CEN/TS 15234:2006

(Main)Solid biofuels - Fuel quality assurance

Solid biofuels - Fuel quality assurance

This Technical Specification defines the procedures to fulfil the quality requirements and describes measures to ensure adequate confidence that the biofuel specification is fulfilled. This Technical Specification covers the whole chain, from supply of raw materials to point of delivery to the end-user.

According to the mandate given for the standardisation work, the scope of the Technical Committee (TC 335) only includes solid biofuels originating from the following sources:

- products from agriculture and forestry;

- vegetable waste from agriculture and forestry;

- vegetable waste from the food processing industry;

- wood waste, with the exception of wood waste which may contain halogenated organic compounds or heavy metal as a result of treatment with wood preservatives or coating, and which includes in particular such wood waste originated from construction and demolition waste;

- fibrous vegetable waste from virgin pulp production and from the production of paper from pulp, if it is co-incinerated at the place of production and heat generated is recovered;

- cork waste.

NOTE 1: The quality assurance systems applied to the operation of conversion plants fuelled by solid biofuels are outside the scope of this Technical Specification.

NOTE 2: Health, safety and environmental issues for solid biofuels are important and need special attention, however are outside the scope of this Technical Specification.

NOTE 3: For the avoidance of doubt, demolition wood is not included in the scope of this Technical Specification. Demolition wood is defined as "used wood arising from demolition of buildings or civil engineering installations" (CEN/TS 14588).

Feste Biobrennstoffe - Qualitätssicherung von Brennstoffen

Diese Technische Spezifikation legt die Verfahren zur Erfüllung der Qualitätsanforderungen fest und be-

schreibt Maßnahmen zur Sicherstellung eines angemessenen Vertrauens auf die Einhaltung der Biobrenn-

stoffspezifikation. Diese Technische Spezifikation umfasst die gesamte Kette, von der Anlieferung der Roh-

stoffe bis zum Lieferort beim Endverbraucher.

Nach dem für die Normungsarbeit zugeteilten Mandat umfasst der Aufgabenbereich des Technischen

Komitees (TC 335) nur feste Biobrennstoffe, die aus folgenden Quellen stammen:

- Produkte aus der Land- und Forstwirtschaft;

- pflanzliche Abfälle aus der Land- und Forstwirtschaft;

- pflanzliche Abfälle aus der Lebensmittel verarbeitenden Industrie;

- Holzabfälle, mit der Ausnahme von Holzabfällen, die im Ergebnis der Behandlung mit Holzschutzmitteln

oder Aufbringung von Beschichtungen halogenierte organische Verbindungen oder Schwermetalle ent-

halten können, und zu denen besonders Holzabfälle gehören, die von Bau- und Abbrucharbeiten

stammen;

- faserige pflanzliche Abfälle aus der Herstellung von natürlichem Zellstoff und aus der Herstellung von Pa-

pier aus Zellstoff, sofern sie am Herstellungsort verbrannt werden und die erzeugte Wärme genutzt wird;

- Korkabfälle.

Biocombustibles solides - Assurance qualité du combustible

Trdna biogoriva – Zagotavljanje kakovosti goriv

General Information

- Status

- Withdrawn

- Publication Date

- 14-Mar-2006

- Withdrawal Date

- 22-Feb-2011

- Technical Committee

- CEN/TC 335 - Solid biofuels

- Drafting Committee

- CEN/TC 335/WG 2 - Fuel specifications, classes and quality assurance

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Feb-2011

- Completion Date

- 23-Feb-2011

Relations

- Effective Date

- 12-Mar-2011

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

CEN/TS 15234:2006 is a technical specification published by the European Committee for Standardization (CEN). Its full title is "Solid biofuels - Fuel quality assurance". This standard covers: This Technical Specification defines the procedures to fulfil the quality requirements and describes measures to ensure adequate confidence that the biofuel specification is fulfilled. This Technical Specification covers the whole chain, from supply of raw materials to point of delivery to the end-user. According to the mandate given for the standardisation work, the scope of the Technical Committee (TC 335) only includes solid biofuels originating from the following sources: - products from agriculture and forestry; - vegetable waste from agriculture and forestry; - vegetable waste from the food processing industry; - wood waste, with the exception of wood waste which may contain halogenated organic compounds or heavy metal as a result of treatment with wood preservatives or coating, and which includes in particular such wood waste originated from construction and demolition waste; - fibrous vegetable waste from virgin pulp production and from the production of paper from pulp, if it is co-incinerated at the place of production and heat generated is recovered; - cork waste. NOTE 1: The quality assurance systems applied to the operation of conversion plants fuelled by solid biofuels are outside the scope of this Technical Specification. NOTE 2: Health, safety and environmental issues for solid biofuels are important and need special attention, however are outside the scope of this Technical Specification. NOTE 3: For the avoidance of doubt, demolition wood is not included in the scope of this Technical Specification. Demolition wood is defined as "used wood arising from demolition of buildings or civil engineering installations" (CEN/TS 14588).

