prEN 438-7

(Main)High-pressure decorative laminates (HPL) - Sheets based on thermosetting resins (Usually called Laminates) - Part 7: Compact laminate and HPL composite panels for internal and external wall and ceiling finishes

High-pressure decorative laminates (HPL) - Sheets based on thermosetting resins (Usually called Laminates) - Part 7: Compact laminate and HPL composite panels for internal and external wall and ceiling finishes

This document specifies characteristics for compact laminate panels and HPL composite panels both for non-structural uses in interior or external wall and ceiling finish applications (including in suspended ceiling).

This document deals with compact laminate panels of thickness 2 mm and greater.

The compact laminate panels are produced by using a high pressure process and the HPL composite panels are produced bonding an HPL sheet to a substrate.

This document covers compact laminate panels with the following types of laminates:

- compact laminates, as defined in EN 438 4:2016;

- exterior-grade compact laminates, as defined in EN 438 6:2016;

- pearlescent compact laminates, metal compact laminates and wood veneer compact laminates, as defined in EN 438 8:2018;

- coloured core layer compact laminates and metal reinforced core layer compact laminates, as defined in EN 438 9:2017.

This document covers full size and cut-to-size compact laminate panels and HPL composite panels, e.g. tiles and sidings.

This document specifies only compact laminate panels and HPL composite panels mechanically fixed using e. g. screws or rivets.

Both the compact laminate panels and HPL composite panels may contain flame retardant to improve their reaction to fire performance.

This document also specifies provisions for the assessment and verification of constancy of performance (AVCP) of the characteristics and includes provisions for marking these panels.

This document does not cover:

a) HPL sheets less than 2 mm thick as defined in EN 438-3:2016, EN 438-8:2018 or EN 438-9:2017, which are not glued on a substrate;

b) overlaid or veneered wood-based panels, where the overlay/veneer is not an HPL;

c) HPL composite panels intended for use as floor coverings;

d) panels used for fire protection of walls or ceilings;

e) performances of installed systems for walls and ceilings with compact or composite high pressure laminate panels.

Dekorative Hochdruck-Schichtpressstoffplatten (HPL) - Platten auf Basis härtbarer Harze (Schichtpressstoffe) - Teil 7: Kompaktplatten und HPL-Mehrschicht-Verbundplatten für Wand- und Deckenbekleidungen für Innen- und Außenanwendung

Dieses Dokument legt die Eigenschaften der Kompaktplatten und HPL Mehrschicht Verbundplatten für nicht tragende Anwendungen für innere und äußere Wand und Deckenbekleidungen fest (einschließlich in Unterdecken).

Dieses Dokument behandelt Kompaktplatten mit einer Dicke von 2 mm und größer.

Die Kompaktplatten werden mithilfe eines Hochdruckverfahren und die HPL Mehrschicht Verbundplatten durch die Verbindung einer HPL Platte mit einem Trägermaterial produziert.

Dieses Dokument behandelt Kompaktplatten mit den folgenden Arten der Schichtpressstoffe:

- Kompakt Schichtpressstoffe nach Definition in EN 438-4:2016;

- Kompaktplatten für die Außenanwendung nach Definition in EN 438-6:2016;

- perlmuttartige Kompakt Schichtpressstoffe, metallische Kompakt Schichtpressstoffe und furnierte Kompakt Schichtpressstoffe nach Definition in EN 438-8:2018;

- Kompakt Schichtpressstoffe mit farbiger Kernschicht und Kompakt Schichtpressstoffe mit metall-verstärkter Kernschicht nach Definition in EN 438-9:2017.

Dieses Dokument behandelt ganze und zugeschnittene Kompaktplatten und HPL Mehrschicht Verbund-platten, z. B. Fliesen und Paneele.

Dieses Dokument legt ausschließlich mechanisch befestigte Kompaktplatten und HPL Mehrschicht Verbund¬platten fest, z. B. mit Schrauben oder Nieten.

Sowohl die Kompaktplatten als auch HPL Mehrschicht Verbundplatten können zur Verbesserung ihres Brandverhaltens flammenhemmende Mittel enthalten.

Dieses Dokument legt darüber hinaus Vorschriften für die Bewertung und Überprüfung der Leistungs-beständigkeit (AVCP) dieser Eigenschaften fest und beinhaltet Vorschriften für die Kennzeichnung der Platten.

Dieses Dokument behandelt nicht:

a) HPL Platten mit einer Dicke kleiner als 2 mm nach Definition in EN 438-3:2016, EN 438-8:2018 oder EN 438-9:2017, welche nicht auf ein Trägermaterial geklebt sind;

b) mit Deckschicht oder Furnier versehene Platten auf Holzbasis, bei denen die Deckschicht/das Furnier kein HPL ist;

c) für die Verwendung als Bodenbeläge vorgesehene HPL Mehrschicht Verbundplatten;

d) Platten für den Brandschutz von Wänden oder Decken;

e) Leistung installierter Systeme für Wände und Decken mit Kompakt oder Verbund Hochdruck Schicht-pressstoffplatten.

Stratifiés décoratifs haute pression (HPL) - Plaques à base de résines thermodurcissables (communément appelées stratifiés) - Partie 7 : Panneaux stratifiés compacts et composites HPL pour finitions des murs et plafonds intérieurs et/ou extérieurs

Le présent document spécifie les caractéristiques des panneaux stratifiés compacts et des panneaux composites HPL, pour une utilisation non structurelle pour des applications de finitions intérieures et extérieures de murs et de plafonds (y compris dans des plafonds suspendus).

Le présent document traite de panneaux stratifiés compacts d’épaisseur supérieure ou égale à 2 mm.

Les panneaux stratifiés compacts sont produits par un procédé haute pression et les panneaux composites HPL sont produits en collant une plaque HPL sur un support.

