prEN 17451

(Main)Fixed firefighting systems - Automatic sprinkler systems - Design, assembly, installation and commissioning of pump sets

Fixed firefighting systems - Automatic sprinkler systems - Design, assembly, installation and commissioning of pump sets

This document specifies design, assembly, installation and commissioning requirements for pump sets for use in sprinkler systems conforming to EN 12845. Where applicable, it can also be used in other water based fixed firefighting systems, including hydrants and hose reels.

Ortsfeste Brandbekämpfungsanlagen - Automatische Sprinkleranlagen - Projektierung, Zusammenstellung, Montage und Inbetriebnahme von Pumpenaggregaten

Dieses Dokument legt die Zusammenstellung von Bauteilen zur Herstellung eines Pumpenaggregats fest, welche den Leistungsanforderungen und Eigenschaften für festgelegte Wassermengen entsprechend der Projektierung, Zusammenstellung, Montage und Inbetriebnahme der wesentlichen Feuerlösch Pumpen-aggregate mit Dieselmotor und Elektroantrieb, die in ortsfesten Brandbekämpfungsanlagen nach EN 12845, CEN/TS 14816 und EN 16925 verwendet werden, entsprechen.

Dieses Dokument ist auch bei Feuerlösch Pumpenaggregaten für Feuerlöschhydranten und schlauch-haspeln anwendbar, sofern diese in der Spezifikation der Wasserversorgung ortsfester Brandbekämpfungsanlagen enthalten sind.

Installations fixes de lutte contre l’incendie - Systèmes d’extinction automatique de type sprinkleur - Conception, assemblage, installation et mise en service des groupes motopompes

Le présent document spécifie l’assemblage d’éléments pour produire un groupe motopompe qui satisfait aux exigences de performance et aux caractéristiques pour les sources d’eau spécifiées, conformément à la conception, à l’assemblage, à l’installation et à la mise en service des principaux groupes motopompes diesel et électriques utilisés dans les installations fixes de lutte contre l’incendie conformes à l’EN 12845, à la CEN/TS 14816 et à l’EN 16925.

Le présent document s’applique également aux groupes motopompes de lutte contre l’incendie pour bouches d’incendie et robinets d’incendie armés s’ils sont inclus dans la spécification des sources d’eau fixes de lutte contre l’incendie.

Vgrajene naprave za gašenje - Avtomatski sprinklerski sistemi - Projektiranje, montaža, vgradnja in preverjanje črpalk

General Information

- Status

- Not Published

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 5 - Sprinkler systems

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Completion Date

- 25-May-2022

Overview

prEN 17451 - Fixed firefighting systems - Automatic sprinkler systems - Design, assembly, installation and commissioning of pump sets - is a CEN draft standard prepared by CEN/TC 191. It specifies requirements for the design, assembly, installation, performance testing, commissioning and handover documentation of pump sets used in automatic sprinkler systems and, where applicable, other water-based fixed firefighting systems (hydrants, hose reels). The document defines essential components, performance criteria and verification procedures for both diesel and electric driven fire pumps.

Key topics and technical requirements

The standard addresses practical and technical aspects of pump set delivery and operation, including:

- Pump set performance and general design principles aligned to EN 12845 requirements.

- Identification and performance characteristics of essential components: pumps, drivers, couplings, baseplates, controllers, batteries, fuel tanks.

- Pump set activation and control logic, including electric and diesel starting methods and monitoring requirements.

- Cooling, by-pass flow and fuel system design (fuel quality, tank design, ventilation).

- Driver sizing and environmental considerations for electrical motors and diesel engines (torque, cooling, exhaust, air filtration).

- Coupling selection, installation and alignment, and baseplate/mounting for vibration and load transfer control.

- Pre-dispatch testing, site commissioning and handover: verification tests, documentation, and performance reports.

- Maintenance programmes and service documentation required at handover.

Practical applications

This standard is intended to ensure reliable, compliant fire pump operation within fixed firefighting water supplies. Typical uses:

- Specification and procurement of complete pump sets for new sprinkler installations.

- Guidance for design and assembly of pump sets used with EN 12845 sprinkler systems.

- Commissioning and acceptance testing procedures for fire pump suppliers and contractors.

- Informing maintenance schedules and service contracts for installed firefighting pumps.

