavement; test specimens are held in a mould with their surface flush with the upper edge of the mould. The susceptibility of bituminous materials to deform is assessed by the rut formed by repeated passes of a loaded wheel at constant temperature. Three alternative types of device can be used according to this standard: large-size devices, extra large-size devices and small-size devices. With large-size devices and extra large-size devices, the specimens are conditioned in air during testing. With small-size devices, specimens are conditioned, in either air or water. NOTE Large-size and extra large-size devices are not suitable for use with cylindrical cores.

This document describes test methods for determining the susceptibility of bituminous materials to deform under load. The test is applicable to mixtures with upper sieve size less than or equal to 32 mm. The tests are applicable to specimens prepared from asphalt mixtures that have either been manufactured in a laboratory or cut from a pavement; test specimens are held in a mould with their surface flush with the upper edge of the mould. The susceptibility of bituminous materials to deform is assessed by the rut formed by repeated passes of a loaded wheel at constant temperature. Three alternative types of device can be used according to this standard: large-size devices, extra large-size devices and small-size devices. With large-size devices and extra large-size devices, the specimens are conditioned in air during testing. With small-size devices, specimens are conditioned, in either air or water. NOTE Large-size and extra large-size devices are not suitable for use with cylindrical cores.

EN 12697-22:2020 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12697-22:2020 has the following relationships with other standards: It is inter standard links to EN 12697-22:2003+A1:2007, EN 12697-22:2020+A1:2023, ISO 48-5:2018, ISO 48-2:2018, EN 12697-35:2025, EN 12697-27:2017, EN 12697-33:2019+A1:2022, EN 12697-6:2020, EN 12697-7:2022, EN 12697-22:2020/prA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12697-22:2020 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/124. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12697-22:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2020

Nadomešča:

SIST EN 12697-22:2004+A1:2007

Bitumenske zmesi - Preskusne metode - 22. del: Preskus nastajanja kolesnic

Bituminous mixtures - Test methods - Part 22: Wheel tracking

Asphalt - Prüfverfahren - Teil 22: Spurbildungstest

Mélanges bitumineux - Méthodes d'essai - Partie 22 : Essai d’orniérage

Ta slovenski standard je istoveten z: EN 12697-22:2020

ICS:

93.080.20 Materiali za gradnjo cest Road construction materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12697-22

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2020

EUROPÄISCHE NORM

ICS 93.080.20 Supersedes EN 12697-22:2003+A1:2007

English Version

Bituminous mixtures - Test methods - Part 22: Wheel

tracking

Mélanges bitumineux - Méthodes d'essai - Partie 22 : Asphalt - Prüfverfahren - Teil 22: Spurbildungstest

Essai d'orniérage

This European Standard was approved by CEN on 18 November 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12697-22:2020 E

worldwide for CEN national Members.