Le présent document couvre les panneaux stratifiés compacts avec les types de stratifiés suivants :

— les stratifiés compacts, tels que définis dans l’EN 438 4:2016 ;

— les stratifiés compacts pour usage en extérieur, tels que définis dans l’EN 438 6:2016 ;

— les stratifiés perlescents compacts, les stratifiés métalliques compacts et les placages bois stratifiés compacts, tels que définis dans l’EN 438 8:2018 ;

— les stratifiés avec couche d’âme colorée compacts et les stratifiés avec couche d’âme à renfort métallique compacts, tels que définis dans l’EN 438 9:2017.

Le présent document couvre les panneaux stratifiés compacts et les panneaux composites HPL entiers et découpés, par exemple dalles et revêtements.

Le présent document spécifie uniquement les panneaux stratifiés compacts et les panneaux composites HPL fixés mécaniquement, par exemple au moyen de vis ou de rivets.

Les panneaux stratifiés compacts tout comme les panneaux composites HPL peuvent contenir un ignifugeant pour améliorer leur performance de réaction au feu.

Le présent document spécifie également les dispositions relatives à l’évaluation et à la vérification de la constance des performances (EVCP) des caractéristiques, et il inclut des dispositions pour le marquage de ces panneaux.

Le présent document ne vise pas :

a) les plaques HPL d’épaisseur inférieure à 2 mm, telles que définies dans l’EN 438 3:2016, EN 438 8:2018 ou l’EN 438 9:2017, qui ne sont pas collées sur un support ;

b) les panneaux à base de bois revêtus ou plaqués lorsque le revêtement/placage n’est pas du HPL ;

c) les panneaux composites HPL destinés à être utilisés comme revêtement de sol ;

d) les panneaux utilisés pour la protection contre l’incendie des murs ou des plafonds ;

e) les performances des systèmes installés pour murs et plafonds avec panneaux stratifiés haute pression compacts ou composites.

Dekorativni visokotlačni laminati (HPL) - Plošče na osnovi duromernih smol - 7. del: Kompaktni laminati in kompozitni paneli HPL za notranjo in zunanjo oblogo zidov in stropov

General Information

- Status

- Not Published

- Publication Date

- 14-Oct-2021

- Withdrawal Date

- 14-Oct-2021

- Technical Committee

- CEN/TC 249 - Plastics

- Current Stage

- 4598 - Decision to abandon - Finalization for Vote

- Completion Date

- 25-Sep-2020

Overview

prEN 438-7 is a CEN draft standard that specifies requirements for compact laminate panels and HPL composite panels used as non‑structural internal and external wall and ceiling finishes (including suspended ceilings). It covers panels produced by a high‑pressure process (compact laminates, thickness ≥ 2 mm) and HPL sheets bonded to substrates (HPL composite panels). The standard applies to full‑size and cut‑to‑size items (tiles, sidings) that are mechanically fixed (e.g., screws, rivets) and may include flame retardants to improve reaction‑to‑fire performance.

Key topics and technical requirements

prEN 438-7 sets out the product characteristics, test methods and conformity assessment relevant to HPL finishes. Major technical topics include:

- Reaction to fire and related mounting/field‑of‑application provisions

- Water vapour permeability for internal/external applications

- Resistance to fixings for mechanically fastened panels

- Bonding strength for HPL composite panels

- Airborne sound insulation and flexural/tensile strength

- Thermal resistance and thermal shock resistance

- Durability under internal and external exposure conditions

- Emissions and content controls: formaldehyde, pentachlorophenol (PCP), VOC releases

- Testing, sampling and assessment procedures for each characteristic

- Assessment and Verification of Constancy of Performance (AVCP), including type testing and factory production control (FPC)

- Marking and labelling requirements

The standard explicitly covers the following laminate types as defined in related EN parts: compact laminates (EN 438-4), exterior‑grade compact (EN 438-6), pearlescent/metal/wood veneer compact (EN 438-8) and coloured/metal‑reinforced core compact (EN 438-9).

It does not cover HPL sheets < 2 mm not glued to a substrate, non‑HPL veneered wood panels, floor coverings, panels intended for active fire protection, or performance of complete installed wall/ceiling systems.

Applications and users

prEN 438-7 is directly applicable to:

- Manufacturers of HPL compact panels and HPL composite wall/ceiling panels

- Product designers and R&D teams specifying laminate constructions and substrates

- Architects, façade engineers and specifiers selecting finishes for internal/external walls and ceilings

- Test laboratories performing conformity and reaction‑to‑fire testing

- Building product certification bodies and regulatory authorities implementing AVCP and CPR (Regulation EU No. 305/2011)

Typical applications include ventilated façades, interior cladding, decorative ceilings and exterior sidings where durable, decorative, mechanically fixed HPL panels are required.

Related standards

- EN 438 series (Parts 2, 3, 4, 6, 8, 9) - HPL test methods and classifications

- EN ISO 13894-1 / -2 - HPL composite element test methods/specifications

- EN 13986 - Wood‑based panels for construction (relation to composite substrates)

- References to CPR (Regulation EU No. 305/2011) for construction product regulatory alignment

Keywords: prEN 438-7, HPL, compact laminate, HPL composite panels, wall and ceiling finishes, reaction to fire, AVCP, CEN.

Frequently Asked Questions

prEN 438-7 is a draft published by the European Committee for Standardization (CEN). Its full title is "High-pressure decorative laminates (HPL) - Sheets based on thermosetting resins (Usually called Laminates) - Part 7: Compact laminate and HPL composite panels for internal and external wall and ceiling finishes". This standard covers: This document specifies characteristics for compact laminate panels and HPL composite panels both for non-structural uses in interior or external wall and ceiling finish applications (including in suspended ceiling). This document deals with compact laminate panels of thickness 2 mm and greater. The compact laminate panels are produced by using a high pressure process and the HPL composite panels are produced bonding an HPL sheet to a substrate. This document covers compact laminate panels with the following types of laminates: - compact laminates, as defined in EN 438 4:2016; - exterior-grade compact laminates, as defined in EN 438 6:2016; - pearlescent compact laminates, metal compact laminates and wood veneer compact laminates, as defined in EN 438 8:2018; - coloured core layer compact laminates and metal reinforced core layer compact laminates, as defined in EN 438 9:2017. This document covers full size and cut-to-size compact laminate panels and HPL composite panels, e.g. tiles and sidings. This document specifies only compact laminate panels and HPL composite panels mechanically fixed using e. g. screws or rivets. Both the compact laminate panels and HPL composite panels may contain flame retardant to improve their reaction to fire performance. This document also specifies provisions for the assessment and verification of constancy of performance (AVCP) of the characteristics and includes provisions for marking these panels. This document does not cover: a) HPL sheets less than 2 mm thick as defined in EN 438-3:2016, EN 438-8:2018 or EN 438-9:2017, which are not glued on a substrate; b) overlaid or veneered wood-based panels, where the overlay/veneer is not an HPL; c) HPL composite panels intended for use as floor coverings; d) panels used for fire protection of walls or ceilings; e) performances of installed systems for walls and ceilings with compact or composite high pressure laminate panels.