Who should use prEN 17451

- Fire protection designers and consulting engineers

- Pump and fire equipment manufacturers and assemblers

- Installation and commissioning contractors

- Building owners, facilities managers and safety officers

- Authorities having jurisdiction and inspection bodies

- Fire system maintenance and service providers

Related standards

- EN 12845 - Fixed firefighting systems - Automatic sprinkler systems (design)

- EN 16925, CEN/TS 14816 - referenced for component and performance requirements

prEN 17451 provides a structured, component-level framework to design, test and hand over reliable pump sets for automatic sprinkler and other water-based firefighting systems. Keywords: prEN 17451, fixed firefighting systems, automatic sprinkler systems, pump sets, EN 12845, diesel pump, electric pump, commissioning, maintenance.

Frequently Asked Questions

prEN 17451 is a draft published by the European Committee for Standardization (CEN). Its full title is "Fixed firefighting systems - Automatic sprinkler systems - Design, assembly, installation and commissioning of pump sets". This standard covers: This document specifies design, assembly, installation and commissioning requirements for pump sets for use in sprinkler systems conforming to EN 12845. Where applicable, it can also be used in other water based fixed firefighting systems, including hydrants and hose reels.

This document specifies design, assembly, installation and commissioning requirements for pump sets for use in sprinkler systems conforming to EN 12845. Where applicable, it can also be used in other water based fixed firefighting systems, including hydrants and hose reels.

prEN 17451 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 17451 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2020

Vgrajene naprave za gašenje - Avtomatski sprinklerski sistemi - Projektiranje,

montaža, vgradnja in preverjanje črpalk

Fixed firefighting systems - Automatic sprinkler systems - Design, assembly, installation

and commissioning of pump sets

Ortsfeste Brandbekämpfungsanlagen - Automatische Sprinkleranlagen - Projektierung,

Zusammenstellung, Montage und Inbetriebnahme von Pumpenaggregaten

Installations fixes de lutte contre l’incendie - Systèmes d’extinction automatique de type

sprinkleur - Conception, assemblage, installation et mise en service des groupes

motopompes

Ta slovenski standard je istoveten z: prEN 17451

ICS:

13.220.10 Gašenje požara Fire-fighting

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2019

ICS 13.220.20

English Version

Fixed firefighting systems - Automatic sprinkler systems -

Design, assembly, installation and commissioning of pump

sets

Installations fixes de lutte contre l'incendie - Systèmes Ortsfeste Brandbekämpfungsanlagen - Automatische

d'extinction automatique de type sprinkleur - Sprinkleranlagen - Projektierung, Zusammenstellung,

Conception, assemblage, installation et mise en service Montage und Inbetriebnahme von Pumpenaggregaten

des groupes motopompes

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 191.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 17451:2019 E

worldwide for CEN national Members.

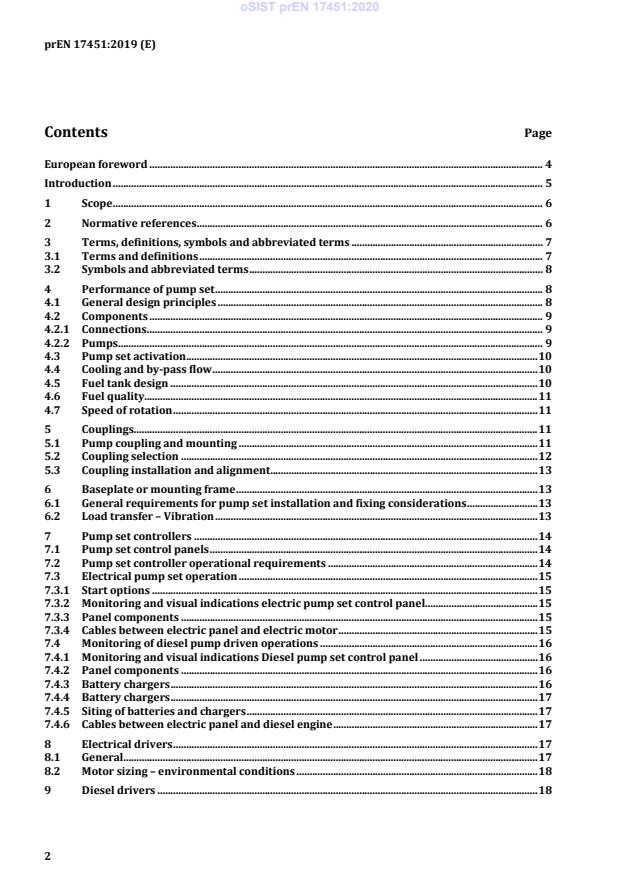

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions, symbols and abbreviated terms . 7