This Technical Specification defines the procedures to fulfil the quality requirements and describes measures to ensure adequate confidence that the biofuel specification is fulfilled. This Technical Specification covers the whole chain, from supply of raw materials to point of delivery to the end-user. According to the mandate given for the standardisation work, the scope of the Technical Committee (TC 335) only includes solid biofuels originating from the following sources: - products from agriculture and forestry; - vegetable waste from agriculture and forestry; - vegetable waste from the food processing industry; - wood waste, with the exception of wood waste which may contain halogenated organic compounds or heavy metal as a result of treatment with wood preservatives or coating, and which includes in particular such wood waste originated from construction and demolition waste; - fibrous vegetable waste from virgin pulp production and from the production of paper from pulp, if it is co-incinerated at the place of production and heat generated is recovered; - cork waste. NOTE 1: The quality assurance systems applied to the operation of conversion plants fuelled by solid biofuels are outside the scope of this Technical Specification. NOTE 2: Health, safety and environmental issues for solid biofuels are important and need special attention, however are outside the scope of this Technical Specification. NOTE 3: For the avoidance of doubt, demolition wood is not included in the scope of this Technical Specification. Demolition wood is defined as "used wood arising from demolition of buildings or civil engineering installations" (CEN/TS 14588).

CEN/TS 15234:2006 is classified under the following ICS (International Classification for Standards) categories: 75.160.10 - Solid fuels; 75.160.40 - Biofuels. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TS 15234:2006 has the following relationships with other standards: It is inter standard links to EN 15234-1:2011, CEN/TR 15569:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TS 15234:2006 is associated with the following European legislation: Standardization Mandates: M/298. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

CEN/TS 15234:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2006

Trdna biogoriva – Zagotavljanje kakovosti goriv

Solid biofuels - Fuel quality assurance

Feste Biobrennstoffe - Qualitätssicherung von Brennstoffen

Biocombustibles solides - Assurance qualité du combustible

Ta slovenski standard je istoveten z: CEN/TS 15234:2006

ICS:

75.160.10 Trda goriva Solid fuels

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL SPECIFICATION

CEN/TS 15234

SPÉCIFICATION TECHNIQUE

TECHNISCHE SPEZIFIKATION

March 2006

ICS 75.160.10

English Version

Solid biofuels - Fuel quality assurance

Biocombustibles solides - Assurance qualité du Feste Biobrennstoffe - Qualitätssicherung von Brennstoffen

combustible

This Technical Specification (CEN/TS) was approved by CEN on 13 September 2005 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to submit their

comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS available

promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in parallel to the CEN/TS)

until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,

Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2006 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 15234:2006: E

worldwide for CEN national Members.

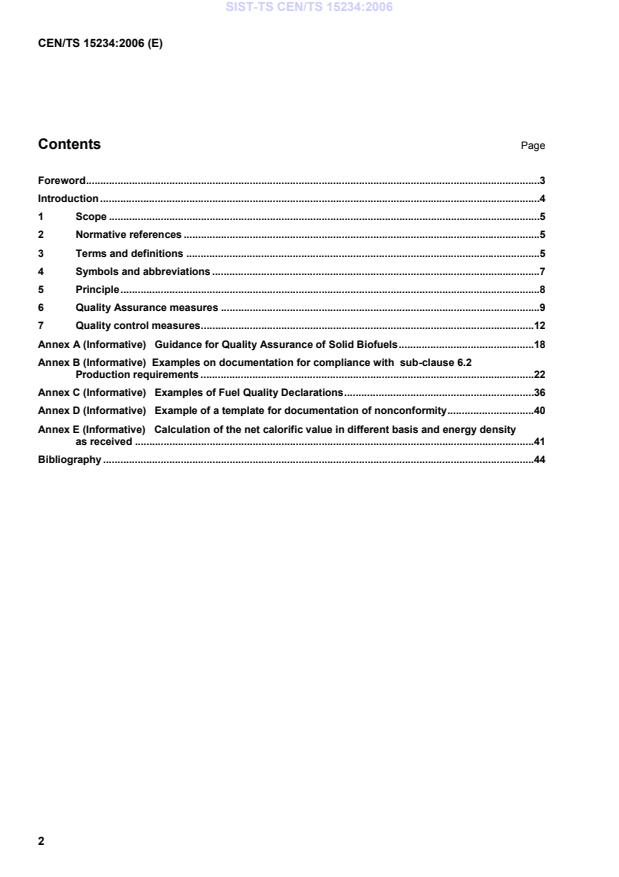

Contents Page

Foreword.3

Introduction .4

1 Scope .5

2 Normative references .5

3 Terms and definitions .5

4 Symbols and abbreviations .7

5 Principle.8

6 Quality Assurance measures .9

7 Quality control measures.12

Annex A (Informative) Guidance for Quality Assurance of Solid Biofuels.18

Annex B (Informative) Examples on documentation for compliance with sub-clause 6.2

Production requirements .22

Annex C (Informative) Examples of Fuel Quality Declarations.36

Annex D (Informative) Example of a template for documentation of nonconformity.40

Annex E (Informative) Calculation of the net calorific value in different basis and energy density

as received .41

Bibliography .44

Foreword

This Technical Specification (CEN/TS 15234:2006) has been prepared by Technical Committee CEN/TC 335

“Solid biofuels”, the secretariat of which is held by SIS.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to announce this Technical Specification: Austria, Belgium, Cyprus, Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden,

Switzerland and United Kingdom.