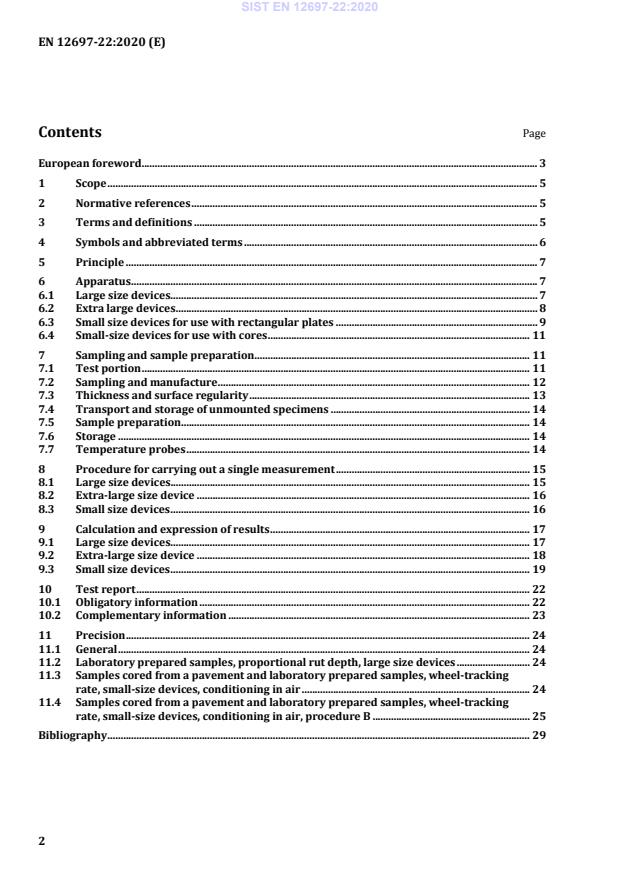

Contents Page

European foreword . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Symbols and abbreviated terms . 6

5 Principle . 7

6 Apparatus . 7

6.1 Large size devices . 7

6.2 Extra large devices . 8

6.3 Small size devices for use with rectangular plates . 9

6.4 Small-size devices for use with cores . 11

7 Sampling and sample preparation . 11

7.1 Test portion . 11

7.2 Sampling and manufacture . 12

7.3 Thickness and surface regularity . 13

7.4 Transport and storage of unmounted specimens . 14

7.5 Sample preparation . 14

7.6 Storage . 14

7.7 Temperature probes . 14

8 Procedure for carrying out a single measurement . 15

8.1 Large size devices . 15

8.2 Extra-large size device . 16

8.3 Small size devices . 16

9 Calculation and expression of results . 17

9.1 Large size devices . 17

9.2 Extra-large size device . 18

9.3 Small size devices . 19

10 Test report . 22

10.1 Obligatory information . 22

10.2 Complementary information . 23

11 Precision . 24

11.1 General . 24

11.2 Laboratory prepared samples, proportional rut depth, large size devices . 24

11.3 Samples cored from a pavement and laboratory prepared samples, wheel-tracking

rate, small-size devices, conditioning in air . 24

11.4 Samples cored from a pavement and laboratory prepared samples, wheel-tracking

rate, small-size devices, conditioning in air, procedure B . 25

Bibliography . 29

European foreword

This document (EN 12697-22:2020) has been prepared by Technical Committee CEN/TC 227 “Road

materials”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2020, and conflicting national standards shall

be withdrawn at the latest by August 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12697-22:2003+A1:2007.

The following is a list of significant technical changes since the previous edition:

— the title no longer makes the method exclusively for hot mix asphalt;

— [Clause 2] ISO 48, Rubber, vulcanized or thermoplastic — Determination of hardness (hardness

between 10 IRHD and 100 IRHD), replaced by: ISO 48-2, Rubber, vulcanized or thermoplastic —

Determination of hardness — Part 2: Hardness between 10 IRHD and 100 IRHD; ISO 7619, Rubber,

vulcanized or thermoplastic — Determination of indentation hardness, replaced by: ISO 48-5,

Rubber, vulcanized or thermoplastic — Determination of hardness — Part 5: Indentation hardness

by IRHD pocket meter method;

— [3.5] Table 1 deleted;

— [Clause 4] symbols for properties in the different methods made more consistent and corrected

through the whole document. Table 2 replaced by new Table 1;

— [Clause 6] moulds added to the list of equipment. Modifications for clarity;

— [6.3.1.2] ISO 7619 and ISO 48 replaced by: ISO 48-5 and 48-2;

— [7.1] new clause added and the order of clauses changed;

— [7.2.1.1] vibratory compactor excluded as a method of sample preparation;

— [7.2.1.2] thickness for mixtures with upper sieve size larger than 22 changed to 80 mm;

— [7.5.1] the text has been modified for clarity. “Plaster of Paris” amended to holding medium;

— [7.6] storage time amended to max 42 days and requirement added for storing samples on a flat

surface;

— [8.1.7] deleted;

— [9.2.1] Formula (2) corrected;

— [9.3.1.2] Formula (7) corrected;

— [9.3.2.2] required rounding of WTS values specified;

AIR

— [9.3.3.2] required rounding of WTS values specified;

W

— [10.1.2] type of roller compactor required to be reported;

— [11.4] precision data for small device, procedure B (air) added;

A list of all parts in the EN 12697 series can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document describes test methods for determining the susceptibility of bituminous materials to

deform under load. The test is applicable to mixtures with upper sieve size less than or equal to 32 mm.