3.1 Terms and definitions . 7

3.2 Symbols and abbreviated terms . 8

4 Performance of pump set . 8

4.1 General design principles . 8

4.2 Components . 9

4.2.1 Connections . 9

4.2.2 Pumps . 9

4.3 Pump set activation . 10

4.4 Cooling and by-pass flow . 10

4.5 Fuel tank design . 10

4.6 Fuel quality. 11

4.7 Speed of rotation . 11

5 Couplings. 11

5.1 Pump coupling and mounting . 11

5.2 Coupling selection . 12

5.3 Coupling installation and alignment . 13

6 Baseplate or mounting frame . 13

6.1 General requirements for pump set installation and fixing considerations . 13

6.2 Load transfer – Vibration . 13

7 Pump set controllers . 14

7.1 Pump set control panels . 14

7.2 Pump set controller operational requirements . 14

7.3 Electrical pump set operation . 15

7.3.1 Start options . 15

7.3.2 Monitoring and visual indications electric pump set control panel . 15

7.3.3 Panel components . 15

7.3.4 Cables between electric panel and electric motor . 15

7.4 Monitoring of diesel pump driven operations . 16

7.4.1 Monitoring and visual indications Diesel pump set control panel . 16

7.4.2 Panel components . 16

7.4.3 Battery chargers . 16

7.4.4 Battery chargers . 17

7.4.5 Siting of batteries and chargers . 17

7.4.6 Cables between electric panel and diesel engine . 17

8 Electrical drivers . 17

8.1 General. 17

8.2 Motor sizing – environmental conditions . 18

9 Diesel drivers . 18

9.1 General . 18

9.2 Power . 18

9.3 Diesel driver sizing . 18

9.3.1 General . 18

9.3.2 Diesel driver sizing - environmental factors . 19

9.4 Motor torque . 19

9.5 Diesel engine equipped with electronic fuel management control . 19

9.6 Cooling system . 19

9.6.1 General . 19

9.6.2 Heat exchanger . 19

9.6.3 Air cooled radiator . 20

9.6.4 Air cooled engine . 20

9.6.5 Cooling system water supply . 20

9.6.6 Cooling system design considerations . 20

9.6.7 Air filtration . 21

9.7 Exhaust system . 21

9.8 Starting mechanism . 21

9.8.1 General . 21

9.8.2 Automatic starting. 21

9.8.3 Emergency manual starting . 21

9.8.4 Test facility for manual starting facilities . 21

9.8.5 Starter motor . 22

9.9 Pump set engine supplier pre-dispatch testing of diesel engine. 22

9.9.1 General . 22

9.9.2 Test procedure . 22

9.9.3 Test report . 22

10 Handover, installation and commissioning . 22

10.1 General . 22

10.2 Pre-dispatch testing . 23

10.2.1 General . 23

10.2.2 Verification of performance . 23

10.3 Documentation . 23

10.4 Pre-commissioning checks . 25

10.5 Diesel set commissioning . 25

10.6 Electrical set commissioning . 26

11 Maintenance programme . 26

Annex A (normative) Pump set installation and fixing considerations . 27

Annex B (informative) Electric motor controllers starting methods explained . 29

B.1 Direct on line . 29

B.2 Star-Delta, open transition . 29

B.3 Star-Delta, closed transition . 30

B.4 Solid state soft starter . 30

B.5 Older or less common starting methods . 31

B.5.1 Autotransformer . 31

B.5.2 Primary resistor . 31

Bibliography . 32

European foreword

This document (prEN 17451:2019) has been prepared by Technical Committee CEN/TC 191 “Fixed

firefighting systems”, the secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

Introduction

This document covers:

— the design and assembly of the pump set in accordance to the requirements of EN 12845, EN 16925

and CEN/TS 14816;

— identification of essential pump set components;

— the performance characteristics for components used within a pump set;

— performance testing requirements for diesel and electric driven pump sets;

— commissioning and handover site testing;

— performance handover documentation;

— servicing and maintenance handover documentation.