Introduction

The overall aim of this Technical Specification is to guarantee the solid biofuel quality through the whole

supply chain, from the origin to the delivery of the solid biofuel and provide adequate confidence that specified

quality requirements are fulfilled.

The solid biofuel supply chain usually consists of the main stages described in Figure 1.

End-user

Combustion

Raw

Identification Production/ Trade and Reception of

unit or

material

and collection of preparation of delivery of solid solid biofuel

other

raw material solid biofuels biofuels by end-user

conversion

unit

Supply chain activities covered by this Technical Specification

Figure 1—Solid biofuel supply chain

The objective of this Technical Specification is to serve as a tool to enable the efficient trading of biofuels.

Thereby:

[1] the end-user can find a biofuel that corresponds to his needs;

[2] the producer/supplier can produce a biofuel with defined and consistent properties and describe the

biofuel to the customers.

Quality assurance measures should establish confidence in the biofuel through systems that are simple to

operate and do not cause undue bureaucracy.

Solid biofuels are specified according to CEN/TS 14961—Solid Biofuels, Fuel Specification and Classes. Each

property specification requirement refers to a CEN Standard or a CEN Technical Specification. With a proper

quality assurance procedure and specification of origin and source (i.e. kind of biofuel) in the whole production

chain, it is possible to reduce or eliminate the parameters that need analysing.

[1]

According to the terminology of EN ISO 9001 a Quality Management system generally consist of Quality

Planning, Quality Control, Quality Assurance and Quality Improvement. This Technical Specification covers

Fuel Quality Assurance and Quality Control.

The users of this Technical Specification may integrate the CEN—Solid biofuels, Fuel Quality Assurance

[1, 2, 3]

Technical Specification in their general quality assurance scheme, e.g. the EN ISO 9000 series . If the

company does not have a quality management system, this Technical Specification can be used on it´s own to

help the supplier in documenting fuel quality and creating adequate confidence between the supplier and the

end-user.

In parallel to the preparation of this Technical Specification a Guide for Quality Assurance of Solid Biofuels

[8]

has produced as a CEN Technical Report .

This Technical Specification for Fuel Quality Assurance is only concerned with the fuel part. To ensure the

efficient use of solid biofuels, the relationship between the fuel and the combustion unit is also important to

consider. It is recommended that the end-users ensure that the combustion technology used and the solid

biofuels are compatible to achieve an optimised burning process. In addition to high efficiency, the

environmental impact is reduced when the combustion process is optimised (e.g. unburnt carbon in the ash

will be reduced; the emissions from the flue gases are reduced, etc.).

1 Scope

This Technical Specification defines the procedures to fulfil the quality requirements and describes measures

to ensure adequate confidence that the biofuel specification is fulfilled. This Technical Specification covers the

whole chain, from supply of raw materials to point of delivery to the end-user.

According to the mandate given for the standardisation work, the scope of the Technical Committee (TC 335)

only includes solid biofuels originating from the following sources:

- products from agriculture and forestry;

- vegetable waste from agriculture and forestry;

- vegetable waste from the food processing industry;

- wood waste, with the exception of wood waste which may contain halogenated organic compounds or

heavy metal as a result of treatment with wood preservatives or coating, and which includes in particular

such wood waste originated from construction and demolition waste;

- fibrous vegetable waste from virgin pulp production and from the production of paper from pulp, if it is co-

incinerated at the place of production and heat generated is recovered;

- cork waste.

NOTE 1: The quality assurance systems applied to the operation of conversion plants fuelled by solid biofuels are outside

the scope of this Technical Specification.

NOTE 2: Health, safety and environmental issues for solid biofuels are important and need special attention, however are

outside the scope of this Technical Specification.

NOTE 3: For the avoidance of doubt, demolition wood is not included in the scope of this Technical Specification.

Demolition wood is defined as “used wood arising from demolition of buildings or civil engineering installations” (CEN/TS

14588).

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

CEN/TS 14588:2003 Solid biofuels – Terminology, definitions and descriptions

CEN/TS 14961:2005 Solid biofuels – Fuel Specifications and classes

NOTE: In the CEN/TS 14961 there is a list (Table 3) of the CEN Technical Specifications for sampling,

sample reduction and determination of biofuel properties.

3 Terms and definitions

For the purposes of this Technical Specification, the terms and definitions given in the CEN /TS14588:2003

and the following apply.

3.1

biomass resource owner

body or enterprise with the right to exploit the biomass resources for energy purposes

NOTE: The biomass resource owner can be a land or forest owner, a company etc.

3.2

chemical treatment

any treatment with chemicals other than air or water (e. g. glue and paint)

NOTE: See informative Annex D in the CEN/TS 14961:2005—Solid Biofuels, Fuel Specification and Classes.

3.3

critical control point

point within or between processes at which relevant properties can be most readily assessed and are also the

points that offer the greatest potential for quality improvement

3.4

customer

the next operator in the biofuel supply chain

3.5

delivery agreement

contract for fuel trade, which specifies e.g. origin and source, quality and quantity of the fuel, as well as

delivery terms

3.6

end-user

consumer (private person, enterprise, utility, etc.) using fuel for energy purposes

3.7

fuel quality declaration

document dated and signed by the producer/supplier to the retailer or end-user, specifying origin and source,

traded form and properties of defined lot

3.8

operator

body or enterprise, which is responsible for one or several activities in the solid biofuel supply chain

NOTE 1: The operator can be, for example, a biofuel producer or a subcontractor to the biofuel supplier.

