EN 388:2003

(Main)Protective gloves against mechanical risks

Protective gloves against mechanical risks

This European Standard specifies requirements, test methods, marking and information to be supplied, for protective gloves against the mechanical risks of abrasion, blade cut, tear and puncture.

This standard is only applicable in conjunction with EN 420.

The test methods developed in this standard can also be applicable to arm protectors which are protective devices separate from the glove or the clothing.

Schutzhandschuhe gegen mechanische Risiken

Diese Europäische Norm legt Anforderungen, Prüfverfahren, Kennzeichnung und Herstellerinformationen für Schutzhandschuhe gegen die mechanischen Risiken Abrieb, Schnitt, Weiterreißen und Durchstich fest.

Diese Norm ist in Verbindung mit EN 420 anzuwenden.

Die in dieser Norm angegebenen Prüfverfahren können auch auf Armprotektoren angewendet werden, die nicht fest mit dem Handschuh oder der Kleidung verbunden sind.

Gants de protection contre les risques mécaniques

Cette Norme européenne indique les exigences, méthodes d'essai, marquage et information à fournir pour les gants de protection en ce qui concerne les agressions mécaniques par abrasion, coupure par tranchage, déchirure et perforation.

La présente norme doit seulement être utilisée en combinaison avec l'EN 420.

Les méthodes d'essai développées dans la présente norme peuvent s'appliquer aux manchettes qui sont des dispositifs protecteurs séparés du gant ou des vêtements.

Varovalne rokavice za zaščito pred mehanskimi nevarnostmi

General Information

- Status

- Withdrawn

- Publication Date

- 16-Sep-2003

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 162 - Protective clothing including hand and arm protection and lifejackets

- Drafting Committee

- CEN/TC 162/WG 8 - Protective gloves

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 02-Nov-2016

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 09-Nov-2016

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 21420:2020 - Protective gloves - General requirements and test methods (ISO 21420:2020) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN ISO 20344:2011 - Personal protective equipment - Test methods for footwear (ISO 20344:2011) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 972:1998+A1:2010 - Tannery machines - Reciprocating roller machines - Safety requirements - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 388:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Protective gloves against mechanical risks". This standard covers: This European Standard specifies requirements, test methods, marking and information to be supplied, for protective gloves against the mechanical risks of abrasion, blade cut, tear and puncture. This standard is only applicable in conjunction with EN 420. The test methods developed in this standard can also be applicable to arm protectors which are protective devices separate from the glove or the clothing.

This European Standard specifies requirements, test methods, marking and information to be supplied, for protective gloves against the mechanical risks of abrasion, blade cut, tear and puncture. This standard is only applicable in conjunction with EN 420. The test methods developed in this standard can also be applicable to arm protectors which are protective devices separate from the glove or the clothing.

EN 388:2003 is classified under the following ICS (International Classification for Standards) categories: 13.340.40 - Hand and arm protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 388:2003 has the following relationships with other standards: It is inter standard links to EN 388:1994, EN 388:2016, EN ISO 13997:2024, EN ISO 21420:2020, EN ISO 12947-1:1998, EN ISO 20344:2011, EN 374-4:2013, EN 972:1998+A1:2010, EN 421:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 388:2003 is associated with the following European legislation: EU Directives/Regulations: 89/686/EEC, 93/68/EEC, 93/95/EEC, 96/58/EC; Standardization Mandates: M/031. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 388:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Protective gloves against mechanical risksGants de protection contre les risques mécaniquesSchutzhandschuhe gegen mechanische Risiken13.340.40Varovanje dlani in rokHand and arm protectionICS:SIST EN 388:2003enTa slovenski standard je istoveten z:EN 388:200301-december-2003SIST EN 388:2003SLOVENSKI

STANDARDSIST EN 388:19961DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 388September 2003ICS 13.340.40Supersedes EN 388:1994English versionProtective gloves against mechanical risksGants de protection contre les risques mécaniquesSchutzhandschuhe gegen mechanische RisikenThis European Standard was approved by CEN on 2 July 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 388:2003 E