Figure 1 identifies the typical pump set components covered by this standard.

Figure 1 — Example of a typical pump set assembly for a diesel driven unit

The performance requirements for the pump set will be by reference to the relevant European

component standards, where available, and for those key components such as pumps, drivers,

couplings, baseplates and controllers. Where suitable component standards do not exist, this document

sets the performance requirements for the pump set.

1 Scope

This document specifies the assembly of components to produce a pump set which meet the

performance requirements and characteristics for specified water supplies in accordance with the

design, assembly, installation and commissioning of the main fire diesel and electric pump sets used in

fixed firefighting systems conforming to EN 12845, CEN/TS 14816 and EN 16925.

This document is also applicable to fire-fighting pump sets for firefighting hydrants and hose reels

where included in the fixed firefighting water supply specification.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

CEN/TS 14816, Fixed firefighting systems — Water spray systems — Design, installation and maintenance

EN 12845, Fixed firefighting systems — Automatic sprinkler systems — Design, installation and

maintenance

EN 16925, Fixed firefighting systems — Automatic residential sprinkler systems — Design, installation

and maintenance

EN 50342-1, Lead-acid starter batteries — Part 1: General requirements and methods of test

EN 50342-2, Lead-acid starter batteries — Part 2: Dimensions of batteries and marking of terminals

EN 590, Automotive fuels — Diesel — Requirements and test methods

EN 60529:1991, Degrees of protection provided by enclosures (IP code) (IEC 60529)

EN 60529:1991/A1:2000, Degrees of protection provided by enclosures (IP code) (IEC

60529:1989/A1:1999)

EN 60529:1991/A2:2013, Degrees of protection provided by enclosures (IP code) (IEC

60529:1989/A2:2013)

EN 60623, Secondary cells and batteries containing alkaline or other non-acid electrolytes — Vented

nickel-cadmium prismatic rechargeable single cells (IEC 60623)

EN IEC 60947-4-1:2019, Low-voltage switchgear and controlgear — Part 4-1: Contactors and motor-

starters — Electromechanical contactors and motor-starters (IEC 60947-4-1:2018)

IEC 60034-1, Rotating electrical machines — Part 1: Rating and performance

ISO 3046-1, Reciprocating internal combustion engines — Performance — Part 1: Declarations of power,

fuel and lubricating oil consumptions, and test methods — Additional requirements for engines for general

use

prEN 12259-12:2017, Fixed firefighting systems — Components for sprinkler and water spray systems —

Part 12: Pumps

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 12845, EN 16925, CEN/TS

14816 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

assembly

design, production and testing of the pump

3.1.2

installation

mounting and commissioning of the pump set in accordance with the pump set manufacturer’s

installation manual and procedures

3.1.3

maintenance

work performed to keep pump sets operable including repairs where required

3.1.4

pump set

assembly which is intended to supply water to automatic sprinkler or water spray systems, comprising

at least a pump, driver or motor, controller unit, partial wiring loom, drive coupling, mounting frame,

baseplate and where required fuel tank

3.1.5

installer

installer of the fire pump set in accordance with the manufacturer’s installation manual and procedures

3.1.6

pump set assembler

entity responsible for the design and build of the pump set

3.1.7

flexible fire pump couplings and flexible connecting drive shafts

integrated unit which provides power transmission from diesel engines or electric motors to fire pumps

that supply water to fire protection systems

3.1.8

all elastomeric coupling

plastic coupling

coupling that relies solely on an elastomeric material for power transmission

3.1.9

driver service factor

design margin specified by driver manufacturers to account for higher torque demand conditions than

normal but which can be encountered under certain extreme operating conditions

3.1.10

coupling safety factor

SFk

safety margin specified by coupling manufacturers to address uncertainties in design

3.1.11

back pull-out type pump

centrifugal pump design type which allows the rotating assembly to be pulled out of the pump casing

without having to remove the pump casing from the piping

3.1.12

Biodiesel

vegetable oil or animal fat-based FAME diesel fuel

NOTE to entry 1: Biodiesel can have 100 % FAME content or blended with petroleum derived diesel fuel in any

proportions.