This document specifies characteristics for compact laminate panels and HPL composite panels both for non-structural uses in interior or external wall and ceiling finish applications (including in suspended ceiling). This document deals with compact laminate panels of thickness 2 mm and greater. The compact laminate panels are produced by using a high pressure process and the HPL composite panels are produced bonding an HPL sheet to a substrate. This document covers compact laminate panels with the following types of laminates: - compact laminates, as defined in EN 438 4:2016; - exterior-grade compact laminates, as defined in EN 438 6:2016; - pearlescent compact laminates, metal compact laminates and wood veneer compact laminates, as defined in EN 438 8:2018; - coloured core layer compact laminates and metal reinforced core layer compact laminates, as defined in EN 438 9:2017. This document covers full size and cut-to-size compact laminate panels and HPL composite panels, e.g. tiles and sidings. This document specifies only compact laminate panels and HPL composite panels mechanically fixed using e. g. screws or rivets. Both the compact laminate panels and HPL composite panels may contain flame retardant to improve their reaction to fire performance. This document also specifies provisions for the assessment and verification of constancy of performance (AVCP) of the characteristics and includes provisions for marking these panels. This document does not cover: a) HPL sheets less than 2 mm thick as defined in EN 438-3:2016, EN 438-8:2018 or EN 438-9:2017, which are not glued on a substrate; b) overlaid or veneered wood-based panels, where the overlay/veneer is not an HPL; c) HPL composite panels intended for use as floor coverings; d) panels used for fire protection of walls or ceilings; e) performances of installed systems for walls and ceilings with compact or composite high pressure laminate panels.

prEN 438-7 is classified under the following ICS (International Classification for Standards) categories: 83.140.20 - Laminated sheets. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 438-7 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/113, M/113_AM1, M/121, M/121_AM1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 438-7 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2019

Dekorativni visokotlačni laminati (HPL) - Plošče na osnovi duromernih smol - 7.

del: Kompaktni laminati in kompozitni paneli HPL za notranjo in zunanjo oblogo

zidov in stropov

High-pressure decorative laminates (HPL) - Sheets based on thermosetting resins

(Usually called Laminates) - Part 7: Compact laminate and HPL composite panels for

internal and external wall and ceiling finishes

Dekorative Hochdruck-Schichtpressstoffplatten (HPL) - Platten auf Basis härtbarer Harze

(Schichtpressstoffe) - Teil 7: Kompaktplatten und HPL-Mehrschicht-Verbundplatten für

Wand- und Deckenbekleidungen für Innen- und Außenanwendung

Stratifiés décoratifs haute pression (HPL) - Plaques à base de résines

thermodurcissables (communément appelées stratifiés) - Partie 7 : Panneaux stratifiés

compacts et composites HPL pour finitions des murs et plafonds intérieurs et/ou

extérieurs

Ta slovenski standard je istoveten z: prEN 438-7

ICS:

83.140.20 Laminatne plošče Laminated sheets

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

August 2019

ICS 83.140.20 Will supersede EN 438-7:2005

English Version

High-pressure decorative laminates (HPL) - Sheets based

on thermosetting resins (Usually called Laminates) - Part

7: Compact laminate and HPL composite panels for

internal and external wall and ceiling finishes

Stratifiés décoratifs haute pression (HPL) - Plaques à Dekorative Hochdruck-Schichtpressstoffplatten (HPL)

base de résines thermodurcissables (communément - Platten auf Basis härtbarer Harze (Schichtpressstoffe)

appelées stratifiés) - Partie 7 : Panneaux stratifiés - Teil 7: Kompaktplatten und HPL-Mehrschicht-

compacts et composites HPL pour finitions des murs et Verbundplatten für Wand- und Deckenbekleidungen

plafonds intérieurs et/ou extérieurs für Innen- und Außenanwendung

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 249.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 438-7:2019 E

worldwide for CEN national Members.