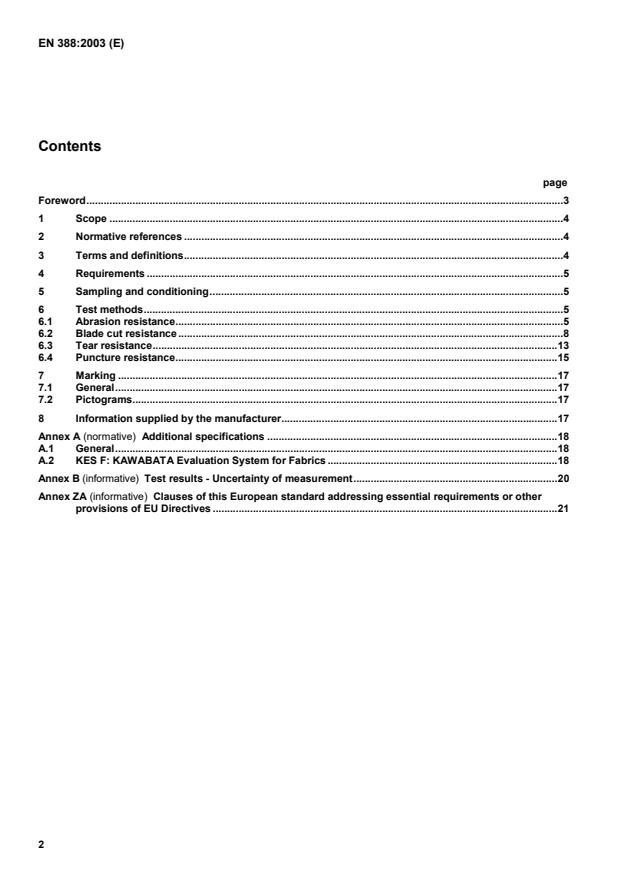

Additional specifications.18A.1General.18A.2KES F: KAWABATA Evaluation System for Fabrics.18Annex B (informative)

Test results - Uncertainty of measurement.20Annex ZA (informative)

Clauses of this European standard addressing essential requirements or otherprovisions of EU Directives.21

Textiles - Determination of the abrasion

resistance of fabrics by the Martindale method -

Part 1:Martindale abrasion testing apparatus

(ISO 12947-1:1998)EN ISO 13997, Protective clothing — Mechanical properties — Determination of resistance to cutting by sharpobjects (ISO 13997:1999).3 Terms and definitionsFor the purposes of this European Standard the following terms and definitions apply:3.1protective glove against mechanical risksglove that provides protection against at least one of the following mechanical risks: abrasion, blade cut andpunctureNOTETear resistance provides information on the mechanical resistance of the glove, but is not indicative of protectionagainst a specific risk. Whilst a high value is normally considered as better, a low value is required in case of possibleentanglement with moving machinery.3.2glove providing a specific protectionglove that is designed to provide an area of improved protection for the whole hand or part of it3.3glove seriessingle glove style or glove type with the same palm material up to the wrist line where the only variants are size,length, left/right hand and colour3.4armpart of the body between the wrist and the shoulder

± 10 %.6.1.3 ApparatusAn abrasion testing machine of the type described in EN ISO 12947-1 as a Martindale Wear and Abrasion machine isrequired. It shall fulfil the following requirement:Pressure on specimen(9 ± 0,2) kPaNOTEMore detailed specifications relative to the apparatus can be found in EN ISO 12947-1. The model number 103 (fourplaces) is appropriate.6.1.4Test specimensFour test specimens shall be taken from four individual gloves of the same glove series.Where the test specimen is made of several unbonded layers, the test is performed on each layer, and theclassification is based on the sum of the number of cycles.6.1.5Test procedureSetting up the machine.A.

General

Mounting test specimensPlace the ring of the specimen holder in position on the mounting plate provided on the base of the testing apparatus.Secure without tension carefully and centrally the test specimen on the metal insert by means of double-sidedadhesive tape under a weight of 10 kg applied during 5 min. Good adhesion can be achieved through the use ofdouble-sided tape which prevents loosening of the test specimen and the inclusion of air bubbles.While ensuring that the ring containing the specimen and metal insert is held firmly in the mounting plate, start toscrew the top of the specimen holder on to the ring, taking care that the screw threads are not crossed. Having startedthe screwing down operation, use both hands to maintain a continuous downward pressure on the assembly againstthe mounting plate.This procedure will normally ensure that the specimen is securely retained in the holder in a wrinkle-free condition andthat it is ready for testing.NOTEAn example of appropriate double-sided adhesive tape is product ref. 465 from 3M. This information is given for theconvenience of users of this standard and does not constitute an endorsement by CEN/TC 162 of the product named. Equivalentproducts may be used if they can be shown to lead to the same results.C.

Mounting abradant1)Secure carefully the abradant 1)

by means of double-sided adhesive tape. Ensure the abradant is flat by placing theweight supplied with the testing machine for this purpose on its surface, and then position and tighten up the retainingframe evenly using diagonally opposite screws in sequence. Make sure that the abradant is held in place firmly andthat there are no tucks or ridges.D.

Mounting specimen holdersMount the test specimen holders on the top plate under a pressure of (9 ± 0,2) kPa and switch on the testing machine.Every time a specimen holder is taken from the machine to check the end point of the specimen for breakthrough,retighten the specimen holder before it is replaced on the machine.If it is necessary to interrupt the test for an appreciable length of time (e. g. overnight or at the weekend) remove thespecimens in their holders and store them face upwards. Protect the specimens by covering them with a clean card orpiece of fabric.E.

Method of assessmentEach test shall be performed with a new abradant. Begin the test and check the test specimens after 100 cycles. Ifthere is no breakthrough continue the test until reaching 500 cycles (performance level 2). If there is no breakthrough,

1) An example of suitable abradant is OAKEY Glass Quality Cabinet Paper Grade F2, Grit 100 – Self-adhesiveabradant is acceptable.This information is given for the convenience of users of this standard and does not constitute an endorsement by CEN/TC 162 ofthe product named. Equivalent products may be used if they can be shown to lead to the same results.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...