NOTE 2: The first operator is a body or an enterprise which operates at the beginning of the supply chain.

3.9

point of delivery

the delivery location specified in the delivery agreement, at which the proprietary rights of and responsibility

for a fuel lot is transferred from the supplier to the end-user

3.10

producer

operator responsible for the production of the fuel or for any operation with the purpose of changing the biofuel

properties

NOTE: The producer can also be the supplier of the fuel.

3.11

quality

degree to which a set of inherent characteristics fulfils requirements

3.12

quality assurance

part of quality management, focused on providing confidence that the quality requirements will be fulfilled

3.13

quality control

part of quality management, focused on fulfilling the quality requirements

3.14

retailer

supplier of (usually packaged) biofuels in (small) quantities to end-user

NOTE: Retailers are usually suppliers to the private household consumers.

3.15

supplier

operator responsible for supplying solid biofuels

NOTE: One supplier may deliver to the end-user directly and take responsibility for fuel deliveries from several

producers as well as delivery to the end-user.

3.16

supply chain

the overall process of handling and processing raw materials to the point of delivery to the end-user

4 Symbols and abbreviations

The symbols and abbreviations used in this Technical Specification comply with the SI—system of units as far

as possible.

d dry (dry basis)

daf dry, ash-free

ar as received

A Designation for ash content (w-% of dry basis)*

ρ Density [kg/m ]

BD Designation for bulk density [kg/m ]*

DE Designation for particle density as received [kg/dm ]*

D Designation for diameter [mm]*

DU Designation for mechanical durability [w-%]*

E Energy density as received [MWh/m loose, solid or stacked volume (amount of energy/volume unit)]

ar

E Designation for energy density as received [kWh/m or kWh/kg, unit is to be stated in brackets]*

F Designation for amount of fines (< 3,15 mm, w-%)

L Designation for length [mm]*

M Total moisture content as received [w-%] on wet basis

ar

M Designation for moisture content as received [w-%]*

P Designation for particle size or particle size distribution [mm]*

q Gross calorific value at constant volume [MJ/kg]

,V,gr

q Net calorific value at constant pressure [MJ/kg]

p,net

*Designation symbols are used in combination with a number to specify property levels in Tables 4—13 and in

informative Annex A in the CEN/TS 14961:2005—Solid biofuels, Fuel Specifications and Classes. For

designation of chemical properties, chemical symbols like S (sulphur), Cl (chlorine), N (nitrogen) are used and

the value is added directly after the symbol.

5 Principle

This Technical Specification covers the Fuel Quality Assurance of the supply chain and the information to be

used in the quality control of the biofuel. This ensures traceability and gives confidence by demonstrating that

all processes along the supply chain (of solid biofuels) up to the point of the delivery to the end-user are under

control.

Procedures to establish confidence in the biofuel include the following requirements:

— first operator in the biofuel supply chain shall document the origin and source of the biofuel.

Origin and source refers to the kind of biofuel, as listed in Table 1 in the CEN/TS 14961:2005 (7.1);

— biofuel shall be traceable through the entire supply chain (7.1.2);

— biofuel producer shall take quality assurance measures to achieve and secure the fuel quality and the

company´s performance relating to the production and/or supply of the solid biofuels (6.2);

— transportation, handling and storage of the fuel should be performed with care and shall be documented by

the operator (6.3);

— supplier to the end-user or retailer is responsible for the biofuel quality and shall make a Fuel Quality

Declaration (6.4);

— for specifications in the Fuel Quality Declaration, CEN/TS 14961 shall be used. The Fuel Quality

Declaration shall include:

origin and source (7.1);

country where the biomass is harvested or first traded as biofuel (7.1.1);

traded form (7.2);

properties (7.3).

Figure 2 illustrates some of the different types of solid biofuel supply chains and appropriate points for

documenting the origin and source and the points for making the Fuel Quality Declaration. Additional

configurations of supply chains are possible.

BIOMASS SUPPLIER END-USER

ORIGIN/SOURCE

Biofuels in bulk material

Biofuel

Operator or owner

producer

End-user

=supplier

Biomass

Operator

resource

owners

Biofuel Biofuel

End-user

producers supplier

Packaged biofuels

Biomass

Biofuel

Biofuel

Operator

resource End-user

producer/

retailer

owners

supplier

Documentation of

Fuel Quality Fuel Quality

origin and source

Declaration Declaration

CEN – Fuel Quality Assurance for solid biofuels

Figure 2 — Examples of the documentation of origin and source and Fuel Quality Declaration in

different biofuel supply chains

6 Quality Assurance measures

6.1 General

Quality Assurance aims to provide confidence that a stable quality is continually achieved in accordance with

the customer requirements. It means that specified requirements are fulfilled, but it does not necessarily mean

a high quality. Customer requirements include, beside a specified biofuel quality, also the quality of the

performance of the company relating to the biofuel or service (such as timing, logistics and proper

documentation). Fuel Quality Assurance needs to be applied to the entire supply chain (see Figure 1).