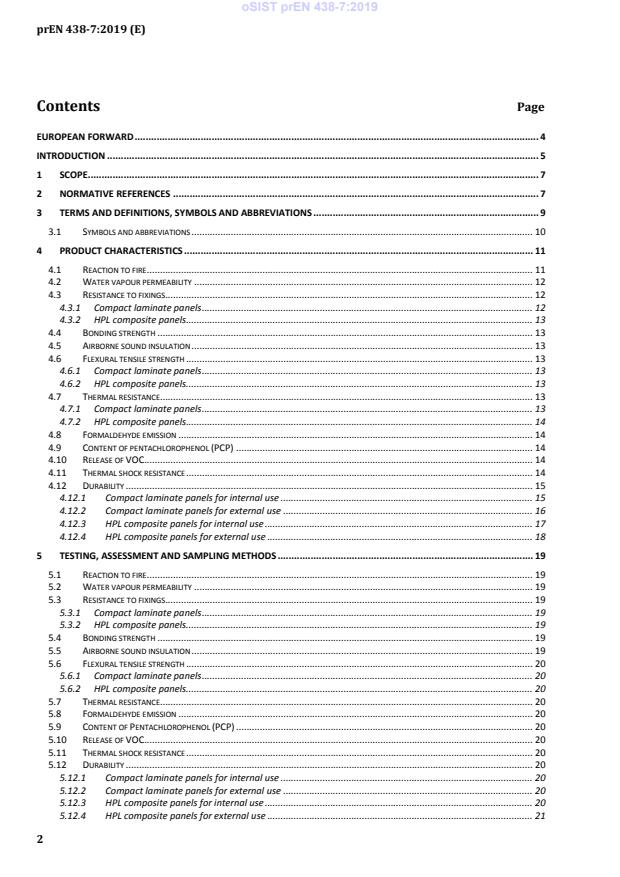

Contents Page

EUROPEAN FORWARD . 4

INTRODUCTION . 5

1 SCOPE . 7

2 NORMATIVE REFERENCES . 7

3 TERMS AND DEFINITIONS, SYMBOLS AND ABBREVIATIONS . 9

3.1 SYMBOLS AND ABBREVIATIONS . 10

4 PRODUCT CHARACTERISTICS . 11

4.1 REACTION TO FIRE . 11

4.2 WATER VAPOUR PERMEABILITY . 12

4.3 RESISTANCE TO FIXINGS . 12

4.3.1 Compact laminate panels . 12

4.3.2 HPL composite panels . 13

4.4 BONDING STRENGTH . 13

4.5 AIRBORNE SOUND INSULATION . 13

4.6 FLEXURAL TENSILE STRENGTH . 13

4.6.1 Compact laminate panels . 13

4.6.2 HPL composite panels . 13

4.7 THERMAL RESISTANCE. 13

4.7.1 Compact laminate panels . 13

4.7.2 HPL composite panels . 14

4.8 FORMALDEHYDE EMISSION . 14

4.9 CONTENT OF PENTACHLOROPHENOL (PCP) . 14

4.10 RELEASE OF VOC . 14

4.11 THERMAL SHOCK RESISTANCE . 14

4.12 DURABILITY . 15

4.12.1 Compact laminate panels for internal use . 15

4.12.2 Compact laminate panels for external use . 16

4.12.3 HPL composite panels for internal use . 17

4.12.4 HPL composite panels for external use . 18

5 TESTING, ASSESSMENT AND SAMPLING METHODS . 19

5.1 REACTION TO FIRE . 19

5.2 WATER VAPOUR PERMEABILITY . 19

5.3 RESISTANCE TO FIXINGS . 19

5.3.1 Compact laminate panels . 19

5.3.2 HPL composite panels . 19

5.4 BONDING STRENGTH . 19

5.5 AIRBORNE SOUND INSULATION . 19

5.6 FLEXURAL TENSILE STRENGTH . 20

5.6.1 Compact laminate panels . 20

5.6.2 HPL composite panels . 20

5.7 THERMAL RESISTANCE. 20

5.8 FORMALDEHYDE EMISSION . 20

5.9 CONTENT OF PENTACHLOROPHENOL (PCP) . 20

5.10 RELEASE OF VOC . 20

5.11 THERMAL SHOCK RESISTANCE . 20

5.12 DURABILITY . 20

5.12.1 Compact laminate panels for internal use . 20

5.12.2 Compact laminate panels for external use . 20

5.12.3 HPL composite panels for internal use . 20

5.12.4 HPL composite panels for external use . 21

6 ASSESSMENT AND VERIFICATION OF CONSTANCY OF PERFORMANCE - AVCP . 21

6.1 GENERAL . 21

6.2 TYPE TESTING . 21

6.2.1 General . 21

6.2.2 Test samples, testing and compliance criteria . 22

6.2.3 Test reports . 23

6.2.4 Shared other party results . 23

6.2.5 Cascading determination of the product type results . 24

6.3 FACTORY PRODUCTION CONTROL (FPC) . 25

6.3.1 General . 25

6.3.2 Requirement . 26

6.3.3 Product specific requirements . 30

6.3.4 Initial inspection of factory and of FPC . 31

6.3.5 Continuous surveillance of FPC for products covered by AVCP 1 . 31

6.3.6 Procedure for modifications . 32

6.3.7 One-off products, pre-production products (e.g. prototypes) and products produced in very low quantity . 32

7 MARKING AND LABELLING . 33

ANNEX A (NORMATIVE) SPECIMEN MOUNTING DETAILS AND EXTENDED APPLICATION RULES FOR SBI FIRE TESTING

.................................................................................................................................................................................... 34

A.1 STANDARD FRAME . 34

A.2 STANDARD SUBSTRATE . 34

A.3 MOUNTING INSTRUCTIONS . 34

A.4 FIELD OF APPLICATION OF TEST RESULTS . 35

ANNEX B (NORMATIVE) PANEL PARAMETERS DEFINING FAMILY OF PANELS IN RELATION TO REACTION TO FIRE

PERFORMANCE . 41

ANNEX ZA (INFORMATIVE) RELATIONSHIP OF THIS EUROPEAN STANDARD WITH REGULATION (EU) NO.305/2011 . 42

BIBLIOGRAPHY . 51

European forward

This document (prEN 438-7:2019) has been prepared by Technical Committee CEN/TC 249 “Plastics” the

secretariat of which is held by NBN.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 438-7:2005.

This document has been prepared under standardization request given to CEN by the European

Commission and the European Free Trade Association.

For relationship with Regulation EU 305/2011 (CPR), see informative Annex ZA, which is an integral part

of this document.

Introduction

An overview of European standards addressing compact laminate panels and HPL composite panels and

related products for building applications is given below.