NOTE to entry 2: See 4.6.

3.2 Symbols and abbreviated terms

For the purposes of this document, the following symbols and abbreviated terms apply.

L basic life rating time by which ten percent of a population of a product will have failed (see

ISO 281)

ECM electronic fuel management control

EMC electromagnetic compatibility

EMF electromagnetic fields

FAME fatty acid methyl ether

FLA full load amperes

FLC full load current

IFN numerical value of the fuel stop power taken as the maximum IFN value in

accordance to ISO 3046-1 for the driver, expressed in kilowatt

LRC locked rotor current

NPSH net positive suction head

NPSHr net positive suction head required

Pdm power distribution module

SFk coupling safety factor

VFD variable frequency drive

4 Performance of pump set

4.1 General design principles

The design details covered in this clause address the general principles which shall be considered for all

pump set designs covered by this document. The design of pump set shall be based on the following

information provided to the pump set assembler:

— flow and corresponding head including details of the safety margin applied for the unfavourable

area, in line with the requirements of EN 12845, CEN/TS 14816 or EN 16925 (e.g. at least 10 % or a

maximum of 0,5 bar higher than that required in the case of EN 16925 or at least 0,5 bar higher

than that required in the case of EN 12845 and CEN/TS 14816);

— flow for favourable area maximum possible demand flow;

— maximum possible suction pressure at pump suction flange;

— available NPSH at low water level in water storage tank at pump suction flange at the maximum

possible demand flow including 1 m safety margin;

— duration of operation for fuel tank sizing;

— driver type (electric or diesel);

— applicable fixed firefighting system design specification: EN 12845, CEN/TS 14816 or EN 16925;

— hazard class against which the fixed firefighting system is designed as given in EN 12845,

CEN/TS 14816 or EN 16925 e.g. LH, OH, HHP or HHS in the case of EN 12845;

— water quality (potable, sea or filtered) description as defined in EN 12845.

The pump set shall be designed to ensure a reliable and stable supply of water at the specified volume

flow and pressure over the operating range and duration in accordance with EN 12845, CEN/TS 14816

or EN 16925.

4.2 Components

4.2.1 Connections

All service interface connection requirements (including electrical, hydraulic and pneumatic) shall be

provided as part of the installation instructions to enable the correct installation of the pump set on-

site. The connections shall be easily accessible and located in accordance with EN 12845, CEN/TS

14816 or EN 16925.

4.2.2 Pumps

Pumps, shall be in accordance with prEN 12259-12:2017 and shall be driven either by electric motors

or diesel engines, capable of providing at least the power required to comply with the following:

a) for pumps with non-overloading power characteristic curves, the maximum power required at the

peak of the power curve;

b) for EN 12845 applications, for pumps with rising power characteristic curves, the maximum power

for any conditions of pump load, from zero flow to a flow corresponding to a pump NPSH required

equal to 16 m;

c) for EN 16925 applications, for pumps with rising power characteristic curves, the maximum power

for any conditions of pump load, from zero flow to the maximum flow on the pump curve.

The pump shall conform to the performance characteristics specified by prEN 12259-12:2017.

Table 1 — Summary of typical prEN 12259-12:2017 pump designs

Type Pump design

1 End suction long coupled

2 End suction closed coupled

3 Axial horizontal split case

4 Multistage inline pumps

5 Single stage inline pumps

6 Ring section pumps

7 Vertical turbine pumps

8 Submersible motor pumps

9 Multistage multi-outlet pumps

End suction pumps shall be of the “back pull-out” type. Pipes shall be supported independently of the

pump.

4.3 Pump set activation

The activation of the pump set shall arise from an externally supplied signal in accordance with the

relevant standard EN 12845, CEN/TS 14816 or EN 16925.

4.4 Cooling and by-pass flow

Arrangements such as by-pass flows shall be made to ensure a continuous flow of water through the

pump sufficient to prevent overheating when it is operating against a closed valve. The by-pass system

can also be required to maintain the operational temperature of the diesel drivers. Any additional flow

requirements shall also be considered.

Water to cool the pump (in the closed valve condition) shall be taken from the sprinkler system water

supply.