The methodology described in Clause 6 "Quality Assurance measures" facilitates the design of a fuel quality

system for producers and suppliers of solid biofuels. Its function is to make sure that:

traceability exists;

requirements that influence the fuel quality is controlled;

end-user can have confidence in the fuel quality.

In sub-clauses: 6.2 Production requirements and 6.3 Transportation, handling and storage, both fuel quality

and company performance aspects, are covered. Sub-clause 6.4 covers the mandatory Fuel Quality

Declaration/labelling from the supplier.

Documentation is an important part of Quality Assurance. In this Technical Specification some documents are

mandatory while other documents are voluntary (see Table 1). For general guidance on “Quality Assurance

measures” see Informative Annex A.

Table 1—Mandatory documents on Quality Assurance measures

Area Mandatory documentation Sub-clause

a)

Traceability of raw material Documenting origin and source 7.1.2

b)

Production requirements Steps in the process chain (Step 1 ) 6.2

Critical Control Points (Step 4)

Criteria and methods to ensure appropriate control at

Critical Control Points (Step 5)

Nonconforming biofuels (Step 6)

Transportation, handling and Description of transportation, handling and storage 6.3

storage after production

Final fuel specification Fuel Quality Declaration/labelling 6.4

a

The producer of the solid biofuel from used wood or by-products and residues from the wood, herb or fruit processing industry

must ensure that the raw material used falls within the scope of the CEN/TS 14961.

b

The steps refer to the steps in the methodology described in sub-clause 6.2.

6.2 Production requirements

The production requirements for solid biofuels vary depending on the complexity of the production process as

well as on the requirements of the biofuel (for example between small-scale users that may require high-grade

biofuels and large-scale users who may take advantage of fuel flexible combustion units). This leads to

different measures and requirements for the Quality Assurance process. The methodology described below

for Quality Assurance of the production shall be used for all processes, but shall be adjusted for the

production requirements of the specific production chain in question.

Methodology for production quality assurance - step-by-step (see also Informative Annex A):

Step 1: Document the steps in the production chain;

Step 2: Define specification(s) for the biofuel(s);

Step 3: Analyse factors influencing fuel quality and company performance;

(This includes transportation, handling and storage see sub-clause 6.3)

Step 4: Identify and document the Critical Control Points for compliance with the fuel specification;

Step 5: Select the appropriate measures that give confidence to customers that the specification(s)

is/are being realised, by:

identifying and documenting criteria and methods to ensure appropriate control of the

Critical Control Points;

monitoring and controlling the production process and making necessary adjustments for

compliance with the quality requirements.

Step 6: Establish and document routines for separate handling of nonconforming materials and biofuels.

If any deviation from the stated specification is noticed in the biofuel, the deviating part shall be

removed from this specific production chain if possible. If the deviating part cannot be taken

away, the producer shall inform the customer immediately and take the necessary corrective

actions. See informative Annex D for an example of a template on nonconformity.

All documents shall be dated and signed by the person assigned and authorised by the producer to do so. It

shall be available, on justified request, to the next customer in the production chain. In informative Annex B

there are some examples to illustrate the fulfilment of document requirements within production chains of

varying complexity.

NOTE: Detailed information like values of parameters in Critical Control Points are for internal use only.

6.3 Transportation, handling and storage

Suitable transportation, handling and storage are very important factors in the final quality of the biofuel. It also

ensures the fuel is kept in a correct environment. Negative influences on these operations should be avoided.

Transportation, handling and storage operations after biofuel production shall be documented by the operator.

This can for example be done in the delivery agreement.

Appropriate methods should be applied in the production, storage and delivery of the solid biofuels and care

should be exercised to avoid impurities and degradation in the fuel lot. Examples of impurities are stones,

pieces of metal, and plastic. Degradation can be caused by moisture absorption. Factors requiring special

attention:

weather and climatic conditions (e.g. risk of rain and snow) during storage and the need for covering;

storage conditions (e.g. ventilation, moisture absorption) and the foreseen duration of storage;

storage construction;

suitability and cleanliness of all equipment;

effects of transportation on the biofuels, e.g. formation of dust;

professional skills of personnel.

6.4 Fuel Quality Declaration and labelling

The Fuel Quality Declaration for the solid biofuel shall be issued by the producer/supplier to the end-user or

retailer. The Fuel Quality Declaration shall be issued for each defined lot. The quantity of the lot shall be

defined in the delivery agreement. The supplier shall date the declaration and keep the records for a minimum

of one year after the delivery. The Fuel Quality Declaration shall state the fuel quality in accordance to the

CEN/TS 14961. Fuel Quality Declarations shall be issued for both solid biofuels handled as bulk material and

for packaged solid biofuels.

The Fuel Quality Declaration shall as a minimum include information on:

supplier (body or enterprise) including contact information;

a reference stating compliance to this Technical Specification;

origin and source (CEN/TS 14961:2005, Table 1);

country where the biomass is harvested or first traded as biofuel

traded form (CEN/TS 14961:2005, Table 2);

normative properties;

chemical treatment if chemically treated biomass is traded;

signature (assigned person), name, date and place.

