EN 12535:2000

(Main)Welding consumables - Tubular cored electrodes for gas shielded metal arc welding of high strength steels - Classification

Welding consumables - Tubular cored electrodes for gas shielded metal arc welding of high strength steels - Classification

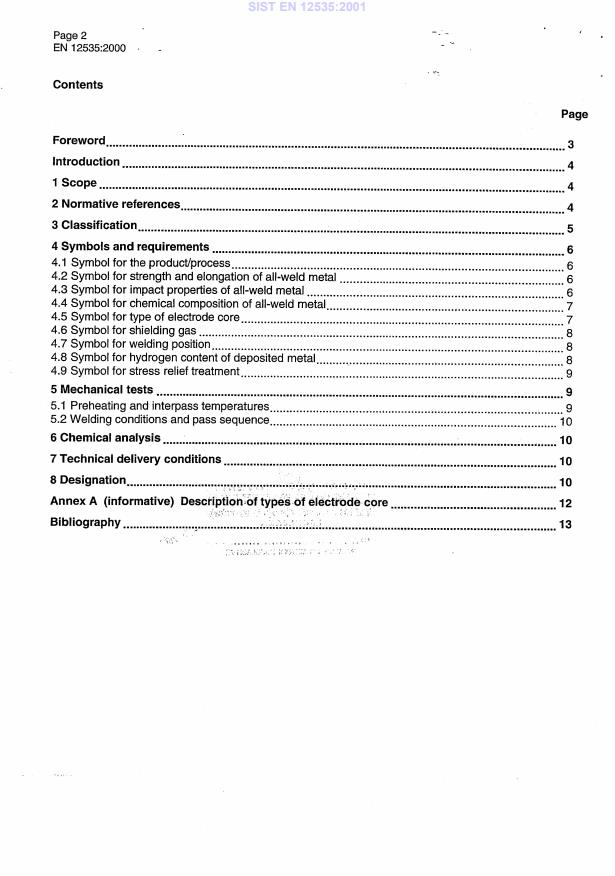

This standard specifies requirements for classification of tubular cored electrodes in the as-welded or stress relieved condition for gas shielded metal arc welding of high strength steels with a minimum specified yield strength higher than 500 N/mm2. One tubular cored electrode may be tested and classified with different gases. It is recognised that the operating characteristics of tubular cored electrodes can be modified by the use of pulsed current, but for the purposes of this standard, pulsed current is not used for determining the electrode classification.

Schweißzusätze - Fülldrahtelektroden zum Metall-Schutzgasschweißen von hochfesten Stählen - Einteilung

Diese Norm legt Anforderungen für die Einteilung von Fülldrahtelektroden basierend auf dem Schweißgut im Schweißzustand für das Metall-Schutzgassch- weißen von hochfesten Stählen mit einer Mindeststreckgrenze über 500 N/mm2 fest. Eine Fülldrahtelektrode kann mit verschiedenen Gasen geprüft und eingeteilt werden. Es ist bekannt, dass die Schweißeigenschaften von Füll- drahtelektroden durch Impulsstrom verändert werden können. In dieser Norm wird aber der Impulsstrom nicht zur Bestimmung der Elektrodeneinteilung benutzt.

Produits consommables pour le soudage - Fils fourrés pour le soudage à l'arc sous protection gazeuse des aciers à haute résistance - Classification

La présente norme spécifie les exigences pour la classification des fils fourrés et du métal déposé à l'état brut de soudage ou à l'état détensionné, pour le soudage à l'arc sous protection gazeuse des aciers à haute résistance ayant une limite d'élasticité minimale spécifiée supérieure à 500 N/mm2. Un fil fourré peut être soumis à l'essai et classifié avec différents gaz. Il est bien connu que les caractéristiques d'emploi des fils fourrés peuvent être modifiées lorsque l'on soude en courant pulsé, mais pour les besoins de la présente norme, le courant pulsé n'est pas utilisé pour la classification des fils fourrés.

Dodajni in pomožni materiali za varjenje - Polnjene žice za obločno varjenje visoko trdnih jekel v zaščitnem plinu - Razvrščanje

General Information

- Status

- Withdrawn

- Publication Date

- 15-Feb-2000

- Withdrawal Date

- 20-Jun-2006

- Technical Committee

- CEN/TC 121 - Welding

- Drafting Committee

- CEN/TC 121/WG 3 - Welding consumables

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-Jun-2006

- Completion Date

- 21-Jun-2006

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 12535:2000 is a standard published by the European Committee for Standardization (CEN). Its full title is "Welding consumables - Tubular cored electrodes for gas shielded metal arc welding of high strength steels - Classification". This standard covers: This standard specifies requirements for classification of tubular cored electrodes in the as-welded or stress relieved condition for gas shielded metal arc welding of high strength steels with a minimum specified yield strength higher than 500 N/mm2. One tubular cored electrode may be tested and classified with different gases. It is recognised that the operating characteristics of tubular cored electrodes can be modified by the use of pulsed current, but for the purposes of this standard, pulsed current is not used for determining the electrode classification.

This standard specifies requirements for classification of tubular cored electrodes in the as-welded or stress relieved condition for gas shielded metal arc welding of high strength steels with a minimum specified yield strength higher than 500 N/mm2. One tubular cored electrode may be tested and classified with different gases. It is recognised that the operating characteristics of tubular cored electrodes can be modified by the use of pulsed current, but for the purposes of this standard, pulsed current is not used for determining the electrode classification.

EN 12535:2000 is classified under the following ICS (International Classification for Standards) categories: 25.160.20 - Welding consumables. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12535:2000 has the following relationships with other standards: It is inter standard links to EN ISO 18276:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12535:2000 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12535:2000 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Schweißzusätze - Fülldrahtelektroden zum Metall-Schutzgasschweißen von hochfesten Stählen - EinteilungProduits consommables pour le soudage - Fils fourrés pour le soudage a l'arc sous protection gazeuse des aciers a haute résistance - ClassificationWelding consumables - Tubular cored electrodes for gas shielded metal arc welding of high strength steels - Classification25.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...