The tests are applicable to specimens prepared from asphalt mixtures that have either been

manufactured in a laboratory or cut from a pavement; test specimens are held in a mould with their

surface flush with the upper edge of the mould.

The susceptibility of bituminous materials to deform is assessed by the rut formed by repeated passes

of a loaded wheel at constant temperature. Three alternative types of device can be used according to

this standard: large-size devices, extra large-size devices and small-size devices. With large-size devices

and extra large-size devices, the specimens are conditioned in air during testing. With small-size

devices, specimens are conditioned, in either air or water.

NOTE Large-size and extra large-size devices are not suitable for use with cylindrical cores.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12697-6, Bituminous mixtures — Test methods — Part 6: Determination of bulk density of bituminous

specimens

EN 12697-7, Bituminous mixtures — Test methods for hot mix asphalt — Part 7: Determination of bulk

density of bituminous specimens by gamma rays

EN 12697-27, Bituminous mixtures — Test methods — Part 27: Sampling

EN 12697-33, Bituminous mixtures — Test method — Part 33: Specimen prepared by roller compactor

EN 12697-35, Bituminous mixtures — Test methods — Part 35: Laboratory mixing

ISO 48-2, Rubber, vulcanized or thermoplastic — Determination of hardness — Part 2: Hardness between

10 IRHD and 100 IRHD

ISO 48-5, Rubber, vulcanized or thermoplastic — Determination of hardness — Part 5: Indentation

hardness by IRHD pocket meter method

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/ui

3.1

nominal thickness

for laboratory prepared specimens, the target thickness, in millimetres, to which the specimens are to

be prepared

Note 1 to entry: The target thickness is the required thickness that is targeted when making the specimen.

3.2

rut depth

reduction in the thickness of a test specimen, in millimetres, caused by repeated passes of a loaded

wheel

3.3

test surface

surface of the test specimen on which the loaded wheel runs

3.4

single test result

value obtained by applying this document, once, to a single test portion

3.5

test portion

number of samples that are required to be tested for a single test result

3.6

tyre track

impression of the tyre on a flat surface when a vertical load is applied

3.7

load cycle

two passes (outward and return) of the loaded wheel

3.8

measurement sequence

test phase corresponding to the completion of n load cycles

4 Symbols and abbreviated terms

For the purposes of this document, the symbols and abbreviations given in Table 1 apply.

Table 1 — Symbols and abbreviated terms

Symbol Definition Unit

d local distance between a reference plane and the j predetermined location on mm

ij

the test surface at the i measurement sequence with multiple measurement

points

NOTE j varies between 1 and 15 and is used for Large Size device

d local distance between a reference plane and the j predetermined location on mm

0j

the test surface before the start of the test (i=0)

d

is the vertical displacement after n load cycles mm

n

d is the vertical displacement initially after 0 load cycles mm

h specimen thickness equal to the thickness of the course or courses of the test mm

piece in which a rut can form

L load applied N

n number of cycles —

n

number of load cycles for rut depth to reach 15 mm using small size device, —

procedure A

Symbol Definition Unit

P measured proportional rut depth calculated as the average depth of a rut at the %

i

i measurement cycle for one specimen

P mean value of P obtained on two or more specimens using large size device %

iLD i

P mean value of P obtained on two or more specimens using extra-large size %

iXL i

device

PRD

mean proportional rut depth for the material using a small size device in air %

AIR

PRD mean proportional rut depth for the material using a small size device in water %