The by-pass system shall not be supplied as a component of the pump set.

NOTE As it can be formed as part of the wider system pipework installation in a manner similar to the supply

of electrical cabling etc.

prEN 12259-12:2017 specifies the minimum by-pass flow for the compliant pump.

The by-pass flow shall be taken into account in the fixed firefighting system hydraulic calculation and

pump selection. This additional flow shall be provided in addition to the fixed firefighting system flow

figures.

The pump set assembler shall specify the required parameters for the cooling circuit and flow.

4.5 Fuel tank design

The fuel tank capacity shall be sufficient to enable the engine to run on full load for the required period

of duty. Minimum values, taken from EN 12845 as follows:

— 3 h for LH;

— 4 h for OH;

— 6 h for HHP and HHS.

The design, installation and maintenance of the fuel and fluid systems shall be fully compliant with the

local safety and environmental requirements for the pump set unit.

The fuel tank shall be of welded steel. Where there is more than one engine, there shall be a separate

fuel tank and fuel feed pipe for each one.

The fuel tank shall be fixed at a higher level than the motor’s fuel pump to ensure a positive head, but

not directly above the engine. Where the tank cannot be installed on the same baseplate or mounting

frame as the pump set unit the fuel lines shall be kept to a minimum length.

The fuel tank shall have a sturdy fuel level gauge and communicate with the main control panel to

enable leak monitoring and low fuel level alarms.

Any valves in the fuel feed pipe between the fuel tank and the engine shall be placed adjacent to the

tank, have an indicator and be locked in the open position. Pipe joints shall not be soldered. Metallic

pipes and steel hoses shall be used for fuel lines.

The feed pipe shall be situated at least 20 mm above the bottom of the fuel tank. A drain valve of at least

20 mm diameter shall be fitted to the base of the tank.

The pump set assembler shall provide suitable connection to allow the fuel tank vent to be terminated

outside the building (see EN 12845:2015, 10.9.6).

4.6 Fuel quality

All diesel fire pump drivers shall use petroleum derived diesel fuel conforming to EN 590 and free from

Fatty Acid Methyl Ester (FAME) content (i.e. 0 % FAME content). Where FAME blended fuel (i.e.

Biodiesel) is used, the FAME content shall be within the limits set in EN 590.

Commercial distillate fuel oils used in diesel engines are subject to detrimental effects from prolonged

storage. Therefore, it is recommended that a proper maintenance schedule is put into place to ensure

the fuel is suitable for engine operation, efficiency, and longevity.

4.7 Speed of rotation

The driver speed shall not exceed 3 600 1/min.

5 Couplings

5.1 Pump coupling and mounting

Flexible fire pump couplings and flexible connecting (drive) shafts shall be sized to meet the required

rated power levels for reliable operation, despite being idle for extended periods.

The coupling between the driver and the pump of horizontal pump sets shall be of a type which ensures

that either can be removed independently and in such a way that pump internals can be inspected or

replaced without affecting suction or discharge piping and without requiring the impeller to be

withdrawn without removing the driver or pump body.

The pump and driver shall be in line direct or close coupled, and the coupling shall be rated for the

maximum torque of the driver under all conditions, and of a design such that if any elastomeric element

used in the coupling to absorb vibration should fail, that the pump shall continue to be driven under all

operating conditions, except that a right-angle gear drive can be used for vertical shaft pumps.

Maximum permissible driver size for closed coupled end suction pumps shall be 55 kW. Diesel driven

pump sets shall not be closed coupled.

Pumps and drivers shall be fitted with a ‘fail safe’ coupling. It shall be of the following type:

— rigid coupling;

— flexible coupling; or

— flexible connecting shaft.

All elastomeric couplings shall not be used.

EXAMPLE Couplings include pin and bushing, jaw, disc, drive shaft or steel-grid-type couplings where the

drive components are metallic.

The pump set shall be designed and assembled such that there shall be ready access for checking the

alignment of resilient couplings when the installation is completed.

5.2 Coupling selection

The following coupling design requirements are required:

— designed for adverse environmental location;

— driveshaft bearings shall have a minimum basic life rating of L as determined by the methods of

ISO 281, for at least 5 000 h operating at the maximum load condition of the pump set;

EXAMPLE No more than 10 % of the population may have been calculated to have failed after no less than 5

000 h operating at the maximum load condition of the pump set.