A template example for a Fuel Quality Declaration (for solid biofuels) is given in informative Annex C1 and

examples of using this template are provided in the informative Annexes C2–C4.

For packaged solid biofuels, quality information shall be labelled on the packaging. Suitable storage conditions

shall also be required on the packaging.

7 Quality control measures

7.1 Specification of origin and source

7.1.1 General

Solid biofuels shall be specified by origin and source in accordance with the CEN/TS 14961:2005 Table 1.

The specification of origin and source shall be presented in the Fuel Quality Declaration described in sub-

clause 6.4. The CEN/TS 14961 allows the possibility to differentiate and specify solid biofuel with the detail

necessary. The supplier and end-user may agree on a more detailed specification of the kind of biofuel. In the

case of blends, origin and source of all fractions shall be stated.

Country/countries where the biomass is harvested or first traded as biofuel (by-products and residues from

wood, herb or fruit processing industry or used wood) shall be stated.

If more detailed information is requested it may be added in the Fuel Quality Declaration.

7.1.2 Traceability

All operators in the supply chain are responsible for the traceability of the origin and source of the material

delivered by them. Documents shall be completed in accordance with CEN/TS 14961:2005, Table 1.

The documents shall be available and provided on justified request throughout the entire supply chain. The

first operator in the supply chain is a body or enterprise, which operates at the beginning of the supply chain.

In the case of solid biofuels produced from by-products and residues from wood, herb or fruit processing

industries, the first operator is the industrial plant.

For used wood the first operator is the first owner who decides to trade or use it as a biofuel. The producer of

solid biofuels from used wood or by-products and residues from wood, herb or fruit processing industries is

responsible for the raw materials falls within the scope of the CEN/TS 14961.

NOTE: When solid biofuels consist of a mixture from a number of first operators, all possible first operators should be

listed as the first operator.

7.2 Specification of traded forms

The traded form of the solid biofuel shall be specified. Table 2 in CEN/TS 14961:2005 shall be used unless

there is no traded form that the biofuel can be identified within. A supplier and end-user can agree upon a

more detailed description of the traded forms.

NOTE: Examples of traded forms are pellets, wood chips, straw bales etc.

7.3 Determination of properties

7.3.1 General

Properties shall be specified according to the requirements in Tables 4 – 13 in the CEN/TS 14961:2005. In

these tables properties are presented as grades. Normative and informative properties in these tables are

summarised in Table 2.

Determination of the properties is dependent on the type of information required and information available.

The supplier is responsible for the properties in the Fuel Quality Declaration.

If the properties being specified are sufficiently known through information about the origin and handling (or

preparation method combined with experience) then physical/chemical analysis may not be needed.

To minimise resources needed, one of the measures in the following order is recommended:

1) using typical values, e.g. laid down in Annex C of the CEN/TS 14961:2005, or obtained by

experience;

2) calculation of properties, e.g. by using typical values and considering documented specific values;

3) carrying out of analysis: a) with simplified methods if available, b) with reference methods.

The responsibility of the supplier to provide correct information in the Fuel Quality Declaration is exactly the

same whether laboratory analysis is performed or not.

If laboratory analysis is needed, sampling as well as physical and chemical analysis shall be performed

according to CEN Technical Specifications for Solid biofuels or methods referable to them.

NOTE 1: Seasonal variation should be taken into account and agreed between the supplier and end-user.

NOTE 2: Properties related to health and safety issues (e.g. smouldering and burning biofuels) are not covered in this

Technical Specification.

NOTE 3: Where any operator in the fuel supply chain suspects serious contamination of land (e.g. coal slag heaps) or if

planting has been used specifically for the sequestration of chemicals, fuel analysis should be carried out to identify

chemical impurities such as halogenated organic compounds or heavy metals.

Table 2—Summary of properties being specified according to Table 4 – 13 in the CEN/TS 14961:2005

Briquettes Pellets Exhausted Wood Hog Log Sawdust Bark Straw Other

olive cake chips fuel wood bales

Normative properties

Particle size (P) or dimensions X X X X X X X X

(D, L)

Shredding X

Moisture (M) X X X X X X X X X X

ar

Ash content (A) X X X X X X X X X X

Particle density (DE), X X

Bale density

Mechanical durability (DU) X

Fines (F), w-% X

Additives X X X

Species of biomass X X

coniferous/

deciduous/

mixture

Chemical treatment Normative only for chemically treated biomass

a a

Sulphur (S) X X

Nitrogen (N) Nitrogen is normative only for chemically treated biomass and exhausted olive cake.

Informative properties

Net calorific value (q ) or If important for its use.

p,net,ar

energy density (E )

ar

If traded on a volume basis the actual volume basis and bulk density should be stated

Bulk density (BD)

(e.g. loose or stacked volume).

Chemical composition (e.g. If important for its use. Properties that are specific to the actual solid biofuel and

content of chlorine, sulphur, considered as containing useful information.

major and minor elements)

a

Sulphur is normative only for chemically treated biomass or if sulphur containing additives have been used in production.

7.3.2 Sampling and sample handling

The sampling procedure is of utmost importance for obtaining a representative sample and by that a reliable

determination of the properties. Samples will be representative when the following methodologies are used:

CEN/TS 14778, Sampling Part 1, Part 2 and CEN/TS 14779.