W

RD the rut depth of the specimen i using a small size device mm

RD mean rut depth for the material using a small size device in air mm

AIR

RD mean rut depth for the material using a small size device in water mm

W

r mean rut depth at the i-th measurement sequence mm

i

S number of measured cross-sections for extra-large device —

TR mean rate of increase of track depth µm/cycle

TR mean value of the determinations of TR µm/cycle

m

w width of the tyre applying the load mm

WTR wheel-tracking rate calculated as the mean rate at which the rut depth increases µm/cycle

with time under repeated passes of a loaded wheel of a small size device

model A in air

WTS wheel-tracking slope, calculated as the mean rate at which the rut depth mm/1 000

W

increases with repeated passes of a loaded wheel of a small size device model B load cycles

in water

WTS wheel-tracking slope, calculated as the mean rate at which the rut depth µm/1 000

AIR

increases with repeated passes of a loaded wheel of a small size device model B load cycles

in air

5 Principle

The susceptibility of a bituminous material to deform is assessed by measuring the rut depth formed by

repeated passes of a loaded wheel at a fixed temperature.

6 Apparatus

6.1 Large size devices

6.1.1 Device simulating a rolling load which shall include

6.1.1.1 Wheel fitted with a 400 × 8 pneumatic tyre without tread pattern and having a track width

of (80 ± 5) mm. The pneumatic tyre pressure shall be (600 ± 30) kPa.

NOTE The Trelleborg T522 BV Extra or Special 6-ply type pneumatic tyre is suitable for this test.

6.1.1.2 The travel of pneumatic tyre relative to the specimen shall be (410 ± 5) mm.

6.1.1.3 The frequency of travel (outward and return) shall be (1,0 ± 0,1) Hz.

6.1.1.4 The rolling load applied to the test specimen shall be (5 000 ± 50) N at the centre of the test

specimen, measured at least when the device is static.

6.1.1.5 The centre line of the tyre track shall be not more than 5 mm from the theoretical centre of

the test specimen.

6.1.1.6 The angle of skew of the wheel shall be (0,0 ± 0,5)°.

6.1.2 Mould(s)

Mould(s) of internal dimensions (500 × 180 × 50) mm or (500 × 180 × 100) mm, all dimensions ± 2 mm,

capable of withstanding the test conditions without distortion.

6.1.3 Depth gauge

Depth gauge to measure local distance from the reference plane, d , to within ± 0,2 mm and with a

ij

2 2

square, rectangle or circular measurement area of between 5 mm and 10 mm . A contact-free sensor

can be used if it leads to the same result.

6.1.4 Ventilated enclosure

Ventilated enclosure with a set temperature that is regulated by a probe installed within the test

specimen such that the temperature within the specimen is maintained at the set temperature ± 2 °C

(see Figure 1)

6.1.5 Temperature sensors

Temperature sensor(s) suitable for installation within a compacted bituminous test specimen and for

the measurement of air temperature.

6.1.6 Temperature monitoring indicator

Temperature monitoring indicator to record the temperature within the test specimen, as shown in

Figure 1.

6.1.7 Steel supporting plate

Steel supporting plate with a surface unevenness of less than 1 mm when checked with a steel rule

across the diagonals and of a thickness such that the deflection under test conditions of this document

shall not exceed 0,5 mm.

6.1.8 Non-stick chemical

Non-stick chemical, such as glycerized sodium oleate.

6.2 Extra large devices

6.2.1 Device simulating a rolling load which shall include

6.2.1.1 General

Wheel fitted with a 6.00-R9 pneumatic tyre without tread pattern and having a track width of

(110 ± 5) mm.

6.2.1.2 The travel of pneumatic tyre relative to the specimen shall be (700 ± 5) mm.

6.2.1.3 The time of travel (outward and return) shall be (2,5 ± 0,5) s.

6.2.1.4 The rolling load applied to the test specimen shall be (10 000 ± 100) N at the centre of the

test specimen, measured at least when the device is static.

6.2.1.5 The centre line of the tyre track shall be not more than 20 mm from the theoretical centre of

the test specimen.