— flexible couplings with polymeric or elastomeric materials shall be of a 'fail-safe' design;

NOTE This means, the wear or failure of the polymeric or elastomeric components is not interrupting the

transmission of full torque from diesel or electric motor to the fire pump.

— distance between the pump and drive shaft ends shall be considered, to allow for maintenance

without disturbing the pump or driver a spacer shall be used;

— coupling failure containment guards shall be provided.

For the selection of couplings the following shall be fulfilled:

— the hubs shall be keyed and have double set screws 90 degrees apart;

—sizing of the coupling shall be based on the rating of the driver not the pump, this shall take the

service factor provided by the driver manufacturer into account.

The selection of the coupling shall withstand the torque between pump and driver. The torque shall be

calculated using the formula:

Power ×1000

τ × SFk

Rotational speed

2 ×π ×

where

τ

is the numerical value of the torque between pump and driver, expressed

in newton metre;

rotational speed is the numerical value of the speed, expressed in 1/min;

=

Power is the numerical value of the fuel stop power taken as the maximum IFN

value in accordance to ISO 3046-1 for the driver, expressed in kilowatt;

SFk is the numerical value of the safety factor coupling.

SFk values shall be provided by the coupling manufacturer.

5.3 Coupling installation and alignment

Couplings shall be installed according to the coupling manufacturers’ instructions. Alignment of the

coupling and shaft shall be within the tolerances defined by supplier.

The integration (including alignment) of the pump, coupling and driver at the pump set assembler

premises shall be in accordance with the component suppliers’ specifications. The alignment and any

other requirements for continued satisfactory use of the coupling shall be recorded in the pump set

installation and maintenance manual for future use.

Final alignment shall be undertaken once the pump set has been fully installed on-site. This alignment

shall be checked to be in accordance with the pump set manufacturers’ specification after the pump

baseplate or mounting frame is installed, bolted down and all pipework connected.

6 Baseplate or mounting frame

6.1 General requirements for pump set installation and fixing considerations

See also Annex A.

The mounting arrangements of the pump can require the use of baseplates or mounting frames. Where

baseplates or mounting frames are required the design of the mounting shall be of sufficient strength

and mass to withstand the static and dynamic forces imposed by the pump set.

The primary characteristics to be considered include:

— alignment;

— weight loading;

— ability to withstand vibration;

— transport;

— fixing details to meet the requirements of the pump set assemblers’ instructions;

— unless otherwise stated see Annex A provides informative guidance on affixing details.

6.2 Load transfer – Vibration

For the load transfer take the impact on the key components such as controllers, couplings, connections

etc. into account and also the influence of these units on the vibration and load transfer.

Where oil resistant flexible pads are used under the baseplate or mounting frame, flexible pipe

connections shall be used.

Examples of baseplates or mounting frames design approaches can be seen in Figure A.1.

7 Pump set controllers

7.1 Pump set control panels

Each pump set (excluding separate jockey pump units) shall be monitored and controlled by a

dedicated control unit. The controller shall be in the same compartment as the pump set and be

installed as close to the pump set as possible.

The controller units and associated electrical connections shall be installed on the pump set baseplate

or mounting frame or be supplied for wall or floor mounting. In all cases all components and

connections shall be mounted at least 200 mm above the base of the compartment floor.

The control panel shall be easily accessible and clearly visible from the pump set unit.

The control panel shall be mounted such that it is not located in areas subject to:

— potential water ingress, such as a sprinklered pump room, unless constructed to a minimum IP 54

rating;

— temperature, humidity ranges or changes which fall outside the specified operating range for the

controller unit;

— mechanical vibration which could damage the controller unit;

— unacceptable levels of EMC interference.

The pump set controller casing shall be constructed from metal and finished with a corrosion resistant

coating (such a powder coating or paint finishes). The panel shall be fitted with tamper proof access

control to prevent unauthorised access. The panel should be marked in accordance with the labelling

requirements of EN 12845, CEN/TS 14816 or EN 16925.

In the case of submersible borehole pumps a plate with its characteristics shall be affixed to the pump

controller.