The transportation, handling, and storage of the sample shall be carried out in such a way that its properties

are unaffected as far as possible.

Lots shall be selected at random for sampling at a frequency that ensures the fulfilment of the quality

requirements. Relevant parties may agree on the sampling frequencies.

The primary sampling point for bulk material is at the point of delivery. If representative sampling is technically

difficult at this point, a point should be chosen where appropriate and representative samples can be taken.

The result of the test should be available, if possible, before the biofuel is used. A back-up sample shall be

kept as a record until the test results are available.

7.3.3 Normative properties

Particle size (P), dimensions (D, L) and shredding

The particle size of the pellets, briquettes, exhausted olive cakes, log woods and straw bales is based on the

diameter and/or length and/or height. The grade shall be chosen from Tables 4—6, 9 and 12 in the CEN/TS

14961:2005.

The diameter of the pellets and briquettes shall be given according to the size of the die used for their

production. The length of pellets shall be determined from a combined sample of 10 specimens taken by

random sampling. For fines see sub-clause 7.3.3.5.

The particle size distribution (P) for wood chips and hog fuel in the delivery lot shall be chosen from Tables

7—8 in the CEN/TS 14961:2005.

The length and thickness of the wood logs is regulated by adjustment of a splitting and chopping machine. If

produced manually then length of wood logs can be regulated by using a tape-measure.

The height, width and length of straw bales will be regulated by adjustment of the baling machine. It is

recommended that the production methods influencing the size of the straw particles are declared. For

instance whether the crop has been thrashed by rotation or oscillation or whether it has been chopped.

For bark, it shall be stated if the bark is shredded or un-shredded.

For other traded forms of solid biofuels specified in Table 13 in the CEN/TS 14961:2005, the particle size is

based on the diameter and/or length. If the dimensions are not suitable to express as diameter and/or length,

other formats may be used, but must then be clearly stated.

The proportion of over-sized particles (for wood chips, hog fuel, sawdust and bark) as well as maximum

dimensions and volume of the largest pieces should be considered in the agreements between the supplier

and the end-user.

Total moisture content as received (M)

The total moisture content as received (M) grade for solid biofuels in the delivery lot shall be chosen from

Tables 4—13 described in the CEN/TS14961:2005.

NOTE 1: The quality of a biofuel should be as homogeneous as possible with special attention to the moisture

variations.

NOTE 2: Suppliers and customers may also agree on a minimum moisture content, which is not specified in the

CEN/TS 14961.

Ash content (A)

The grade for ash content of solid biofuels in the delivery lot shall be chosen from Tables 4—8, 10—13

described in the CEN/TS 14961:2005.

Particle density and bale density

For briquettes the particle density (DE) grade shall be chosen from Table 4 in the CEN/TS 14961:2005.

Bale density shall be stated by categories according to the CEN/TS 14961. Bale density is determined by

measuring weight and volume.

Mechanical durability (DU), fines and additives

For pellets the mechanical durability (DU) grade shall be chosen from Table 5 in the CEN/TS 14961:2005.

If any additive is used, the amount (w-%) and type of additive shall be stated.

The amount of fines (F, w-%) of pellets (< 3.15 mm), at the production site before delivery, shall be declared

by the producer to the retailer or to the end-user. Different requirements, such as the amount of fines on

delivery to the end-user, can be agreed between the supplier and the end-user.

NOTE: Mechanical durability influences the stability and amount of fines in the pellets and briquettes during the

handling and transportation.

Species of log wood and straw bales

For log wood, the type of wood: coniferous, deciduous or mixture shall be stated. Species of straw shall be

stated.

Chemical treatment

If any chemical treatment has been added to the raw material and/or added in the biofuel supply chain this

shall be stated in the Fuel Quality Declaration.

NOTE 1: Chemically treated biofuels that may contain halogenated organic compounds or heavy metals as a result of

treatment with wood preservatives or coating, are not included in the scope of this Technical Specification.

NOTE 2: Chemical treatment before harvesting of biomass does not need to be stated. Where any operator in the fuel

supply chain suspects serious contamination of land (e.g. coal slag heaps) or if planting has been used specifically for the

sequestration of chemicals, fuel analysis should be carried out to identify chemical impurities such as halogenated organic

compounds or heavy metals.

Sulphur (S)

If chemically treated biomass and/or sulphur containing additives are used for pellets and briquettes, the

sulphur content (S) shall be stated according to Tables 4—5 in the CEN/TS 14961:2005.

Nitrogen (N)

When chemically treated biomass and/or olive exhausted cake is traded, nitrogen (N) shall be stated by using

the Tables 4—13 in the CEN/TS 14961:2005.

7.3.4 Informative properties

Net calorific value as received (q ), energy density as received (E ) and volume

p,net,ar ar

The net calorific value as received, q (net calorific value of the moist biofuel) is calculated according to

p,net,ar

the informative Annex E based on the net calorific value of the dry matter (q ) or the net calorific value of the

p,net

dry and ash free matter (q ), ash and moisture content.

p,net,daf

The net calorific value of the dry matter (q ) or the net calorific value of the dry and ash free matter

p,net,d

(q ) can either be determined in the laboratory or estimated by using the typical values of the biofuels

p,net,daf

reported in Annex C of the CEN/TS 14961:2005.