EN 438-2:2016+A1:2018, High-pressure decorative laminates (HPL) — Sheets based

on thermosetting resins (usually called laminates) — Part 2: Determination of

properties

Test methods EN ISO 13894-1:2015, High-pressure decorative laminates — Composite elements —

Part 1: Test methods (ISO 13894-1)

EN 16094:2012, Laminate floor coverings — Test method for the determination of

micro-scratch resistance

EN 438-3:2016, High-pressure decorative laminates (HPL) — Sheets based on

thermosetting resins (usually called laminates) — Part 3: Classification and

specifications for laminates less than 2 mm thick intended for bonding to supporting

substrates

EN 438-4:2016, High-pressure decorative laminates (HPL) — Sheets based on

thermosetting resins (usually called laminates) — Part 4: Classification and

specifications for Compact laminates of thickness 2 mm and greater

EN 438-5:2016, High-pressure decorative laminates (HPL) — Sheets based on

thermosetting resins (usually called laminates) — Part 5: Classification and

specifications for flooring grade laminates less than 2 mm thick intended for bonding to

supporting substrates

EN 438-6:2016, High-pressure decorative laminates (HPL) — Sheets based on

Product

thermosetting resins (usually called laminates) — Part 6: Classification and

standards

specifications for Exterior-grade Compact laminates of thickness 2 mm and greater

Classification,

EN 438-8:2018, High-pressure decorative laminates (HPL) — Sheets based on

specifications

thermosetting resins (usually called laminates) — Part 8: Classification and

specifications for design laminates

EN 438-9:2017, High-pressure decorative laminates (HPL) — Sheets based on

thermosetting resins (usually called laminates) — Part 9: Classification and

specifications for alternative core laminates

EN ISO 13894-2:2015, High-pressure decorative laminates — Composite elements —

Part 2: Specifications for composite elements with wood-based substrates for interior

use (ISO 13894-2)

EN 13329:2016+A1:2017, Laminate floor coverings — Elements with a surface layer

based on aminoplastic thermosetting resins — Specifications, requirements and test

methods

EN ISO 10874:2012, Resilient, textile and laminate floor coverings — Classification

for internal and external wall and ceiling finishes (This document)

EN 13986:2004+A1:2015, Wood-based panels for use in construction —

Product

Characteristics, evaluation of conformity and marking

standards

EN 14041:2018, Resilient, textile and laminate floor coverings — Essential

characteristics

EN 13964:2014, Suspended ceilings — Requirements and test methods

EN 438-1:2016, High-pressure decorative laminates (HPL) — Sheets based on

General

thermosetting resins (usually called laminates) — Part 1: Introduction and general

standard

information

1 Scope

This document specifies characteristics for compact laminate panels and HPL composite panels both for

non-structural uses in interior or external wall and ceiling finish applications (including in suspended

ceiling).

This document deals with compact laminate panels of thickness 2 mm and greater.

The compact laminate panels are produced by using a high pressure process and the HPL composite

panels are produced bonding an HPL sheet to a substrate.

This document covers compact laminate panels with the following types of laminates:

— compact laminates, as defined in EN 438-4:2016;

— exterior-grade compact laminates, as defined in EN 438-6:2016;

— pearlescent compact laminates, metal compact laminates and wood veneer compact laminates, as

defined in EN 438-8:2018;

— coloured core layer compact laminates and metal reinforced core layer compact laminates, as defined

in EN 438-9:2017.

This document covers full size and cut-to-size compact laminate panels and HPL composite panels, e.g.

tiles and sidings.

This document specifies only compact laminate panels and HPL composite panels mechanically fixed

using e.g. screws or rivets.

Both the compact laminate panels and HPL composite panels may contain flame retardant to improve

their reaction to fire performance.

This document also specifies provisions for the assessment and verification of constancy of performance

(AVCP) of the characteristics and includes provisions for marking these panels.

This document does not cover:

a) HPL sheets less than 2 mm thick as defined in EN 438-3:2016, EN 438-8:2018 or EN 438-9:2017,

which are not glued on a substrate;

b) overlaid or veneered wood-based panels, where the overlay/veneer is not an HPL;

c) HPL composite panels intended for use as floor coverings;

d) panels used for fire protection of walls or ceilings;

e) performances of installed systems for walls and ceilings with compact or composite high pressure

laminate panels.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 438-2:2016+A1:2014, High-pressure decorative laminates (HPL) — Sheets based on thermosetting

resins (usually called laminates) — Part 2: Determination of properties

EN 717-1:2004, Wood-based panels — Determination of formaldehyde release — Part 1: Formaldehyde

emission by the chamber method

EN 12664:2001, Thermal performance of building materials and products — Determination of thermal

resistance by means of guarded hot plate and heat flow meter methods — Dry and moist products of medium

and low thermal resistance

EN 13501-1:2018, Fire classification of construction products and building elements — Part 1:

Classification using data from reaction to fire tests

EN 13238:2010, Reaction to fire tests for building products — Conditioning procedures and general rules

for selection of substrates

EN 13823:2010+A1:2014, Reaction to fire tests for building products — Building products excluding

floorings exposed to the thermal attack by a single burning item

EN 13986:2004+A1:2015, Wood-based panels for use in construction — Characteristics, evaluation of

conformity and marking

EN 16516:2017, Construction products: Assessment of release of dangerous substances — Determination of

emissions into indoor air

EN ISO 178:2019, Plastics — Determination of flexural properties (ISO 178:2019)

EN ISO 1183-1:2019, Plastics — Methods for determining the density of non-cellular plastics — Part 1:

Immersion method, liquid pycnometer method and titration method (ISO 1183-1:2019)

EN ISO 7049:2011, Cross-recessed pan head tapping screws (ISO/FDIS 7049:2011)

EN ISO 10140-1:2016, Acoustics — Laboratory measurement of sound insulation of building elements —

Part 1: Application rules for specific products (ISO 10140-1:2016)

EN ISO 10140-2:2010, Acoustics — Laboratory measurement of sound insulation of building elements —

Part 2: Measurement of airborne sound insulation (ISO 10140-2:2010)

EN ISO 10140-4:2010, Acoustics — Laboratory measurement of sound insulation of building elements —

Part 4: Measurement procedures and requirements (ISO 10140-4:2010)

EN ISO 10140-5:2010, Acoustics — Laboratory measurement of sound insulation of building elements —

Part 5: Requirements for test facilities and equipment (ISO 10140-5:2010)

EN ISO 10456:2007, Building materials and products — Hygrothermal properties — Tabulated design

values and procedures for determining declared and design thermal values — Technical Corrigendum 1 (ISO

10456:2007)