Except in the case of submersible borehole pumps, the pump controller shall be situated in the same

compartment as the electric motor and pump.

7.2 Pump set controller operational requirements

Each pump set controller panel shall:

a) start the motor automatically on receiving an activation signal, which may take the form of either:

1) a normally closed signal, or;

2) short circuit and open circuit monitoring shall be provided for all other actuation

configurations.

b) start the motor on manual actuation (EN 16925 pump sets do not require this functionality);

c) stop the motor by manual actuation only (EN 16925 pump sets may stop the pump automatically

upon completion of the automatic test cycle or pressure maintenance cycle, where this functionality

is included. This automatic stopping functionality shall be disabled in a fire condition).

7.3 Electrical pump set operation

7.3.1 Start options

Starting mechanism shall be capable of a minimum of six start sequences per hour.

Any starting method can be employed, provided the starting method can meet the locked rotor current

demand for a time period in excess of 75 % of the motor burn-out time and operate the pump at

nominal duty within 15 s from controller receipt of pump initiation signal.

See Annex B for further information on starting methods.

NOTE The use of variable frequency drivers is not specified within this document at this time due to the

absence of supporting usage criteria and reliability data.

7.3.2 Monitoring and visual indications electric pump set control panel

The following conditions shall be remotely monitored and visually indicated on the control panel and

available for remote monitoring:

— voltage available to the controller on all phases;

— pump on demand (one or both pressure switch initiation signals active);

— pump running (signal derived from pressure switch downstream of the pump outlet to confirm

pump running at pressure);

— pressure switch wiring continuity failure [see 7.2, a) 2)];

— start failure;

— automatic test cycle (applies only to pump sets for EN 16925 application);

— pressure maintenance cycle (applies only to pump sets for EN 16925 application).

NOTE Cabling continuity to pressure switches monitoring can be required by some authorities.

7.3.3 Panel components

The fuses in the pump controller shall be high rupture capacity, capable of carrying current for 75 % of

the burn out time of the motor in locked rotor condition.

In addition, the electric motor for the pump shall be protected by fuses sized no less than 1,15 times the

nominal load.

The controller shall be equipped with an ammeter to monitor motor running and starting current.

Contactors shall comply with utilization category AC-3 of EN IEC 60947-4-1:2019 and be sized to at

least 115 % of motor full load current.

7.3.4 Cables between electric panel and electric motor

The cable size to be used shall be determined by the rating of the fuse in front of it, based on the

principle that in case of a short circuit the fuse will trip without melting the cable. This shall be at least

125 % of the full load current demand.

7.4 Monitoring of diesel pump driven operations

7.4.1 Monitoring and visual indications Diesel pump set control panel

7.4.1.1 General

The conditions detailed in EN 12845, CEN/TS 14816 or EN 16925, as applicable, shall be provided, in

the case of EN 12845 the following shall be monitored and visually indicated on the control panel:

— battery charger status;

— battery status;

— low jacket water temperature;

— engine running;

— failure to start;

— pump on demand;

— low oil pressure;

— high water temperature;

— low fuel level;

— auto start inhibited;

— hours run meter;

— tachometer.

NOTE Cabling continuity to pressure switches monitoring can be required by some authorities.

7.4.1.2 Remote alarm signal panel

The engine running, auto start inhibited and fault alarm signals shall be made available for connection

to the monitored remote locations.

7.4.2 Panel components

The controller shall be equipped with a charge rate ammeter to monitor each battery set.

7.4.3 Battery chargers

Two separate battery chargers shall be provided and shall be used for no other purpose. Batteries shall

be either open nickel-cadmium prismatic rechargeable cells complying with EN 60623 or lead-acid

positive batteries complying with EN 50342-1 and EN 50342-2.

Batteries shall be selected, used, charged and maintained in accordance with the requirements of the

battery supplier's instructions.

A hydrometer, suitable for checking the density of the electrolyte, shall be provided.

7.4.4 Battery chargers

Each starter battery shall be provided with an independent, continuously connected, fully automatic

and constant potential charger, as specified by the battery supplier. It shall be possible to remove either

charger while leaving the other operational. Chargers for lead acid batteries shall provide a float voltage

of (2,25 ± 0,05) V per cell. The nominal charging voltage shall be suitable for local conditions (c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...