6.2.1.6 The angle of skew of the wheel shall be (0,0 ± 0,5)°.

6.2.2 Moulds

Mould(s) of internal dimensions (700 × 500) mm, all dimensions ± 5 mm, capable of withstanding the

test conditions without distortion. The height of the mould corresponds to the nominal thickness of the

test specimen at the ends. The height of the side edges correspond to the nominal thickness of the

specimen or exceed it by a maximum of 20 mm.

6.2.3 Depth gauge

Laser sensors to measure local deformation within ± 0,2 mm. Laser sensors shall be capable to measure

rut depth with interval maximum 2 mm at least in 3 cross-sections as indicated in Figure 2.

6.2.4 Ventilated enclosure

Ventilated enclosure with a set temperature that is regulated by a probe installed within the test

specimen such that the temperature within the specimen is maintained at ± 3 °C of the test temperature

(see Figure 2).

6.2.5 Temperature sensors

Temperature sensor(s) suitable for installation within a compacted bituminous test specimen and for

the measurement of air temperature.

6.2.6 Temperature monitoring indicator

Temperature monitoring indicator to record the temperature within the test specimen, as shown in

Figure 2.

6.3 Small size devices for use with rectangular plates

6.3.1 Wheel-tracking apparatus

6.3.1.1 General

Wheel-tracking apparatus consisting of a loaded wheel that bears on a sample held securely on a table.

The table beneath the wheel or the wheel above the table moves backwards and forwards while a

device provided monitors the rate at which a rut develops in the surface of the test specimen. Vertical

play in the loaded wheel mechanism shall be less than 0,25 mm. The apparatus shall include

6.3.1.2 to 6.3.1.7.

6.3.1.2 Tyre of outside diameter between 200 mm and 205 mm fitted to the wheel. The tyre shall be

treadless and have a rectangular cross profile with a width of w where w = (50 ± 5) mm. The tyre

thickness shall be (20 ± 2) mm. The tyre shall be of solid rubber with a hardness number

of (80 ± 5) IRHD units when measured in accordance with ISO 48-5 and ISO 48-2.

NOTE A steel wheel has also been used with the small-size device, but the test will be more severe and the

result will not be comparable with that from a compliant test.

6.3.1.3 Means of applying a load to the wheel: The wheel load under standard test conditions shall

w

be 700× ± 10 N, measured at the level of the top of the test specimen and normal to the plane of

the sample table.

This loading may conveniently be achieved by the use of a weighted cantilever arm.

6.3.1.4 Sample table, constructed so as to enable a rectangular laboratory-prepared test specimen

to be held firmly in place with its upper surface horizontal and in the required tracking plane and with

its centre positioned to ensure symmetrical tracking motion.

6.3.1.5 Wheel-tracking machine, constructed so as to enable the test specimen in its cradle to be

moved backwards and forwards under the loaded wheel in a fixed horizontal plane or the loaded wheel

to be moved backwards and forwards on the fixed specimen. The centre-line of the tyre track shall be

not more than 5 mm from the theoretical centre of the specimen. The centre of the contact area of the

tyre shall describe simple harmonic motion with respect to the centre of the top surface of the test

specimen with a total distance of travel of (230 ± 10) mm and a frequency of (26,5 ± 1,0) load cycles per

60 s for the test device.

NOTE This form of motion is most readily achieved by a reciprocating drive from a flywheel but alternative

drive mechanisms are satisfactory as long as the motion conforms to the above requirements.

6.3.1.6 Carriage and frame of steel with minimum inside dimensions of 260 mm × 300 mm. Vertical

play in the carriage shall be less than 0,25 mm when measured at the four corners of the carriage with

the carriage being subjected to the operating load, and the thickness of its bottom plate shall be not less

than 8 mm.

6.3.1.7 Device to measure the vertical position of the loaded wheel to ± 0,2 mm with a range of not

less than 20,0 mm.

6.3.2 Means for temperature control

Means for temperature control such that the temperature of the test specimen during testing is uniform

and maintained constant at the specified temperature ± 1 °C.

NOTE A constant temperature room enclosing the machine or a water bath are two methods of meeting this

requirement.

