EN 1402-5:2003

(Main)Unshaped refractory products - Part 5: Preparation and treatment of test pieces

Unshaped refractory products - Part 5: Preparation and treatment of test pieces

This standard specifies methods for the preparation and treatment (curing, drying and firing) of test pieces from unshaped refractory materials. The dimensions of the test pieces are specified. The methods are applicable to dense and insulating castables and to mouldable materials (plastics and ramming mixes) with the four types of chemical composition defined in ENV 1402-1.

Ungeformte feuerfeste Erzeugnisse - Teil 5: Herstellung und Behandlung von Probekörpern

Dieser Teil dieser Europäischen Norm legt Verfahren für die Herstellung und Behandlung (Lagern, Trocknen und Brennen) von Probekörpern aus ungeformten feuerfesten Erzeugnissen fest. Die Maße der Probekörper werden festgelegt.

Die Verfahren sind für dichte Feuerbetone, wärmedämmende Feuerbetone und Rammmassen mit den in prEN 1402 1 festgelegten vier Arten der chemischen Zusammensetzung anwendbar.

Produits réfractaires non façonnés - Partie 5: Préparation et traitement des éprouvettes

La présente partie de cette Norme européenne spécifie des méthodes de préparation et de traitement (cure, séchage et cuisson) d'éprouvettes de produits réfractaires non façonnés. Les dimensions des éprouvettes sont spécifiées.

Les méthodes s'appliquent aux bétons denses et isolants ainsi qu'aux matériaux moulables correspondant aux quatre types de compositions chimiques définies par Ie prEN 1402-l.

Neoblikovani ognjevzdržni izdelki - 5. del: Priprava vzorcev za preskus

General Information

- Status

- Withdrawn

- Publication Date

- 14-Oct-2003

- Withdrawal Date

- 30-Nov-2012

- Technical Committee

- CEN/TC 187 - Refractory products and materials

- Drafting Committee

- CEN/TC 187/WG 2 - Unshaped refractory materials

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Dec-2012

- Completion Date

- 01-Dec-2012

Relations

- Replaces

ENV 1402-5:1999 - Unshaped refractory products - Part 5: Preparation and treatment of test pieces - Effective Date

- 22-Dec-2008

- Effective Date

- 26-Dec-2012

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 1402-5:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Unshaped refractory products - Part 5: Preparation and treatment of test pieces". This standard covers: This standard specifies methods for the preparation and treatment (curing, drying and firing) of test pieces from unshaped refractory materials. The dimensions of the test pieces are specified. The methods are applicable to dense and insulating castables and to mouldable materials (plastics and ramming mixes) with the four types of chemical composition defined in ENV 1402-1.

This standard specifies methods for the preparation and treatment (curing, drying and firing) of test pieces from unshaped refractory materials. The dimensions of the test pieces are specified. The methods are applicable to dense and insulating castables and to mouldable materials (plastics and ramming mixes) with the four types of chemical composition defined in ENV 1402-1.

EN 1402-5:2003 is classified under the following ICS (International Classification for Standards) categories: 81.080 - Refractories. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1402-5:2003 has the following relationships with other standards: It is inter standard links to ENV 1402-5:1999, EN ISO 1927-5:2012, EN ISO 3822-3:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1402-5:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