EN ISO 10456:2007/AC:2009, Building materials and products — Hygrothermal properties — Tabulated

design values and procedures for determining declared and design thermal values — Technical Corrigendum

1 (ISO 10456:2007/Cor 1:2009)

EN ISO 12572:2016, Hygrothermal performance of building materials and products — Determination of

water vapour transmission properties — Cup method (ISO 12572:2016)

EN ISO 13894-1:2015, High-pressure decorative laminates — Composite elements — Part 1: Test methods

(ISO 13894-1:2000)

CEN/TR 14823:2003, Durability of wood and wood-based products — Quantitative determination of

pentachlorophenol in wood — Gas chromatographic method

3 Terms and definitions, symbols and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

high-pressure decorative laminate(s) (HPL)

sheet(s) consisting of decorative surface layer(s) and core layers bonded together by a high pressure

process

Note 1 to entry: Typical values for the high pressure process are: a temperature of ≥ 120 °C and a pressure

of ≥ 5 MPa.

3.1.2

surface layer

upper decorative layer consisting in one or more sheets of fibrous material (usually paper) impregnated

with aminoplastic thermosetting resins (usually melamine based resins) or other curable resins or other

decorative design surfaces which are not necessarily treated with thermosetting resin

Note 1 to entry: The surface layers can appear on one or both side(s) of the laminate(s). In case of one-sided

laminates, the back of the sheet(s) may be made suitable for adhesive bonding to a substrate.

Note 2 to entry: Examples of decorative design surface are metal foils, wood-veneers or textiles.

3.1.3

core layer

core layer consisting of fibrous materials (usually paper) impregnated with thermosetting resins (usually

phenolic based resins) or other curable resins, eventually reinforced by metal layer(s) or metal mesh(es)

and others which are not necessarily treated with thermosetting resin

3.1.4

compact laminate panel

panel consisting of decorative surface layer(s) and core layers bonded together by a high pressure process

with a thickness of 2 mm or greater

3.1.5

HPL composite panel

panel produced by adhesively bonding an HPL to one or both sides of a substrate

3.1.6

substrate of the HPL composite panels

board to which the HPL is bonded

Note 1 to entry: The substrate can be a wood based product (e.g. particleboard, plywood or fibreboard), a mineral

board (e.g. calcium silicate), an expanded honeycomb, a metal sheet or plastic material, organic or inorganic fibre

boards.

3.1.7

pearlescent compact laminate panel

compact laminate panel, the surface layer of which consists of a pearlescent effect decorative paper, which

is impregnated with aminoplastic thermosetting resins (usually melamine based resins)

3.1.8

metal compact laminate panel

compact laminate panel, the surface layer of which consists of a thin layer of metal

3.1.9

wood veneer compact laminate panel

compact laminate panel, the surface layer of which consists of a wood veneer, which is covered by a

protective melamine layer

3.1.10

coloured core layer compact laminate panel

compact laminate panel, the core layer of which consists of coloured fibrous materials (usually paper)

impregnated with aminoplastic thermosetting resins (usually melamine based resins) or fibrous

materials (usually paper) impregnated with coloured aminoplastic thermosetting resins (usually

melamine based resins)

3.1.11

metal reinforced core layer compact laminate panel

compact laminate panel, the core layer of which consists of metal layer(s) or mesh(es) and cellulosic

fibrous layers (usually paper) impregnated with phenolic thermosetting resins or aminoplastic

thermosetting resins (usually melamine based resins)

3.1.12

exterior-grade compact laminate panel

compact laminate panel for use under outdoor weather conditions such as direct sunlight rain and frost

3.1 Symbols and abbreviations

3.2.1 Symbols

For the purposes of this document, the following symbol applies.

t nominal thickness of the laminate

3.2.2 Abbreviations

For the purposes of this document, the following abbreviations apply.

ACF Pearlescent compact laminate with improved fire retardance

ACS Standard grade pearlescent compact laminate

BCS Standard grade Coloured core layer compact laminate

CGF Compact laminates with improved fire retardance

CGS Standard grade compact laminates

EDF Exterior-grade compact laminate with improved fire retardance, intended for severe outdoor

conditions

EDS Standard exterior-grade compact laminate, intended for severe outdoor conditions

EGF Exterior-grade compact laminate with improved fire retardance, intended for moderate outdoor

conditions

EGS Standard exterior-grade compact laminate, intended for moderate outdoor conditions

FR Flame Retardant

MCF Metal compact laminate with improved fire retardance

MCS Standard grade metal compact laminate

RCF Metal reinforced core layer compact laminate with improved fire retardance

RCS Metal reinforced core layer standard grade compact laminate

WCF Wood veneer compact laminate with improved fire retardance

WCS Standard grade wood veneer compact laminate

4 Product characteristics

4.1 Reaction to fire

4.1.1 The reaction to fire shall be assessed and classified in accordance with 5.1.

4.1.2 Only the interior grade non-flame retardant Compact laminate panels and HPL composite panels

1)

may be classified without the need for testing (CWT), as specified in Table 1 .

Table 1 — Classes of reaction-to-fire performance

Minimum

b

Minimum

Class

overall

a

Product detail density

Product (excluding

thickness

(kg/m )

floorings)

(mm)

Interior grade non-

Compact HPL meeting EN 438-4,

FR

1 350 6 D-s2,d0

Type CGS

Compact HPL panels

Composite panels comprising

Wood-

non-FR grade HPL meeting the

based core

requirements of EN 438-3,

minimum

12 mm wood-

adhesively bonded to both sides

density

Interior grade non- based core

of non-FR grade wood-based

FR HPL composite with

core of minimum thickness D-s2,d0

panels with wood- HPL ≥ 0,5 mm

12 mm complying with

based substrates bonded to

HPL

EN 13986, using PVAc or

both sides

minimum

thermosetting adhesive at an

density

application rate of 60 g/m to

1 350

120 g/m

a

Either directly fixed (i.e. with no air gap) to a material having a reaction to fire class of A2-s1,d0 or

better and a density of at least 600 kg/m ; or mounted on a timber or metal batten support frame, with a non-

ventilated (i.e. void open only at the top) air gap of at least 30 mm, the reverse face of the cavity so formed

having a reaction to fire classification of A2-s2,d0 or better.

b

Classes as provided for in Table 1 of the Annex to Decision 2000/147/EC.