The energy density as received (E ) in the delivery lot is calculated using the net calorific value as received

ar

and the bulk density.

The amount of energy the solid biofuel lot has, usually determined by measuring the mass per lot and by

determination of moisture content and if needed, the net calorific value. These properties are usually obtained

by analyses in laboratories.

The amount of energy contained in the amount of biofuel delivered over a month or during another agreed

period of time is calculated with the aid of the above calculated and measured results. For small lots and in

incidental use the method given above may be too laborious to apply. In these cases, the amount of energy

contained in the fuel delivery lot can be determined on the basis of bulk volume and jointly agreed energy

3 3

density per volume (MWh/m loose). Bulk volume (m ) can be determined according to the size of the delivery

vehicle. Energy density per volume (MWh/m loose) can be calculated by the bulk density and by the typical

net calorific values of solid biofuels (see CEN/TS 14961:2005, informative Annex C) and the moisture content.

Bulk density (BD) and volume basis

Bulk density as received (BD) is obtained by dividing the weighed mass of the load by its volume. Weighing

and volume measurement is carried out in a manner agreed upon by supplier and end-user. Bulk density

should be specified when traded on a volume basis.

3 3

It is recommended, when trading log wood that the volumetric measurement is specified (m solid, m stacked

or m loose). The proportion of the logs that are split should be stated and the cut-off surfaces of the logs

(even and smooth or uneven), and also if mould and decay exists, should be specified according to Table 9 of

the CEN/TS 14961:2005.

Chemical composition

Chlorine (Cl) should be stated by using Tables 4—5, 7—11 and 13 in the CEN/TS 14961:2005.

When solid biofuels other than those listed in Tables 4—12 of CEN/TS 14961:2005 are traded, sulphur (S)

content should be stated using Table 13 in the CEN/TS 14961:2005.

Other properties e.g. major and minor elements that are specific to the actual solid biofuel and considered as

containing useful information can also be specified.

NOTE: Where any operator in the fuel supply chain suspects serious contamination of land (e.g. coal slag heaps) or if

planting has been used specifically for the sequestration of chemicals, fuel analysis should be carried out to identify

chemical impurities such as halogenated organic compounds and heavy metals.

Additional information

Special attention should be paid to the ash melting behaviour for some biomass fuels, for example eucalyptus,

poplar, short rotation coppice, straw, miscanthus and olive stone. The end-user and the fuel supplier of the

biofuels should agree if laboratory analysis is needed. Laboratory analysis should be carried out in

accordance with standardised methods.

Appropriate methods should be applied in the production, storage and delivery of the solid biofuels and

sufficient care should be exercised to avoid impurities and degradation in the delivery lot.

If the wood burning appliance requires particularly high quality briquettes, pellets, wood chips or log wood, the

quality grades can be chosen from informative Annex A in the CEN/TS 14961:2005.

7.3.5 Accuracy in determination of properties

In each CEN—Technical specification for determination of properties of solid biofuels, the precision

(repeatability and reproducibility) is estimated (when available).

To avoid bias and to secure laboratory proficiency, including reproducibility, repeatability, and precision etc.,

[4, 5, 6 and 7]

the use of reference samples and comparison with other laboratories is recommended .

Annex A

(Informative)

Guidance for Quality Assurance of Solid Biofuels

A1. General

This informative annex gives practical guidance for compliance with Clause 6 Quality Assurance measures

and the methodology described in 6.2. The purpose of the guidance is to help operators within the supply

chain of solid biofuels design an appropriate quality assurance system (for a complete biofuel supply chain or

a specific part of the chain).

Quality in terms of Quality Assurance does not necessarily mean a high quality but a steady and continually

achieved quality in accordance with the customer´s requirements. The customer is the next operator in the

supply chain. Customer requirements include, not only the fuel quality, but also the quality of the company’s

performance, such as documentation (Fuel Quality Declaration, labelling of packaging, system for traceability,

etc.), timing and logistics (to provide biofuels in time and to agreed performances criteria).

In the guidance there are six consecutive steps. Each step is described in sub-clause 6.2, (see Figure A1

below). For examples of documentation, see informative Annex B.

1 2 3 4 5 6

Document Define Analyse Identity and Select Establish and

the steps in specifications factors document approriate document

the supply for the fuels influencing Critical measures that routines for

chain fuel quality Control give confidence separate

and Points for to customers handling of non-

company compliance that the conforming

performance with fuel specifications materials and

specification are being biofuels

realised

Figure A1—Methodology for quality assurance

A.2 General methodology for the development and implementation of quality

assurance

Step 1: Document the steps in the process chain

A flow diagram is recommended to illustrate the process-chain under consideration

It should not be more detailed than necessary. For examples of flow diagrams see informative Annex

B. The flow diagram should be carefully assessed with the purpose to emphasising the quality

assurance aspects.

To support the structure and information provided in the process chain an allocation of responsibilities

may be helpful. This is likely to be a useful starting point when assessing a process in the light of

Quality Assurance.

Many quality parameters have nothing to do with the physical and chemical properties altered during

the processing of the bi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...