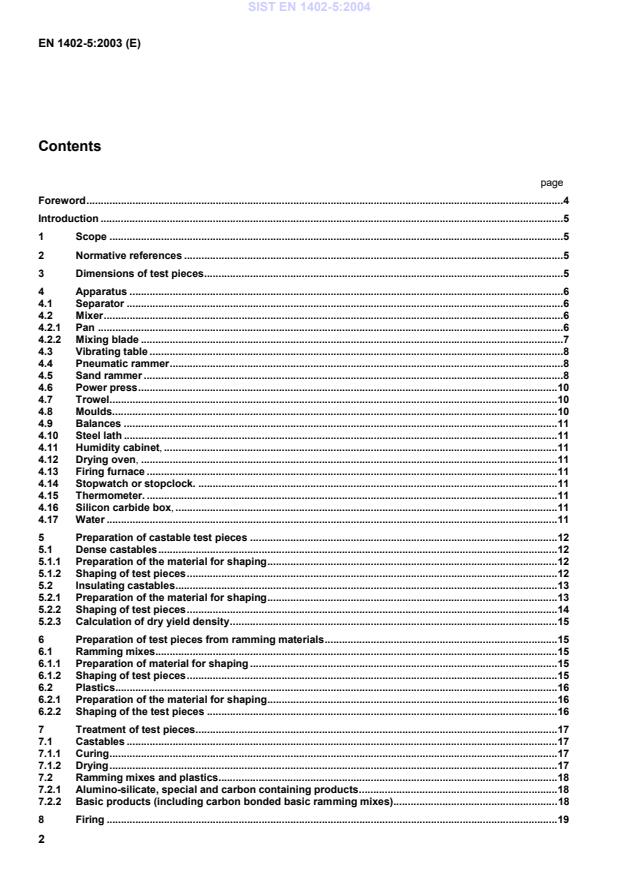

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Neoblikovani ognjevzdržni izdelki - 5. del: Priprava vzorcev za preskusUngeformte feuerfeste Erzeugnisse - Teil 5: Herstellung und Behandlung von ProbekörpernProduits réfractaires non façonnés - Partie 5: Préparation et traitement des éprouvettesUnshaped refractory products - Part 5: Preparation and treatment of test pieces81.080Ognjevzdržni materialiRefractoriesICS:Ta slovenski standard je istoveten z:EN 1402-5:2003SIST EN 1402-5:2004en01-maj-2004SIST EN 1402-5:2004SLOVENSKI

STANDARDSIST ENV 1402-5:20001DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1402-5October 2003ICS 81.080Supersedes ENV 1402-5:1999English versionUnshaped refractory products - Part 5: Preparation andtreatment of test piecesProduits réfractaires non façonnés - Partie 5: Préparationet traitement des éprouvettesUngeformte feuerfeste Erzeugnisse - Teil 5: Herstellungund Behandlung von ProbekörpernThis European Standard was approved by CEN on 20 June 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1402-5:2003 ESIST EN 1402-5:2004

Length: 230 mm; width: 114 mm; thickness: 64 mm; Shape B:

Length: 230 mm; width: 64 mm; thickness: 54 mm; Shape C:

Length: 230 mm; width: 64 mm; thickness: 64 mm. The width of the test piece as tested shall correspond to the height during preparation. The vibration of the testpiece during preparation shall be recorded, and for shape C the compaction surface shall be marked for reference.The selection of test pieces for each type of material shall be as given in Table 1, except that for basic densecastables and ramming materials, test pieces with a diameter of 50 mm and height of 50 mm ± 1 mm arepermissible. Shape C shall be used as the referee shape.SIST EN 1402-5:2004

Shape B or C Shape A

Direct Characterization b

X

Other tests

X

Max Grain Size >15 mm Direct Characterization b X a

Other tests

X

Insulating castables

X

RammingMaterials Ramming mixes X

Plastics X

a For these materials, shapes B and C are prepared by cutting from shape A. b Tests for which results are directly obtained from the bars without size modifications are modulus of rupture, coldcompressive strength, and permanent change in dimensions on heating.4 Apparatus4.1Separator A riffle sampler, suitable for use with the maximum particle size of the product, or a shovel for the quarteringmethod. The riffle separation shall be at least 2,5 times the maximum grain size.4.2Mixer4.2.1Pan See Figure 1. The pan shall be symmetrical around axis A and shall have a capacity of 15 l to 30 l. Both the panand the mixing blade (see 4.2.2) shall be constructed from a material that does not react with the test material. SIST EN 1402-5:2004

2453Figure 3 — Modification of sand-rammer for workability test4.6Power press A hydraulic type press shall be equipped with suitable moulds for forming test pieces of the required size. Thepress shall be capable of applying a minimum of 10 MPa pressure to the moulded face.NOTEThe power press should only be used for shaping test pieces from plastics.4.7Trowel Pointing type or stiff-bladed spatula shall have a typical size of 150 mm length and 50 mm width.4.8Moulds Moulds shall be capable of being dismantled and shall be watertight. They shall be made from a material that doesnot react with the material to be tested. For compaction by pneumatic rammer, the moulds shall be rigid so that they do not warp during ramming.NOTE 1Steel or similar material is recommended to withstand the stroke of the rammer.SIST EN 1402-5:2004

and specialdense castables Regular 1 0,75

Defloculated +Chemically Bonded 5 max.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...