6.3.3 Straightedge

Straightedge, at least 300 mm long.

6.3.4 Callipers

Callipers capable of measuring the thickness of a test specimen to an accuracy of ± 1 mm.

6.3.5 Talc or steatite

6.3.6 Moulds

Mould(s) with internal dimensions of at least 260 mm by 300 mm and depth, after placing packing

plates if necessary, of the nominal thickness ± 5 mm. The mould(s) shall be capable of withstanding the

test conditions without distortion.

NOTE The width of the mould can have an influence on the deformation due to shear.

6.3.7 Holding medium

Holding medium, e.g. plaster of Paris or a polyester resin and hardener.

6.4 Small-size devices for use with cores

6.4.1 General

The equipment listed in 6.3.1 to 6.3.4 with the apparatus listed in 6.4.2 to 6.4.7.

6.4.2 Abrasive disc circular saw

Abrasive disc circular saw capable of cutting through 200 mm diameter cores of compacted bituminous

mixtures to provide a nominally ridge-free surface.

6.4.3 Core clamping assembly

Core clamping assembly comprising two steel, glass or other suitable stiff plates, and clamping blocks

for holding the prepared core in place whilst it is bedded in the holding medium.

NOTE The clamping blocks can be of any material strong enough to support the mass of the loaded wheel and

have a central hole capable of accommodating cores with diameters close to 200 mm.

6.4.4 Cleansing solvent

Cleansing solvent, e.g. mixture of 90 % acetone and 10 % kerosene by volume, for cleaning the rubber

tyre after use.

6.4.5 Holding medium

Holding medium, e.g. plaster of Paris or a polyester resin and hardener.

6.4.6 Containers

Containers for mixing the holding medium (disposable paper cups are suitable).

6.4.7 Spirit level

Spirit level, at least 100 mm long.

7 Sampling and sample preparation

7.1 Test portion

For this test, a test portion to represent one material shall consist of a set of test specimens as defined in

Table 2.

Table 2 — Minimum set of specimen

Device Minimum set of test specimen

Large or extra-large size device 2

Small size, Procedure A, testing in air 6

Small size, Procedure B, testing in air 2

Small size, Procedure B, testing in water 2

7.2 Sampling and manufacture

7.2.1 Laboratory prepared samples

7.2.1.1 Manufacture

The component materials shall either be

— laboratory produced bituminous mixtures, mixed in accordance with EN 12697-35 or

— plant produced bituminous mixtures, sampled in accordance with EN 12697-27.

The test specimens shall be compacted in their moulds in accordance with EN 12697-33. The bulk

density shall be measured either by dimensions in accordance with EN 12697-6 or, after extracting the

sample from the mould, by one of the other methods in accordance with EN 12697-6 or EN 12697-7.

The bulk density of the two (or six) specimens used to measure the rut depth or the wheel-tracking rate

of a given mixture shall not deviate by more than ± 1 % of the mean bulk density.

7.2.1.2 Nominal thickness

For large size devices and without specific requirement, the thickness of the specimen shall be:

— 50 mm for mixtures intended to be used in layers less than or equal to 50 mm;

— 100 mm for mixtures intended to be used in layers greater than 50 mm.

For extra-large size devices and without specific requirement, the thickness of the specimen shall be

60 mm.

For large and extra-large size devices and if the thickness is to be specified, it shall be:

— 30 mm; or

— 50 mm; or

— 60 mm; or

— 75 mm; or

— 100 mm.

In the case of mixtures that are designed to be laid at a range of thickness, the thickness of the specimen

should be the point in the design thickness range nearest or about 2,5 times the upper sieve size of the

mix.

For small size devices the nominal thickness of the specimen shall be that at which the mixture will be

laid on the road, or in the case of mixtures that are designed to be laid at a range of thickness, shall be

the point in the design thickness range nearest:

— 25 mm for mixtures with upper sieve size less than 8 mm;

— 40 mm for mixtures with upper sieve size larger or eq

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...