NOTE Compact HPL panels are to be understood as compact laminate panels.

4.1.3 Compact laminate panels and HPL composite panels shall be tested according to 5.1.1 and the

results evaluated and expressed as class A1 to F together with the information to identify the mounting

and fixing conditions as provided in Annex A.

1) th

Commission Decision 2003/43/EC of 2003 January 17 (OJEU L 13 of 18.01.2003) as amended by

th

Commission Decision 2003/593/EC of 2003 August 7 (OJEU L 201 of 8.08.2003) establishing the classes of

reaction-to-fire of certain construction products.

4.1.4 For reaction to fire, the classification of the thinnest either compact laminate panels or HPL

composite panels of the family tested shall be valid for all thicker products of that family. However, testing

of thicker product may be used to prove a better classification.

Panel parameters defining family of panels in relation to reaction to fire performance shall be as listed in

Annex B, Table B.1.

4.2 Water vapour permeability

4.2.1 The water vapour permeability shall be expressed as the water vapour resistance factor μ.

4.2.2 The value of the water vapour resistance factor shall be taken from Table 2 in both conditions wet

and dry.

Table 2 — Water vapour resistance factors

Product Density Water vapour resistance factor

a

Wet cup μ Dry cup μ

Compact laminate ≥ 1 350 kg/m 110 250

panel

Particleboard substrate density 300 kg/m 10 50

HPL composite

Particleboard substrate density 600 kg/m 15 50

panel

Particleboard substrate density 900 kg/m 20 50

Fibreboard substrate density 400 kg/m 5 10

HPL composite

Fibreboard substrate density 600 kg/m 12 20

panel

Fibreboard substrate density 800 kg/m 20 30

a

Linear interpolation for intermediate density values is possible.

4.2.3 When a better performance is sought for declaration, the water vapour resistance factor of the

compact laminate panels and HPL composite panels shall be defined and determined in accordance with

5.2 and the values obtained shall be expressed in both conditions wet and dry.

4.3 Resistance to fixings

4.3.1 Compact laminate panels

4.3.1.1 The resistance to fixings of compact laminate panels shall be expressed as the screw holding

value from Table 3.

Table 3 — Screw holding value for compact laminate panels

Compact laminate panels thickness (t) Screw holding value

mm N

2 ≤ t < 4 250

4 ≤ t < 6 1 000

6 ≤ t < 8 2 000

8 ≤ t < 10 3 000

t ≥ 10 4 000

4.3.1.2 When tested, the resistance to fixings of compact laminate panels shall be done by

determining the resistance to the axial withdrawn force of wood screws from the panel in accordance

with 5.3.1. The value shall be expressed as screw holding value in newton (N).

4.3.2 HPL composite panels

The resistance to fixings of HPL composite panels shall be done by determining the resistance to the axial

withdrawn force of wood screws from the face (face screw-holding) in accordance with 5.3.2. The value

shall be expressed as screw holding value in newton (N).

4.4 Bonding strength

The bonding strength of HPL composite panels shall be done by determining the surface bond strength in

accordance with 5.4 and the obtained value shall be expressed in MPa.

4.5 Airborne sound insulation

The performance of the airborne sound insulation for compact laminate panels and for HPL composite

panels shall be determined as sound reduction index R (C;C ) in accordance with 5.5 and expressed as

w tr

value in dB.

4.6 Flexural tensile strength

4.6.1 Compact laminate panels

The flexural tensile strength of compact laminate panels shall be done by determining both the flexural

strength and the flexural modulus of elasticity in accordance with 5.6.1, and both results expressed in

values as MPa.

4.6.2 HPL composite panels

The flexural tensile strength of HPL composite panels shall be done by determining the perpendicular

tensile strength in accordance with 5.6.2 and the result expressed in value as MPa.

4.7 Thermal resistance

4.7.1 Compact laminate panels

4.7.1.1 The thermal resistance of compact laminate panels shall be expressed as value of thermal

conductivity of 0,3 W/(m K) according to EN ISO 10456:2007, Table 3 (see Material group: plastic solid,

phenolic resin).

4.7.1.2 When the thermal resistance of compact laminate panels is tested, it shall be done in

accordance with 5.7 and the result expressed as value in (m K/W).

4.7.2 HPL composite panels

4.7.2.1 The thermal resistance of HPL composite panels shall be calculated on the base of the thermal

conductivity value of each layers and their thicknesses and expressed as unique value of thermal

resistance in (m K/W).

4.7.2.2 When the thermal resistance of HPL composite panels is tested, it shall be done in accordance

with 5.7 and the result expressed as value in (m K/W).

4.8 Formaldehyde emission

4.8.1 Formaldehyde emission levels from compact laminate panels and from HPL composite panels

shall be measured according to 4.8.2 or/and 4.8.3.

4.8.2 When the formaldehyde emission is tested according to 5.8.2, the result shall be evaluated and

expressed according to Table 4.

Table 4 — Classes for emission of formaldehyde

Criteria for classes

Class E1 ≤ 0,13 mg/m air

Class E2 > 0,13 mg/m air

4.8.3 When the formaldehyde emission is tested according to 5.8.3 the result shall be expressed as value

in µg/m .

4.9 Content of pentachlorophenol (PCP)

4.9.1 Performance without testing

If in the relevant documentation provided by the supplier of the wood based substrate of HPL composite

panels is reported that it contains less than 5 ppm of pentachlorophenol (PCP), no testing of HPL

composite panels is necessary and the indication “PCP ≤ 5 ppm” shall be expressed.

4.9.2 Performance with testing

If the wood based substrate of HPL composite panels contains raw materials that include PCP, then the

substrate shall be tested according to 5.9.

When the obtained value of 5 ppm is exceeding, the indication “PCP > 5 ppm” shall be expressed for the

HPL composite panel, otherwise the declaration “PCP ≤ 5 ppm” shall be expressed.

4.10 Release of VOC

The release of volatile organic compounds (VOC) for compact laminate panels and HPL composite panels

is limited to the emissions of dangerous substances into indoor air with exception of formaldehyde and

PCP (already covered in 4.8 and 4.9).

The compact laminate panels and HPL composite panels shall be tested according to 5.10 and the result

expressed as value in µg/m .

4.11 Thermal shock resistance

4.11.1 The thermal shock resistance for compact laminate panels only shall be done by determining the

change of appearance, the change of flexural strength and the change of flexural modulus of elasticity

according to 5.11.

4.11.2 The obtained results of these characteristics shall be evaluated according to the concerned criteria

in Table 5.

Table 5 — Characteristics of thermal shock resistance performance

Compact laminate panels intended for

Characteristics

external application

Appearance rating ≥ 4

Change in flexural strength (D ) ≥ 0,80

s

Change in flexural modulus of elasticity (D ) ≥ 0,80

m

4.11.3 After evaluation of the results of the characteristics, the performance shall be jointly expressed

with indication “compliant”.

4.12 Durability

4.12.1 Compact laminate panels for internal use

4.12.1.1 General

The durability of the compact laminate panels for internal use shall be done by determining the resistance

to immersion in boiling water and the density, in accordance with 5.12.1 and expressing the results with

the corresponding values.

The resistance to immersion in boiling water is expressed as appearance, mass and thickness increase.

4.12.1.2 Appearance

The appearance shall be tested according to 5.12.1.1. The result shall be evaluated according to the

criteria in Table 6 for the respective type of compact laminate panels.

4.12.1.3 Mass increase

The mass increase shall be tested according to 5.12.1.1. The result shall be evaluated according to the

criteria in Table 6 for the respective type of compact laminate panels.

4.12.1.4 Thickness increase

The thickness increase shall be tested according to 5.12.1.1. The result shall be evaluated according to the

criteria in Table 6 for the respective type of compact laminate panels.

4.12.1.5 Density

The density shall be tested according to 5.12.1.2. The result shall be evaluated according to the criteria in

Table 7 for the respective type of compact laminate panels.

4.12.1.6 Evaluation of results

The results of the characteristics specified in 4.12.1.2 up to 4.12.1.5 shall be evaluated according to the

criteria reported in Table 6 and Table 7 for the respective type of compact laminate panels.

Table 6 — Minimum criteria for resistance to immersion in boiling water

Type of Compact laminate panels

Metal

Coloured

Pearlescent Metal Wood veneer reinforced

Compact core layer

Attribute Unit compact compact compact core layer

laminate compact

laminate laminate laminate compact

laminate

laminate

CGS CGF ACS ACF MCS MCF WCS WCF BCS RCS RCF

[%]

2 mm ≤ t < 5 mm ≤ 5, ≤ 7, ≤ 5,

Mass ≤ 7,0 NA NA NA NA ≤ 5,0

0 0 0 ≤ 5,0 ≤ 7,0

increase

t ≥ 5 mm ≤ 2, ≤ 3, ≤ 2,

≤ 3,0 NA NA NA NA ≤ 3,0 ≤ 2,0 ≤ 3,0

0 0 0

[%]

2 mm ≤ t < 5 mm ≤ 6, ≤ 9, ≤ 6,

Thickness ≤ 9,0 NA NA NA NA ≤ 6,0

0 0 0 ≤ 5,0 ≤ 7,0

increase

t ≥ 5 mm ≤ 2, ≤ 6, ≤ 2,

≤ 6,0 NA NA NA NA ≤ 4,0 ≤ 2,0 ≤ 3,0

0 0 0

Surface rating

Gloss finish ≥ 3 ≥ 3 ≥ 3 ≥ 3 NA NA NA NA ≥ 3 ≥ 3 ≥ 3

Other finishes ≥ 4 ≥ 4 ≥ 4 ≥ 4 NA NA NA NA ≥ 4 ≥ 4 ≥ 4

Appearance

Edge rating ≥ 3 ≥ 3 ≥ 3 ≥ 3 NA NA NA NA ≥ 3 ≥ 3 ≥ 3

No No No No

dela dela delam delam

Core delamination NA NA NA NA NA NA NA

mina mina inatio inatio

tion tion n n

NA: not applicable due to the composition of the material.

Table 7 — Minimum criteria for density

Type of Compact laminate panels

Coloure

Metal

Pearlescent Wood veneer d core

Compact Metal compact reinforced core

Unit Compact compact layer

laminate laminate layer compact

laminate laminate compact

laminate

laminate

CGS CGF ACS ACF MCS MCF WCS WCF BCS RCS RCF

[kg/m ≥ 1 35 ≥ 1 35 ≥ 1 35 ≥ 1 35 ≥ 1 35 ≥ 1 35 ≥ 1 10 ≥ 1 10 ≥ 1 35 ≥ 1 35

≥ 1 400

] 0 0 0 0 0 0 0 0 0 0

4.12.1.7 Expression of performance

After evaluation of the results of the characteristics specified in 4.12.1.2 up to 4.12.1.5, the performance

shall be jointly expressed with indication “compliant”.

4.12.2 Compact laminate panels for external use

4.12.2.1 General

The durability of the compact laminate panels for external use shall be done by determining the wet

conditions and the density in accordance with 5.12.2 and expressing the results with the corresponding

values.

The resistance to wet conditions is expressed as appearance and mass increase.

4.12.2.2 Appearance

The appearance shall be tested according to 5.12.2.1. The result shall be evaluated according to the

criteria in Table 8 for the respective type of compact laminate panels.

4.12.2.3 Mass increase

The mass increase shall be tested according to 5.12.2.1. The result shall be evaluated according to the

criteria in Table 8 for the respective type of compact laminate panels.

4.12.2.4 Density

The density shall be tested according to 5.12.2.2. The result shall be evaluated according to the criteria in

Table 8 for the respective type of compact laminate panel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...